The main features of plastic pipes include lower price and weight, increased service life, and ease of installation. Particularly noteworthy is the ability to connect pipes without soldering or with it, but in a faster way than metal analogues.

Let's figure out what options there are for connecting polypropylene pipes and how to apply various assembly technologies at home.

One way to connect a pipeline Source atyourserviceplumbingcompany.com

Polypropylene pipes: connection methods

The choice of technology for assembling a plastic pipeline depends on the type of products and their properties. The methods used for joining sections are divided into two large groups:

- The first one is “hot”.

This involves welding or soldering, that is, heating the material to change its state of aggregation. This method is used to form a deposit at the joint, and ensures the absence of leaks and uniform distribution of mechanical loads.

A welded joint is, first of all, a one-piece type of installation. This type of pipe connection is permanent and is used until the expiration date of the products. This method is more often used to achieve high pipeline strength. Soldering is done using special equipment or improvised tools.

Method of connecting polypropylene pipes by soldering Source vodatyt.ru

- The second is “cold”.

Involves connecting polypropylene pipes without soldering. This method is used when quick joining is necessary, in the absence of welding skills.

The installation method in this option is detachable or threaded. It can be used when connecting thin pipes, polypropylene and metal. When using this “cold” method, connecting elements are used - polypropylene fittings, the sizes and dimensions of which are selected to match the main product - pipes.

Knowing how to connect polypropylene pipes without soldering, you can pre-select elements suitable for operating conditions and ensure quick assembly.

Installation of polypropylene pipes using improvised means Source moikolodets.ru

Welding and installation of a separate part of the pipeline system

When installing a separate part of the pipeline (node/main):

- measure and cut the required pipe size;

- weld the chain on a fixed surface, and then install it in the planned area. That is, we first solder the assembly, and then connect it suspended with other sections;

- in the most difficult to reach places, use American ones.

Soldering the knot on weight

We solder pipes by weight:

- determine which side is the most difficult for weight soldering and start with it;

- Initially, the pipe and the connecting element/assembly are welded on one side according to standard measurements, observing the established time for soldering;

- then (on the other hand) the connecting element heats up first, for a couple of seconds longer, and after that the pipe heats up a couple of seconds less than usual (in essence, you give time to the connecting element to warm up the pipe).

It is difficult to solder parts by weight, so to warm up it is recommended to press on the elements with improvised means (special scissors, etc.). It is better to invite an assistant for weight soldering.

Installation of the soldered assembly

First of all, the required assembly is welded on a hard surface. When it is ready, we proceed to the connection with the already installed pipes:

- Mark the cut areas on the working highway with a pencil. There is no need to cut out an area for the entire fitting or other connecting element. It is necessary to take into account that pipes will be inserted into it (for example, a tap measuring 10 cm, the holes for connecting to the pipes take up 4 cm in total, then you need to cut 6 cm of pipe);

- cut the installed pipes on both sides with special scissors;

- clean the pipes with a degreaser and dry them from water;

- clean the elements;

- start welding the assembly. Start from a more difficult place.

“Hot” joining method: welding options

When using this method, 2 welding options are used:

- Soldering pipe to pipe is the most popular method.

- Fusion welding of couplings (adapters).

The first method is used when welding pipes with a diameter of more than 40 mm. The second is on pipes with a diameter from 16 to 40 mm. In this case, the fitting is needed not only to adjust the direction of pipe laying, but also as a supply of material for melting.

Various configurations of couplings (adapters) Source education-web.ru

Coupling configurations are selected based on the characteristics of the pipeline. The following types of adapters are available:

- Corners . Change of direction in any direction.

- Tees . Distribution of water supply and change of direction.

- Couplings . Docking without changing direction.

The following elements also apply:

- Bypass fittings.

- Ball valves.

- Combined products including metal-plastic.

- Threaded inside or outside pipes.

The nuances of working on a water pipeline under pressure

For insertion into the pressure pipeline, electric-welded saddles and clamps with a built-in cutter are used. It is located in a special sealed nozzle housing. To drill into plastic, it is often enough to turn it with a hex key. But there are also models for a drill.

The presence of a sealed branch with a cutter inside ensures that there is no splashing of water when drilling a pipe under pressure

Some similar designs have a built-in valve. Then, after drilling is completed, the cutter is raised, the valve is closed, and the attachment with the drill is removed. Instead, a drain pipe is installed.

However, there are also products on sale with a discharge pipe, which is directed sideways from the drill (parallel or at an angle to the connected water supply).

The use of linings with an internal cutter allows you to cut into any water pipes. It doesn't matter whether they are under pressure or not. But such attachments are much more expensive than conventional clamps and saddles.

They greatly simplify the insertion process, but you will have to spend money on them. At the same time, in terms of the tightness of the resulting connection, they are neither superior nor inferior to standard solutions.

