The pump, or in other words the drain pump for a washing machine, is one of the main technical components that ensures the normal operation of the entire mechanism, and in order to determine the cause of the breakdown, you need to understand the following points:

- pump composition;

- types of pumps;

- differences in their work;

- nuances of service.

Usually a part that has failed cannot be repaired, and therefore in this situation you have to buy a new spare part and install it. To do this, you need to carefully disconnect the faulty pump and put a new one in its place, following all the rules so as not to completely break the unit. Each brand has its own important nuances, so if the user is not confident in his abilities, it is better to turn to specialists.

The principle of operation of the pump, its application and location

During operation of the washing machine, water is supplied inside the device under pressure, that is, the intake occurs automatically as soon as the necessary programs are selected and the “START” button is pressed. The process then proceeds according to the following scenario:

- the solenoid valve is brought to the open position;

- a pressure switch (sensor for monitoring the liquid level in the tank) measures the required volume of water;

- the path of the liquid runs through the compartments where the necessary detergents (washing powder) are located, water mixes with them, and thus enters the tank in dissolved form;

- the liquid under pressure enters in the required volume into the chamber where the laundry is stored.

During the process and completion of the wash, the water pump comes into play. It is he who drains and pumps out dirty waste liquid after washing or excess water after rinsing. The pump is involved in almost all washing modes!

As soon as a signal from the electronic module is sent to the pump, waste water will begin to be pumped into the sewer due to the impeller of the device. The fluid path is as follows:

- Water enters through a rubber pipe, which is connected to the tank and volute using special clamps

- Next, the liquid enters the pump through a special filter located in the volute; it protects the pump impeller from debris, to avoid jamming of the impeller.

- Next, the liquid comes out through the drain hose, which is connected to the volute. The dirty liquid phase is pumped out until the waste liquid is completely pumped out of the washing machine tank.

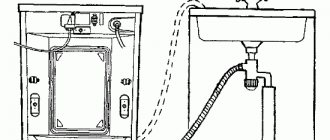

During washing, the water is already in the lower part of the unit, which is why the end of the drain hose must be secured above the drain pump, since if this is not observed, the water will begin to drain from the machine by gravity. The drain hose must be installed at least 80 cm along its entire length!

The electric drain pump is located at the bottom of the unit under the tank. It is attached to a plastic volute, usually with three screws, and the volute, in turn, is attached to the body of the unit from the front side. This arrangement is convenient for quick access to it, if, for example, you need to clean it of debris or drain liquid from the system.

There are two types of pumps used in washing machines:

- The circulation type of pump is used in conjunction with a conventional pump; they are used in new models of premium class machines such as Indesit, Ariston, etc. This option supplies water directly to the washing area and circulates throughout the system, which improves washing efficiency.

- machines from a more budget type or not of a new generation, such as the Daewoo bubble machine (Daewoo), are equipped with a simple pump, for example from Askoll, which simply drains the waste liquid into the sewer.

Repair of the drain pump of a washing machine, as a rule, is not carried out; most likely, spare parts in such devices will have to be replaced. That is, you will have to completely replace the broken pump with a new one.

ATTENTION! You can also inspect the device yourself for blockages or pump failure. But when inspecting the internal mechanism, you must first disconnect the equipment from electricity. Using a special device, such as a multi-mmmeter, check the contacts going to the pump and make sure there is no voltage, and only then continue working. All these precautions are necessary because the work is carried out near an open source of water.

The procedure for replacing an old pump with a new one

How you replace a worn washing machine pump depends on the specific brand and model. Usually they unscrew the bolts and remove the cover, clean it, and then replace the pump. The unscrewed pump is thrown away or sold (gave away) for spare parts.

Tools and accessories

To dismantle the pump with your own hands and replace it with a new one, you will need a set of tools and components: drain pump assembly, axle, impeller, cuff, pulley, gasket, contacts and sensor.

When purchasing a new pump and spare parts for it, you need to be prudent. It is better to take the dismantled unit and go to the store with it. The same should be done with components.

