Most modern gas boilers are energy dependent. Interruptions in the power supply completely stop their operation, which not only affects comfort, but also risks freezing of the coolant, and subsequently emergency depressurization of lines or heating devices. Fortunately, the solution is quite simple - installing a generator. Even the simplest models are often sufficient to ensure the operation of the automation of a boiler, circulation pump or turbine.

There are generators that run on gasoline, gas or diesel fuel, generators that are manually started or provide completely autonomous operation of the heating system, standard or inverter, synchronous or asynchronous - all these selection criteria are worth considering in more detail.

Minimum power values

This is the second criterion that deserves close attention (after choosing a standard or inverter version) when you need to buy a generator.

It is not difficult to determine its power. To do this, the starting and functional power of all connected devices is added up. A reserve of 20-30% is added to the result.

The minimum power for boiler operation is reflected in its documents. The indicators of electricity consumption and power consumption are also indicated there. As a rule, these parameters are in the range of 120-180 W. Approximately 150 W is required for the circulation pump and turbine, if it is installed in the boiler.

Calculation example:

One boiler is connected to the generator. Then for full operation a minimum of 0.5 - 0.62 W is required. This is the result of this arithmetic: 120-180 + 150 + 150 + 20-30%. It turns out 504-624 W.

Today, buyers have the opportunity to purchase devices with parameters of 0.6 - 7 kW. In 90% of situations, this is enough for devices producing 0.8 - 1 kW. In other cases, the total power of all equipment connected to the generator is calculated.

Model examples

There are plenty of brands of boilers. And users often wonder about the selection of a generator for a boiler of a particular brand.

Below are examples of certain boiler models and the most suitable modifications of gasoline generators.

First: Boiler - Baxi Ecofor 24.

Suitable generators:

- Hitachi E50. Price tag – 44 thousand rubles. Power – 4.2 kW.

- Huter DY2500L. Cost – 18 thousand rubles. Power – 2 kW.

Second: Boiler - Vaillant 240/3.

He needs a high-quality stabilizer, for example Resanta ASN-1500, especially if the electricity is turned off every 4-5 hours.

A suitable generator is Hyundai HHY 3000FE. It has an integrated AVR, modest fuel consumption and a power of 2.8 kW. Starts with a key and cable. Price tag – 42,000 rubles.

Third: Bosch Gaz 6000w device. It does not depend on the phase and for high-quality work is complemented by the Stihl 500I stabilizer

For complete stability and safety, it is accompanied by a SWATT PG7500 generator with a power of 6 - 6.5 kW. Cost – 40200 rub. It can work without breaks for 8 hours. Equipped with AVR.

Fourth: wall model Buderus Logamax U072-24K. This is a powerful dual-circuit modification with automatic electric ignition.

An inverter generator is required. For example, Enersol SG 3 with a power of 7-8 kW. It costs about 60,600 rubles.

Fifth: boiler Proterm 30 KLOM. This is a phase dependent floor standing model.

It is usually used in conjunction with the Stihl type stabilizer R 250T. A suitable generator option is Elitech BES 5000 E. It costs about 58,300 rubles. Power – 4-5 kW.

The sixth is the Navien Ice Turbo device - 10-30 kW.

It is optimal to use the ABP 4.2-230 Vkh-BG generator with a power of 4 kW and an average price tag of 55 thousand rubles.

If you need a reliable supply of fuel while camping or in the country when there is no electricity, then it is optimal to use a generator that produces a pure sine wave, the Huter HT 950A.

This is a convenient compact petrol model with low fuel consumption. It can work continuously for 6-8 hours if it is fully charged.

The engine here has one cylinder and two strokes. This guarantees smooth and stable operation of the entire generator.

Other advantages:

- The tank cap is located in such a way that it is convenient to control the fuel level and refuel.

- Overload protection available.

- Low noise levels.

- Special indicators allow you to monitor the oil level and control dangerous situations.

- Availability of replaceable air filter and muffler.

- The engine is reliably protected from external influences by a shock-resistant housing.

- There is an exhaust pipe that removes gases. Therefore, the device can only be used outdoors or indoors with strong ventilation.

- To use the device, no special skills or knowledge are required.

- Modest price - 6100 rubles.

