Having realized the dream of purchasing a country house, many buyers are faced with difficulties in choosing a suitable boiler for heating the building. How much power is enough to maintain a comfortable temperature level? What type of boiler will satisfy the buyer's needs? The purchase is important, so when choosing a gas boiler, you should carefully study all its characteristics.

Types and design of a gas boiler

Before we talk directly about all the components of a gas boiler, we need to consider what options there are for these heating devices. Of course, they all have a similar structure, but, nevertheless, some models are equipped with individual features that are characteristic only of them. The classification of boilers operating with gas is as follows:

- samples of floor and wall type. If we talk about convenience, then wall-mounted equipment, which is more typical for private buildings, would be more acceptable. The main advantage of a floor-standing unit is its much greater power, as a result of which it can be used to heat a room with a very significant area. Such models are very often used in production;

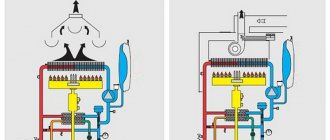

- gas boilers of atmospheric and turbocharged type. To understand how gas heating with an atmospheric boiler works, you can recall the principle of operation of a standard stove, where air from the room enters a specially designed chimney due to natural draft. Turbocharged devices are equipped with a fan, which is included in the design, and the fuel combustion chamber is completely closed, so all the required amount of air comes from the street (more: “How does a turbocharged gas boiler work - principle of operation, advantages and disadvantages”);

- mechanisms with one and two circuits. The design of a gas boiler with one circuit is designed so that this equipment is used exclusively for heating rooms, while devices with two circuits can also play an important role in the water supply system, providing the room with hot water;

- boilers equipped with a conventional burner or a modulating burner (for more details: “What are the types of gas burners for heating boilers - types, differences, rules of use”). In the second case, the power of the operating equipment is automatically regulated, due to which fuel costs can be significantly reduced;

- devices with electronic or piezoceramic ignition. The first option is more convenient, since it is possible to ignite the fuel in the combustion chamber without the direct participation of the owners, and in the second case, it is necessary to turn on the device every time you start it by pressing a certain button.

Advantages and disadvantages of dual-circuit devices

The advantages of a double-circuit heating unit are as follows:

- Economical fuel consumption. The direction for comparison is to use a double-circuit boiler or a single-circuit boiler with indirect heating.

- Compact sizes. The overwhelming majority of double-circuit boilers are wall-mounted heating devices. They are easy to place both in utility rooms and in small kitchens.

- Versatility. There is no need to buy additional equipment and resolve issues with its compatibility with the boiler.

In one unit, a flow-through water heater, a heating device and a circulation pump have already been successfully combined into a single automated system.

Obviously, along with the advantages, there are also disadvantages:

- Impossibility of simultaneous operation of the heating and DHW circuit. In this regard, significant consumption of hot water can cause a decrease in the temperature in the house.

- Power limitations of wall-mounted models. Compact wall-mounted boilers, due to the minimum size of the burner, are not able to provide the required temperature conditions at maximum pressure. A similar disadvantage is observed when water intake points are located remotely.

- Sensitivity to water quality. The secondary plate heat exchanger is demanding on the quality of the water consumed. The presence of impurities causes the use of means to reduce its hardness and clean the coolant.

Another criterion for evaluating a double-circuit boiler is its cost. The price of a double-circuit heater is higher than the price of a single-circuit analogue.

However, if we consider the presence of a hot water system and ways to resolve the issue in the case of installing a single-circuit boiler, then if indirect heating is included in the boiler assembly scheme, the price of a double-circuit boiler will be lower.

Design and principle of operation of a gas heating boiler

As mentioned above, most heating boilers are similar in design. But in order to understand how to use a gas boiler correctly, you need, of course, to know what structural parts this equipment consists of. The basis of a standard gas boiler is the following elements:

- rectangular gas burner

. This design includes nozzles, which serve as a point for conducting gas into the combustion chamber. Thanks to these elements, the flame is distributed evenly, which makes the combustion of the coolant inside the system more efficient; - heat

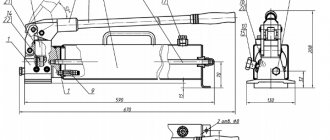

exchanger This device is a metal box equipped with a built-in battery. Inside this box there are pipes through which the coolant circulates. Heating of water occurs due to the fact that the heat exchanger, heating up from the gas burning inside the chamber, transfers heat to it. If in a single-circuit type boiler there can be only one heat exchanger, then in double-circuit devices there can be two (primary and secondary); - circulation pump

