Increased noise negatively affects a person’s psychophysical state: insomnia, irritability, stress, etc. appear. If at work and on the way home you have to somehow put up with a high noise load, then in a home environment the situation with the roar of cars, children's screams, loud conversations, music, barking dogs and other sounds penetrating into an apartment or house is unacceptable. It is necessary to take measures to increase the level of sound insulation of housing.

Of the main elements of a residential building, window openings are the weakest link in retaining and dampening sound waves: through them about 90% of street noise enters the premises. What does the sound insulation of plastic windows depend on, how to increase it in already installed blocks, how to choose the right double-glazed windows when ordering them, says the constant expert of the site StroyGuru.com.

A little theory

In order for visitors to understand where the “legs come from” in the matter of soundproofing windows, and not take everything on faith, it is necessary to have an idea of the physics of the process. So a little theory. May acousticians forgive me for the simple language of explanation and not always correct comparisons, but it won’t work any other way.

What is noise and its types

At the everyday level, the concepts of sound and noise are identified. This can be seen using a simple example: no one sees the difference in the concepts of sound insulation and noise insulation, which is not entirely correct. Sound is the rapid vibration of molecules (atoms) of air or another medium (water, solids). Noise is a collection of non-periodic sounds of varying intensity and frequency. Therefore, in the future we will talk about noise, but consider the physics of the propagation of sound waves. And this is not a contradiction. After all, noise consists of many such sound vibrations.

In theory, noise has several classification criteria: origin, propagation medium, etc. So, according to the method of propagation, which is important for further understanding of the issue under consideration, airborne and structural noise are distinguished.

Airborne noise

All sounds that travel from a noise source to a person’s ear through the air are called airborne noise. These are: music from the radio, barking dogs, birds singing, thunder, screams or quiet speech, etc. In the figure below, the artist schematically represents this type of propagation of sound waves.

Structure-borne noise

The second way noise propagates is structural. Here, elements of buildings and structures serve as conductors of sound waves. This means that in a pure field there can be no structural noise in principle. Only inside buildings. But there is a nuance: the human ear cannot hear structural noise directly. Only when the sound wave breaks out of the wall, floor or ceiling and continues to move through the air does a person hear sounds. How the physics of the process works can be seen in the figure below.

Therefore, neighbors on the first floor can clearly hear the noise of drills, hammer drills and other construction tools from the upper floors of the building. Or the slamming of the front door spreads across all floors (that’s why a door closer is needed). The list of sounds can be continued for a long time. But one thing needs to be noted: structural noise occurs when one of the elements of the sound source is the building structure itself.

With a minimum gap between the wall, floor or ceiling, there will be no structural noise. For example, if you crush stone on a soundproofing material with a hammer drill, then the neighbors above, below and on the sides will hear the operation of the tool due to airborne noise, but the roar will not be carried throughout the building, i.e. no structural noise occurs.

Or another example: some neighbors hear the clicking of heels on the laminate flooring, others do not. In the second case, when laying the flooring, the master fulfilled all the requirements of regulatory documents and did not create sound bridges between the floor and the wall, as well as the ceiling of the neighbor below.

There are exceptions when airborne noise can turn into structural noise. This requires a coincidence of two factors: the sound pressure of airborne noise must be extremely strong, and the mass of the enclosing structures, on the contrary, must be small.

From what has been said, we can draw the first conclusion: windows protect only from airborne noise from the street.

Physics of sound wave propagation

In airborne noise, the sound wave moves directly through the air (acousticians say: longitudinal wave) due to the vibration of gas molecules present in the atmosphere (therefore, there is complete silence in a vacuum). Those. Noise propagates from the sound source in all directions. This movement wastes energy. Therefore, as the distance from the source of sound waves increases, the sound strength decreases.

When meeting an obstacle, a sound wave, firstly, must shake the molecules of a denser substance for further movement, which requires significantly more energy than when moving through air, and secondly, the sound is reflected from a denser medium (a classic example, an echo in a forest ). As a result, a greatly attenuated noise breaks through the barrier.

In this case, the following picture is observed: less energy is spent on passing a single piece of dense material (the main part of it is spent on exciting the first layer of denser material) than when overcoming an obstacle of the same thickness, divided into sheets installed one behind the other at a short distance. In addition, we should not forget about reflected sound. It is one thing when it is reflected once and another when it is reflected several times.

