Gas boilers are simple and easy to use, do not cause problems during maintenance, and effectively cope with their functional task. They are bought much more often than their electric and solid fuel counterparts, but not everyone knows that before turning on a gas boiler in an apartment or private house, preparatory measures need to be carried out.

In the article we present you will find useful information about starting a gas unit and the rules for preparing it for the upcoming work. We will talk about the features of filling the heating circuit with water. We'll show you how to enable and select the settings you need.

HOW TO REPLACE A GAS BOILER WITH A NEW one

It would seem that it could be simpler than replacing an already installed boiler with a new one. The design documentation has already been prepared, the specifications have been completed. But, not everything is so simple. The fact is that, according to existing requirements, replacement is equivalent to redevelopment of the premises and requires re-approval.

The re-registration process begins with an application for replacement submitted to the gas distribution organization.

To obtain technical specifications, you will need to submit the following documents:

- Documents evidencing ownership of the house and surrounding area.

- Passport.

After receiving the application, Gorgaz will put the boiler in the queue for shutdown. Further work is performed in the following order:

- Removing the old boiler.

- Obtaining technical specifications.

- Making a new project.

- Coordination of documentation and connection.

Replacing a boiler is faster and does not require the same financial costs as when connecting a gas boiler room for the first time.

Regulations, laws and regulations

Let's immediately look at what decrees regulate such connections at the legislative level. They will help you implement your plans without problems with local authorities, without danger to health and life, and, moreover, with minimal waste of time and money.

You will need for review:

- SP 60.13330.2016 - “Heating, ventilation and air conditioning.”

- SP 62.13330.2011/SNiP 42-01-2002 - this describes gas distribution systems in detail.

- SP 41-108-2004 - a document on apartment-to-apartment heat supply using gasification.

- SP 402.1325800.2018 - “Rules for the design of gas consumption systems.”

And of course, general research into the documentation of your apartment building is necessary.

IS IT POSSIBLE TO REPLACE THE GAS BOILER YOURSELF?

It is impossible to replace a gas boiler yourself, without contacting regulatory organizations, and is punishable by a fine. In practice, a large number of owners of private houses still change their boiler equipment without approval.

After violations are identified, they simply pay a fine and pay for the production of a new project. Provided that the power of the thermal unit has not been changed upward, usually no approval will be required. Legalizing a replacement is often easier than completing all the documents in accordance with current legislation.

IS A NEW PROJECT NEEDED WHEN REPLACING A GAS BOILER

The project specifies the model, type and power of the heating unit. In addition, each boiler has its own serial number, indicated in the technical passport and included in the project documentation. Therefore, when replacing, you will need to make a new project indicating new data.

You must go through the following registration steps again:

- Obtain technical specifications for replacing a gas boiler. At this stage, the gas distribution company can change the performance of the unit based on the actual living area of the house.

- Make a new project.

- Obtain approval by providing a gas distribution project, technical specifications, and the results of checking the chimney duct.

- Replace the old unit with a new one.

When replacing an old gas boiler with a new one, the following documents are needed:

- Passport.

- Documents of the owner of the residential premises.

- Technical passport for gas equipment.

- Technical conditions.

Standard prices for replacing already installed gas equipment are 1000-1500 rubles, depending on the region.

Ignition instructions

Heaters differ in the type of ignition, so when starting different modifications there are some nuances. Before turning on the device, you need to read the ignition instructions to ensure everything is done correctly. Let's look at ignition using the example of the Italian boiler "Ariston". Before turning it on, it is important to check the system for leaks. For this purpose, the thermostat is turned on to maximum so that the switching occurs automatically. Ariston ignition process:

- the device is connected to the power supply, and the heating regulator is set to the desired temperature value;

- When the pump is turned on, a slight noise is heard;

- when all air pockets in the pipes are eliminated, the noise will disappear;

- When the electric ignition is triggered, the boiler turns on automatically.