. Using this device, the pressure that occurs in a circulation system operating on a forced principle is regulated. Not all boilers are equipped with such a part; - expansion tank

. The main purpose of this element is to temporarily remove coolant, which is necessary in the case of heating and expansion of water. This tank is equipped with a special container that can be suitable for any gas boiler. If you plan to use heating equipment over large areas, you can install another expansion tank; - a device responsible for removing fuel combustion products

. In atmospheric boilers, this element is connected to a separate chimney that has natural circulation, and in turbocharged mechanisms there is already a double coaxial type exhaust pipe, in which combustion products are removed by means of a built-in fan; - an automatic system that serves as the boiler control center

. Its main element is an electronic circuit that allows you to set the desired operating mode of the boiler based on the data displayed on the installed sensors.

In order for the service life of a gas boiler to be as long as possible, it is important that each of its elements functions reliably and properly (about

Protection system

Almost all models of modern gas boilers have a highly effective multi-level protection system. First of all, in the event of a gas supply interruption, the solenoid valve, which is responsible for the flow of fuel into the boiler, automatically closes. However, a significant drawback is that the valve does not open automatically when the gas supply is restored. In this case, the boiler must be restarted manually. If there is a power outage, then after it is restored the system starts up on its own.

Modern models have a long range of protective functions. One of the most important is to protect the system from freezing.

That is, the temperature of the coolant is constantly monitored by special sensors. And if it drops to a critical temperature, the system independently starts the boiler to warm up the coolant. Another extremely important and useful function is that to ensure high-quality performance, the system automatically starts the circulation pump once every certain period of time and “drives” the coolant. Thus, all elements are constantly maintained in working order.

If a malfunction occurs in the system, information about this will immediately be displayed on a special screen located on the control unit. Having discovered a malfunction and calling a service center specialist, you should definitely tell him the error code that appears on the display. Thus, the technician will arrive knowing in advance about the breakdown - and will be able to restore the system to functionality in the shortest possible time.

Gas boilers are quite economical - special equipment allows you to reduce not only fuel consumption, but also the calculation of a gas heating boiler, the energy consumption consumed by the system, and the efficiency of a gas heating boiler is acceptable.

Circulation pump operation

What the performance indicators of the circulation pump will be depends, first of all, on the power at which the boiler operates, and this device does not have much influence on the operation of the entire system. It is very important that the pipes through which the coolant circulates are made of high-quality material, for example, steel or good plastic.

Operating rules

During operation of an open-type gas boiler, it is necessary to ensure a sufficient air supply in order to ensure complete combustion of gas.

Otherwise, the efficiency of the unit will be low, and the volume of unburned gas will be large, with possible release into the room. In closed fireboxes, it is also important to monitor the sufficiency of air and the functionality of the blower fan. Basic rules for the safe operation of a heating boiler operating on gas fuel if there is a gas smell:

- immediately turn off the gas valve to the burner device;

- open windows for ventilation;

- in closed-type boilers, forced ventilation is turned on in the chimney system of the gas boiler;

- do not use electrical switches and matches;

- immediately turn off the open flame;

- report an emergency to the gas service.

Autonomous heating is gaining popularity; for many homeowners it has become as necessary in the cold season as an air conditioning system in the summer - an affordable level of comfort in residential premises that ensures normal life activities.

The main function in this is performed by modern boiler installations - technologically advanced, innovative units capable of solving multi-level thermal problems.

Operating principle of the expansion tank

This device has a significantly more serious impact on the operation of the gas boiler. This device is designed so that in the event of an excess of coolant in the system, which usually occurs due to overheating of the coolant, the excess water is stored and subsequently used again. Approximate calculations show that the total volume of such a tank should be about 10% of the total water in the heating system, therefore, for the installation of such equipment, it is important to have data regarding the length of the pipes and the capacity of the heating system. To understand in more detail the features of installing a gas boiler, you can always study additional photos of all its structural parts and watch videos on their installation, which can always be found from specialists involved in connecting such equipment. Video about the construction of a gas heating boiler:

Boiler power. How to choose it?

