You can ensure comfort in an apartment or house if there is complete silence and tranquility. Unfortunately, it is impossible to be alone and quiet in multi-storey panel buildings. Because of the thin partitions, you get the feeling that your neighbors are sitting next to you and discussing something. You can only save yourself from such discomfort by using high-quality sound insulation.

@Knauf

There are two types of noise in the apartment: airborne and vibration. The first is formed during conversation, loudly playing music and other types of sounds transmitted through the air. As for vibration, it can be transmitted over hard surfaces. This noise occurs when operating power tools, household appliances, or when using a hammer. You can get rid of unpleasant and intrusive noises if you use comprehensive sound insulation.

Today, there are many different soundproofing technologies that can be used in residential areas. Depending on the preferences of the apartment owner, you can choose the optimal solution not only in terms of characteristics, but also cost. We will try to look at how to choose the right sound insulation for an apartment, as well as the characteristics and features of the material in this article.

There are two main methods of soundproofing rooms: using a frame and frameless sound insulation. Depending on the parameters of the apartment, you can choose the optimal solution. Of course, if the apartment area is large, then any sound insulation can be used, but if there is not much space, then frameless sound insulation will be the optimal solution. For frameless insulation of a room from noise, the Knauf acubord soundproofing panel is suitable. The products are presented in the form of soundproofing boards, which provide maximum soundproofing effect, while the thickness of the products is relatively small.

Advice! Using such materials, you can most effectively protect your apartment from airborne and vibration noise, which is the main problem of multi-story buildings.

In cases where there is room to turn around, Knauf Acoustic Sound Insulation can be used as an insulating material. Soundproofing boards consist of thin fibers. The characteristics of the product make it possible to improve the noise insulation performance to 52 dB, which is not bad at all. Due to the environmental friendliness of the product, it can be used in various rooms, since it does not have a negative impact on the human body and health. In particular, Knauf acoustics are used for soundproofing apartments, houses and cottages; in addition, it is possible to use insulating boards in public spaces. German manufacturers guarantee effective protection against various types of noise and sounds.

It should be remembered that in order to isolate vibration sound on the frame structure, it is necessary to use cushioning elements in the form of tape. Only in this way will it be possible to completely silence the room.

What is liquid sound insulation

What is liquid noise insulation?

Let’s consider the concept of “liquid noise insulation” in more detail. This is a unique product that can be easily applied to the ceiling, floor and walls to protect the room from various sounds. Polyurethane foam fills any cracks and creates a reliable monolithic layer. Sound insulation is indispensable if you need to get rid of insects and rodents. The method is universal, with a lot of advantages and no disadvantages!

Distinctive features

The main advantage of Knauf panels is their excellent quality, because they are manufactured using modern equipment using German technology. Contrary to this, the price of the product is quite acceptable for the average buyer, especially those undertaking large-scale renovations. If you compare gypsum-based slabs and soundproofing wool, the differences will be significant.

The first difference is the structure of the material. The second is that there is no need to build a frame for the gypsum panels. Knauf soundproof plasterboards are also used for leveling walls and ceilings. The soundproofing layer in them is no more than 5 cm, which makes the material very convenient for finishing small rooms. Today there are many ways to achieve complete sound insulation. If there is a chance to use a frame that will not damage the space, then the craftsmen recommend choosing fiber panels - they “eat up” any unpleasant noises and sounds as much as possible.

There is also a dry soundproofing mixture Knauf Akustikputz. It combats extraneous noise, has no joints during application, is homogeneous in its structure, and does not require fastening. Before working with such a mixture, there is no need to level the walls and ceiling.

Types of liquid sound insulation

Now the market can offer consumers various soundproofing materials. All of them are distinguished by: manufacturer, characteristics, quality and price. Here is a rating of well-known polyurethane foam products:

- Synthesia is a material from a Spanish manufacturer. A compromise of low cost and high efficiency. Made from safe components.

- Ecotermix is a material created through joint production of our country and the Middle Kingdom. Has a competitive price. The product can be used in absolutely any room. In addition, it will protect them from mold and mildew. Thanks to fire resistance - 100% safe!

