It is convenient when developers offer apartments in new buildings for occupancy in a rough version - with bare walls, floors, and ceilings. Such a purchase makes it possible to create the apartment of your dreams using any materials, bypassing the stages of disappointment with the quality of major renovations. Finishing from scratch is cheaper than alterations, and is very significant, especially if you do everything yourself. Soundproofing is the most expensive measure when creating comfort in an apartment. You won't need it unless you are deaf from birth. In other cases, costs for materials cannot be avoided.

When to install soundproofing?

Sound conduction in a high-rise building is a tricky thing. You will always be aware of how the people from the next apartment live, or endlessly conflict with them because of the scales that your young musician is learning. By protecting one wall from neighbors with soundproofing materials, you can hear them through the floor or ceiling. The entire structure of the house is tied into a single system, so sound insulation will have to be installed all around, not forgetting to isolate the nursery from the living room, the kitchen from the bedroom, as well as the bath and even the entrance doors.

Soundproofing is the second priority stage of furnishing an apartment in a new building after installing a toilet and sink. It can be combined with insulation of the walls of the room.

Soundproofing substrates

This group of building products allows you to increase the insulating properties of the coating in a panel house without completely dismantling existing structures. Due to their small thickness, the materials do not cause the floor level to rise above the permissible level. Depending on the type of finishing layer, acceptable height, and acoustic characteristics of the substrate, a product with suitable parameters is selected.

Roll and slab substrates based on natural cork are popular. In addition to environmental friendliness, durability, and immunity to moisture, they successfully combine low thermal conductivity with the ability to absorb acoustic vibrations. A tangible result is achieved by using modern multi-layer products, for example, a felt coating reinforced with a polymer base.

Natural cork backing.

Cheap and relatively effective materials include substrates made of soft wood-fiber boards; despite the name, the material is not subject to deformation, maintaining its original thickness under load, which allows it to be used under type-setting and panel parquet and laminated coverings. The choice of soundproofing substrates in the retail chain is significant; manufacturers are constantly expanding their range of products, but when purchasing them, one must not forget that, despite advertising promises, the capabilities of thin materials are limited, although often sufficient.

Types of sound insulation

Soundproofing of apartments is divided into two types:

- Sound reflective (material that returns decibels back).

- Sound-absorbing.

Soundproofing materials are used both in new buildings and in old apartments. Some of their types are suitable for soundproofing bathrooms, some for entrance or interior doors. Manufacturers offer a wide range of soundproofing materials, there is plenty to choose from.

- Thin, dense materials are heavy and can rival concrete walls in noise-reflecting properties. Their price is quite high.

- Sandwich panels combine sound-absorbing and sound-reflecting materials. They are mounted on a frame, thereby reducing the area of the room. They belong to the middle price segment.

- Mineral wool slabs serve as excellent sound insulation from general background sounds, but do not protect against impact noise. They are the most accessible material.

Types of noise

Let's start with the fact that the noises are different from each other. Currently, experts divide them into four groups:

- Drums. For example, neighbors hammer a nail into the wall separating your apartment from theirs.

- Airborne. These include conversation, the cry of a child, the cry of an animal or bird, waves from music.

- Structural. This type includes wave vibrations inside a building, which are transmitted through its supporting structures. For example, the movement of the elevator, the creaking of the front door, waves inside the ventilation system from the rotation of the fan propeller.

- Reflective. A complex species, which is a subspecies of all the previous ones. Essentially, these are sound waves that penetrate the interior of the apartment and are reflected from objects located inside the rooms.

As you understand, we will be interested in the shock and air sounds that come from the neighbors’ apartments. How can you get rid of them, and if not completely, then at least partially. Option one is to install a sound insulation system on the wall. But you need to understand that sound insulation must in this case perform two functions at once.

- This is actually insulation, that is, reflective ability, which does not allow noise to penetrate into your apartment from neighbors.

- And the ability to absorb sounds. This feature will save your neighbors from noise coming from your apartment.

Preliminary work on soundproofing the apartment

Soundproofing an apartment begins with identifying and removing cracks (potential sound transmitters). Detected defects are repaired with putty or sealant. Particular attention should be paid to communication pipes. They are tightly wrapped with sound-proofing material, such as polyethylene foam, mineral wool or fiberglass, and the insertion point is carefully sealed.

USEFUL INFORMATION: Plywood under linoleum on a wooden floor

An outlet in the wall will serve as a “speaker” from neighbors if it is not protected. Before installing the socket box, a noise insulator made of non-combustible material is placed in it.

Styrofoam

This material is often used for sound insulation. Its advantages:

The walls are lined with polystyrene foam. The material releases volatile substances in very low concentrations, so it does not harm health. In exceptional cases, individual intolerance to polystyrene foam is observed.