The heating power of the boiler is calculated based on the area of the heated building. The generally accepted figure is 1 kW per 10 square meters. This takes into account the power required directly for heating, with compensation for lost efficiency (efficiency factor) due to room ventilation, as well as taking into account a small power reserve. Thus, we can calculate that if the ceiling height is about three meters, then 10 square meters will require 0.6 kW of heat, which with an increase of 30% to compensate for efficiency losses from building ventilation and with a reserve of up to 30% of power will give us the same figure of 1 kW per 10 square meters. Too large a reserve of boiler power is also not desirable in order to save both on resource costs and on the cost of the boiler itself. Accordingly, an area of 200 square meters will require a heating system with a capacity of 20 kW. At the same time, it is worth taking into account the energy efficiency of the room - window area, insulation of walls and floors, as this significantly increases energy costs to create a comfortable temperature in the room.

Installation stages

Installation of a wall-mounted gas boiler is carried out by specialists using the following technology:

- Preparing the room for placing the unit in accordance with regulatory requirements.

- Creation of a ventilation system.

- Installation of fasteners and brackets.

- Installation of the unit.

- Supply and connection of heating system pipes.

- Connecting cold water supply.

- Connecting gas boiler equipment to a gas source.

- Installation of wiring, connection of electrical appliances and automation.

- Installation of a chimney.

- Checking, preparing and test running the boiler.

Important! In the room where the gas boiler is installed, safety regulations must be strictly observed. Wall decoration is allowed only from non-combustible materials. In addition, the presence of an air gas sensor is a mandatory condition for operating the unit.

Method for removing combustion products

Boilers are divided into devices with natural or forced draft. Firstly, the installation of a chimney pipe is required. Secondly, combustion products are removed in a forced manner - thanks to a fan built into the chimney pipe.

Gas boilers operating on natural draft are also called devices with an open combustion chamber. The oxygen necessary for gas combustion is taken from the room - this is their disadvantage. Access to outside air is required in the room with the boiler. This results in a slight draft. Lack of oxygen negatively affects health.

Some boilers are equipped with a coaxial chimney. They are called gas boilers with a closed combustion chamber.

Combustion products are discharged through a coaxial chimney, called a “pipe-in-pipe”. These are two pipes of different diameters inserted into one another. Gas combustion products are removed through a pipe of smaller diameter. And fresh air from the street enters the space between the pipes, which is heated by the inner pipe. As a result, the efficiency of the boiler increases.

The advantages of such a chimney are obvious:

- Oxygen is taken from the street.

- Small chimney size, since a coaxial chimney can be installed in an external wall located next to gas equipment.

- Such a chimney can be installed anywhere in the room and be horizontal, inclined or vertical, which allows.

- Boilers with a coaxial chimney are more economical, although their cost is higher.

Steam boilers. Technical characteristics of steam boilers

Our organization provides a full range of services for operational, commissioning and environmental-thermal testing of steam boilers of any type and volume

Steam boilers. Technical characteristics of steam boilers

A steam boiler is a device designed to produce steam at a pressure higher than atmospheric pressure due to the heat generated by burning fuel. The main elements of the boiler are the firebox and heat exchange surfaces.

Water is supplied to the boiler, which is called feed water. The feedwater in the boiler is heated and then converted into saturated or superheated steam of the required parameters. Steam parameters mean its pressure and temperature. The main consumer of water steam generated in boiler plants is steam power plants, and it can also be used for technological needs.

Steam boilers. Technical characteristics of steam boilers

Operating principle of steam boilers

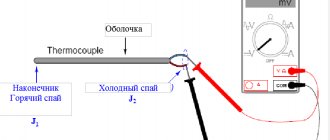

The conversion of feedwater into steam occurs in the heating surfaces of the boiler. Boiler heating surfaces include evaporative, superheating and economizer surfaces.

Evaporative heating surfaces are usually located in or directly behind the boiler firebox. In them, water is heated to saturation temperature and a so-called steam-water mixture is formed.

Superheaters are designed to produce superheated steam. They are located behind the combustion chamber.

Economizer heating surfaces are designed to preheat feedwater using the heat of combustion products leaving the boiler.

Basic elements of the boiler

- drums - designed to separate saturated steam from water, remove excess moisture from it, and also as a device in which the amount of water necessary for reliable operation of the boiler is accumulated;

- air heaters - heating surfaces in which the air entering the firebox and necessary for burning fuel is preheated;

- burner devices - devices for burning fuel in the boiler furnace. The burner devices of modern boilers primarily ensure the most efficient combustion of fuel from the point of view of chemical processes and a reduction in the amount of harmful substances formed during the combustion process and emitted into the atmosphere.

- devices for regulating the superheating temperature of steam - heat exchangers of various types and injection desuperheaters.