Experts recommend choosing original models rather than cheap analogues. If you don’t have enough money, instead of a new pump you can purchase a used part from a similar model

Things are simpler with tools. To work you will need a knife and a Phillips screwdriver. To check the functionality of the electrics (wiring, contacts, sensors) you will need a multimeter.

Replacing the pump in popular washing machines

To inspect the pump yourself, you need to know its location. It is located below, but you can get to it in different ways. In Samsung, Beko, LG, Candy, Ardo, Ariston, Indesit and Whirlpool , access to the pump is possible through the bottom, in Zanussi and Electrolux - through the rear panel. To get the pump in machines from Siemens, Bosch and SMA AEG , you will need to disassemble the front panel.

The drain pump for the popular brands Samsung, Indesit, LG and Beko is quite expensive, but replacing it does not present any difficulties. It is carried out through the bottom of the device.

This is done in the following sequence:

- The device is disconnected from the power supply.

- The water is shut off.

- The machine is lowered to its side, taking into account that the pump should be on top.

- The bottom, which is usually held on by latches, is dismantled.

- The pump is unscrewed and pulled out.

- The part is disconnected from the board.

- The clamps holding the pipes are loosened and the remaining liquid is drained.

- The pipe and drain hose are removed.

The new device is installed in the reverse order.

The nuances of replacement in models of German brands

Pumps for Siemens and Bosch are expensive and difficult to install. Access to the pump is only possible through the front panel.

Sequencing:

- The device is disconnected from electricity and water.

- The rear mounting screws are unscrewed to remove the top of the machine.

- The cover is pulled up and removed.

- The internal PVC panel covering the drain valve is dismantled.

- The valve is disconnected from the system, and the remaining water is sent to the container.

- The powder tray is removed, the bolts on the control panel are unscrewed, and it is dismantled.

- The cuff is removed from the front wall and placed in the drum.

- Unscrew the screws and bolts that hold the pump.

Finally, all that remains is to finish dismantling the old pump and install a new one.

In machines Ariston, Zanussi , and others with a vertical loading type, the pump is replaced through the rear panel, which is part of the device with circuit boards and other functional parts. The operating sequence is the same as in horizontal loading machines.

Types of washing machine pumps

Washing machines use more than fifty types of pumps, each with one or another design difference.

All of them are divided into two types:

- Circulating. Provide water movement in the machine. Installed on expensive devices, for example, Bosch, Siemens and Hansa.

- Drain. Pump out the water after each washing stage and after rinsing.

Many popular models use a single pump that performs pumping and draining functions. Pumps for pumping/circulating/draining water are made on an electromagnetic basis. In addition to them, washer-dryers also have pumps made in the form of a small engine with an impeller (fan).

The design of the pump is quite simple, consisting of a stator, rotor and impeller. The rotor rotates in one direction or the other, so when the impeller is blocked by foreign objects, it jerks in different directions. The most reliable are synchronous pumps with a magnetic rotor, characterized by high power and miniature dimensions.

The pump is considered one of the most important elements of the washing mechanism. Its type may vary depending on the manufacturer’s brand and design features

Structurally, the drain pump or pump, as it is also called, is a unit consisting of two units. One of them is a motor with an impeller, the second is a plastic pipe called a volute. On one side of the pipe there is a seat for the engine, on the other there is a recess for the filter cover. When used correctly, the volute, unlike a motor with an impeller, is almost resistant to wear.

In older models, the pump has two impellers: one of them is used to cool the engine, the second is used to circulate water. A special feature of these devices is the oil seal, which prevents water from flowing from the snail into the motor. Modern machines have one impeller and no seals, since the electrical and mechanical parts are separated.

The average lifespan of a pump is 3-7 years, but the problem can arise even earlier. This happens when a household appliance is used incorrectly, when various small objects get into it. They stop the impeller, which leads to pump failure

Particularly costly will be repairs after the electronic control module burns out due to a short circuit in the winding. Pump breakdown is a standard situation that occurs during a long service life of the unit and intensive frequency of operation of the device.