The above diagram of the movement of sound allows us to draw a second conclusion: the difference between the energy of the wave that approaches the barrier and that which breaks through the barrier is an indicator of the level of sound insulation of the material that gets in the way of the noise.

When are soundproof windows needed?

The human body is designed in such a way that it quickly gets used to a constant background noise of up to 40 dB and does not notice it. Noises above this figure begin to irritate. And the louder something rumbles, squeaks, squeals, etc. outside the window, the faster the apartment owner leaves his comfort zone.

To understand whether soundproof windows are needed, it is necessary to assess the sound load of the street. Taking measurements yourself is extremely difficult. Therefore, homeowners should focus on the approximate noise level of various sources, shown in the table in the photo below.

Noise level from different sources.

From the given data it is clear that soundproof double-glazed windows are needed for windows facing busy streets, highways, construction sites, airfields (75-100 dB), and railways (65-90 dB).

At the same time, an ordinary city street creates noise in an apartment at the level of a running computer - about 35 dB. Therefore, noise insulation of windows from the road is not required here.

Double-glazed windows with the highest level of noise absorption

A double-glazed window, the sound insulation of which is guaranteed to provide comfortable conditions for work or living, must be combined. This means that in one model it is recommended to use an additional glass partition, triplex and inert gas. Thanks to this design, the window receives multi-level protection:

- first, the waves are reflected by the polymer film and partially absorbed by the triplex double glass;

- then they are extinguished by a central partition dividing the glass unit into chambers;

- in the last chamber, the noise that has overcome the obstacles is absorbed by an inert gas.

If such a design is not able to ensure silence in the interior, then it is recommended to strengthen the sound-absorbing system with another element. We are talking about a special film based on A-resins, which is used to cover the outside of the window. It is also capable of effectively absorbing sounds and is guaranteed to increase the level of sound insulation of a double-glazed window.

Reasons for low window sound insulation

To combat the negative consequences of any phenomenon, you need to know their causes. This fully applies to increased noise in the apartment. Here the root of evil must be sought in:

- thickness of glass - thin glass conducts sound well;

- double-glazed window formula. There are two factors at work: a small distance between the glasses or it is poorly chosen and at a certain noise frequency the middle glass resonates (can amplify the sound almost 2 times);

- the presence of gaps between the sash and the frame - along with the draft, noise also creeps into the room. Moreover, the larger the hole, the noisier;

- errors when installing window sills and slopes;

- cheap frames (applies only to profiles made of PVC and metal-plastic from little-known manufacturers).

In addition, you should not forget about ventilating the room. With an open or half-open window, street noise easily enters the apartment. The solution to the problem is either other methods of ventilation, or using a window for air exchange during periods when no one is at home.

Where should soundproof windows be installed?

The main task that the quietest double-glazed windows are designed to solve is to reduce the level of penetration of external noise into the room. First of all, they are installed in the windows of apartments and houses located in cities, since here the level of street noise remains high, both day and night. The quietest plastic windows are also used for glazing houses, which, although not located within the city, are located in close proximity to sources of constant noise - suburban highways, railways.

Factors influencing the level of sound insulation of windows

When choosing a double-glazed window, you need to take into account factors affecting the conductivity of sound waves by the window. Among them:

- thickness of the glass unit;

- distance between glasses;

- glass thickness;

- sash tightness;

- the size of the technological gap between the wall and the window block;

- view of the balcony door;

- glazing of a balcony (loggia).

Glass thickness. The thicker the glass unit, the better it absorbs noise. There are two factors here: the thickness of the glass and the distance between them. We’ll talk about the glass a little lower, but here we’ll talk in more detail about the air gap between the glasses, and to be more precise, about the thickness of the chamber. Indeed, as the distance between the glass panes in a double-glazed unit increases, the level of noise absorption increases.

Distance between glasses. It is known that in double-glazed windows the middle glass resonates, amplifying sounds. There are two ways to combat this.

- Make glazing from glass of a small area (split the double-glazed window structure into several sections). But not everyone likes this solution to the problem.

