You started a large wash, loaded the laundry into the washing machine, but suddenly, instead of the usual operating algorithm, something went wrong: it freezes, does not switch modes, leaks, vibrates strongly, extraneous sounds appear, the hatch door does not open or close - there may be malfunctions a bunch of.

As a rule, the occurrence of malfunctions is accompanied by improper operation of the equipment or due to natural wear and tear of parts; in rare cases, manufacturing defects are possible. But, whatever the malfunction, one thing is important - the breakdown cannot be ignored.

Troubleshooting

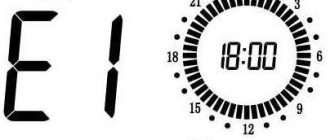

Modern automatic washing machines are equipped with an electronic display and a self-diagnosis system that monitors the operation of the device and, in the event of a malfunction, displays the corresponding error code.

If during washing the program is interrupted and an error code is displayed on the screen, just open the instructions and see what exactly it means. Some of the error codes are not directly accessible to the user, but are displayed when performing a service test.

An alternative to error codes is a combination of flashing lights. This warning system is found in washing machines with analog control and without a display. The operating instructions contain descriptions of the main signals that allow the user to find out the cause of the breakdown. In some cases, errors can be eliminated yourself, and in some cases you cannot do without a service specialist.

If the washing machine is equipped with a mechanical control, you will have to look for the fault yourself, based on the characteristic symptoms. So, if the laundry is dirty after washing, it is possible that the SMA does not pick up the powder or does not heat the water. There may be no breakdown at all, and the reason for the poor quality of washing is due to an incorrectly selected program.

If the machine refuses to drain water and stops with a full tank, first of all you need to check it for possible blockages: drain filter, hose, impeller, sewer pipes. The presence of problems with the bearing will be indicated by traces of oil and water on the floor, rusty spots on clothing, a characteristic grinding sound during operation, and a whistling sound, the smell of burning rubber and a sudden stop of the drum indicate a possible rupture of the drive belt.

As a rule, only an experienced technician can finally determine the cause of the malfunction and carry out high-quality repairs of washing machines after a visual inspection and detailed diagnostics using testing equipment and special tools.

Useful tips for troubleshooting

The following troubleshooting tips may not be necessary if you always use the machine correctly. The easiest way to protect electronics is to unplug them. The power plug must be unplugged between washes (or the circuit breaker must be turned off). It is also recommended to shut off the water supply in order to maintain the functionality of the sensors and supply valves for a long time.

When eliminating problems with your own hands, you should never act primitively or rush. There is no need to try to repair the power cable, it is completely replaceable. Before any work, you should disconnect the machine from the network, examine the location of the operation, and select the appropriate tool.

You need to act carefully and carefully. If you are not completely sure of the causes of the breakdown and the ability to eliminate them, it is recommended to call a qualified specialist.

Common washing machine problems

Quite often, service center clients come to us with the following problems:

Doesn't take up water

If water does not flow into the washing machine, first of all you need to check that the flow is not blocked and there is good pressure. Another reason may be a malfunction of the hatch lock, or UBL (hatch locking device). The machine will not start pumping wash water until the door is locked.

The device will not draw water in the following cases:

- The inlet strainer is clogged - you can clean it yourself, following the instructions.

- The inlet filter is faulty.

- The pressure switch is not working correctly.

- The control module is faulty.

- The inlet hose is kinked.

Doesn't drain water

Usually the problem occurs due to malfunctions of individual components of the device, and due to blockages:

- drain filter,

- drain pump impellers,

- siphon and sewer pipes,

- drain hose,

- pipe connecting the drain hose and the pump.

If the reason for a full tank is not clogged, then it is likely that the drain pump is burnt out, the pressure switch is faulty, or the control module is the problem.

Doesn't heat water

The most common reason is a breakdown of the heating element. Most often, the heater burns out due to power surges or large scale deposits. In addition, it is prone to damage from foreign objects, such as bra wires and other clothing items, and all kinds of debris from pockets. Also, lack of heating occurs due to a broken temperature sensor or a malfunction in the control module.