IS IT POSSIBLE TO REPLACE A GAS BOILER WITH AN ELECTRIC BOILER?

Replacement is quite possible, but for this you will have to obtain permission from another organization involved in electricity supply. Documents are needed only if the electric boiler has a power of more than 8 kW. Up to this performance limit, the unit belongs to ordinary household water heating devices of the boiler type, therefore, it is installed without permits or approvals.

For productive electric boilers, a separate power supply line will be required. You will need to make a project and obtain permission to increase the amount of electricity allocated. Separately, you need to write a statement about disconnecting the gas boiler from the main line.

ARE THERE PENALTIES FOR INSTALLING OR REPLACING A BOILER WITHOUT A PERMIT?

Installing a boiler without permission is a strict violation of existing standards and is equivalent to redevelopment of a residential premises. This omission is punishable by penalties imposed after they are identified during the next inspection by gas workers.

Serious violations lead to gas supply being cut off. After paying the imposed fines and correcting the identified defects, the equipment is allowed to be put into operation again.

Request a call

Call around the clock, we work without holidays and weekends.8 495 744 67 74

Our contact page

The emergency service operates around the clock in Moscow and the Moscow region. Departure to the nearest areas is planned according to the schedule.

Precautionary measures

Despite the desire of manufacturers to ensure the safety of gas appliances, they can still become a source of danger. The Ministry of Emergency Situations regularly reminds owners of any gas-powered equipment about the following precautions:

- You need to buy gas-powered appliances from organizations that have the appropriate sales license.

- Installation should only be carried out by specialists from the relevant services.

- The kit should include an instruction manual.

- It is prohibited to change the design of the device in any way.

- A technical inspection must be carried out annually.

- It is prohibited to reduce ventilation openings in windows and walls.

- If there are sealed windows, it is necessary to organize air flow.

- Materials that can quickly ignite should not be stored in the boiler room.

- It is prohibited to increase the coolant temperature above 90°C.

Heating a house 100 m²

Really, honestly, really

| Heating a house 100 m² from | RUR 49,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 10 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 25,000 rub. |

| Radiator pipe routing | 12,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 49,500 |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 100 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 120,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

House heating

What to do if problems occur

Let's look at breakdown situations using the example of Italian Baxi boilers. Italian wall and floor heaters are an example of quality and efficiency. But even with proper use, malfunctions may arise that require prompt correction.

The following problems may appear in Baksi models:

- the burner does not light;

- during operation, popping noises are heard in the firebox;

- the boiler overheated;

- the device is very noisy;

- The sensor has failed.

The probable causes of breakdowns are associated both with violations of operating rules and with reasons beyond the control of the user:

- moisture has entered the device;

- low quality coolant;

- the pressure in the gas pipeline has decreased;

- voltage drop in the electrical network;

- errors were made during installation.

Violation of at least one rule or norm leads to breakdowns, incorrect operation and unnecessary costs.

Heating a house 150 m² - 52,500 rub.

Really, honestly, really

| Heating of a house 150 m² from | RUB 52,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 10 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 25,000 rub. |

| Radiator pipe routing | 15,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 52,500 |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 150 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 200,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

House heating

Frost protection

One of the important rules for operating heating systems is to ensure the minimum permissible coolant temperature. If water is poured into the system, freezing occurs at low temperatures, and pipes and radiators become unusable. In modern models, this problem is solved - the user is relieved of the need to monitor the coolant.

For example, the boilers of South Korean Navien [/anchor] provide reliable protection against freezing. Navien is cheaper than its European counterparts, but these boilers have all the necessary protection functions, which greatly simplifies their use.

When the coolant temperature drops below 10°C, the circulation pump starts automatically. If the coolant cools down to 6°C, the burner automatically turns on, warming the coolant to 21°C.

Heating a house 200 m² - 72,500 rub.