- Use chambers of different thicknesses. In this case, the inner glass will be shifted to one of the edges, as a result of which the resonant frequencies in the air chambers do not coincide and do not add up.

Glass thickness. The thickness of the glass also affects the level of noise absorption (the thicker, the better the protection from a noisy street). But here you need to look for a middle ground. After all, as the weight of the glazing increases, the load on the sash fittings increases. In this case, improved sound insulation can be achieved using different thicknesses of glass and chambers.

Seam tightness. The greatest tightness of the fit of the sash to the frame is achieved with three sealing contours (central contour in the middle).

The size of the gap between the wall and the frame. When installing a window block, the gaps (technological gap) between the wall and the profile should not be more than 2 cm. According to the technology, the gaps are foamed with polyurethane foam, which is a good conductor of sound. Therefore, as the distance between the frame and the wall increases, more foam is needed, which turns the perimeter of the block into a place with poor sound insulation.

For reference: polyurethane foam, like polystyrene foam, is not a sound-absorbing material.

The problem can be partially solved by plastering the slopes followed by putty. The use of plastic or plasterboard slopes increases noise due to resonance.

View of the balcony door. Few people pay attention to the appearance of the balcony door. And in vain. Partial glazing has poor sound insulation: noise easily breaks through the plastic part under the glass. It is necessary to choose a door option with full-height glass.

Glazing of a balcony (loggia). Glazing a balcony or loggia radically solves the problem of street noise: it is practically inaudible.

How does the quality of installation affect sound insulation?

Proper installation is also important. It means that:

- The structure must not be skewed, as a result of which the sash will not fit tightly and there will be no sound absorption effect;

- sealing of the seam and window opening must be done efficiently using special polyurethane foam with a sound insulation value of 60 dB;

- The gap should not exceed 30 mm.

Therefore, it is very important to contact exclusively specialists. When ordering installation of a structure from, you can be sure that all necessary rules will be followed. Our company's installers are qualified professionals who have been trained at the Rehau Academy.

Window sound insulation class

The above measures can be used in a system of measures to protect housing from excess noise, individually and in combination. Therefore, double-glazed windows have different levels of sound insulation. To help the consumer understand the ability of a window structure to block noise, they are assigned a sound insulation class. By and large, this classification refers to the sound insulation of double-glazed windows, because Profiles from different manufacturers have approximately the same sound wave absorption rates.

Table 1. Sound insulation classes of plastic windows.

| Classes | Sound insulation of PVC windows, dB |

| 1 | up to 30 |

| 2 | 30-32 |

| 3 | 32-34 |

| 4 | 34-36 |

| 5 | 36-40 |

| 6 | 40+ |

The first class includes wooden windows with one glass, familiar to residents of the Soviet Union. They block no more than 20 dB of noise. This also includes budget plastic windows with single-chamber double-glazed windows (formula - 4x16x4) - they can absorb 27 dB of sound waves.

A single-chamber double-glazed window with different glass thicknesses (6x16x4) reduces the level of external noise by up to 32 dB.

A single-chamber double-glazed window with three-layer glass (triplex) combats noise most effectively. 4x12x9 glazing absorbs up to 42 dB. By increasing the number of cameras (4x10x4x10x9), the indicator can be increased to 44 dB.

Which windows to choose

Choosing the best double-glazed window for sound insulation is not enough. It needs to be framed - that is, select a window frame. Not every glass unit is suitable for the best glass unit. The main reason is the thickness of the glass unit. A good noise-proof double-glazed window requires a thick frame.

How thick is the glass unit in which windows is it installed?

| 24 mm and 32 mm | Veka Euroline |

| 36 mm | Satels |

| 40 and 42 mm | Veka Softline 70 |

| 44 and 52 mm | Veka Softline 82 |

Popular models of soundproofed windows

Trying to find the best manufacturer for the quietest windows is doomed to failure. All leading brands (KBE, Rehau, Salamander, etc.) supply consumers with a profile with the same level of sound insulation. If there is a difference, it is no more than 1-2 dB, which in practice is not detected by human hearing. Double-glazed windows, which mainly determine the noise level in an apartment or house, are not produced centrally. There are several reasons:

- Only in new buildings can you use standardized sizes of window blocks. In all other cases, they are individual, and, therefore, double-glazed windows must be made to fit the assembled frames, which is extremely difficult to do in large-scale production;

- when ordering a window, apartment owners can choose a different design of the window unit, which cannot be taken into account when manufacturing double-glazed windows at a large enterprise;

- transportation of double-glazed windows over long distances leads to large losses of glass;

- There are GOST restrictions on the time between the manufacture of a double-glazed window and its installation in the frame.