When to add water?

During normal operation, the inlet valve receives a signal from the control module. As a result, the valve opens and the liquid is filled. If the pump is turned on and the valve remains closed, an emergency situation occurs. For the convenience of supplying water to the washing machine, the following option is offered:

- Unscrew the screws on the top cover. Remove the cover and underneath it is the valve.

- There are 2 wires suitable for the valve, to which terminals are connected. The latter are connected to 2 wires leading out. They are connected to the power supply according to the diagram below.

- The output is a relay. It is connected to the pump. It turns out to be a kind of water pressure machine for the pump. A connection has appeared between the valve and the pumping device - as soon as the machine gives a signal to draw water, the relay is activated and the pump starts working. This scheme is easy to implement without the help of specialists. It will allow you not to sit near the device, watching it fill.

Signs of breakdown

The SMA itself is capable of detecting possible pump malfunctions and displaying the OE error code on the display.

If this does not happen, there are other ways to identify a failure of the drain assembly. The reasons for pump failure may be the following:

- Abnormal noises or silence during the cycle when the pump should be running. In the first case, a strong hum is heard, but the water does not drain; in the other, the device simply does not turn on.

- The garbage filter is clogged or the hose is kinked. Small objects and dirt prevent the fluid from draining, the pump runs idle.

- Wedging of the pump impeller. It is determined when you try to turn it by hand through the filter socket.

What to do if it does not meet the required indicators?

In villages, other small settlements or the private sector, the pressure level often does not exceed 0.1 bar . This is not enough to connect household electrical appliances to the water supply network; none of them will be able to work in such conditions. But a way out can be found in any situation.

Buying a pump

A popular solution to the problem is to purchase a pump that increases water pressure. The cost of this equipment is not very high, from 2000 rubles. You will have to pay about the same amount for installation.

Drain pump device

The drain pump for a washing machine has the following technical characteristics:

- power consumption - usually from 25 to 40 W;

- type of fastening to the volute - screw or fastening with latches;

- contact arrangement - paired or separate;

ATTENTION! When choosing a new pump, be sure to pay attention to the type and technical characteristics of the old pump, since the new one may not be suitable for some of the above parameters.

The pump in the washing machine differs not only in appearance, but also in the type of “snail” filter installed inside them. Very often the filter becomes clogged, and in this case the water is not completely drained from the chamber, then the dirty liquid stagnates and an unpleasant odor appears inside the drainage system. In this case, it is necessary to check the condition of the filter. You will need some tools, since the device cannot be removed with bare hands. The filter can be cleaned and the problem may be resolved.

The internal structure looks something like this:

The pump rotor is a permanent magnet in the form of a cylinder, which is located in a plastic casing. When the system starts up, the rotor first turns on, then the impeller, located on the shaft at an angle of 180 degrees, begins to move. The impeller relative to the armature should have a small stroke; this is necessary for normal engine starting, since there is a load due to water.

The rod, or otherwise the magnetic core, has two insulating windings that are connected to each other. The whole design is similar to an asynchronous motor, where there is also a moving and a stationary part. The moving part is a rotor in the form of a cylinder, and the stationary part is a magnetic core with windings.

This is how a simple washing machine pump works.

For example, if the impeller of the impeller falls off from the pump, this will inevitably lead to the need to replace the pump, since it cannot be repaired.

The washing machine's circular pump only allows liquid to flow in one direction.

For example, in the pump of a Samsung washing machine, a sealing collar is used to block the independent entry of liquid. This is necessary to prevent water from leaking into the bearing. Also, such mechanisms are equipped with a rotor shaft, which passes through a central collar bushing, which is crimped in the form of a spring ring.

Before the cuff is secured in the desired bushing, it must be lubricated with a special technical lubricant. The product is applied in a thick layer so that when starting work it gets into all the necessary gaps. This action has a positive effect on the operation of the mechanism and significantly increases its service life.