Standard or inverter

The inverter differs from a standard household generator in the presence of an inverter system and an electronic stabilizer. Thanks to this system, the AC sine wave has no distortion and is stabilized to an ideal frequency of 50 Hz. Of course, inverter models are 20-50% more expensive than regular ones.

Inverter model Daewoo GDA 1500i with manual start.

In general, the advantages of inverter generators for a gas boiler are:

- higher quality output electricity, which is safer for boiler automation;

- the operation of the generator is adjusted automatically depending on the load size, which often makes it possible to reduce the operating speed of the internal combustion engine and, accordingly, its service life and fuel consumption;

- inverter devices are compact in size;

- lower levels of vibration and noise (up to 50-60 dB) allow you to feel comfortable even in the same room with a running electric generator

Please note that there are currently no inverter models larger than 6 kW. To operate the generator, you need a charged battery capacity, which, under higher loads than the maximum permissible (for example, at 6 kW at 4 kW maximum), will quickly discharge and you will have to turn off some of the devices for recharging.

In addition, the battery is part of a single structure and after its service life has expired (4-9 years depending on operating conditions), it will be necessary to replace the entire inverter unit assembly.

How to choose a water softener for a gas boiler and extend the life of the heat exchanger

Selection and calculation of the inverter

When calculating the required output power of the inverter, it must be taken into account that the presence of circulation pump electric motors in the load circuit will cause an increase in both constant current consumption, which determines the so-called power factor of the electric motor (cosine phi), and a significant current load at the time the pumps start. The maximum power consumption should not be more than 75% of the maximum power of the inverter output stage, especially for line-interactive devices in which the inverter operates constantly.

For an example of calculation, let's take a system consisting of a Baxi Fourtech gas boiler and two Oasis 25/2 pumps. Since the boiler electronics itself does not have an inductive load component, we will take its rated electrical power of 130 W into account without correction. The pumps have a rated power of 35 W. If the manufacturer did not also indicate the power consumption (in this case, 60 W), it could be defined as two times the nominal. Consequently, the consumption of two pumps will be 120 W in steady state, setting a double margin for the starting current and summing it up with the consumption of the boiler itself, we get a figure of 370 watts. Taking into account the power reserve for the inverter output stage, we will need a converter with a power of at least 0.5 kW.

If the inverter manufacturer indicates its power in kilovolt-amperes (kVA), you can convert it to kilowatts by knowing the power factor (cos φ) of the inverter itself. Thus, an uninterruptible power supply with cos φ=0.8 and a power of 1 kVA has a real power of 800 W.

The second parameter when choosing an uninterruptible power supply is the time during which it can supply power to the intended load. When calculating it, it must be taken into account that, on average, the functionality of the UPS output converter is maintained when no more than 75% of the battery capacity is exhausted. For example, if we use a battery with a capacity of 60 Ah, it can actually deliver no more than 45. Then, taking into account the average inverter efficiency of 80%, we get the following:

- The load from the previous example in steady state is 250 W, taking into account the losses in the inverter, we obtain the power taken from the battery at 312 W.

- At a nominal voltage of 12 V, this power means a current consumption of 26 A - a fully charged battery can supply the load for approximately 1.7 hours.

The type of uninterruptible power supply you choose determines both the budget and the features of the electrical network used. If the voltage in the network is relatively stable, it is enough to purchase an “offline” class UPS, but if the voltage fluctuates greatly, it would be more reasonable to either supplement it with an external stabilizer, or immediately buy an “online” or line-interactive class inverter. Since inverters of the required power usually use external batteries, it is worth checking what maximum charging current they can provide.

Considering that the optimal current for charging a battery is 10% of its nominal capacity, a device with a stated charging current of 6 A will work with batteries with a capacity of up to 60 ampere-hours.

Other criteria

Having solved the questions with the main technical points, pay attention to the following:

- Duration of work without pauses. Ordinary household models are not capable of working 24/7. After all, their engine needs cooling breaks. More massive and powerful units can withstand from 12 to 16 hours. Compact versions, weighing less than 10 kg, work without rest for 3-5 hours.

- Launch method. There are only two options: manual and automatic. The second guarantees complete autonomy of the heating network. But only expensive and powerful devices have this option.

- Noise indicators. They are determined by the functional engine speed, the ability to control them and the presence of sound insulation. Almost all low-power generators have a special casing that insulates sound.