- Demilex is good, high-quality American sound insulation, but not everyone can afford it. The product is of the highest class.

- Bayer is a German foam known throughout the world. Popular due to its availability and German quality.

Based on the planned amount of money and the required characteristics, you can choose the appropriate liquid sound insulation.

Prices and solutions for soundproofing walls in an apartment

Frameless system "Economy"

with a thickness of 25mm, a weight of 20kg per 1 square meter, it has the lowest price and will add 7-9dB to the sound insulation of the wall. Allows you to remove airborne noise (not loud conversations, not loud TV sound). Will not help with structural and impact noise.

We advise you to study - Which concrete mixer is better to buy - comparison of characteristics and specific models

Frameless system "Standard"

, system thickness 28mm, weight 21kg per 1m2, additional sound insulation index 8-10dB. It is 13-15% more expensive than the frameless Economy system. Allows you to remove airborne noise (normal conversations, TV sound). Will not help with structural and impact noise.

Frameless system “Standard+”

, system thickness 38.5 mm, weight 25 kg per 1 m2, additional sound insulation index 10-12 dB. More expensive than the frameless “Standard” system by 15-18%. Allows you to remove airborne noise (loud conversations, loud TV sound). Will not help with structural and impact noise.

Frameless system "Premium"

, system thickness 34mm, weight 26kg per 1m2, additional sound insulation index 10-12dB. Such a system will be 59-65% more expensive than the frameless “Standard+” system. Allows you to remove airborne noise (quarrels, the cry of a child, the sound from the TV of deaf neighbors). Will not help with structural and impact noise.

Frame system "Economy",

thickness 60mm, weight 29kg per square meter, not significantly more expensive than the frameless “Standard+” system, but will add 17-19dB to the sound insulation of the wall. Allows you to remove airborne noise (quarrels, the cry of a child, the sound from the TV of deaf neighbors). Reduces structural and impact noise levels.

Frame system "Standard",

thickness 80mm, weight 30kg per square meter, 15-17% more expensive than the Economy frame system, will add 17-19dB to the sound insulation of the wall. Allows you to remove airborne noise (quarrels, the cry of a child, the sound from the TV of deaf neighbors). Reduces structural and impact noise levels.

Frame system “Standard+”,

thickness 80mm, weight 35kg per 1 square meter, only 8-10% more expensive than the “Standard” frame system, will add 18-20dB to the sound insulation of the wall. Allows you to remove airborne noise (quarrels, the cry of a child, the sound from the TV of deaf neighbors). Significantly reduces structural and impact noise levels.

The Premium frame system

is

the best sound insulation for walls. thickness 85mm, weight 38kg per square meter, 13-15% more expensive than the “Standard+” frame system, will add 20-22dB to the sound insulation of the wall. Allows you to remove airborne noise (quarrels, the cry of a child, the sound from the TV of deaf neighbors). Can eliminate structural and impact noise by 95-98%.

Pros and cons of liquid sound insulation

Like any material, liquid insulation has its pros and cons. Speaking about the advantages, it is worth highlighting the following:

Advantages and disadvantages

In addition to sound insulation, you will improve the thermal insulation of the room. In winter, you can save a lot of money on heating.

The product can be used to treat cracks in window and door openings.

Polyurethane foam has high adhesion to various types of surfaces. Thanks to this, you can do without prior preparation.

Thanks to polyurethane foam, you can seal the entire area of the room.

Considering that conventional sound insulation can reach a thickness of 4 cm, polyurethane foam will help save space in a small room.

The weight of the material is low, so there is no load on the walls.

Difficult to dismantle. It is very difficult to remove sound insulation from the wall.

Styrofoam

This material is often used for sound insulation. Its advantages:

- easy;

- accessible;

- environmentally friendly;

- comfortable in using;

- can be formed, cut and processed.

The walls are lined with polystyrene foam. The material releases volatile substances in very low concentrations, so it does not harm health. In exceptional cases, individual intolerance to polystyrene foam is observed.