Washing machine pump repair

From life

A breakdown of a washing machine is like “out of the blue.” Everything happens suddenly and rapidly. You arrive home late at night after work. Tired, no strength. Things don’t work out at work with your boss, and with your colleagues too.

Not good. You turn on the TV. A plate under your nose. You try to look at the screen with one eye and... instantly your face ends up in food. You are sleeping and seeing your tenth dream. You wake up and then it starts...

You remember that you forgot to wash your shirt. You scold yourself for being a “bad person.” You quickly put the shirt into the drum of the washing machine, pour in the powder with trembling hands, and leave it for 30 minutes. Bang! The car “stalled” - in the language of avid motorists. Panic, horror, thoughts of a reprimand at work! What to do? How to be?

Real-time repair

The Stirrem.ru company will never leave its clients in trouble, even in the most critical situation. We will promptly help you fix any damage.

Within a short period of time after your call, the technician will arrive on site. Our company’s specialists will perform preliminary diagnostics of the device and carry out repairs.

Below, you can learn more about the function of the pump and find out what it is.

What is a pump?

water pump

in a washing machine this is a very important element. It is a miniature pump, which is located at the very bottom of the device. While the machine is running, all used water goes down the drain. It is the pump that allows you to speed up this process and drain excess water faster. There are two types of pumps:

Nowadays, as a rule, they are no longer installed with an impeller. But they can still be found on older Ariston and Indesit models.

If it so happens that there is water left in the drum during washing, the reason most likely lies in the pump. How to repair a pump

read below...

"Attention! We do not recommend doing self-repairs. It’s better to entrust this matter to professionals.” DIY repair

DIY repair

“Remember ! All of the following is relevant only for a pump with an impeller mechanism.”

What do you need? To be honest, apart from a regular knife and a Phillips screwdriver, nothing. So let's get started right away.

2) Next you will need to remove the back wall of the washing machine. As a rule, all fastenings are held on with ordinary self-tapping screws. After which, having carefully examined the device, we find the pump itself in the lower corner. We disconnect the wires coming from it, unscrew the pump, remove the hoses.

3) After which, you need to disassemble the pump itself. To do this: unscrew the pump volute from the pump body itself. We write down the order in which the engine was installed. Then we carefully remove the engine with the impeller from the snail itself. Let's check if everything is in order. We manually turn the impeller blades; as a rule, they should spin easily (intermittent movements are allowed.)

4) Basically, the breakdown occurs due to the fact that during the use of the washing machine, under the influence of hot water, the casing becomes deformed. Therefore, the impeller blades freely touch it and a breakdown occurs.

"Warning! Don't cut too much. If you remove excess, the pump’s performance will decrease.”

6) Then we put everything back together in reverse order and start the car.

If you succeeded, congratulations. If not, then there is only one option - buying a new pump.

. You can install and purchase a pump from our company at an affordable price. See below for more details...

About us again

Rest assured, using the services of our service center, you can forget about your problems. We work from 9.00 to 21.00, and around the clock. Who said Saturday and Sunday are days off? Taking care of our clients is more important than relaxation. We will create a schedule for the specialist’s arrival individually for you and select the desired day.

We guarantee you quality and reliability. All parts for repairs are purchased from our German partners. Therefore, the part installed in your washing machine can last for many more years.

The company has a transparent pricing policy. And for our regular customers there are various discounts and promotions. Read more

Hurry! Place your order right now and get a discount on 3 services!

Possible causes of pump malfunctions

Problems with LG washing machine pumps must be corrected. To do this correctly and not harm household appliances, it is very important to identify the true cause of the problem.

In most cases, the following facts lead to pump malfunctions:

- Breakdown is often caused by a serious blockage in the drainage system of the machine. This process involves the pipe, the filter and the pump itself.

- Breakdowns also occur due to severe blockage of the sewer system.

- If there are defects in electrical contacts and important connections.

Before you rush to replace the washing machine pump yourself, you should rule out other equipment problems that may occur.

Where can I get lubricant?