Really, honestly, really

| Heating a house 200 m² from | RUB 72,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 15 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 35,000 rub. |

| Radiator pipe routing | 25,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 72,500. |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 200 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 250,000 rubles

Detailed estimate for installation of heating system

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

Self-diagnosis

The process of operating heaters is simplified if they have a self-diagnosis function. Almost all European manufacturers have equipped their products with it.

For example, German Bosch heaters, displaying error codes on the display, allow the user to quickly understand the cause of the problem and take measures to eliminate it. If code A7 appears on the screen, it is clear that the hot water temperature sensor is faulty.

If A8 is displayed, the connection to the BUS bus is broken. This function greatly simplifies the use of gas equipment, making it easier and more comfortable.

Heating a house 250 m² - 87,500 rub.

Really, honestly, really

| Heating of a house 250 m² from | RUB 87,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 20 pcs)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 45,000 rub. |

| Radiator pipe routing | 30,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | 87,500 rub. |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 250 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 300,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

Heating a house 250 m²

8 [email protected] ROUND THE CLOCK

Russia, Moscow, ☞ Pyatnitskoe highway, 55A Russia, Moscow, Mitino, ☞ 3 Mitinsky lane, 1 (ARCHIVE) Russia, Moscow, ☞ Yana Rainis boulevard, 19, cor. 1 Russia, Moscow, ☞ Marina Raskova, 10 kor. 4 Russia, Moscow, ☞ 1st Grayvoronovsky proezd, 2A Russia, Volokolamsk, ☞ Novo-Soldatskaya street, 23с3 Russia, Golitsino, ☞ Petrovsky pr., vl 5 с 1 Russia, Elektrougli, ☞ st. Central, 50 Russia, Klin, ☞ Moskovskaya st., 31 Russia, Konakovo, ☞ Lenina, 7A Russia, Podolsk, ☞ st. Fedorova, 19 Russia, Tula region, ☞ Plavsk Russia, Chelyabinsk, ☞ Komsomolsky pr-t, 2, kor. 315 Russia, Ramensky urban district, ☞ Chulkovo village Russia, Republic of Crimea, Yalta urban district, urban settlement ☞ Beregovoye

Pre-launch process

The sequence of actions to prepare for startup depends on the type of gas boiler being installed. It can be single-circuit or double-circuit, with a closed or open combustion chamber, floor-mounted or wall-mounted. The first launch is always associated with an increased level of responsibility and risk, so it must be carried out in compliance with all the nuances and subtleties.

The instructions for the gas boiler contain simple explanations according to which you need to start a specific model. The gas boiler must by this time be connected to communications in accordance with the agreed project. The first start-up is carried out after connecting the heating system into a single whole and installing equipment, radiators, and pipes.

Gas boilers with a closed combustion chamber do not require a large chimney. Also, their positive characteristic is the ability to be located close to the wall with a gap of 2 cm, which allows you to save space in the apartment

According to fire safety rules, the gas boiler should be located in places protected from the possibility of ignition, away from flammable objects and materials. In this case, the heating unit should be located at a certain distance from the wall and floor. The exact distance value is individual for each boiler and is indicated in the instructions.

Wall-mounted models are hung on anchors so that there is a small gap between them and the plane of the wall. The boiler must be installed strictly exactly at the water level. Distortions and tilts of the equipment are unacceptable.

After installing the gas boiler to the wall, it is necessary to connect the device to the pipe supplying cold water. To do this, you need to remove the plugs from the receiving pipes.

In addition, a coarse water filter and a mud filter are installed at the inlet of communications to the boiler, which will protect the internal pipeline of the unit from clogging and sedimentation. Ball valves are installed on all pipes when piping.

Installing and running pipes to the boiler is an important task. The end result should not only be beautiful and aesthetically pleasing, but also provide easy access to key parts of the system

Before starting the boiler, an important step is to install a gas pipe to it. This work cannot be carried out independently. You will have to invite craftsmen from the GorGaz branch with which you have a service agreement.