Conclusion: it is not correct to talk about the rating of manufacturers of double-glazed windows, because There are several of them in each region.

Several large companies supply double-glazed windows for new buildings in Russia:

- "Oknasalut" - in addition to standard double-glazed windows, it produces soundproofing ones;

- "Izolux" - specializes in the production of conventional and impact-resistant glazing using triplex;

- Alutop is a company with several production sites.

Design of noise-proof windows

These window products are manufactured using frames made of plastic (Rehau, KBE, Novotex) or wooden (pine, oak, larch) profiles, the width of which is sufficient for installing sound-insulating double-glazed windows. The components of the design are a double-glazed window with noise-insulating properties and German ROTO fittings, which ensure reliable operation and tightness of the product's opening sashes when closed.

Plastic profile

Wood profile

Aluminum profile

Recommendations for selection depending on noise level

Replacing a simple double-glazed window with a soundproofing one is expensive. Therefore, when making a decision, it is necessary to evaluate the noise intensity level and its frequency range during busy hours.

The highest level of sound insulation for double-glazed windows (class 6) should be chosen for windows facing buildings under construction, busy highways, railways, and airports.

An important indicator when choosing soundproofing glazing is the vibration frequency of sound waves. High frequencies are well absorbed by a two-chamber asymmetrical double-glazed window (glass thicknesses and distances between them are different). The low frequency range (typical of industrial enterprises, railways, construction sites) is perfectly neutralized by triplex (with stratophone film), asymmetrically installed with thick glass.

In addition, the size of the glass must be taken into account. It has a rigid structure, which is why it begins to vibrate under the influence of sound waves, amplifying the sounds. On large glass areas the intensity of vibrations is higher. On small ones it is much lower. Therefore, preference should be given to designs with small sections of glass.

If you choose between types of windows and manufacturers, then wooden Finnish windows provide the maximum soundproofing effect. There is no leader among manufacturers of plastic window structures. Both REHAU, KBE, and VEKA supply profiles with approximately the same noise-insulating properties to the building materials market. Another question is that different double-glazed windows can be installed in them. But here everything depends on the installer company.

Finnish window.

Glass insulation: soundproofing bags

Windows with increased sound insulation are a good option for residents who have already completed renovations and do not want to completely change their profiles. It will be simpler, more convenient and cheaper to install a new double-glazed window without affecting the profile. The weak area in terms of noise transmission is the glazing, and not the sashes or frames. This modification has a number of limitations in terms of the depth of the landing site in the profile, but the noise level noticeably reduces.

It will not be possible to install a multi-chamber element in a frame in place of a single-chamber one.

Manufacturers

I produce double-glazed windows for industrial enterprises and small private organizations. Some window manufacturers also assemble double-glazed windows, but some work only with large organizations.

The main ones:

- Oknasalut;

- ISOLUX;

- Alutop.

Their products are the best choice in terms of cost and quality. Advanced technologies are used in production to increase the energy efficiency of solutions.

How to improve the sound insulation of already installed windows

If over time the noise load in the room begins to increase, you can improve the sound insulation of the windows in the apartment with your own hands. This is done in several ways:

- seals are changed;

- fittings are adjustable;

- sealing of the installation gap is improved;

- the insulation of slopes and window sills is improved;

- soundproof blinds are hung;

- Breather is installed.

Replacing seals

Seals installed in metal-plastic windows lose their consumer properties over the years: they crack and shrink (reduce in volume), which is described in detail in the work “How to replace rubber seals on plastic windows.” As a result, the tightness of the sashes to the frame decreases. Through micro-slits, street noise begins to break into the apartment or house. For example, if there is a small gap of only 1 mm between the window sash and the frame, then the sound insulation is reduced by 1.5–2 times.

Replacing rubber seals not only improves sound insulation, but also retains heat (the level of thermal insulation increases).