Thanks to its porous structure, the material effectively absorbs vibrations. If you install soundproofing boards correctly, you will be able to reduce the noise level. Polystyrene foam has good functional characteristics. It is light in weight, which means it is easy to transport.

The slabs can be stored for a long time in an unheated room, they will not deteriorate or lose their properties. Foam plastic has a low melting point, regular foam melts at a temperature of + 145 degrees, and epoxy at a temperature of + 170 degrees. Lights for 4 seconds, after which it goes out if there is no source of fire nearby.

What is the essence of liquid sound insulation?

What is liquid sound insulation in a simple sense? This is a composition that must be applied to the surface of walls, floors and ceilings to achieve sound insulation. Sound, as everyone knows, can be vibrational (associated with the use of power tools and household appliances) and airborne (transmitted through the air, for example, screams, music and TV turned on at high power).

No insulating material can cope with all types of noise at once, with the exception of liquid noise. Although the material has not been on sale for very long, it has already earned the trust of consumers. Due to the softness of the composition, when it hardens, it forms a barrier that does not allow extraneous sounds to pass through.

Note! Polyurethane foam is not suitable for finishing, since after drying the surface becomes lumpy. Sheathing with chipboard or plasterboard is required.

Preparation

Before starting “global” noise insulation in apartments, after which you can enjoy the silence, it will be necessary to carry out some preliminary work

In addition to the fact that you need to eliminate all existing wall cracks or holes in the corners, you will also need to pay attention to the sockets. Usually in panel buildings the holes for them were made through at one time, and therefore the neighbors could be aware of everything that was happening to those living behind the wall

They will also need to be fenced off with soundproofing material.

Water supply and heating pipes should also not be ignored, especially those that pass through walls. Their entry and exit points must be carefully sealed using soundproofing sealant. They allow noise and joints where the walls connect to the floor or ceiling to pass through well. They also need to be sealed well.

Soundproofing plaster

Soundproofing plaster

Soundproofing can be achieved using soundproofing plaster. It contains special components. These are granules measuring 5 mm. For granules, use pumice or expanded clay. When drying, gas escapes, causing the coating to become porous. Thanks to the loose structure, noise is retained.

Plaster is a 100% safe “eco” material. It is safe for children's rooms. Will not harm those with allergies. A relief plastered wall can decorate the interior.

Applying plaster

Before starting work, you need to prepare the surface: level, clean and apply a primer. It is advisable to add 10% lime paste, then it will grip more firmly.

If you want the wall to be smooth after plastering, you need the soundproofing mastic to have a layer of no more than 2-3 cm. If you plan to finish painting the walls, give preference only to water-dispersion paints.

Advantages of frameless technology

Frameless sound insulation technology has many advantages. Among the first, we should highlight the ease of work.

In addition, surfaces require virtually no preparation. If the base is level, it only needs to be treated with a primer to increase adhesion to the adhesive layer. The master will not need to install a profile system, which involves additional costs of materials and effort.

In some cases, decorative finishing is not needed, which is true if cork panels are used for sound insulation.

What is thin sound insulation

What is thin sound insulation?

This type of insulation can be made using different sound-proofing materials: thermal and sound insulation, polyurethane foam, cork, etc. The main advantage is that the thickness does not exceed one centimeter.

Unique features of fine sound insulation

Now popular are subtle means of protection from third-party sounds without reducing space. Thin soundproofing membranes are great for walls, partitions, floors and ceilings. The advantages include: low thickness, efficiency, environmental safety and easy installation.

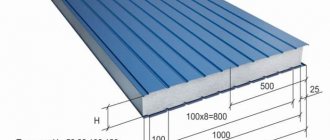

System design

To reduce the penetration of extraneous sounds, it is necessary to create a structure in the form of a slab of soundproofing layer and plasterboard. It is fixed using mounting holes and acoustic dowels, through which noise does not pass. The panels are installed using a tongue-and-groove connection. This is convenient and eliminates the distance between sheets.

The thickness of such a protective system varies from 20 to 120 mm. Due to certain parameters, the sound decreases by 9-18 dB. To completely eliminate the gaps between the plates, additional tape with soundproofing properties is used for the seams.