Let's figure out what installation power is suitable for a particular home

A 5 kW gas unit is suitable for a small country house where you need to connect lighting and cook food on an electric stove. Equipment with a power of 10 to 20 kW can be used in small houses. It will provide energy to all household appliances necessary for comfort. There is an automatic start system function. If the equipment is air cooled, its operation is limited to 12 hours, after which a cooling time is required. To improve cooling, the generator can be installed outdoors, but to operate the equipment in frosts down to -30, the device must be equipped with a protective casing.

Operation of liquid-cooled equipment can last 10 days, after which an oil change is required. Such generators are widely used in country cottages and dachas. Gas generators with a capacity of 25 kW or more are used at industrial facilities, very large houses, dacha cooperatives, etc. Determine which household appliances will be powered by an automatic power supply system in the event of an emergency power outage from the station - this will allow you to correctly calculate the power required from the device.

Synchronous and asynchronous system

To make the right choice, you should know their distinctive characteristics. They are set out in the following table:

Characteristics Synchronous Asynchronous Voltage and frequency Stable and high-precision retention Variation in a significant spectrum Electrical overloads High vulnerability to them when starting in standard mode. Resistance to them when starting in a similar mode. Cost Higher Lower Design Complex Simple Maintenance criteria Requires frequent and serious service and inspection Less demanding and unpretentious

Synchronous models are purchased when a scrupulously precise amount of current is required, and the voltage in the network often changes over a wide range.

Devices of the second category are a good budget option and protect the heating network from power surges. This is especially true in domestic conditions. But for this it is recommended to supplement the devices with uninterruptible power supplies (UPS).

Why does the boiler go out when the power goes out?

In the event of power outages or accidents, the boiler automation is unable to perform its functions and immediately turns off the burner. This is ensured by the very design of the gas valve: it is pressed by the current passing through the coil.

If there is no current, it closes immediately.

Power outages, unfortunately, are not uncommon in Russia. So boiler owners have to sit in a cold house, although gas may be present in the mains. It cannot be lit without electricity, and tampering with the boiler can result in a fine from technical inspection authorities, as it leads to fire safety violations.

How long is uninterrupted power supply required?

According to current legislation, all residential private households belong to category 3 of uninterrupted power supply, which allows the energy supply organization to legally suspend power supply for up to 3 days.

As a rule, all emergency situations are resolved within 1 business day, but the most severe and prolonged accidents occur during periods of heavy snowfall. So in 2022, heavy snowfall led to a break in a high-voltage power line in the Pskov region. The accident took more than 3 days to resolve. 20,000 people were left without electricity in sub-zero outside temperatures.

Appearance of various designs of gasoline generator housings Source Pk-asia.kz

Choosing a heating boiler for your home

Today, the modern market offers a wide variety of boilers from foreign and domestic manufacturers. How to make the right choice and not make a mistake? Can't figure out the cost of a heating boiler for your home? You can, of course, entrust the choice of a boiler for heating your home to a qualified specialist if he will design a hot water supply and heating system. He will be able to ensure the best combination of system elements, tell you which boiler to choose and how to obtain the permits required for its installation. But it’s quite possible to figure out the priorities yourself when choosing a boiler that can economically heat your house.

For any home, the most important communications are: plumbing, energy, heating and sewerage. The quality of heating has a direct impact on the degree of comfort of the house and on how expensive its maintenance will be, especially during the heating period.

Selecting a generator for the boiler

For a gas boiler with an electronic control unit, it is preferable to purchase an inverter gas generator. Its price is noticeably higher than a simple one: 20-40 thousand rubles. versus 5-7 thousand, but it provides a sinusoidal voltage waveform and a stable frequency and voltage. In an inverter generator, an unpretentious input rectifier and a filter feed the inverter - a DC-to-AC voltage converter with excellent quality.

Before buying a generator, you need to find out what kind of power the boiler and pumps, if any, require. In the simplest case, it is enough to connect the terminals of the gas generator to the boiler power plug and start the generator engine. You can then light the boiler in the usual way.

When electricity becomes available, the generator can be turned off and switched to the power grid.