Adjusting fittings

Over time, the pins and scissors of metal-plastic window blocks lose their original properties as a result of wear. This is especially noticeable on windows used for ventilation. Old or worn fittings do not provide high-quality pressing of the sash to the frame, leaving small gaps. Noise and cold easily penetrate into them from the street. In such a situation, it is necessary to adjust the locking mechanism (you can see how to properly perform adjustment work here).

A tight fit of the sash to the frame is the key to good sound insulation.

Sealing the installation gap

Rarely, there are violations of the technology for filling the assembly joint with foam (dust is left behind, the primer is applied unevenly, the applied layer of foam turns out to be of different densities, etc.). In this case, you can’t count on good sound and heat insulation. The problem is solved by the homeowners themselves. To do this, you need to remove the slopes, window sill and ebb, remove the old foam and seal the seam again. How to do everything correctly is described in detail in the material, which can be found at the link.

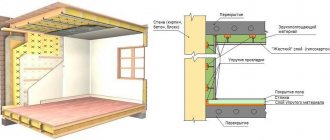

Insulation of slopes and window sills

Noise can also break through slopes with a window sill. The reason, again, is a violation of the installation technology: voids are left between the wall and the finishing material. Elimination of the cause is traditional: dismantling and subsequent installation according to the rules. All stages of work can be viewed here.

The technological processes listed above can be performed independently: there are no complex technologies. If you don’t want to do repairs, specialists will help. Any company that installs windows deals with sound insulation of double-glazed windows.

Installation of soundproof blinds

In addition to the methods listed above to improve the sound insulation of window openings, you can use the installation of special blinds that reduce the strength of the sound wave. Their difference from the classic analogue is the presence of a soundproofing layer of fibers that absorbs noise passing through the window.

This design has its pros and cons.

- reduces all types of street noise;

- do not take up much space;

- fit well into any interior.

- high price;

- The window is constantly closed, as if it is not there.

Breezer

It sounds unexpected, but even if you follow all the previous recommendations for improving the sound insulation of a window opening, the full effect will not be achieved. The reason is banal: ventilation. Without it, the level of humidity and carbon dioxide (CO2) in the room increases, and it becomes stuffy. That’s why vents or micro-ventilation modes were invented in modern window designs. But having opened the access of fresh air to the apartment, the owner simultaneously opens the window opening, literally wide open, to the noise of the street.

Conclusion: only by closing the window forever can you achieve good protection from outside noise. Unfortunately, many apartment owners either do not know about this or forget about such a “trifle”. You can understand the owners: the population of Russia and the countries of the former Soviet Union is accustomed to the fact that a window is also a structural element of room ventilation. Therefore, keeping the sash slightly open is normal. In fact, there are many other ways to get fresh air from the street while keeping the window tightly closed. One of them: installing a breather.

A breather is a compact device capable of supplying purified, if necessary, humidified, heated or cooled outdoor air into a room. At the same time, without missing the noise of the street. Thus, in a small device, the designers managed to get both a humidifier and an air purifier, an air conditioner or a fan. The shape of the breather can be round, square or oval. By size - large or small. Powered by electricity. Unlike air conditioners, they are economical and almost silent (the operation of the fan can be heard, and even then not in all models - it depends on the manufacturer).

The breather is installed on the wall inside the apartment. There are two factors holding back the widespread use of the device:

- price - you can buy it for 30.0-300.0 thousand rubles;

- Difficulty of installation - you won’t be able to drill a hole of the required diameter in the wall with your own hands.

City noise comparisons

A person is constantly surrounded by acoustic pollution, the level of which quite often exceeds the recommended levels. Comparative figures for urban noise in dB:

- office equipment, household vacuum cleaner – 60;

- traffic on a busy highway - 80;

- train movement – 90;

- repairs in the building – 100;

- car horn - 120;

- flying plane - 140.

Common Myths

The theory given at the beginning of the article allows us to dispel some of the myths floating around in commercials. Here is a short list of technologies that promise to magically improve the sound insulation of plastic windows, but in reality, nothing but the loss of a certain amount of money gives the owners of an apartment or house.