It is best purchased in specialized stores that sell equipment for repairing household appliances. Often, washing machine manufacturers also produce lubricants, claiming that this particular lubricant is suitable for a particular brand of machine. In cases where the cost of such a lubricant does not allow you to purchase it, you can buy an ordinary one, it will be no worse.

What you definitely shouldn't do is save money. Some owners of washing machines lubricate the sealing part with ordinary vegetable oil, others use grease for this purpose. In this case, not only will the machine not work better, but with a high probability the thrifty owner will have to repair it within a few months.

How and what to replace

If the problems are more serious and regular cleaning of contaminated parts cannot be avoided, then you will have to resort to replacing the washing machine pump. It is not at all necessary to completely disassemble the equipment for this. In the case of LG machines, all stages of work can be carried out through the bottom.

The algorithm of actions will be as follows.

- Drain all the water from the tank, remember to turn off the water supply.

- To make the replacement process more convenient, it is better to place the device on its side so that the drain pump is on top. If you don’t want to stain the floor finish, then you should spread something like an old and unnecessary sheet under the machine.

- Next you will need to remove the bottom panel. You can do this with literally a single click. If the machine is an old model, where the panel needs to be unscrewed, then you will need to disassemble this part very carefully.

- Unscrew the pump from the base. It is usually attached to screws located on the outside, near the drain valve.

- Pressing the machine pump from the side of the drain valve, pull it towards you.

- Disconnect all wires from the pump.

- It is imperative that you drain all remaining water from the pump, if there is still any there. Take any container for this. Slightly loosen the clamps holding the drain pipe.

- After you remove the nipple and drain hose, get rid of any remaining fluid.

- If the “snail” is in good condition, there is no point in spending money on a new one. You will need to insert the old part, but with a brand new pump.

- To remove the snail, you will need to unscrew the bolts that secure it, and then unscrew the screws connecting the snail and the pump.

- Do not rush to attach the new pump to the cochlea. First, the latter must be thoroughly cleaned of dirt and accumulated mucus. Pay special attention to the area where the new pump will “sit”. It should be clean there too.

- Attach the cleaned “snail” to the new pump, but in the reverse order. The next step is to connect the pipes. Don't forget about connecting the wires.

Cleaning internal contaminants

To do this, use a screwdriver to pry the latch on the motor body on both sides and remove it from the reel.

There are also so-called “non-separable” motors, but they can also be “treated”.

After disconnecting the body with the blades from the coil, we will see a monolithic part. The crosspiece seems impossible to remove. But there is a little trick.

- Take a regular hair dryer, set it to the lowest temperature, put on gloves, and start heating the shank of the part (its long part). Do this with care.

- After a while, when the shank has warmed up well, pry up the crosspiece with a screwdriver and carefully remove it (along with the magnet) from the body.

There may be a lot of dirt on the magnet and in the area from which it was removed. Everything needs to be thoroughly cleaned, after which you can remove the magnet itself from the shaft. You will see a bearing that requires cleaning and lubrication, respectively. Also lubricate the bearing on the bottom of the housing.

Then insert everything into place, with slight pressure until it clicks. The O-ring located under the blades should fit tightly into place.

The figure below shows a dirty motor from an Indesit brand machine.

In motors of this type, in addition to the above procedures, it may be necessary to replace the seals.

What you need

To repair an LG washing machine yourself, you will need to prepare all the necessary tools. You will also need spare parts for the device.

Tools

To carry out all the necessary work you will need the following devices:

- screwdriver;

- tool with a blunt blade;

- penknife;

- multimeter;

- pliers.

Spare parts

Repairing a branded washing machine in the event of a pump breakdown must be carried out armed with a number of spare parts. In this case, the following units will be needed:

- new drain pump;

- impeller;

- axis;

- contacts;

- pump sensor;

- cuff;

- special rubber gasket;

- closet.

When selecting the necessary replacement elements, you need to take into account that they must be ideal for the LG washing machine.

Ideally, you will need to remove the old drain and contact the store salesperson for help. The store employee should help you find suitable analogues. You can also navigate the selection of spare parts by finding out the serial numbers of the parts. They must be applied to all components of the pump located in the washing machine.