Gas workers will calculate the required length of the pipe, lay it, install a gas meter and seal it. In order for the device to work for a long time and not smoke, you need to take care of the supply of good gas.

Also, for a gas boiler, for safety reasons, it is advisable to install a separate power line with its own automatic circuit breaker installed at the entrance. A socket should be placed close to the device, at a distance of 30-50 cm from the body. Grounding must be done; it will protect users from receiving electric shocks in the event of a breakdown on the housing.

Reliable and high-quality pipes are the key to the longevity of the heating system. You should buy pipes and radiators only from trusted manufacturers. A cheap product in this case will only bring problems

A boiler installed in a private house is equipped with its own chimney. It should go outside through the wall or through the attic space to the street. The chimneys of boilers in city houses up to five floors are connected to a public smoke shaft.

Depending on the specific device, the amount of work required to install the chimney varies. Some devices with a closed chamber are also equipped with a pipe to supply air to the combustion zone.

Upon completion of all preparatory work, you need to fill the heating system and the boiler itself with cold tap water. After filling, the system is checked for leaks. Then a remote control panel and a thermostat are mounted on the wall, to which temperature sensors are connected.

Features of filling the system with water

Before you ignite the gas boiler and activate the system, you need to properly fill the heating system and all its elements with water. To begin filling the heating equipment and the circuit connected to it with water, first disconnect the boiler from the power supply. We still need to turn off the gas supply.

Next, you need to turn on the water by opening the valve or tap that supplies cold water, as well as the make-up tap located at the bottom of the boiler. The exact location of the make-up tap is indicated in the instructions for the device.

The technician checking the system must definitely go around all the rooms along the pipes and radiators and check them for the presence of water leaks. If a leak is detected, you need to shut off the water supply and begin to fix the problem.

Before filling the system with water, you need to make an additional bypass of all heating devices and make sure that all connections are tight and tight.

You can drain the water from the system completely or shut off the corresponding link. Then you need to unscrew the leaking pipe connection, drain the water or screw in the plug. Afterwards, the necessary material and tools are prepared, the plugs are unscrewed, and the pipe is tightly reconnected to the radiator using sealant. Next, you need to check the tightness of the system again.

The intake of water is accompanied by a characteristic sound. It is important to unscrew the valve slowly and gradually, avoiding sudden movements. If you open the tap suddenly, there is a high probability of air pockets occurring. Simultaneously with the system being filled with water, the gas boiler pressure gauge shows the current pressure in the system.

The operating pressure must be found in the instructions for using the boiler. When the pressure reaches the operating range, you need to stop the water supply by closing the valve. Typically, the operating range of the boiler is a pressure value of 1.5 - 2 atmospheres.

It is recommended to fill the system with water in the warm season. If the temperature outside is sub-zero, you should preheat the room using a portable radiator to about 20 degrees Celsius.

Removing air pockets

Upon completion of the filling stage, the system must be checked for air pockets, excess air must be bled off and, if necessary, cold water must be added. If you do not bleed off excess air, the radiators will not heat up enough, since there will be a space in them that is not filled with heated coolant.

The Mayevsky tap is a simple device that is a needle valve. It is used to bleed air from the batteries.

To make the first start successful, you should go around each radiator with a screwdriver or other tool and bleed the air from the heating devices. Some batteries are equipped for this procedure with an air vent, a Mayevsky valve, which can be controlled by hand.

The air from the pipe system and the heating devices connected to it is drained until water flows. While the air flows, a characteristic hissing sound is made.

For convenience, it is worth preparing in advance a basin or ladle into which the water will be drained, as well as a rag, which is then carefully used to cover the stream of water so as not to stain the wall or nearby appliances. After the air has been released, you need to tighten the radiators tightly so that water does not leak from them.

Modern boilers are equipped with devices that allow you to automatically remove air pockets from the heating system. However, such devices do not always effectively cope with the task assigned to them. Therefore, you often have to bleed the air manually.