To extend the life of the heating element, it is recommended to regularly descale the washing machine. For this purpose, special decalcifying agents (tablets or powders) are used, which effectively remove lime deposits on heating elements, pipes and all internal surfaces. Also, as a preventive measure, it is recommended to install a filter system (mechanical - to retain sand, rust and other suspended matter, polyphosphate - to soften water).

The drum does not spin

If the washing machine is equipped with a weight sensor, the equipment may refuse to work due to excess weight. Typically this situation is accompanied by a corresponding error code. To fix the problem, just stop the wash and remove some items from the drum.

Mechanical failures include wear or damage to the bearing assembly, or the entry of a foreign object between the tank and the drum. If you have any of these problems, you will not be able to spin the drum even by hand.

If the electrical part malfunctions, the drum rotates freely by hand, but does not rotate during washing. This situation may be associated with the following malfunctions:

- The drive belt has fallen off, broken or stretched.

- The motor brushes are worn out.

- The engine burned out.

- The control module is faulty.

- The tachogenerator (Hall sensor) has failed.

The door (hatch) does not open

The problem may be caused by the following faults:

- broken handle,

- breakdown of the mechanical part of the washing machine lock,

- breakdown of UBL.

But this situation does not always arise due to a breakdown. First of all, do not forget that in any washing machine, the designers provide for a delay in the unlocking response (about 1–2 minutes). Therefore, if the washing machine door does not open, try waiting a little and then try again.

Perhaps it was all due to a one-time electronics failure. Unplug the CMA power cord from the outlet and wait 10-15 minutes - the door should unlock. If there is water left in the car, the control unit will not give the UBL command to unlock the hatch. And this also needs to be taken into account.

Important! If the washing machine door does not open, there is no need to use physical force or insert a screwdriver or other objects into the gap between the loading hatch.

In some SMA models, a special cable is provided for emergency opening of the hatch (located near the drain filter). If he is not there, it is better not to risk it and invite a specialist.

Jumps during the spin cycle

The washing machine can jump due to improper installation, improper operation, or due to natural wear and tear of the components.

Remember: the SMA must be installed on a flat, non-slip surface. For precise adjustments, use a level and the washing machine's adjustment screws. And do not forget to remove the transport bolts before starting.

Always adhere to drum loading rates recommended by the manufacturer. Exceeding them leads to overweight and, as a result, it is difficult for the machine to cope with the increased load, especially at high spin speeds - it begins to jump. Jumps can also be caused by imbalance. Therefore, it is important not only not to exceed the recommended loading rates, but also to distribute things evenly throughout the drum.

There are a number of components in the SMA that are responsible for the stability of the SMA and vibration damping. These are tank springs, counterweight, shock absorbers, bearings. Over time, these parts wear out and require replacement.

Vibrates or makes noise during operation

Increased noise and vibration of the MCA during operation can indicate a number of malfunctions:

- Wear of shock absorbers - parts designed to dampen vibration.

- Loose engine mount.

- Destruction of the counterweight (in most cases, washing machine manufacturers use concrete blocks as a counterweight, which over time begin to crumble due to constant vibration and can split into several pieces).

- Wear of tank mounting springs.

- Worn bearings or seals.

It is quite difficult to eliminate these defects on your own, so it is better to immediately use the services of specialists.

Gives an electric shock

The washing machine must be connected to a separate cable line with grounding or an RCD (residual current device). This will provide protection against electric shock, since in the event of a leak, the current will flow through the ground wire or the RCD will trip. But in the absence of grounding, a situation is quite possible when the body of the MCA is electrocuted. The leakage current also passes to other objects located nearby: faucet valves, metal pipes, bathtub. That's why they get electric shocks.

This can happen for the following reasons:

- Damage to the insulation of the heating element.

- Malfunction of the socket or power cord, incorrect connection to the electrical network.

- Motor insulation breakdown.

- Interference filter failure.

- The power button is faulty.

Knocks out the machine

Sometimes a situation arises when the meter goes off while the washing machine is running and the light goes out in the entire apartment. This may happen for the following reasons:

- The washing machine cord or plug is damaged.

- Short circuit of the heating element.

- Short circuit of the control module (occurs due to corrosion on the board).

- Motor short circuit due to water leakage inside the equipment.

- Failure of the power button.