If the pumps in the system have three-phase motors, then the generator inverter must also be three-phase, and the boiler automation will be powered from one of the inverter phases. This applies to fairly powerful heating systems that heat medium-sized buildings and large cottages. Such a system must provide uninterrupted power supply to the boiler automation and pumps from an inverter operating together with the electrical network, through a bypass or even online. The generator is started in such systems to avoid draining the batteries for too long.

The power of the purchased generator should be selected with a 30-50% margin of the power consumed by the boiler together with the pumps. This will reduce the load on the generator engine and ensure its longevity.

If the boiler can operate from a gas generator, but has a separate neutral and phase, that is, it is not connected with a plug into a socket, but is mounted with a cable in the electrical panel, then a special generator connection diagram will be required, which prevents the simultaneous operation of the network and the generator. A single-phase inverter generator can be connected to such a boiler in any way, i.e. both of its terminals are equal in this case. The RCD should work with this connection.

The table shows examples of some 220 V gas generators.

| Model | Power | Reliability | Noise | Price | Weight | Launch | Fuel consumption | Working hours | Service | Reviews |

| DDE GG950DC | 625 W | 4 | 65 dB | 4400 rub. | 18.5 kg | manual | 0.72 l | 5.8 h | — | good |

| DENZEL DB950 | 650 W | 5 | 62 dB | 4800 rub. | 17 kg | manual | 0.7 l | 5 hours | — | great |

| FAVORITE PG950 | 950 W | 4 | — | 4990 rub. | 16 kg | manual | — | — | — | — |

| Most Power G800L | 650 W | 4 | quiet | 5027 rub. | 17 kg | manual | 0.69 l | 4 hours | There is | good |

| CHAMPION GG951DC | 650 W, inverter | 4 | very quiet | 5250 rub. | 19 kg | manual | 0.65 l | 4.6 h | There is | great |

| Hammer GNR800B | 600 W | 5 | quiet | 5990 rub. | 18 kg | manual | — | 8 hours | There is | great reviews |

| DDE DPG1201i | 1 kW, inverter | 4 | 58 dB | 6490 rub. | 12 kg | manual | — | 4.5 h | — | good |

| DDE DPG1201i | 1 kW, inverter | 4 | 65 dB | 6610 rub. | 13 kg | manual | — | 5 hours | — | normal |

| Eurolux G1200A | 1 kW | 4 | 75 dB | 6680 rub. | — | manual | 0.58 l | 9 hours | There is | very stable |

| Caliber BEG-900I | 900 W, inverter | 4 | 70 dB | 6590 rub. | 12 kg | manual | 0.52 l | 8 hours | There is | works well, lightweight |

| Redbo PT2500 | 2.2 kW | 5 | — | 6990 rub. | 38 kg | manual | — | 14 h | — | — |

| Eurolux G3600A | 2.5 kW | 5 | 77 dB | 9002 rub. | — | manual | 0.8 l | 18 h | There is | great |

| FAVORITE PG3000 | 2.5 kW, inverter | 5 | — | 9620 rub. | 36 kg | manual | — | 13:00 | There is | great |

| Kölner KGEG 5500 | 5.5 kW, inverter | 4 | 72 dB | 20493 rub. | 78 kg | manual | 1.6 l | 12 h | There is | good |

| CHAMPION GG650 | 5 kW | 5 | — | 22100 rub. | 77 kg | manual, starter | — | 13:00 | There is | very reliable |

| Bort BBG-6500 | 5.5 kW, inverter | 5 | 75 dB | 20750 rub. | 77 kg | manual, starter | 1.8 l | 12 h | There is | good |

| Daewoo Power Products GDA 12500E-3 | 10 kW, inverter, 220/380 V, 3 phases | 4 | — | 159,000 rub. | 165 kg | manual, starter, autostart | 4.2 l | 5 hours | There is | good |

| ENERGO EB 15.0/400-SLE | 12.6 kW, 220/380 V, 3 phases | 4 | 75 dB | 227700 rub. | 135 kg | starter, autostart (AVR) | 4 l | 6.2 h | There is | — |

| EUROPOWER EP16000TE (Honda) | 13 kW | 5 | 77 dB | RUR 293,791 | 152 kg | starter, autostart | 5.1 l | 4 hours | There is | good power plant |

| ENERGO EB 14.0/230-SLE | 11 kW, 220 V, 1 phase | 4 | 74 dB, with soundproof casing | RUB 554,480 | 930 kg | starter, autostart | 3.9 l | 6 hours | There is | — |

The best known manufacturers and models: characteristics and prices

Denzel GT-950i

One of the best inverter gasoline generators for a gas boiler with a power of 0.9 kW and economical fuel consumption of 0.5 l/hour. Designed for continuous operation for 4.5 hours, it has compact dimensions, a more stable and quiet 4-stroke internal combustion engine, a body in the form of a soundproof casing, which makes its operation quite quiet.