Thanks to its porous structure, the material effectively absorbs vibrations. If you install soundproofing boards correctly, you will be able to reduce the noise level. Polystyrene foam has good functional characteristics. It is light in weight, which means it is easy to transport.

The slabs can be stored for a long time in an unheated room, they will not deteriorate or lose their properties. Foam plastic has a low melting point, regular foam melts at a temperature of + 145 degrees, and epoxy at a temperature of + 170 degrees. Lights for 4 seconds, after which it goes out if there is no source of fire nearby.

Soundproofing the floor in the apartment

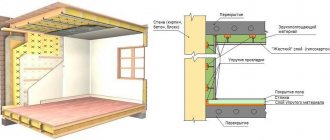

The most popular method of soundproofing the floor in an apartment at the moment is installing a “floating” floor.

- The base is lined with a sound insulator (basalt slabs, mineral wool).

- Covered with film.

- The cement screed is poured.

- Finishing materials are laid.

The second option for sound insulation involves installing the floor on joists. The lags are fastened to gaskets made of material that dampens vibration. The space between them is filled with tightly laid sound-absorbing slabs.

There is another option: to use sound insulation materials of the ZIPS-POL system in the apartment. This system is assembled from sandwich panels equipped with elastomer point supports. The method is convenient for quick DIY installation.

Important! The legislation of the Russian Federation provides for liability for the lack of shockproof (falling objects, steps) protection of the floor in the apartment.

Drywall

To create reliable sound insulation, you need to choose a material of high density. Drywall, designed to suppress sound vibrations, contains special membranes and mineral wool. To enhance the sound insulation effect, many sheets should be laid. To make a sound-absorbing structure, you need to use 2 sheets of gypsum plasterboard or use a combination of gypsum plasterboard + gypsum plasterboard.

Drywall can withstand significant loads. It is fire resistant and not susceptible to moisture. The material can be formed and does not crumble. For high-quality insulation, exclusively dense plasterboard is used.

Soundproofing of apartment walls

When installing soundproofing in a small apartment, you have a choice: either sacrifice space, protecting yourself from noise, or listen to the working elevator and voices on the stairs, preserving the territory. The most rational way out in such a situation is to use thin but effective soundproofing materials. They are expensive, but worth the money.

Materials that partially avoid noise:

- Cork panels laid without gaps.

- Tufted wallpaper with a noise-insulating layer.

- Plaster.

If the area of the apartment allows, you can use less expensive materials for sound insulation, such as slabs of fiberglass, mineral wool, and dense foam. They are fastened using a frame or frameless method.

Important! A metal profile is an excellent conductor of sound, therefore, when installing the frame, the attachment points are isolated from the load-bearing surface with vibration-isolating materials, and the profile itself is carefully filled with a sound insulator.

Frameless sound insulation methods are less labor-intensive and easier to implement. As a result, less time is spent on installing the material. In addition to this, there is no possibility of making a mistake when assembling the frame, which will inevitably entail alteration of the structure.

For example:

MaxForte SoundPro is a new generation roll composite material. Created taking into account theoretical developments in the field of building acoustics. With a thickness of 12 mm, it provides maximum protection against airborne and impact noise. An irreplaceable material in small apartments. No glue or chemicals included. It also acts as fire retardant and thermal insulation.

USEFUL INFORMATION: Which chandeliers are chosen for rooms with suspended ceilings?

Advantages:

- Completely non-flammable.

- Not afraid of water.

- Without phenol and odor.

- Easy to install.

- Maximum class “A” for sound absorption.

Video on how to install sound insulation without making a frame with MaxForte SoundPro:

An expensive but high-quality material is liquid sound insulation. To install it in an apartment with your own hands, you do not need to have any special experience. It is applied to the wall surface before attaching rough finishing sheets (plasterboard, plywood, OSB) or to the sheet material with which the surfaces will be sheathed.

Silence is the key to peace

It’s difficult to talk about peaceful living if you hear extraneous sounds from everywhere - both day and night. The neighbor's TV playing early in the morning, barking dogs and other noises and sounds interfere with proper rest. Constantly noisy neighbors cause irritation, and scandals often arise for this reason. Poor sound insulation can easily ruin your mood.

Even if you ask your neighbors to be quieter, this is unlikely to achieve anything, so you can’t do without good sound insulation in a city apartment. How to improve the sound insulation of an apartment?

It is not necessary to entrust this task to professionals, since their services are not cheap. It is much more economical to purchase the necessary materials, study the basic principles and soundproof the home on your own.

Soundproofing is quite a troublesome task, but the effort is worth it in order not to experience discomfort in the future due to outside noise.