Mechanical joining method without soldering: connection options

Soldering as a method of joining pipeline sections is more often used during installation supervision in production. In everyday life, the most popular technologies are express installation without welding.

The time-tested practice of joining without the use of special tools ensures high quality joints of plastic pipes without soldering using couplings.

The widely known method is based on the use of shaped parts. With their help, you can not only ensure the continuation of the water supply circuit, but also change its direction, distribute the working medium or block the flow.

Advantages of installation technology without heating:

- Finished polypropylene products are cheaper to connect using this method than metal ones due to the low cost of fittings.

Connections of plastic pipes without soldering using couplings Source stroy-podskazka.ru

- The design of the fittings makes it possible to manually assemble a complete engineering system of drainage, water supply, and sewerage.

The size and technical capabilities of parts are determined by their configuration (shape, wall thickness, combination).

Connection using compression fittings

When choosing how to connect plastic pipes for water supply without soldering, many people often use the compression fitting method. With this connection method, the process of heating adjacent parts is eliminated. A special coupling, under mechanical action (crimping), reliably fixes the two ends of the tubes equipped with o-rings inside. After installing the adapter, the joints are lubricated with silicone sealant.

Switching from metal-plastic to polypropylene using fittings is an indispensable way to join pipes made of different materials.

The advantages of this method:

- a minimum set of tools is used for installation;

- Even a beginner can trust the pipeline connection;

An example of lubricant used when installing polypropylene pipes Source construct.smazka.ru

- a reliable connection is created at the installation site of the compression fitting;

This method, first of all, is good because it can be used when updating cast-iron water pipes with polypropylene analogues. This method is also in demand when assembling heating systems, including the installation of radiators.

Connection using adhesives

Among the docking options that make it possible to do without special equipment is the use of assembly adhesives.

The base composition of the adhesive is polyvinyl chloride mixed with a solvent. Manufacturers also add various additives and plasticizers to it to improve adhesion at joints.

Advantages of the method:

- joining products using an adhesive provides the assembled structure with the necessary characteristics of strength and tightness;

- upon completion of work, a reliable connection is formed at the installation site, invisible during visual inspection;

- No special skills are required for docking.

Important ! During work, safety precautions should be observed, do not work near open sources of fire and avoid contact of the composition with the skin.

Fitting polypropylene pipes before gluing Source www.asvshop.com

See also: Catalog of companies that specialize in engineering communications.

How to install with glue

Before connecting polypropylene pipes, you need to prepare the necessary parts, tools and provide conditions for installation work.

The surfaces on which the adhesive composition will be applied should be treated with a degreaser. To apply the composition, a brush with bristles made from natural materials is suitable. It is also recommended to ensure the room temperature ranges from 5 to 35 degrees.

Considering that the pipeline parts will be joined with a minimum gap, a thin layer of glue will be sufficient. Holding the pipes until they set usually does not exceed 20-30 seconds. Upon completion of work, it is recommended to ventilate the room well, while drafts should be avoided.

How to make a tap into a main water supply

Before starting the main water supply, you must go through all the permitting approvals necessary to obtain permission from the responsible institution (Vodokanal). Undoubtedly, it is better to go through this process legally than to receive a fine for an illegal connection, since sooner or later it will still be revealed during a routine inspection by the volume of water consumption

Before submitting documents, it is necessary to calculate the volume of water required in a house or apartment and, as a result, the size of the diameter of the supply line. Once all approvals have been received and permits are available, work can begin. Mostly, if possible, it is planned to tap into an existing well, but if this is not possible, then it is possible to install a new one, opposite the place of water supply.

The well is planned to be built to the depth of the main pipe route. The outlet should face towards the house. Next, after completing all the work, it is necessary to hand it over to the employees of the controlled organization in a certain way, with the sealing of the metering point and the tap that shuts off the incoming water.

How metal-plastic and polypropylene pipes are joined

There is only one way to install pipes made of different materials. This is a threaded installation, since soldering and gluing products cannot be used here.

This is explained by the fact that the joint must not only be hermetically sealed, but also be able to experience high dynamic loads (maximum pressure difference).

Quick installation of pipes from various materials Source glawtruba.ru

Before connecting a metal-plastic pipe with a polypropylene pipe, you need to select the necessary parts:

- Metal-plastic products are equipped with special tips.

- Polypropylene sections, in turn, are equipped with a coupling on which a thread is applied.

Let's compare the advantages and disadvantages of fiberglass and aluminum reinforcement

Comparative characteristics of polypropylene pipes with an aluminum layer and those reinforced with glass fiber are carried out according to their key indicators:

- Linear expansion when heated. The value of this indicator is the same and ranges from 0.03 to 0.035 millimeters per meter.