According to reviews from the owners, the mobility of the generator allows it to be used not only to power the boiler, but also other equipment in the house, and to take the generator to the garage or fishing at any time.

Daewoo Power Products GDA 1500I

An excellent, more powerful 1.4 kW inverter synchronous gas generator, which is enough to provide electricity to the most complex heating systems. The four-stroke engine is housed in a soundproof casing, making its operation virtually silent. However, the model has higher fuel consumption - 1.25 l/h, which is still compensated by the presence of an inverter and the ability to adjust the speed. With a sufficiently high power, it has only one outlet.

Through practice, the generator has proven itself to be optimal in performance, reliable and durable.

Cost : 17,000 rub.

Huter DY5000L

Powerful 4.5 kW dual-fuel (gas/petrol) synchronous generator. Designed to power not only the boiler, but also the full-fledged electrical network of an average country house. Designed for continuous operation for 9-9.5 hours, the generator automatically turns off when overheated, overloaded or low oil level. No obvious shortcomings were observed due to the practice of use.

CHAMPION IGG980

An excellent inverter gasoline generator with a power of 1.1 kW and economical fuel consumption of 0.6 l/h. It is distinguished by an extremely affordable price, small size, greater power than stated by the manufacturer, and the ability to adjust it. But, like other inexpensive models, it has characteristic disadvantages in the form of a low-quality sinusoid at the output, noisy operation, poor assembly, which causes oil and gasoline leaks.

Connecting a gasoline generator

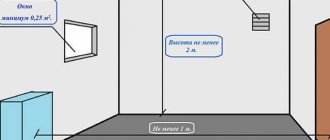

In this process, first of all, you need to take into account that the device runs on fuel. And after burning it should come out. For this purpose, an exhaust hood is created.

There should be free space around the device itself: 1-2 m. This provides access to the device for various purposes: refueling, manual starting or repair.

Before connecting the unit to the boiler, read the instructions. To connect to the network, a distribution panel is used, in which an automatic fuse is installed.

Both devices must be grounded. You can proceed according to the standard scheme:

This way you guarantee safety and the appearance of zero. These are mandatory conditions, without which the system will not be able to identify the flame and the boiler will not start.

If the generator is installed for the entire house, then a common network is used to ground it.

For both units to function correctly, the output must have a 50 Hz sine wave. If the indicators are different, it will be difficult to start the boiler. IHD can correct the situation.

In general, the algorithm for connecting a generator to a boiler has the following steps:

- Finding the necessary contacts in both devices (the diagram in the instructions helps with this).

- Connection and insulation of wires.

- Grounding of devices.

These operations look simple, but it’s better to trust them to professionals.

Rules for installing a UPS for a gas boiler

The UPS must not be placed near the cold water supply pipes of double-circuit boilers (condensation forms on them), or near heating pipes, so as not to interfere with the cooling efficiency of the inverter. Batteries should also not be exposed to low or extremely high temperatures.

The UPS cannot be used in conjunction with lead-acid batteries unless this is expressly stated in the operating instructions for this uninterruptible power supply. Differences in the charging current characteristics of lead-acid and gel batteries may cause the UPS charger to not operate properly.

It is advisable to use offline class devices in conjunction with a voltage stabilizer connected between them and the external network.

When using a phase-dependent gas boiler in a heating system together with a UPS, its output is connected to the load through an isolation transformer. This is due to the fact that when an inverter operates, both of its outputs are phases relative to ground, while a phase-dependent boiler requires a clearly defined phase and neutral of the supply. This is what an isolation transformer is used for, one of the terminals of the secondary winding of which is grounded.

Pivot table

In the following table you can get acquainted with 9 popular and efficient UPSs on the market, which are divided into 3 subgroups. From the names you can understand that the main factor is the required uptime.

We also took into account the heated area of the house: the larger it is, the higher the power consumption of the boiler and pumps.