How to make acoustic insulation of a ceiling: instructions

For insulation, they usually use plasterboard and other soundproofing materials, which are placed between the gypsum boards.

Before starting the main sound insulation, simple preparatory work is performed. They install auxiliary suspension systems to choose from: suspended (installation on a metal frame and gypsum board sheathing), suspended (frame with installation of slabs) or tension (installation on brackets, tension of fabric or film).

All cracks must be treated with sprayed insulating material. Soundproofing foam for ceiling insulation is ideal for this purpose.

Quite often panels and mineral slabs are used for ceilings. The work process looks like this:

- They make a frame on the ceiling.

- Fill it with basalt or mineral wool.

- Sheathed with plasterboard.

- Putty.

- Paint is applied.

Soundproofing ceilings and walls video

Protection against structural noise

Structural noise is transmitted in the form of vibrational sound waves to load-bearing structures and main walls of buildings. Even with triple-glazed windows in apartments located near a busy road, monotonous annoying noise is constantly heard. This unpleasant factor can be eliminated with the help of laying sound insulation along the load-bearing structures of the walls, especially at the joints of the structures. For this purpose, various types of roll materials are used:

- Fiberglass, rolled or strip material, refers to porous fiberglass products with elastic properties. Due to its elasticity, raw materials perfectly absorb vibration waves. Used for insulating walls using a frame method and installing multilayer panels. This sound insulation is quite effective for sealing joints in wall structures.

- Vibroacoustic sealant is recommended for filling joints between building structures, while reducing the spread of vibration vibrations. The anti-corrosion material is not destroyed by sunlight, can be used for all types of building materials: from concrete to varnished wood, has no pungent odor and is safe to handle.

- Elastomeric materials (porous rubber, elastic plastic, etc.) serve to reduce the pressure of structural noise flow on structural elements of a house. For example, to ensure a high level of sound absorption, it is recommended to install tape seals made of elastomeric elastic materials around the perimeter of doorways. Such gaskets adhere well to all types of surfaces.

- Silica gasket roll materials made from environmentally friendly fiber are used in rooms with high fire safety requirements. They are used as an insulating material at the joints of building structures.

Soundproofing walls: step-by-step instructions

- First, you need to get rid of all the cracks using putty.

- Disconnect all sockets, disassemble, fill the hole with fiberglass. You can take mineral wool. After this, treat with gypsum mixture. Put the sockets back.

- Seal the heating system at the junction with the wall with a sealant with an elastic structure.

- Attach the profile to the wall at a distance of two centimeters. Place rubber or cork in the space.

- Place mineral wool, glass wool or slabs.

- Secure the gypsum board with self-tapping screws.

- Seal the joints with mesh and putty.

- Paint the walls or hang wallpaper.

Some useful tips when choosing material for noise and sound insulation.

For a reliable result after soundproofing walls, ceilings or floors, it is necessary to take into account some nuances.

- Whatever manufacturers and sellers promise when offering ultra-thin panels and slabs, effectiveness depends on the thickness of the soundproofing material. A barrier with a thickness of at least 50 mm can absorb sound waves. In such isolation, noise “gets stuck” both on one side and on the other. Of course, you will have to sacrifice room space, but sound insulation will be more effective.

- To soundproof the ceiling, it is better to use basalt mineral wool with a thickness of at least 30 mm and a density of at least 40 kg/m3.

- Before carrying out work, you should make sure that there are no cracks, voids, or joints, and if there are any, seal them with putty. It is also necessary to fill all holes under sockets, switches, distribution boxes with foam or other material.

- If you want to carry out comprehensive sound insulation of your apartment with modern materials, then it is better to contact acoustics specialists who will calculate the required level of noise absorption and the necessary characteristics of the material.

Soundproofing walls under wallpaper

Wallpaper is a popular type of decoration for residential walls. Liquid sound insulation under wallpaper is carried out as follows:

- The materials are prepared and cut into pieces. The size is selected individually.

- Wallpaper and plaster are removed from the walls. Cracks are removed using special solutions.