Doesn't wring out

Problems with spinning can occur due to SMA overload or imbalance. Under such conditions, the electric motor experiences increased load. He tries to spin the drum, but he doesn't succeed. As a result, the program freezes or ends and the laundry in the drum remains wet. To solve the problem, just stop the wash, drain the water and remove some of the items from the machine, distributing the rest evenly.

If the reason for the lack of spin is not due to overload or imbalance, problems should be looked for in the following nodes:

- The drain system is clogged, the drain pump or pressure switch is broken - if the tank is full of water, the spin cycle will not start.

- The tachogenerator is broken, due to which the control unit receives erroneous data and is unable to set the required spin speed.

- Wear of the motor brushes leads to the fact that the drum does not develop the required speed.

- Failure of the ball bearing group.

- Control module malfunction.

Doesn't wash off powder

There are not many reasons why the washing machine does not pick up powder. It could be:

- The inlet filter is clogged, causing water to enter the machine with less pressure and, as a result, not washing away all the powder in the tray.

- Damage to the intake valve - due to power surges or software failures, it can become blocked in a half-open state or not open completely, which also leads to a drop in pressure and the situation described in the previous paragraph.

- The nozzle is clogged, causing water to not flow into the loading tray.

- Failure of the “water gun” - a device that flushes powder from the cuvette into the tank.

The control unit does not work

There are software and hardware failures of the control unit. The first ones can be fixed by flashing the firmware, but with physical damage everything is much more complicated. From a repair point of view, they are considered the most difficult. Moreover, in some cases (for example, if tracks and many elements are damaged), it is more expedient to replace the assembled part than to carry out repairs. The control module fails due to:

- voltage surges and constant voltage drops in the network,

- moisture getting on the connector contacts or the board (which leads to a short circuit),

- high humidity in the room (which leads to oxidation of contacts).

To protect electronic components from failure due to power surges, it is recommended to connect the washing machine through a household stabilizer.

Doesn't turn on

There are many reasons why the washing machine does not turn on at all:

- There is no power at the outlet.

- The power button does not work.

- The interference filter has failed.

- Problems in the control unit.

To determine the cause of the malfunction, the technician carries out a series of diagnostic measures - he calls the electrical circuit of the device (from the plug to the electric motor), diagnoses the interference filter and the electronic unit, and checks the functioning of the buttons.

Design and operation of an automatic machine

To decide to repair a machine yourself, you must first of all have a good understanding of its structure and operating principle.

Main parts of the unit:

- engine;

- electric heater;

- drain pump;

- water tank and laundry drum;

- electronics (control panel);

- water intake valve;

- frame.

After selecting a program and starting it, the first wash cycle begins. It includes drawing water and heating it. Water can be heated to a certain temperature, which is controlled using a sensor and timer. Detergents are added.

The place where dirty laundry is loaded is the drum. When washing, it swings and rotates in both directions. The amount of water is also controlled by a separate sensor

Water is drawn in through a valve. When a signal is received that there is enough water, the valve closes. Depending on the selected mode, several cycles of filling and draining are carried out. After the last rinse, the spin cycle begins. Here the drum spins at full power.

The diagram shows all the main elements. Draining is carried out through a drain pump. It is equipped with a filter that will prevent debris from entering the pump, protecting it (+)

The housing includes not only the walls of the washing machine, but also a hatch. The round door on the front wall allows you to observe the movement of the laundry in the drum and has protection against turning on if it is not closed tightly.

After switching off, the door does not open immediately. This protection is based on a bimetallic sensor. The latch opens only after the sensor has cooled.

Washing machine repair: do it yourself or in a professional workshop?

Some users, not wanting to overpay for the services of qualified specialists, decide to repair the equipment themselves. Today on the Internet there are many instructions, manuals, specialized literature, answers to questions about malfunctions of washing machines and, in principle, if you have the necessary experience and knowledge, then why not. For example, you can easily remove and clean the drain filter and wash the inlet strainer yourself.

But as for more complex breakdowns that require disassembling equipment, it is better to contact specialists. The fact is that disassembling washing machines may require equipment that the home craftsman does not have at hand. In addition, some SMA models have unique design features and arrangement of elements that are easily damaged during disassembly.