Each subgroup presents models for houses up to 100 sq.m (power consumption of boilers and pumps - 100-150 and 30-50 W) and for 100-200 sq.m. (150-200 and 60-100 W). 9 best UPS for gas boilers

| Group 1: UPS for short (up to 2 hours) and rare (2-4 times a year) outages | ||

| 1. |

Ideal for: a boiler in a small house up to 100 sq.m with a stable voltage of 220 V | 11000₽ |

| 2. |

Ideal for: boilers without external circulation pumps in a small house up to 100 sq.m. | 10800₽ |

| 3. |

Ideal for: connecting boilers and pumps in houses of 100-200 sq.m. | 12900₽ |

| Group 2: UPS for long-term (from 2 hours) and frequent (from 5 times a year) outages | ||

| 4. |

Ideal for: sensitive boilers and pumps in houses of 100-200 sq.m. with unstable voltage | 16800₽ |

| 5. |

Ideal for: boilers and pumps in houses of 100-200 sq.m with stable voltage | 12900₽ |

| 6. |

Ideal for: boilers with built-in pump in houses up to 100 sq.m. | 10325₽ |

| UPS for combined operation with an electricity generator | ||

| 7. |

Ideal for: uninterruptible power supply to boilers and pumps with unstable voltage | 19350₽ |

| 8. |

Ideal for: boilers with ultra-low voltage and high noise requirements | 17700₽ |

| 9. |

Ideal for: expensive boilers with sensitive electronics | 21600₽ |

Now let’s take a closer look at the characteristics of the models, study customer reviews and watch video reviews.

How to choose a gas generator?

Before choosing a generator for a gas heating boiler, you need to understand for what period you need to reserve electricity.

Situations in which uninterrupted power supply to a gas boiler may be required:

- Regular short-term (up to 2 hours) power outages. They may be associated with a worn-out network or exceeding the consumption limit.

- During the elimination of minor accidents, carrying out planned work, connecting new consumers. Power may be out for up to six hours.

- Emergency shutdown after short circuits or breakdowns in the package transformer substation. The problem resolution period is up to 24 hours.

- Outages due to severe weather conditions. A quick response from repair teams is impossible. Duration: up to three days.

The next step is choosing a specific model.

The main criteria for choosing a gas generator are:

- price;

- power;

- noise level;

- maximum duration of work;

- output current quality.

To determine which generator is needed for a modern gas boiler, each point should be analyzed in detail.

Power - to select this parameter, you need to know the power of the gas boiler. If you plan to connect other devices, their total power is taken into account. 20-30% should be added to the resulting value.

A shortage of active generated power in the power system can lead to a drop in the frequency of the supply voltage

When determining the dimensions, you need to estimate the area of the room. The more compact the model, the higher its cost. Imported gas boilers are demanding on the quality of the supplied current.

In this case, you need a device capable of generating a stable voltage of the required parameters. The noise level of most generators during operation is up to 80 decibels. For inverter models this figure is lower.

Recommendations: do not choose cheap generators. This is a dubious saving, since low-quality equipment is guaranteed to lead to a gas boiler quickly failing.

When choosing a generator, all factors should be taken into account. The more often and for a longer period of time a power outage occurs, the more work the generator has to do.

Types of UPS

According to their design, uninterruptible power supplies are divided into three types:

Online inverters for boilers, unlike offline ones, have a built-in stabilizer at the input and, thanks to this, switch to backing up power from the battery only when the network power is turned off. When its voltage deviates from 220 V, the stabilizer operates. This scheme is more expensive, but also more effective when used in a network with strong daily voltage fluctuations (for example, a low-power substation in the private sector). An offline inverter under such conditions will go into standby mode too often, requiring the installation of a separate voltage stabilizer in front of it.

Line-interactive inverters are the most advanced class of devices. In them, the input voltage is immediately converted into direct current, supplied to the output inverter, and the battery is connected between the blocks. A conventional welding inverter is constructed in a similar way (if you do not take into account the battery). Thus, the supply voltage is always stabilized, and when it is turned off, there is no delay in switching the UPS output from the external network to the inverter.

A new generation of autonomous power sources - inverter gas generators

These backup power supply devices are capable of providing boiler automation, welding equipment, freezers, and power tools with high-quality power supply with a stable voltage.