- After drying, apply glue and glue the backing. When everything is dry, seal the joints with masking tape.

- Moving on to wallpapering.

You can also use slabs or mats under the wallpaper. They are attached to the wall with screws, and sheets of drywall are placed on top.

Installation

Installation technologies for modern soundproofing materials vary depending on the material chosen.

Using dowel nails

Such a system is used in such materials as Phonestar GW. The panels are fastened using special dowel-nails, which are inserted into the designated holes in the panels. You need to drill holes in the wall in advance to connect it and the panels.

Detailed instructions for installing panels to soundproof a room.

Installation should begin from left to right and from bottom to top. Before installing the outer panel, its outer edges are cut off. The starting bar is installed close to the wall.

Applying plaster

Installing acoustic plaster yourself can cause many problems, as it requires certain skills. Beacons are pre-installed, which allow you to create a flat surface.

The plaster application process consists of three stages. The first step involves spraying a thick mixture as a base. The second stage involves filling the voids. The third is needed to consolidate the result.

Adhesive base

Such materials produced by SOFTBOARD are applied to a specially prepared adhesive base. Liquid nails intended for this purpose can be used as glue. Liquid nails are applied along the edges and in a couple of places in the center. First, the surface of the base is leveled using plaster.

The process of installing soundproofing material under wallpaper should not cause much difficulty, especially if you have certain skills. In order to get an excellent result at the end of the repair, you must fully comply with the installation technology:

- Preparing the wall surface. First you need to prepare the work surface where the material will be glued. To do this, it is necessary to eliminate defects in the form of large cracks. This is done using plaster, which is applied with a spatula; the surface is first primed. There should be no previous material left on the wall.

- Cutting strips. Soundproofing underlay for walls is sold in rolls over 10 meters long. Before gluing, it must be divided into strips equal to the height of the room. If possible, this should be done with a small margin, especially in the absence of practical skills, so that there is room for maneuver.

- Applying glue. Depending on the material used, the adhesive is applied to various surfaces; when using a non-woven backing, the adhesive is applied exclusively to the walls; polyurethane material requires additional application to the backing itself.

- Gluing strips. After applying the glue, you can proceed to gluing the strips. This must be done carefully to ensure neat joints. They should not stick out or puff up. Additionally, you can apply paper tape to the joints to obtain a better result.

- Drying. After completing the work, you need to let the glue dry. It is prohibited to perform any manipulations with the substrate within 72 hours. Only after the expiration of the period can the finishing work begin.

Modern soundproofing materials make a person’s life much more comfortable, eliminating extraneous noise, which can cause significant harm to his health. However, installation of the material also has its drawbacks, but they are compensated by a large number of positive aspects. It is up to everyone to decide whether to use it or not.

In the video you will see the process of sound and noise insulation of walls, and will also tell you what materials are needed and their cost.

Step-by-step application of sound insulation

The application method is similar to painting. The “Shumka” must be applied evenly and carefully. Several layers will be required. Try not to stay in one place for too long with the spray and do not allow high foaming.

Preparatory stage

It is advisable to remove peeling elements from the wall. Cover the floor with construction film so as not to spoil it. It is recommended to close sockets and electrical wires.

Primer

This step will help improve adhesion to the coating. It can be applied manually or with a spray bottle. The primer will protect against mold in the future.

Applying sound insulation

The work takes place in two stages. First a thin layer, then a dense one. In the process, they use a tool that operates under pressure. When the insulating layer is 3 cm, you can finish finishing.

Drying

After carrying out all the above materials, you only need one thing - let the insulation dry thoroughly. Drying time may vary among different manufacturers. Read the instructions for use.

Popular materials

- Isoplaat tiles, for the production of which pine wood fibers are used. The thickness of the tile is 10 mm, dampens sounds up to 23 decibels. The tiles are attached to the wall using glue. Recommended for final finishing.

- ZIPS panels, consisting of plasterboard facing sheets and sandwich panels. They are made of dense and soft layers. The thickness of the material depends on the chosen model and can vary from 40 to 130 mm. Sound insulation is 10 decibels. They are attached to the surface using structural units, and for installation to walls it is recommended to use soundproofing gaskets.