Soundproofing film

Literally at every step, window installers offer to improve the sound insulation of double-glazed windows using a “magic” film. But if you look closely at the theory of sound wave propagation, it becomes obvious that such protection cannot stop even 0.5 dB of noise. Firstly, the film itself is thin, which is a key factor. Secondly, it is tightly glued to the glass. Therefore, the wave practically does not spend additional energy on overcoming the established obstacle.

One acoustician spoke beautifully on this topic: “soundproofing films for windows are the same as soundproofing wallpaper for walls.” True, at least the thickness of the material is a little greater.

Filling the chambers of double-glazed windows with inert gas

It is believed that the use of argon or krypton in the chambers of double-glazed windows can improve the thermal insulation properties of glazing, which, by the way, is controversial. This also includes improving sound insulation. The idea is beautiful. But its author does not know physics well. After all, the denser the medium, the easier sound propagates through it. Now let’s compare the specific gravity of atmospheric air and argon: 1.2754 kg/m3 versus 1.78 kg/m3, i.e. Argon is heavier and therefore conducts noise better.

It turns out that pumping inert gas into double-glazed windows to combat noise is equivalent to pumping car tires with nitrogen to soundproof the cabin.

Some “couch” experts advise discharging the air in the chambers. In this case, noise protection really improves. But another problem awaits the authors of the idea: the collapse of the glass with its physical destruction. After all, no one has canceled atmospheric pressure. At low temperatures, the bending of glass into the chamber takes on critical values.

A three-chamber double-glazed window has greater sound insulation than a two-chamber one.

Even during the massive replacement of wooden window blocks produced in the USSR, a myth was born that a double-chamber double-glazed window protects better from noise than a single-chamber one, and a 3-chamber one is superior to a 2-chamber one in this indicator. Most likely, the source of the misconception was the presence of two and three cameras in a double-glazed window, which seemed at that time the height of perfection. In reality there is no linear relationship. This is especially clearly visible when comparing 2-chamber and single-chamber windows. If the thickness of the glazing (package) and the installed glass are equal, a single-chamber window protects better from noise - in a double-chamber package, the middle glass resonates.

The situation is slightly better with a three-chamber double-glazed window. Measurements have shown that the extra chamber delays an additional 1 dB of noise compared to a two-chamber window. But is it worth installing three-chamber glazing for the sake of 1 dB? After all, a bunch of problems await the owners:

- the window will be 30-50% more expensive;

- the cost of installation is also higher due to the complexity of installation work and the use of reinforced fasteners;

- the wide profile of the block will eat up the window sill - it simply won’t exist (with the exception of very thick walls);

- excess glass makes the sash heavier by 25-30%. The fittings are standard. Therefore, when opening a window wide open, the probability of the sash sagging tends to 100%;

- four glasses absorb more sunlight, as a result of which there is no bright illumination in the room, and the glazing itself will look like a darkened spot (similar to poorly washed glass).

Frame material affects sound insulation

Another misconception based on the desire of sellers to sell more expensive wooden frames. After all, the theory of sound wave propagation, confirmed by practical measurements, states that nothing depends on the type of window block profile. The exception is aluminum windows. However, there is a solution to the problem here too - placing noise-insulating material in the chambers of the profile. In this case, the characteristics of metal frames in terms of noise protection are better than their plastic or metal-plastic counterparts.

Let us emphasize once again: the level of sound insulation of a window depends on the glass unit formula and the pressing force (tightness) of the sashes to the frame.

The purchase of wooden windows is justified only when appearance, tactile sensations, etc. are taken as selection criteria. (the advantages of wooden windows can be seen here).

Noise-proof curtains

Another magical remedy is noise-proof curtains. They can certainly absorb one or two decibels of noise, but you can’t count on more. The hum of the street will still penetrate into the room - no amount of fabric will help. And here is the time for the authors of the technology: what time of day do they plan to use their idea? During the day it will be gloomy indoors, and at night the street noises will subside. In addition, the question arises about heating the room - circular air circulation is blocked by curtains. It will be mainly the window opening that heats up.

Multi-chamber profiles

The translucent surface of window structures occupies more than seventy percent of the block, therefore it is the main one in terms of sound insulation. The remaining 30% is neutralized by the profile, which must also be taken into account if maximum absorption of external noise is required.

A high-quality profile is divided by internal partitions into isolated sections (some modifications include up to seven such sections).