- Reliability of the reinforcing layer. Due to the special manufacturing technology, the fiberglass layer is more uniform, the products are made without seams or joints. The aluminum braid is fastened by welding, a seam is formed at the joints, and in some modifications the foil coating is overlapped. We can conclude that the aluminum layer is inferior in this regard to fiberglass reinforcement

- Material resistance to oxygen diffusion. The fiberglass layer reliably protects the cavity from the penetration of oxygen molecules. The foil coating allows oxygen to pass through, which leads to the development of oxygen corrosion.

- Ease of installation and strength of connections. Soldering polypropylene pipes with an aluminum layer requires attention and accuracy. In order not to damage the reinforcing layer, preliminary cleaning is carried out. Glass fiber reinforced polypropylene pipe is installed without pre-treatment.

- Thermal conductivity. Compared to glass fiber reinforced pipes, a pipeline made of polypropylene pipes with an aluminum layer heats up faster.

- Environmental Safety. Polypropylene does not emit toxic substances and therefore installation from this raw material is permitted in residential premises and public buildings.

- Plastic. Both types of products work equally under conditions of overheating by high coolant temperatures. Even when in contact with hot water heated to boiling temperature, the piping retains its original shape and the integrity of the system.

If we compare the production technology of reinforced polypropylene pipes, the conclusion arises that glass fiber reinforcement is a more advanced development with great development prospects.

Bell-shaped technology for assembling plastic pipelines

Fixation using this method is justified only when operating in low pressure systems. The insert into the socket ensures quick and easy installation, suitable for sewer and drainage engineering systems.

The ends of the pipes at the installation site must have a precisely adjusted diameter.

The section with the socket is, accordingly, inserted into the end of the pipe with a seal. The work will not require special knowledge or the purchase of special fittings.

The procedure for assembling pipelines by driving them into a socket

To eliminate possible diametrical errors in the joined sections, there is a rubber ring in the socket tip. The task of this element is to ensure tightness under mechanical stress on the pipeline.

Assembly of various polypropylene pipes Source www.uponor-usa.com

To facilitate the driving process itself, lubricant is used. The composition is applied to the smooth part of the end cut. The docking process is controlled using markings. This will prevent the user from driving the pipe too deep and damaging the section.

Normalized immersion of the bell allows not only to ensure material savings, but also to maintain a standard gap, which is necessary to compensate for loads during linear expansion - phenomena that occur with temperature differences.

Common Possible Errors

Often, when preparing for work, specialists or site owners inattentively prepare materials and components of components according to diameters and characteristics. It is important to consider the intended use both in terms of size and temperature characteristics.

The work must be planned, also depending on the weather conditions, taking into account the temperature regime of the surrounding air.

When soldering the material, carefully ensure that the existing pipe does not burn through, in order to avoid applying additional patches and unnecessary elements, as this will weaken the insertion site.

Classification of fittings and adapters

Assembling pipelines using special nozzles is the most popular method of wiring engineering systems. In order to select the necessary types of fittings for polypropylene pipes, you should familiarize yourself with their detailed classification.

For the manufacture, release and supply of technical polypropylene products, the provisions of state standard No. 52134 of 2003 are used.

Types of fittings for polypropylene pipes Source ecomont.ru

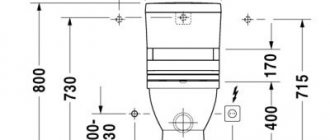

Installation parameters of pipes and fittings

In the selection of polypropylene pipes and adapters to match the technical design of the building, simple physical principles are used.

The dimensions of fittings for polypropylene pipes in mm can be selected depending on the diameter of the polypropylene pipes, their thickness, and resistance to temperature influences.

For a home where there is free space and the mechanical strength of pipelines is important, elements with a thickness of 16 mm or more are laid. This takes into account the difference between the internal and external diameters of the products. The thickness of the pipes and fittings will compensate for the missing characteristics.

The first among the installation parameters is the operating pressure, indicated by the PN marking.

| PN10 or 10 bar | PN16 or 15 bar | PN20 or 20 bar | PN25 or 25 bar | |

| Pipe outer diameter | 16-110 mm | |||

| Wall thickness | From 1.9 to 10 mm | From 2.7 to 18.4 mm | From 3.4 to 6.9 mm | |

| Maximum temperature | 45°C | 60°C | 75°C | 95°C |

| Scope of application | Cold water supply, low pressure pipelines | |||

| Reinforcement | No | No | Eat | Eat |

In this case, you should not focus only on the wall thickness parameters. If there is reinforcement (fiberglass), the outer diameter of the pipes increases.

Selecting fittings for polypropylene pipes by size is not so difficult, you just need to find tables of recommended adapters and their diameters.