Having completed bleeding the air from the closed heating circuit, they begin to fill the space freed from air pockets with water. Without this operation there will be no working pressure in the system, because it is not filled enough.

To replenish the circuit with water, connect the unit to the power supply, open the feed tap and press the “Power” button. In this case, the pump should start and the boiler burner will try to ignite. However, after a couple of seconds, the electronics will block all attempts, and the display will display an error code, because gas does not flow to the injectors.

This procedure will need to be repeated several times. It will be necessary to recharge until all the air comes out of the pipes and devices of the boiler, as well as the circuit connected to it. When the stage of filling the system and freeing it from air pockets is completed, you need to check the pressure and open the gas supply.

The circulation pump ensures the movement of the coolant. The manufacturer is prohibited from performing any manipulations with it independently, otherwise the warranty obligations automatically become void. If the pump breaks down, simply replace it

Before igniting the boiler, the gas engineer carefully checks that the connection diagram corresponds to the design solution on the basis of which it was assembled. The technician once again makes sure that the pressure in the system corresponds to the parameters recommended by the manufacturer. Tests the tightness of all communication lines and their connection points.

Checking and flushing the system

In order to ensure the high quality of the work performed and prevent possible water leaks, plumbers recommend performing a pressure test of the system before starting the boiler. This procedure will require expensive equipment - a pressure pump. However, there is no need to buy it, as it will only be needed for half an hour to check the system.

You can borrow such a device from friends or rent it. You can also use the service of an on-call technician who will independently check the system and correct any problems that have arisen if necessary.

The purpose of pressure testing is to identify leaky areas of the system and eliminate them. A system that has gone through this process is guaranteed to serve for a long time and will not fail at the most inopportune moment.

There are two methods of crimping: with a water column or with compressed air. The essence of the procedure is pumping air or water into the system to establish a pressure level in it approximately one and a half times higher than the working one. After pumping, it is necessary to record the pressure value on the pressure gauge and wait 10 - 15 minutes.

Before performing pressure testing, it is important to take into account the characteristics of all elements that make up the heating system. In addition to checking the functionality of the system, it is also important not to damage its structural elements with excessively high pressure.

If at the end of this period of time the pressure remains at the same level, then the system is considered pressurized and has no leaks. If the pressure has dropped, then you need to identify the place where water is leaking and eliminate this problem. Then carry out the procedure again.

Please note that before installing a new unit, flushing a circuit that has been in operation for several years must be done. All ]gas equipment[/anchor] warn that installing a gas boiler in an old circuit that has not been cleared of mineral deposits is prohibited. Failure to comply with the rule will result in the boiler owner losing his warranty.

This process is carried out in two stages. Initially, rough washing is carried out. In this way, the largest contaminants are removed. The pressure in the system when flushing should be about 3.5 atmospheres. After the water is agitated under pressure, it is released from the system through a drain valve.

In this case, the coarse filter often becomes clogged. It may need to be washed once or twice. Finish washing is carried out using pressure pumps.

After finishing washing, you need to check the coarse filter. It must be uncontaminated. Supplying contaminated water to the boiler is highly undesirable

After completing the preparatory work, you can start launching the device.

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | Price |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 1st scheduled departure | from 14 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 1st scheduled departure | from 20 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 2 scheduled trips | from 22 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 2 scheduled trips | from 30 000 ₽ |

| Service contract for wall-mounted gas boiler | with 1st scheduled departure | from 10 000 ₽ |

| Service contract for wall-mounted gas boiler | with 2 scheduled trips | from 15 000 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Boiler room repair, diagnostics and prevention

| Name of works | Volume | Price |

| On-site inspection and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| On-site inspection and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5,500 ₽ |