On a note! Based on the personal experience of numerous residents of panel houses who have soundproofed their apartments, the best sound insulator is mineral wool.

Other materials can be combined with each other and supplemented with mineral wool, but no other sound insulator has such a high level of sound absorption, and it is also cheap and practical. The choice can be made on one of the types of wool, for example, basalt or fiberglass.

Soundproofing materials of cotton type are sold in various versions: in the form of slabs (very convenient to use), in rolls, in the form of mats. The main thing is that it is not a half-hard variety: although such material has a smaller thickness, its degree of noise absorption is less.

It is this thinness parameter that wool-based insulators lack. Thin sound insulators make it possible to use space economically, but in terms of creating comfortable living conditions they also thermally insulate surfaces

Taking into account the fact that plasterboard will also be used to mask the sheathing and insulation, the living space will be reduced by about 10 cm from all surfaces for which you will soundproof

All surfaces need insulation, although many believe that it is enough to take such measures only for walls - this is a misconception. The floor, ceiling and other surfaces of the room also cannot be ignored. In addition, it is pointless to count on complete sound insulation, since when constructing panel-type houses, they do not adhere to the rules for protecting building structures from extraneous sounds.

Important! Nothing can completely get rid of structural noise waves transmitted by vibrations through the components of building structures - they can only be reduced. If someone starts renovations on other floors, the echoes of the work will inevitably be heard in your apartment

If someone starts renovations on other floors, the echoes of the work will inevitably be heard in your apartment.

Soundproofing the ceiling in a new building

Noise from the upper apartment can be avoided in two ways:

- Due to sound insulation of its own ceiling.

- By giving the neighbors above you a soundproofing floor.

The same materials and technologies are suitable for soundproofing the ceiling of an apartment as for walls. At the same time, flooring materials for your neighbors will cost you about the same amount, but the height of the room will remain the same.

Electrical distribution boxes.

These boxes, in which the electrical wiring is connected, are usually installed at the top of the wall. Often you may not be aware of them because they are hidden behind the wallpaper. It is very easy to find by lightly tapping. Exactly as in the previous example, the holes for installing distribution boxes are through and are covered with a thin layer of plastic on top.

Tip: Soundproofing electrical distribution boxes can be done in the same way as electrical outlets. We strongly recommend that you contact an electrician, since fire safety depends on the correct wiring!

Door soundproofing

In a new building, the entrance doors that are installed are usually the cheapest ones. They freely allow sound and cold into the apartment. To solve this problem, it is necessary to eliminate the gaps between the wall and the jamb, as well as the jamb and the door. This will help:

- The outer covering of the door is leatherette or leather with a layer of insulating materials. The fastening of the sheathing is done by overlapping the cracks.

- The internal cavity of the door is filled with mineral wool, foam plastic or liquid sound insulation. In this case, rubber gaskets are glued to the jamb, eliminating the gaps between it and the door.

- Installation of a second entrance door. This creates a heat- and noise-insulating air layer.

To prevent the sound of the TV from disturbing children's sleep, soundproofing interior doors in an apartment is done using the same methods.

Benefits of using high-quality soundproofing frame systems

There is an opinion that soundproofing walls in a new building leads to a significant increase in the time and cost of finishing work. But facts are stubborn things, and they indicate the opposite. A team of qualified specialists performs high-quality installation of a frame soundproofing system within one day. At the same time, the overall time and cost of repair work may be reduced. This happens for the following reasons:

- Installation of sound insulation is combined with the laying of electrical and telecommunication cables and the installation of sockets. This eliminates the need for gating the walls. This method does not affect the fire hazard - the filler made of mineral fibrous materials does not ignite and does not support combustion;

- The need for “wet” work is reduced, since there is no need to level the walls with a layer of plaster before decorative cladding;

- A minimal amount of dust and construction debris is generated, which means less time is required for cleaning and removal costs.

As you can see, timely and competently executed noise insulation measures provide homeowners with only additional benefits.

Sound insulation of windows

Glass itself is an excellent sound insulator. Sounds from the window can only penetrate through the cracks left when installing double-glazed windows. They can be easily removed with your own hands - just carefully cover them with plaster or putty.

For sound insulation, it is necessary to adjust the frames. You can check how tightly they fit using a sheet of paper. Clamp the sheet in the sash and pull. They pulled it out without effort - the connection is bad, the rubber seals need adjustment or replacement.

When installing windows, you must initially use high-quality materials. If the windows themselves do not allow noise to pass through, then the polyurethane foam on which they are mounted is an excellent conductor of noise, since it is light, hard, and has a closed cellular structure.