Other requirements for water supply

In addition to pressure, there are a number of conditions that must be observed for the devices to function properly:

- water purity;

- compliance of the size of the room with the dimensions of the washing machine (minimum 2 cm of margin on all sides);

- optimized wiring: in old apartments where the wiring has never been changed, it is necessary to connect an additional special cable;

- high-quality floor covering that can withstand the vibration of a washing machine;

- arrangement of drainage of used water.

Repair stages

Often the pumps in the design of LG washing machines stop working properly due to simple contamination. You should not immediately run to the store for a new pump, because there is a possibility that the old part just needs to be cleaned. For these types of repairs, the DIYer will need a spare container, a rag, and a brush.

Work order.

- Start the drum rotation mode of the machine. A couple of minutes will be enough to successfully drain all the water from the device.

- Be sure to unplug the machine from the electrical outlet. Open the cover at the back. Find where the special drainage hose is located and pull it towards you.

- Hold the hose over the prepared empty container. Drain all remaining liquid there.

- With extreme care, turn the fitting in a counterclockwise direction. Remove the drain filter.

- Using a brush, very carefully and carefully clean both the inner and outer surfaces of the filter part. At the end of your actions, do not forget to rinse this element under water.

- After completing all of the above steps, install the filter in its original position. Next, fix the hose in reverse order and reinsert it into the machine. Close the unit cover.

Dismantling the unit

The liquid pumping unit is built between the drain channel from the tank and the volute - the socket into which the filter is screwed. In LG, as in washing machines of other brands, the pump is located at the bottom of the case. It consists of an impeller enclosed in a casing and a motor. To get to the pump unit, you need to perform the following steps:

- Disconnect the machine from electricity, water, and sewerage.

- Drain the contaminated liquid from the tank through the emergency hose or filter socket.

- Move the device, lay it on its left side: through the open bottom of the case, an overview of the pump and associated parts will open.

- Unscrew 2-3 mounting screws, loosen both clamps, remove the pipes. Disconnect the wires and remove the pump.

All of the above work can be done with your own hands. In more complex models with a drum for 8 kg of dry laundry, the bottom of the machine body is closed, there are additional shock absorbers and sensors. It is better to entrust such devices to specialists - they will be able to repair SMA with a guarantee for up to one year.

How to disassemble the pump

The reasons for pump repair can be a series of events: wear of the oil seal - subsidence of the bushing and shaft - axial play of the impeller - hooking of the housing - shearing of the pin. As a result, the turntable rotates freely on the drive shaft from the motor. Electric pump disassembly sequence:

- To remove the snail, turn the lid counterclockwise. If the mount is bolted, unscrew the screws.

- Pry the case latches and disconnect it.

- Release the magnet with the impeller and remove any accumulated dirt.

- Lubricate the bearings (there are 2 of them) or replace them with new ones if they are damaged.

If the problem turns out to be a broken gasket, install a new one. Depending on the condition of the impeller, further repair actions will be determined.

After the picture becomes clear with the mechanical part, we move on to the electrical half of the pump. Inspect the integrity of the coils: whether there is any burning on them from breakdown, breakage of copper wires. If defects are found in the electrical system, the entire pump is replaced.

Repair

There are LG models equipped with a non-separable type pump. For an untrained person, trying to fix a pump of this design is just a waste of time. Approximately the same situation arises when, after opening the pumping device, it turns out that the impeller is partially destroyed.

It will not be possible to restore the part at home. It is not advisable to buy separately: there are many types of electric pumps, the price is low. It makes direct sense not to restore a worn-out pump, but to replace it with a new one.

How to choose a new pump

When going to the store to buy the required pump, it is useful to know about the method of connecting the plastic pipe (volute) to the drain filter: for LG, Zanussi models - with 8 latches.

You can also order the part from the device manufacturer. In order not to make a mistake with your choice, you need to be careful and know the information about the item you are purchasing:

- the best way is to show the seller the old hydraulic pump;

- rewrite the serial number of the part and model of the SMA;

- pay attention to how the wires are connected, where the contact group is located (front or rear).