Steam boilers. Technical characteristics of steam boilers

Classification of steam boilers

Steam boilers are divided according to their purpose into three main types: energy, industrial and waste heat boilers.

Industrial steam boilers, unlike power boilers, produce saturated steam, which has the boiling point of water.

Waste heat boilers can produce both steam and hot water.

Steam boilers according to their parameters are divided into:

- low steam output – up to 1 t/h of steam;

- average steam output - from 1 t/h to 10 t/h steam;

- high steam output - over 10 t/h of steam .

Our contacts

The specialists of our organization will perform installation, adjustment, maintenance, and verification of gas-using equipment of any type and volume in the city of Dnepr and the Dnepropetrovsk region.

To carry out the work, we have all the relevant documents issued by government bodies, as well as laboratories certified by government control bodies.

+380 63-852-66-89 +380 96-669-11-03

Feedback form. (Ask a question, leave your contact details, send a message – and we will contact you as soon as possible.)

The best known manufacturers and models: characteristics and prices

Now let's look at specific models so that you understand the difference between them. Still, the characteristics differ not only between specific models, but also between different companies. These are the most popular boilers in Russia.

Single-circuit

Let's start with boilers that are designed exclusively for heating.

BAXI ECO Four 1.24

Reliable fourth generation Italian boiler with a closed combustion chamber. The wide LCD display makes it easy to monitor and adjust the temperature. They do this using two modes. The first one is suitable for radiators. You can select a range from 30 to 80 degrees. The second mode involves the use of heated floors. The adjustable range is from 30 to 45 degrees. Safe operation is ensured by the most modern sensors. There is protection against freezing, pump pump blocking and a three-way valve.

Another feature is the modulating burner, which allows you to minimize noise when turned on. The boiler reaches the last 5 degrees of the set temperature at the minimum flame. Gas consumption at an efficiency of 91.2% is 2.78 m³. This model perfectly combines efficiency and European quality. But many owners say that the boiler is afraid of voltage surges, so it is better to install a stabilizer. Otherwise, this is a problem-free, most popular and widespread gas wall system in Russia.

Protherm Panther 25 KTO

The Protherm company produces its equipment in Slovakia and is part of the famous German corporation Vaillant Group. The model has gained quite significant popularity due to its efficiency and reliability: efficiency reaches 92.8%, closed combustion chamber, copper heat exchanger and pipes. Convenient control, high-quality spare parts, protection against freezing, overheating and pump blocking.

If you buy a boiler from the same company, you will get a single compact device. The boiler can be installed directly under the boiler, and all communications can be hidden in a special casing.

The boiler perfectly heats two-story buildings. You don't even have to install an additional pump. The owners themselves say this. Modulating burner and pneumatic gas valve ensure low noise levels. Excellent build quality. But the price is higher than similar models from other manufacturers.

Viessmann Vitopend 100-W A1HB 24 kW

A turbocharged model from a German manufacturer, which is considered the standard of quality. It is distinguished by one of the lowest practical gas consumption indicators in the price segment (although the maximum consumption is not a record low - 2.77 m3/hour). It is also known for its almost silent operation (double noise insulation), modulating burner, and a huge list of safety systems.

Modern automation allows you not only to regulate the temperature, but also to program the operation of the boiler for a week in advance - a rather rare function for this price category. The controls are simple, so don't worry about not understanding the functionality. And if you want to install a backup boiler, then the Viessmann Vitopend 100-W A1HB002 is best suited. After all, it has the ability to cascade connect two boilers. To obtain hot water, you can connect an indirect heating boiler.

Among the shortcomings, one can note only vulnerability to voltage surges (the protective mechanism is designed for 170-253 V, which is not always enough). Please note that today there are three generations of the model: A1HB001, A1HB002 and A1HB003.

<

The best German gas boilers The most efficient, reliable and functional models on the market

BAXI Duo-tec Compact 1.24

One of the best representatives of condensing boilers, repeatedly taking first place in authoritative ratings, is considered one of the “smartest” representatives of the budget segment. For example, Think technology allows it not only to adapt to different operating conditions (weather, gas composition, chimney parameters), but also to control different temperature zones.

The maximum gas consumption is only 2.61 m³ per hour, the efficiency is 105.7%. The heat exchanger is made of stainless steel, so it is not afraid of harsh operating conditions. A filter is installed at the cold water inlet. The model is single-circuit, but the three-way valve is already built-in. Despite the fact that the boiler is a condensing boiler, its dimensions are not particularly large. Yes and weight too. According to reviews from owners and installation experience, the boilers have been operating without problems for more than 7 years and are known for their high reliability.