USEFUL INFORMATION: Floating plasterboard ceiling with lighting: design options (9 photos)

Therefore, when installing windows or doors, it is necessary to use special soundproofing foam, which, unlike conventional polyurethane foam, has properties important for sound insulation:

- High density to reflect sound wave;

- Elasticity to reduce vibration transmission;

- High-quality filling of cavities and cracks to prevent sound from leaking into the room.

MAXFORTE SoundFLEX foam has these characteristics .

Compared to conventional construction foams, the use of MAXFORTE SoundFLEX foam adds more than 10 dB to sound insulation, which is equivalent to a 2-3 times reduction in perceived noise.

Window.

Few people know that through the windows not only the noise of the street or traffic intersection, but also the sound from your neighbors’ home theater can penetrate into the apartment. If you replace old frames with modern metal-plastic structures, the problem will be solved very quickly. But sometimes minor edits to the old stuff can give a more effective result. It should also be noted that very often one can hear complaints that after dismantling a wooden window for metal-plastic ones, some types of extraneous noise become more audible. The reason for this is the so-called “masking effect”, which was created due to street noise.

Advice: To soundproof an old structure, first of all you should replace the glass, which was previously 4 mm thick with thicker, modern ones - 5-6 mm. Immediately after dismantling, coat the frame structure with transparent silicone sealant. The installed window must be strictly in size. Place the glass tightly into the silicone seam, then press it with glazing beads and remove any protruding excess.

It is very important to attach a special rubber seal around the entire perimeter of the sash, which has a section in the shape of the English letter “D”. Today on the construction market you can find a great variety of different seals for such purposes.

If, after the operations performed, the window sash closes with force, then it is better to seek recommendations from a carpenter, who will determine in which places the layer of wood needs to be removed.

Before installing metal-plastic windows, you need to understand that thicker double-glazed windows (3 glasses) do not provide higher sound insulation compared to standard single-chamber options with the same total glass thickness.

| Note. We advise you not to use drywall when leveling slopes, due to the fact that resonance phenomena in the air can reduce the noise insulation index of the window structure. It is correct to use cement mortar for these purposes. |

Soundproofing the bathroom

When choosing a material for soundproofing a bathroom, take into account the high humidity of the room and its size.

When using hygroscopic soundproofing materials, additional protection against moisture penetration will be required. Otherwise, over time, an unpleasant odor will appear in the bathroom, which is difficult to get rid of. This method “eats up” a lot of space. In cross-section, it looks like a 3-layer structure: sound insulation – waterproofing – finishing.

Other methods of soundproofing a bathroom are not much more expensive, but much more effective.

- Polymer membranes up to 4 mm thick are not afraid of moisture and are easily glued to wall surfaces.

- Soundproofing panels. Kraft paper with mineral filler.

- Special plaster with porous fillers. The maximum effective layer of material is 25 mm.

If you have a steel bathtub that greatly increases the noise from flowing water, you can soundproof it using polyurethane foam or polyethylene foam. The materials are applied or glued to the bottom of the bathtub.

Sewer and water pipes are excellent conductors of sound. They are wrapped with soundproofing tape or polyethylene foam, ensuring no gaps.

To isolate yourself from the noise of neighboring apartments, basalt fiber slabs are attached to the ceiling and floor of the toilet and bathroom.

Make sure that all parts of the sound insulation fit snugly against each other. Don't leave any loopholes for sounds.

Soundproofing base

This design is sometimes called a “floating floor,” emphasizing the separation of the finishing surface and the interfloor panel. The sound insulation functions in it are performed by rigid slabs made of ecowool, mineral wool or extruded polystyrene, as the most suitable for this purpose. They are laid on a leveled base over a waterproofing membrane, and the perimeter of three to five centimeters is filled with soft stone wool.

A protective leveling screed with a thickness of one and a half to five centimeters is applied on top of the insulating slabs, on which the clean floor is mounted. This coating effectively dampens the energy of sound waves, although polystyrene is often mistrusted, considering it more of a heat insulator.

Sound insulation with bulk material, dry screed.

Good performance is provided by bulk materials, among which expanded clay of small and medium fractions is the leader. It is used to create a base for a screed, as a sound and heat insulating backfill between joists and for installing floors on a dry screed. An alternative to expanded clay is perlite or vermiculite, traditionally used for insulation and insulation of floors.

Myths and reality of acoustic plaster

Some people praise it, while others call it ineffective, accusing manufacturers of quackery. We can say that the truth is somewhere in the middle. Sound insulation under plaster will not completely protect against noise, but it will be insignificant and will no longer be perceived as an irritating factor.

Soundproofing materials are presented in a wide range. Experts advise purchasing them from reliable, well-established suppliers who are ready to provide certificates for their products.

Source