In addition, some of the profile chambers may contain a special filler, which also has a positive effect on the soundproofing qualities of the structure.

Recommended background noise levels

According to current sanitary standards, the maximum permissible level of noise exposure, which does not pose a danger even with prolonged exposure, is 40 dB at night and 55 during the day. Such indicators do not harm the body, but in urban conditions they are often exceeded.

With constant exposure to 70 - 90 dB, which corresponds to street traffic, the operation of a motorcycle engine, a negative effect on the nervous system is possible. And exposure to 100 decibels can cause significant hearing loss.

Methods for increasing sound insulation properties

Each room owner can increase the level of sound insulation of the window opening filling element with his own hands, following a number of useful recommendations:

The best solution, provided that the window obstruction has been in use for more than 10 years, would be to completely replace the double-glazed windows along with the profiles with a new high-quality product.- If the window unit has been installed recently, and, according to the quality certificate, it must meet sound insulation requirements, the problem is most likely hidden in incorrect adjustment of the fittings.

- Switching the trunnions into winter or demi-season mode, if they were previously set to the summer position.

- Correction of the position of the counter plates of the locking mechanisms.

- Replacement of sealing tapes on all contact surfaces of moving elements, or in places of physical wear.

- Replacement of accessories.

- Installation of new double-glazed windows in old frames.

- Cleaning and re-foaming installation gaps with the installation of sealing tapes.

When purchasing new consumables, it is necessary to pay increased attention to their quality, technical characteristics and brand recognition. If a product has many positive reviews from satisfied users online, the consumer can have no doubt about the quality.

How to improve the sealing of an assembly seam with your own hands?

One of the most common problems with weakening the sound insulation properties of a window structure is incorrect or insufficient filling of the installation gap. The owner of a property can improve the sealing of this structural element based on the following technological map:

All decorative finishing elements are dismantled along the perimeter of the window.- The sealing membranes are successively removed from the gap, and then the mounting foam.

- The surface of the plastic or wooden profile, as well as the wall structure, is cleaned of foam residues, dust and degreased.

- The mounting plane is dried with a hairdryer.

- Special noise-insulating foam is pumped into the gap from a cylinder with a gun, in an even layer, filling each gap.

- When the foam is created, you should wait 12 to 24 hours for it to polymerize.

- When the material has dried, its remains outside the window profile are carefully removed with a construction knife.

- The surface of the foam is protected with a thin layer of silicone or acrylic sealant.

- Hydro- and vapor barrier membranes are installed on the outside and inside.

- The finished unit is re-closed with decorative overlays.

Before purchasing sealants and foam, it is recommended to ensure their quality and also check the date of manufacture. As a rule, materials for sealing seams lose their performance properties within 12 months after production.

Installation of special structures

If the problem with repairing or restoring old building envelopes does not cause significant improvements, experts recommend replacing the window with the installation of a new, sound-proofing product.

When manufacturing such structures, developers focus on installing a large number of cameras in the profile , as well as installing effective glass on the outside, which is not subject to vibrations due to vibration effects. In addition to noise protection, such designs also significantly increase the energy efficiency of the space being used.

Soundproof blinds

Special blinds, for example, the RAUVOLET Acoustic-line series from REHAU, will help create acoustic comfort. The products are profile strips with perforations and a soundproofing layer. A special fiber in the structure absorbs sound waves, isolating low- and high-frequency sounds indoors. Blinds with a sound-absorbing effect have at least three advantages over standard ones:

- They reflect and absorb noise near the window and at some distance from it.

- Significantly save space in comparison with curtains, drapes, curtains.

- Absorbs sound vibrations in a wide frequency range.

DIY window repair

The first thing that needs to be done, having discovered that the windows are letting in cold and sound from the street, is to carry out minor window repairs and adjust the fittings. First, check the cleanliness and elasticity of the sealing rubber. If it becomes hard or cracked, it must be replaced with a new one. No special tools are required for this, and the seal itself is sold in any specialized store. Next, you need to check the correctness of the sash clamp, which is controlled by the clamping bolt on the fittings on the edge where the handle is located, as well as the lower and/or upper hinge on the side of the hinge group.

If the clamping is insufficient, this can be easily corrected by carefully adjusting the above fittings.