Before installing pipes at home without a soldering iron, you need to select the sizes of fittings and couplings in mm or inches Source image.isu.pub

Using couplings

An ordinary coupling for plastic pipelines is a fairly simple part in its design. It consists of:

The coupling can be found at the nearest plumbing store, or, if you have certain skills and knowledge, you can make it yourself. In this case, the characteristics of the coupling must strictly correspond to the dimensions of the products being connected. Ordinary couplings are suitable for both pressure plastic pipelines and pipelines without pressure. With their help, they provide a reliable connection of polypropylene without the use of a soldering iron.

To form a connection, the ends of the pipes must be inserted into the coupling so that they touch in the middle. The ends must pass through washers, gaskets and nuts. Then you need to tighten the nuts tightly so that the pressure on the gaskets is strong enough.

Joining plastic pipes with a coupling provides a 100% sealed seam, even without the use of soldering. But in certain cases, for example, if the pipe is short or adjacent directly to the floor (or other horizontal surface), it is not possible to install an ordinary coupling.

For such difficult cases, a clamping coupling was invented. How to use it? First you need to clean the edge of the plastic pipe. Then you need to unscrew the coupling and put all the fastening parts on the plastic product in the correct sequence. Moreover, the sealing ring should ultimately be located at a distance of at least one centimeter from the edge of the product.

Then you need to insert the body of the clamping coupling into the end of the plastic pipe. And then you need to move all the existing rings to this body and tighten the bolt. And to the thread located on the other side of the coupling, it will be necessary to attach an “American” fitting with a plastic pipe connected to it.

To control the strength of the connection, you must carefully pull the coupling towards you, holding the pipe to which it is attached with your free hand. The coupling must remain stationary. If it moves, it means that the wrong size part was selected. That is why it adheres so poorly to the pipeline. However, this is easy to fix - you just need to tighten the threads.

Fastening methods used in everyday life

Each apartment owner independently determines the level of installation quality he requires. Some people use soldering, while others use adapters or other alternatives.

"Hot" soldering of pipes

Considering soldering as the most reliable and durable method of fastening, some private property owners use this method of pipeline installation. In the absence of special equipment, they use a gas burner. In this case, you can save on purchasing a soldering iron and work with pipes of any diameter.

Workflow Features:

- The gas burner must be selected according to the type of fuel used. The gas with the highest combustion temperature is suitable for thicker pipes.

- It is best to select pipe sections of the same diameter. This will ensure an aesthetic appearance of the engineering system, preservation of operating parameters in all sections of the pipeline and the absence of difficulties during soldering.

- Before starting installation, it is recommended to mark (cut) the entire contour, clean the ends of the joints, and degrease them with a special compound.

Installation of polypropylene pipes using a gas burner Source ytimg.com

What are the features of connecting a pipe to a centralized system?

Work on inserting into a plastic water pipe, into a steel or cast iron pipeline is entrusted to water utility specialists or a qualified contractor (with the knowledge of the water supply organization).

Self-tapping, even into a public plastic water pipe, is prohibited by law. It is illegal to make an additional connection to the centralized water supply, bypassing the metering devices.

Note! Planning an individual connection to a centralized system should begin with obtaining official permission. Independent connection is punishable by material and administrative penalties.

You should apply for the appropriate permit from the department to which the required pipeline belongs. In the case of water supply, this is the city water utility or an organization that maintains water communications in a village or town. To obtain permission to tap into a pipe, you must have documents for the land plot and house with you.

The permit for tapping into a centralized pipe will contain:

- exact data on the insertion location;

- additional information depending on the purpose of the work.

indication of the diameter of the pipeline and outlet;

After receiving permission, you should contact the SES. After this, the insertion project is prepared and registered, and a work estimate is drawn up.

Briefly about the main thing

Lightweight, durable plastic pipes are easily connected to any materials in a variety of ways. There are detachable and non-detachable installation methods:

- The first option includes the use of compression fittings, threaded elements, and couplings.

- The second option uses “cold” and “hot” welding and gluing. The connection occurs using special compounds, for example, solder tapes and pastes, glue, epoxy resin, or simply by heating the plastic to the melting point.

When choosing how to connect metal-plastic with polypropylene at home, pay attention to the technology of compression fittings or threads with plastic elements.

Today, this is the only way to connect dissimilar sections, for example, cast iron and plastic. With compression fittings, the pipe connection can be quickly updated if necessary by replacing parts. The same cannot be said about the soldering method.

When there is no special tool at hand, electrical fittings can be used. Once connected, these elements quickly solder individual sections of the pipeline.

Before installation using the detachable method, you need to select fittings for the pipeline based on operational characteristics (temperature, pressure, dimensions). Fittings marked PPG are suitable for heating systems.