The dimensions of inverter devices are approximately one and a half times smaller than those of traditional models.

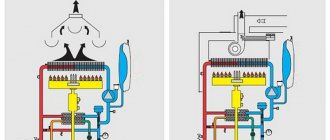

Operating principle of the inverter unit:

- alternating current is supplied to the input from the generator;

- passage of the rectification circuit;

- a smoothing circuit is used to stabilize the current;

- transformation into sinusoidal current - conversion circuit;

- generation of alternating current with a stable voltage.

Gasoline inverter-type mini-power plants are characterized by a reduced noise level - 50-60 dB. The sound of operating equipment is noticeable, but does not cause irritation or deterioration in well-being.

Another important advantage of such power plants is their efficiency. The power can reach 2 kW and with intensive use only 20 liters of fuel are consumed within a week.

https://youtube.com/watch?v=mUmyZjFNrbY

how to connect the boiler to the generator

This article deals only with the problem of connecting gas boilers to a generator.

And you are reading this article for two reasons:

- You already have a boiler and a generator, and the boiler does not want to work with the generator, while the gas burner tries to ignite, but goes out after 3-5 seconds.

You are just planning to buy a generator to power the boiler in the event of a centralized power supply failure.

There is only one reason - the absence of a hard zero on the generator. Every modern boiler contains a device that controls the presence of flame in the combustion chamber. This is called "gas control". The principle of operation is to continuously measure the ionization current flowing between a metal pin insulated from the burner body and the combustion chamber body itself. The “phase” is supplied to the pin, and the phase is 220 volts in relation to the “ground”, and the body is the “ground” - 0 volts. The boiler control board measures the ionization current, and if it is within acceptable limits, then everything is fine, gas is supplied, there is a flame, the gas burns, there is no danger. If there is no ionization current, or it is small (less than 20mA), the control board interprets it as the absence of flame in the combustion chamber and gives a signal to re-ignite the burner, and so on several times. If the ionization current does not appear, the gas supply is blocked for safety reasons.

In Generators that do not have a zero, there is a sinusoidal voltage at the output with an amplitude of 220 volts, but this voltage, or more correctly, the potential difference, is present between two “holes” in the output socket. And if you measure the potential difference between the “housing” of the generator and each of the “holes” of the socket with a voltmeter, then 220 volts will not work - but the tester will show 110 and 110 volts at idle, and for example 50 and 170 volts under load. If the power plug from a gas boiler is plugged into such a generator, then not 220 volts, but 110 will be supplied to the pin. This voltage will not be enough for the normal value of the ionization current and the gas control system will work.

What to do? The conclusion suggests itself - you just need to connect one of the holes in the generator output socket to zero (the zero bus of the house). But this cannot be done for inverter generators; the zero bus is connected to the ground bus at the entrance to the house. Therefore, it turns out that you are shorting one of the outputs in the socket to the same generator housing, because According to operating rules, the generator housing must be grounded. In this case, there is a high probability of failure of the generator coil.

There is only one way out - installing an isolating transformer. The connection diagram is shown in Fig. Physically, we separate the output circuit of the generator from the input circuit of the boiler and have every right to connect one of the transformer outputs to the zero bus of the house. Such a connection will not have any negative effect on the generator coils. Another advantage when installing an isolation transformer is its ability to smooth out sudden voltage surges. A transformer is a coil, and a coil is an inductance, and inductance always resists a sharp rise (edge) of a signal.

BAXi specialists (link to the BAXI boiler manufacturer forum website) advise solving this problem by using a specially designed Teplocom GF device.

Connection instructions

Scheme of combining a gas boiler and a generator with grounding.

Connecting a gas boiler to a generator is quite simple; it is only important to ground the “zero”. But if the generator does not have a clearly defined “zero” and “phase”, there are 2 methods of grounding:

- Use a 220/220 separation transformer corresponding to the power of the gas boiler. Consider one of the terminals of its secondary winding as “zero” and ground it.

- Take the phase with a higher potential to ground as “zero” and ground it.

Without grounding, the gas boiler will not operate from the generator, since the ionization flame sensor will not function. If the generator is connected to the electrical network at home, grounding is not required, since it is already carried out in the electrical network.