Requirements according to GOST, SNiP, SP and SanPin

According to SP 23-03-2003 “Noise Protection”, the following sound insulation requirements are imposed on windows:

| Functional purpose of the operated spaces in the building | Standard indicator of sound insulation of premises, dB, subject to heavy traffic of vehicles on the street during rush hour | ||||

| Noise impact from outside from 60 dB | Noise impact from outside from 65 dB | Noise impact from outside from 70 dB | Noise exposure from outside from 75 dB | Noise impact from outside from 80 dB | |

| Hospital rooms and reception rooms | 16 – 17 | 19 – 21 | 24 – 26 | 29 – 31 | 34 – 36 |

| Residential premises in apartments and private houses of category A | 16 – 17 | 19 – 21 | 24 – 26 | 29 – 31 | 34 – 36 |

| Residential premises in apartments and private houses of categories B, C | — | 16 – 17 | 19 – 21 | 24 – 26 | 29 – 31 |

| Living spaces in dormitories at universities, factories, or in buildings intended for social rented accommodation | — | — | 16 – 17 | 19 – 21 | 24 – 26 |

| Rooms for guests in hotels, boarding houses, inns, category A | 16 – 17 | 19 – 21 | 24 – 26 | 29 – 31 | 34 – 36 |

| Rooms for guests in hotels, boarding houses, inns, category B | — | 16 – 17 | 19 – 21 | 24 – 26 | 29 – 31 |

| Rooms for guests in hotels, boarding houses, inns, category B | — | — | 16 – 17 | 19 – 21 | 24 – 26 |

| Used spaces in country holiday homes, boarding schools for the disabled, children's accommodation | 16 – 17 | 19 – 21 | 24 – 26 | 29 – 31 | 34 – 36 |

| Office space in business centers of category A | — | — | 16 – 17 | 19 – 21 | 24 – 26 |

| Office space in business centers of category B, C | — | — | — | 16 – 17 | 19 – 21 |

In addition to the above SP, the sound insulation indicator of the space being used is also standardized by the following regulations:

- GOST 23499-2009 “Soundproofing and sound-absorbing construction materials and products. General technical conditions".

- GOST R ISO 10140-2012 “Laboratory measurements of sound insulation”

According to these documents, each manufacturer of window units develops its own specifications, on the basis of which new products are subjected to mandatory tests with the issuance of a certificate of compliance with these technical conditions. The noise insulation indicator is also indicated in the product quality certificate when it is delivered to the buyer.

External background noise

The urban environment provides residents with access to various opportunities to improve their quality of life. New roads are being built and buildings are becoming denser. Creating comfortable housing requires the presence of an effective barrier between the interior and the external environment. The main factor in its creation is the installation of high-quality noise-proof windows.

The perception of noise depends on the distance of its source and the frequency characteristics of the sound. Window designs most effectively protect against high-frequency acoustic pressure, which our ears define as “louder.”

To isolate from low sound, massive structures are needed - low-frequency sound vibrations pass quite freely even through walls.

| Noise Source | Sound pressure level, (dB) |

| Quiet street | 40 |

| Normal conversation | 45 |

| City street | 60 |

| Mobile phone ringing | 70 |

| Busy freeway | 75 |

| Motorcycle, dog barking | 90 |

| Metro | 100 |

| Car alarm, horn | 120 |

Materials used for sound insulation

The main thing in choosing a material for soundproofing windows is its reliability and safety. A sealant made of silicone and sealant is best suited for these purposes.

First of all, it is necessary to remove all the cracks and gaps that have formed over time between the window and the wall. Typically, polyurethane foam is used for this. After the foam has dried, a layer of plaster or putty is applied to get rid of small cracks.

The windows have rubber seals that require periodic replacement. If they become thinner, the window fits worse, which means noise will penetrate more into the apartment. The old gum is removed, after which the remaining glue is thoroughly cleaned from the windows. The new seal is attached only to a clean surface. After gluing the rubber band, you need to let the glue dry, and only then close the window.

You should pay attention to how well the sashes are pressed against the frame, and the frame is pressed against the slopes. If the installation is poor, in places where parts of the glass unit are adjacent to each other, cracks may form that allow noise to pass through. You can get rid of it using sealant and sealant. Read about the types and types of sealants for PVC windows in this article.