When compared with the condensing boiler market, the model cannot be called the most efficient, but for its extremely budget price it is one of the best offers in terms of technical parameters.

Rinnai BR-UE30

Technological and smart Japanese boiler. A modulating burner with turbocharging, a copper heat exchanger and pipes, the boiler has very compact dimensions characteristic of Japanese models. The maximum gas consumption is only 2.87 m³ per hour, which is very significant for a power of 29 kW. For comparison, European boilers of 24 kW usually have approximately the same consumption. The set includes a remote control that can be hung separately in any convenient place.

It is possible to connect an indirect heating boiler, as well as disinfect it using the Anti-Legionella function. Switching to hot water will occur automatically using a built-in three-way valve. Rubber seals are installed at the joints, an anti-vibration insert is installed on the rear wall, and the front cover is additionally thickened. All this allows you to reduce the noise from the operation of the boiler to a minimum. There are many advantages, but the disadvantages include the high price of the boiler itself and spare parts (the need for which, of course, is rare in practice).

Review of Rinnai gas boilers The closest analogue of standard German quality

Dual-circuit

Most buyers still prefer double-circuit boilers, since they do not need to spend money on an additional water heater.

BAXI ECO-4s 24F

One of the most popular double-circuit boilers on the Russian market. Inexpensive, but very reliable. Closed combustion chamber, primary heat exchanger - copper, efficiency 92.9%. The maximum gas consumption is only 2.73 m³ per hour. The boiler is equipped with protection systems against freezing, overheating and condensation. At the same time, the boiler is well adapted to domestic conditions: unstable gas or water pressure, often not the cleanest coolant, automation and pump tolerate minor voltage drops.

Owners often note changes in temperature, but this is a problem with almost all instantaneous water heaters. To keep the temperature stable, you need good pressure in the water supply. As for unstable voltage in the electrical network, the boiler can withstand small surges. European assembly leaves no doubt about the quality. A filter is installed at the cold water inlet, which can significantly extend the service life of the heat exchanger and circulation pump. Considering the cost of the boiler, there are simply no disadvantages.

BAXI LUNA-3 240 Fi 25

Another, newer model from the Italian manufacturer BAXI. It differs from the previous one in its convenient control panel, which has a built-in programmer. This allows you to set a separate temperature for each day of the week. Capable of operating in underfloor heating mode. The maximum efficiency is 93%, and the gas consumption is quite acceptable - 2.84 m³ per hour. Long service life and efficient operation are ensured by a copper heat exchanger with anti-corrosion coating.

Many users do not understand the difference between the ECO and LUNA series. Everything is simple here. LUNA boilers have higher quality components, which is why they cost several thousand rubles more. It's like comparing a cheap smartphone and Apple. Both the quality and functions are better. For example, the boiler produces up to 14 liters of water per minute, since the secondary heat exchanger is quite voluminous. But LUNA is also a little larger in size. If finances and space allow, I would still recommend choosing this model.

Vaillant turboFIT VUW 242/5-2

German quality, reliability, ease of maintenance and operation - these are the associations that arise in my mind when I hear about the Vaillant company. It seems to me that this is one of the best gas wall-mounted boilers for heating a private home. Firstly, high efficiency, which reaches 93.5%. Secondly, low gas consumption compared to similar models. Only 2.66 m³ per hour. Thirdly, the company has already managed to prove that wall-mounted boilers can operate for 5, 7, 10 or more years without breakdowns. And numerous reviews confirm this.

Separate heat exchangers are installed, so there is no need to worry that the boiler will quickly clog. The main one is made of copper. The secondary heat exchanger, as is customary, is made of steel. A high-quality hydraulic unit, to which the company pays special attention. All pipes are copper, not rubber, connections are threaded, excellent build quality. All necessary protection systems are present. The turbine, servo drive and ignition operate almost silently.

I wouldn’t say that the boiler is budget, but it’s not too expensive either. Of course, when compared with European analogues. The company cares about its customers, so the turboFIT VUW 242/5-2 takes into account the comments of the owners of previous models. Even the price has become lower. Today they are excellent for Russian conditions. The boiler is equipped with a pump from the famous and reliable Grundfos company, as well as Sit automation. The disadvantages include expensive spare parts. Also, do not forget that it is advisable to connect the boiler through a voltage stabilizer.