| Cleaning the burner (atmospheric) | power up to 60 kW | from 2,000 ₽ |

| Cleaning the burner (supercharged) | power up to 60 kW | from 3,500 ₽ |

| Cleaning the burner (atmospheric) | power from 60 to 170 kW | from 8,500 ₽ |

| Cleaning the boiler combustion chamber | power up to 60 kW | from 4,000 ₽ |

| Cleaning the boiler combustion chamber | power from 60 to 170 kW | from 6,000 ₽ |

| Checking and pumping up pressure in the expansion tank | without dismantling work | from 2,500 ₽ |

| Checking and pumping up pressure on the expansion tank | with dismantling and installation | from 4 500 ₽ |

| Refilling the heating system with a pump | system volume up to 200 liters | from 3 000 ₽ |

| Replacement of heating element, pump, heat exchanger, with coolant drain | for a unit | from 3 000 ₽ |

| Conversion of a gas boiler to liquefied gas | for a unit | from 3 000 ₽ |

| Burner settings | gas / diesel | from 2 500 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

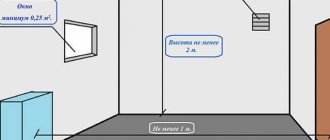

Posting rules

- The area of the room in which the heater is installed is at least 7.5 m².

- Ceilings - from 2.2 m.

- There must be a window providing access to air from the street.

- The door should open in the direction of movement of the person leaving the room.

- It is prohibited to install switches in the boiler room. If they are already installed, you will have to take them outside the premises.

- It is necessary to equip supply and exhaust ventilation. For every m³ of fuel consumed - 15 m² of air.

- The distance from the heater to elements capable of burning is 25 cm or more. To non-combustible elements - 5 cm. From the chimney to combustible parts - 40 cm, to non-combustible parts - 15 cm.

- The device is mounted on a perfectly flat plane, without slopes.

Cost of installing boiler equipment

Installation

| Solid fuel boiler (15% of the boiler cost) no less | PC | from 10 000 ₽ |

| Floor-standing gas/diesel boiler (15% of the cost of the boiler) no less | PC | from 10 000 ₽ |

| Pellet boiler (10% of the cost of the boiler) no less | PC | from 15,000 ₽ |

| Wall-mounted single-circuit boiler up to 30 kW | PC | from 9 000 ₽ |

| Wall-mounted 2-circuit boiler up to 30 kW | PC | from 10 000 ₽ |

| Pump (D, up to DN 32) | PC | from 3 150 ₽ |

| Pump group (pump, shut-off valve assembly) | PC | from 2 500 ₽ |

| Expansion tank for heating system (up to 100 l.) | PC | from 2 500 ₽ |

| 3-way valve (D, up to 1 1/4″) | PC | from 2500 ₽ |

| 3-way valve mixer servo drive (D, up to 1 1/4″) | PC | from 3 150 ₽ |

| Chimney (D, up to 250 mm.) | m/linear | from 2,500 ₽ |

| Boiler (water heater, up to 200 l.) | PC | from 8 500 ₽ |

| Boiler (water heater, up to 500 l.) | PC | from 10,000 ₽ |

| Boiler safety groups | PC | from 2 250 ₽ |

| Water Heater Safety Groups | PC | from 2 250 ₽ |

| Boiler manifold | PC | from 5,500 ₽ |

| Hydraulic separator | PC | from 2,500 ₽ |

| Heated floor temperature control groups (thermostatic valve, thermostat with clamp-on sensor, bypass valve, starter) | PC | 3 750 ₽ |

| Fuel tank connection | PC | 5 000 ₽ |

| Fuel filter installation | PC | 2 000 ₽ |

| Air vent, thermometer, pressure gauge per unit | PC | 650 ₽ |

| Ball valve, mud filter, check valve | PC | 500 ₽ |

| Check the cost by phone: | 84957446774 |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Commissioning works

| Commissioning of a wall-mounted gas boiler | PC | from 10 000 ₽ |

| Commissioning of boiler house up to 60 kW (protherm, ferroli, baxi, dakon) | PC | from 14,000 ₽ |