- Kraft wall panels are made from wood fibers, included in the boards, wax paper (on the front side), corrugated paper (on the back side). The thickness is 12 mm, dampens sound up to 23 decibels. You can paste over the walls in the apartment, and then attach wallpaper to the panels, as well as for final finishing.

- EcoZvukIzol panel made of 7 layers of cardboard profiles and quartz sand. The thickness is 13 mm, and the sound insulation level is 38 decibels. The panels are attached to the wall with ordinary adhesive for installing drywall.

- Isotex tiles and panels made from softwood fibers. The products have two types of thickness - either 12 mm or 25 mm, but the noise insulation level is 23 decibels. They are mounted using connections called tongue-and-groove.

Article on the topic: Proper arrangement of acoustics in the studio: ensuring the absence of sound distortion

Areas of application of polyurethane foam

This versatile material is suitable for protecting different rooms. Insulation will help protect the room from moisture and noise, and retain heat during the cold season.

Moisture protection

High humidity is a problem that can be eliminated with the help of paint and varnish material. Most paints have waterproofing properties. Sometimes special paint with soundproofing properties may be required. After this, the walls will cope with any exposure to water.

The paint should be suitable not only for interior, but also for facade decoration. In addition to resistance to humidity, resistance to ultraviolet radiation and temperature changes is desirable. The composition should contain additives against fungus and mold.

Noise protection

The greatest degree of sound insulation can be achieved if the paint is applied in a dense layer. A brush or roller is perfect for the job. Paint will help get rid of not only sounds, but also vibration.

Alternative options

There are even more progressive options that provide sound insulation of walls. Modern materials are tremozvukoizoil and ZIPS. The first is synthetic, which, according to buyers, has excellent performance characteristics, but in order to achieve the maximum effect, you will have to lay several layers of this material.

If we talk about ultra-dense ZIPS panels, then this material is considered the best on the market. It combines sound-reflecting and noise-absorbing parameters, which is ideal for furnishing an apartment in a multi-story building. It is easy to install, but such a purchase, unfortunately, can significantly affect the repair budget.

Other manufacturers

You can also find Tecsound and Soundguard products. These manufacturers offer original developments, for example, membranes, the effectiveness of which is comparable to using a regular gypsum board sheet. Only in the latter case will the thickness of the partition increase by 5-7 mm, but this will reduce costs several times.

In order not to be unfounded, as an example we give a test of the Texound material:

And here is a small test comparison of gypsum board and Soundguard

Pay attention to the different box designs. Everything is done in order to demonstrate the advantage of ZI, which really does not exist:

These manufacturers also have mineral wool-based materials that are really effective. However, unlike Russian analogues, their cost is 3-5 times higher.

Advantages of substrates

When choosing modern materials for wallpaper, most craftsmen give preference to cork backing. It simultaneously acts as insulation and soundproofing element. Advantages of substrates:

- Suitable for rooms with thin partitions.

- The structure is dense, so no frame is required.

- Waterproofs the apartment.

- There is no need to lay additional building materials before the facing layer. You can immediately glue wallpaper onto the additional spacer.

- Resistant to temperature changes. Retains moisture in the wall.

- Suitable for harsh climates.

- The substrate is impervious to aggressive environments. The antibacterial layer prevents the formation of fungal compounds.

- Smoothes out uneven walls: depressions, bulges.

- No special skills required for installation.

Before starting repairs, select a gasket that is suitable for such sound insulation. It is important that it is combined with the facing building material.

TechnoNIKOL

The Technonikol Corporation was founded in 1992 and specializes in the production of roofing materials, hydro- and thermal insulation. Sound insulation is represented by slabs of mineral wool based on basalt rocks, as well as rolled material based on bitumen-polymer.