The pump power is indicated on the label; it is approximately the same for different models and does not have a decisive influence on the choice. Advice from a knowledgeable specialist when purchasing will be useful.

Installation

Before installing a new pump, you need to clean all parts of the drain assembly: pipes, volute, socket and the filter itself. After preparing the system elements and seats, they proceed to installation work. Assembly order:

- Attach the hydraulic pump to the volute.

- Install and secure the pipes and pump.

- Connect the wires to the motor terminals.

- Return the machine to an upright position.

- The SMA repair has been completed. All that remains is to connect the device to water and sewerage, insert the cord plug into the socket, and do a test run.

Selecting a pump for washing machine repair

If the pump has served for more than 5 years, and diagnostics show the need to replace it, you will need to purchase a new one. To increase the service life of your pump, you need to choose it correctly.

When choosing a pump, consider the following parameters:

- Attachment to the cochlea : with 3 screws or 3, 4 and 8 latches. The mountings of the new pump should be the same as the old one. Otherwise, it simply won't fit.

- Method of connecting wires : “chip” and “terminals”. If, instead of a pump with a chip, you purchase a model with terminals in the form of terminals, you will need to trim the double wires at the end, strip and install the terminals.

- Placing a contact group . Can be located behind or in front. The location doesn't matter much. This does not affect the operation of the pump.

- Manufacturer of drain pumps . There are several universal brands: Coprecci, Arylux, Mainox, Hanning, Plaset, Askoll. Pumps from these manufacturers are interchangeable.

- Pump power indicated on the sticker. This parameter is not very important, since it is approximately the same for all models.

It is difficult for an ordinary person to understand the design features of pumps, so when choosing a new device, it is better to consult a professional.

Image gallery

Photo from

Pump with output in the form of a “chip”

Connecting wires to the pump to the terminals

Rear position of the contact group

Placing the contact group at the front

The design diversity of drain pumps is, first of all, determined by the features of the plastic pipe (volute) and the debris filters combined with them.

In modern models, manufacturers use three types of pumps:

- on three volute screws ( Samsung, Indesit, Ardo );

- on three volute latches ( AEG, Bosch );

- on eight snail latches ( LG, Zanussi ).

Pumps of the same type are interchangeable. For example, a Samsung pump is suitable for an Indesit brand car and vice versa.

How to clean the pump

The pump cleaning operation consists of the fact that you will need to very carefully clean one component of the pump - the impeller. To fully clean the impeller, it will also need to be removed.

The process of removing the impeller is simple: using a screwdriver, you need to remove the screws that connect the 2 parts of the pump. When these parts are separated, you will see a small head. This will be the impeller. During operation of the unit, this head rotates, due to which water is drained.

Clean it of dirt, wool fibers, hair, threads and other debris and wipe the inner snail of the element. At the end of the event, assemble the pump, install it in place, also assemble and properly secure the other removed elements. When the device is finally assembled, perform a test wash. If water is filled and drained in accordance with the norm, and no knocks or noises are heard when the device is operating, then you have done everything correctly.

Don't forget about the filter. Not every time the pump is the cause of a water drainage failure. The machine may refuse to drain water due to a clogged drain filter.

You can clean the washing machine pump filter while dismantling the pump, since when you get to this element, you will still be removing the filter plug. Simply immediately remove all debris and foreign objects from it, and then remove the pump itself.

SMA with reservoir

This model is from the Slovenian brand Gorenje. Thanks to this SMA, you can do laundry even without running water. The body is white. High energy efficiency class. Energy consumption - 0.14 kWh/kg. Noise level during washing/spin - 58/71 dB. Equipped with a 100 liter tank. There is no possibility of connecting to a water supply. Specifications:

| Maximum load, kg | 7 |

| Spin speed, rpm | 800 |

| type of instalation | freestanding |

| Load Type | frontal |

| Tank material | plastic |

| Energy class | A++ |

| Washing class | A |

| Spin efficiency class | D |

| Water consumption, l | 54 |

| Number of programs | 18 |

| Dimensions (WxDxH), cm | 60x60x85 |

| Weight, kg | 77 |

| Cost, rubles | 22 000 |

| Drying | No |

The lack of quality water supply should not become an obstacle to comfort. There are different ways to solve the problem - from installing special injection equipment to purchasing an SMA with reservoirs. The first option requires installation work, but will allow you to enjoy all the delights of automatic washing.