| Commissioning of boiler house up to 60 kW (Vaillant, Viessmann, Buderus) | PC | from 18,000 ₽ |

| Commissioning of boiler house from 70 to 120 kW (protherm, ferroli, baxi, dakon) | PC | from 20,000 ₽ |

| Commissioning of a boiler house from 70 to 170 kW (Vaillant, Viessmann, Buderus) | PC | from 25,000 ₽ |

| Commissioning of a cascade boiler house (2 boilers or more) | PC | from 30,000 ₽ |

| Commissioning of electric boiler up to 6 kW | PC | from 7 000 ₽ |

| Commissioning of electric boilers from 8 to 30 kW | PC | from 8 500 ₽ |

| Commissioning of a pellet boiler up to 50 kW | PC | from 14 000 ₽ |

| Commissioning of pellet boiler from 60 kW to 100 kW | PC | from 18,000 ₽ |

| Commissioning of a boiler room with a pellet boiler up to 60 kW | PC | from 20,000 ₽ |

| Check the cost by phone: 8 495 744 67 74 | _____________ | |

| The exact cost is calculated after receiving the technical | _tasks_ |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Safety system

Gas-powered appliances require serious monitoring. It is provided either by a person or an automation system. The latter is capable of providing multi-stage protection that prevents dangerous situations and increases equipment safety. The main task of the protection system is to turn off the device in time by stopping the fuel supply.

Let's look at the stages of protection using the example of the Proterm Wolf KSO floor-standing boiler. These modern devices have multi-stage protection. One of the stages is an ionization sensor that controls the flame. If the fire goes out, a signal will be sent to the control unit, it will shut off the fuel supply and prevent an accident.

The combustion chamber has a temperature sensor that monitors the heating of the coolant and prevents the firebox from quickly burning out. “Wolves” are equipped with a KTD system - chimney draft control. It prevents the accumulation of carbon monoxide. If there is no draft, combustion products begin to accumulate in the chimney, and the thermostat heats up. When the temperature limit is reached, the thermostat contacts open and the flow of fuel stops.

Automatic protection

Modern heater models are equipped with electronic control and measuring instruments that generate signals for the control unit. Automation, receiving signals from sensors, coordinates the work of all nodes. Elements that prevent various types of malfunctions and problems are safety valves, expansion tanks, air valves, smoke detectors and other devices.

Dangerous situations

The greatest danger is a malfunction associated with the operation of the burners. If the flame goes out, gas may accumulate in the room, which will subsequently cause an explosion. Reasons for the fire going out:

- gas pressure has dropped below the permissible norm;

- no draft in the chimney;

- the supply voltage has disappeared;

- The pilot light went out.

In an emergency, it is necessary to immediately shut off the fuel supply to the burners - automatically or manually. Modern versions are equipped with automation devices necessary for prompt shutdown of equipment. The operation of such devices is not only convenient, but also safe.

How to prevent gas accumulation indoors

Modern safety standards provide for the installation of gas analyzers in boiler rooms; they are necessary for signaling when gas appears in the room. A special electronic valve reacts to their signals, automatically stopping the flow of fuel to the burners.

What other safety regulations are there?

- Do not disassemble or dismantle gas appliances yourself.

- Handle the power cord carefully.

- Do not place foreign objects on the device.

- Don't stand on the boiler. Do not stand on chairs, tables or other unstable objects to clean the wall-mounted boiler.

- Monitor the coolant and add it to the system on time.

- Be careful - in some modifications the use of antifreeze is prohibited.

- If you smell gas, immediately turn off the gas and open windows and doors. Leave the boiler room and call the gas service.

In order for the operation of a household gas boiler to be safe and uninterrupted, the user must read the instructions for it in advance. By choosing models equipped with automation, the consumer increases the comfort of use and safety. By following the rules for the use of gas appliances in everyday life, for their installation and maintenance, the number of emergency situations can be reduced to a minimum.