- to soundproof the floor under the screed, use the Technoflor and Technoelast line;

- for work with walls, partitions and suspended ceilings, choose Technoacoustic

A special feature of floor coverings is the combination of sound and waterproofing properties. This is very convenient if work is carried out in wet areas or you need to fill the screed. Main technical characteristics of TechnoNIKOL

| Characteristics/Product Line | Technoflor | Technoacoustic | Technoelast |

| Peculiarities | Dense slabs 1200×600 mm made of stone wool, covered on one side with fiberglass. For sound and heat insulation of floors. Non-flammable. | Slabs 1200×600 mm made of basalt fiber for installation in a frame system. They provide absorption of extraneous noise and also act as thermal insulation. Non-flammable. | Bitumen-polymer material in a 10×1 m roll with an aluminized film on the top side. For floor work. Suitable for waterproofing premises. |

| Modifications and their purpose | Standard – for floating floors, laying the screed directly on the material. Prof – for any floors with increased loads. | Packages with different numbers of slabs. | Acoustic C - without a base with a self-adhesive overlap on the sides. The soundproofing fabric is glued with a bitumen binder with a metallized film. Acoustic Super A350 - with a fiberglass base and double-sided coating with a bitumen-polymer binder. On one side there is a thermally bonded sheet, on the other there is an aluminized film. Provides absolute waterproofing. |

| Thickness, mm | 40 and 50* | 50 | 2.5 and 4.8** |

| Surface density, kg/m² | 4.4 and 8.6 | 2,1 | 0.7 and 2.2 |

| Impact noise level reduction index for floor modifications, ΔLnw, dB | 37-39 | — | 23 and 26 |

| Average sound absorption coefficient, αw | — | for low and high frequencies: 0.4-0.8 for mid frequencies: 0.8 | — |

| Price, rub./m² | 190 and 405 | 116 | 241 and 231 |

* The first value is for Standard, the second is for Prof. ** The first value is for Acoustic S, the second is for Acoustic Super A350.

Be sure to watch a short video about using Technoacoustics to reduce noise transmission through walls:

Description of mineral wool brand "Knauf"

View gallery

Mineral wool "Knauf" is also called stone wool and is made, no matter how funny it may sound, from stones. This material is also called basalt wool, the production of which uses stones of lava origin. They are melted down, and then binders are added to them. The fibers are formed into rolls or solid slabs.

Mineral wool can be produced using different technologies using different materials. The production process affects the technical characteristics of basalt and mineral wool. Traditional mineral wool is good, but can be susceptible to moisture, dust and be harmful. All these troubles were overcome within the framework of modern production. As a result, it is possible to obtain an almost ideal insulation.

Knauf mineral wool is produced without the use of formaldehyde and phenolic resins. Almost all the negative reviews about the dangers of mineral wool used to be aimed precisely at the fact that when exposed to high temperatures, the material begins to emit phenol fumes, which are quite toxic.

The material described does not contain harmful resins, and therefore no harmful fumes. The same can be said about the ability to emit dust. It negatively affects a person's lungs and irritates the skin. However, most often mineral wool does not generate dust. This characteristic is characteristic of glass wool. However, if the mineral wool fibers are poorly formed, they can break, which causes the release of dust.

Specifications

The panels are manufactured using high-tech equipment.

The ends of the slab can be smooth or have the appearance of a locking system. Panel sizes:

- width –1200 mm;

- length - 2 or 2.5 m;

- thickness - 12.5 mm;

- weight 1 m2 - from 8.5 to 9.6 kg;

- density—from 650 to 730 kg/m3.

Advantages of Knauf Acoustic sound insulation:

- quick installation;

- the panels are easy to process;

- harmless environmentally friendly material;

- service life more than 25 years.

The slabs are used for soundproofing interior spaces in office, residential and administrative buildings. They are mounted on metal profile frames on the walls and ceiling. Sheets of flexible material fit tightly to each other.

The light weight and other characteristics of the Knauf Acoustic sound insulation make it possible to transport and fasten the slabs without much difficulty. The products do not lose volume, which allows them to maintain technical characteristics longer than those promised by the manufacturer. Immediately after installation you can feel the quality of sound insulation.

In addition, the installation of slabs makes it possible to improve the thermal insulation characteristics of the room, which is an additional advantage of Knauf Acoustic products.