Instructions for grounding a gas boiler in a private house

It is important to understand that the generator, like the internal combustion engine of a car, during its operation emits a sufficient amount of combustion products in the form of exhaust gases. Therefore, you need to take care of the ventilation system, preferably forced. To do this, you need to install ventilation to the generator itself; an excellent solution is to completely divert all exhaust gases to the street by connecting a corrugation to the exhaust pipe.

Compliance with all safety rules: exhaust to the street through a corrugated hose, additional forced ventilation of the room, fire protection of floor and wall coverings.

To start the generator, follow the instructions in the instructions; as a rule, it contains schematic images that describe a simple algorithm.

How to insure the operation of the boiler

In such conditions, many boiler owners prefer to back up the power supply for their heating. There are opportunities for this, it is not prohibited, and the market offers choice. Batteries can be used in conjunction with inverters. This device resembles a computer UPS, only slightly more powerful. As a rule, boiler automation consumes quite a bit of electrical power, but this already depends on the overall configuration of the heating system. If it has pumps, then their operation is often necessary, that is, they do not simply increase the efficiency of coolant circulation, but are included in the heating design as a necessary element.

Then the overall energy consumption increases.

Also, in some cases, autonomous generators based on internal combustion engines may be suitable: gasoline or diesel generators. Gasoline generators can be powered from a gas main if a particular model allows the carburetor to be replaced with a special device. There are models that already provide for switching from gasoline to gas. There are generators with gas equipment that can be connected to natural or liquefied gas.

Of course, to power an autonomous power plant designed to generate electricity for the needs of a gas boiler and other heating equipment, a gas version of the engine would be best suited. With sufficient power - from 10 kW - such a power plant could back up the entire power grid of a cottage during a power outage. The market offers a lot, but this solution is not cheap.

The boiler automation system consumes power of about one to two hundred watts - what is needed to power the gas electric valve and draft, flame and pressure sensors in the line. If the system has pumps, then the power consumption increases significantly: a household single-phase heating pump has a power consumption of 300 watts and above. Under such conditions, the load on the inverter increases and very expensive equipment is required.

Many boiler owners are forced to look for cheap solutions - this is due to the level of average income in Russia. Is it possible to use a gas generator for a boiler? This solution seems very effective: the cost of gasoline generators is low, and the power is sufficient in many cases.

Unfortunately, the stability, frequency and shape of the output voltage provided by a gasoline generator for a gas boiler may not be sufficient in the case of a cheap model.

If an inexpensive generator powers boiler automation in a system without pumps, then its power is quite sufficient, but a non-sinusoidal and “jumping” voltage can lead to unstable operation of the gas valve or electronics power source. Modern power supplies are all pulsed; they are quite tolerant of power supply errors from the mains, but when powered by an autonomous generator with a low-quality voltage, they can operate unstably and even fail. Control units and controllers consume power of the order of several tens of watts.

Which is better to choose: petrol, diesel or gas

The first step is to decide on the choice of fuel on which the generator will operate. There are three options worth considering:

Compact and mobile gas generator in a soundproof casing.

- Gasoline generator – the most common solution; there are many models of varying power to choose from. The advantage of gas generators is their most affordable price. Many models are made in a lightweight plastic case with a sound insulation layer and have compact dimensions. To operate even the most demanding gas boilers, inexpensive gasoline models with a capacity of 0.6-0.8 kW are sufficient.

Classic diesel power plant. - Diesel generator – more economical generators with a long service life are used to provide electricity not only to the heating boiler, but also to the entire house. Diesel fuel consumption is 20-30% less, with the same cost of 92-grade fuel recommended for use in gasoline models. However, diesel generators are less environmentally friendly and require a high-quality ventilation system (usually forced), and have less compact dimensions.

Electric generator running on natural or liquefied gas - A gas generator is the most economical and environmentally friendly of the above types; there is no need for constant refueling; devices with autostart are completely autonomous. In addition to natural gas, they can operate on liquefied (cylinder) gas. If you have the opportunity to purchase more expensive equipment and want to connect the power plant to the gas main, it is better to choose a gas generator.

The principle of operation on any type of fuel is the same: the fuel is burned in the internal combustion engine, the rotor with magnets inside the stator winding spins, converting thermal energy into electric current. There are models with both 1 socket and 2-3 sockets for powering several devices at the same time.