Repairing washing machines requires knowledge, experience and the availability of components. When performing independent repairs, the owner of the equipment risks not only not being able to cope with the malfunction, but also aggravating the breakdown, thereby incurring more serious financial costs.

Worn motor brushes

If the brushes on the motor are not changed in time, this may cause the washing machine motor to stop working. You can determine the problem yourself by inspecting the collector. If during operation it sparks strongly (not necessarily around the entire perimeter), then the problem is obvious. If parts are replaced, at first they may also spark, which is normal, it’s just that the new brushes have not yet gotten used to the commutator. Loss of power is also a wake-up call. Warped brushes may not produce enough current and the motor will not be able to turn the drum.

It is recommended to install original brushes, since analogues can cause many problems during installation for several reasons. Analog brushes have slightly different dimensions and shapes, so they will have to be pre-treated. Finding a brush of the required length can take a long time, since different brands of washing machines differ greatly in this component. A self-made brush requires additional verification of its smooth movement without lateral play, which can cause jamming.

How to choose motor brushes

The durability of the brush is affected by its hardness. The presence of a copper tip is mandatory if it was also installed on the old brush. Graphite brushes should not be used; they are designed for low voltage use. After installing the brush, you need to let the motor run at low speeds.

Source

Compliance with operating rules is the key to trouble-free operation of the washing machine.

Most of the breakdowns occur due to the fault of the owner due to improper handling of the equipment, as the specialists of our service center have repeatedly convinced themselves of this. It is important to follow the operating rules of the equipment stated by the equipment manufacturer. But, unfortunately, many users neglect them. As a result, the machine breaks down and requires repair. Moreover, as a rule, users make the same mistakes during operation:

- Clothing pockets are not checked, as a result of which coins, SIM cards, and debris clog the drain filter, and in some cases end up in the pump (which leads to its combustion). This also includes the situation when a bra bone ends up in the drum.

- They overload the SMA - constant overloads and imbalance lead to premature wear of the SMA components, such as motor brushes, shock absorbers and bearings.

- Small children are left unattended, who can ride on the door, twist the programmer handle in all directions, etc.

- They neglect the correct installation and connection of the SMA, which causes a lot of problems during operation: increased vibrations, noise during operation, jumping during the spin cycle, self-draining.

- The equipment is installed in a room with a high level of humidity, which leads to oxidation of buttons, connectors, control boards and, as a result, to a short circuit.

- They do not do preventative descaling.

To ensure that your washing machine lasts for many years and does not break down, take care of the correct connection (to a separate cable line, with grounding or an RCD). A voltage stabilizer will protect you from constant power surges in the network, and the installed water filter at the washing machine inlet will provide additional protection against scale, blockages in the inlet filter and other system components. Regularly descale your SMA using citric acid, vinegar or specialized products. Follow all appliance manufacturer recommendations.

We hope that your washing machine will work for a long time and without complaints!

The washing machine does not turn on

This problem manifests itself in different ways: the machine may not turn on at all or may only trigger light sensors. First you should check the power supply - inspect the socket and plug. At the junction with the cord, breaks and cracks occur. The plug must be firmly connected.

If the source of the malfunction is not found, then you next need to check the status of the child protection program, which blocks all functions of the washing machine. To disable protection on the scoreboard, you need to dial a special code using the buttons.

Recommendations for proper care

Any equipment needs to be looked after and a washing machine is no exception. It must be kept clean, tidy and dry at all times. Here are some care tips:

- Periodically wipe the body and interior with a damp sponge and a special detergent. After that, go over with a dry cloth and let the machine dry completely.

- It is advisable to remove the wire and hose from under your feet, especially if there are small children in the house.

- The removable detergent trays need to be cleaned.

- Before washing, do not forget to turn the pockets inside out so that nothing remains in them. For clothes with metal inserts or other hard parts, use special bags.

- Be sure to inspect the centrifuge after washing and spinning. Small hard objects such as buttons, coins or other clothing items caught in it will cause malfunction. Immediately remove any excess from the drum.

- The composition of tap water contains many impurities, so you need to constantly monitor the condition of the drain filter and pump and clean it periodically.

- Wash the inside of the machine with special liquids and run it on a wash cycle without any items. This is what the manufacturer recommends.

- Do not allow scale to form on the heating element.