Source of the article: https://270076.ru/stiralnye-mashiny/kakoe-davlenie-nuzno-dla-stiralnoj-masiny/

Prevention of breakdowns

To avoid having to frequently repair an LG washing machine with your own hands, you should take preventive measures. Let's get to know them.

- Always inspect your laundry very carefully after washing. Try to ensure that small parts do not penetrate into the drum of the machine - they can cause subsequent breakdowns and malfunctions.

- You should not send overly dirty items to the wash. It is advisable to soak them in advance, and only after that use the washing machine.

- Items that are likely to cause serious blockage in household appliances (with long threads, pellets or bulky pile) must be washed exclusively in special bags, sold in many stores.

- A washing machine made by LG must be treated with the utmost care and precision, as is the case with other equipment. In this way, you can easily and simply avoid many problems with such a useful and necessary unit.

Recommendations for use

To extend the life of the drain pump, it is recommended:

Before washing, clean recesses and pockets on clothing from debris, coins and other foreign objects.- To avoid accessories getting into the tank, wash items with buttons, beads, clasps and other decor in closed mesh bags.

- Clean the drain filter and its housing after each wash cycle.

- If a foreign object gets stuck in the drum, carefully remove it with tweezers or pliers and carefully examine the joint between the drum and the tank.

- If an abnormal knocking or clanging sound occurs during washing, stop the operation of the SMA, drain the water through the filter, and inspect the tank from below through the heating element socket.

With proper care, a sump pump can last up to 10 years.

How to extend the life of the pump

Advice from household appliance service technicians will help you extend the operating time of your washing machine, reduce the likelihood of breakdowns, and save on repairs. Many recommendations overlap with the requirements of the SMA operating instructions. Trouble-free operation of the device is facilitated by the following actions:

- Before washing, empty clothing pockets of small objects, pre-clean fabrics from dried dirt and pet hair;

- use laundry bags for items with beads, appliqués, and other decorations;

- pay attention and respond in a timely manner to leaks and extraneous sounds when the machine is operating.

The cause of failure is also increased vibrations of the case - the wires powering the pump can fray. Therefore, you must initially install the unit in accordance with the standards. Sometimes the SMA control unit fails.

If trouble does occur, you should not use parts purchased from random sellers or used parts. Such repairs will not last long; they will lead to even greater damage.

Where is the pump located

To remove the pumping system from the body of an automatic washing machine (WMA), there are different methods, depending on the model of the unit. Models from Whirpool, Samsung, Ariston, Beko, LG, and others do not have a bottom. Accordingly, you can remove the pump by tilting or laying the device on its side and disconnecting the bottom panel (open the door or hatch). After which you will see the screws that secure the volute with filter to the front plate.

Everything is very simple in SMA Electrolux and Zanussi. Just open the back cover of the machine and you will see the required unit that needs to be disassembled. The most difficult access to the required part is in SMA AEG, Bosch and Siemens. You can get to the pump only by removing the front wall of the washing machine.

What determines the cost of repairs?

When calculating the cost of services for replacing the drain pump, we take into account:

- Car model;

- Pump type;

- Scale of work.

The average cost of services is from 700 rubles. To find out the price in advance, please contact us with details.

The cost of replacing the pump

| Washing machine brand | Replacement cost* (without spare part) |

| Visit of the master | For free |

| Bosch washing machine | from 900 ₽ |

| Washing machine Indesit | from 850 ₽ |

| Samsung washing machine | from 950 ₽ |

| LG washing machine | from 950 ₽ |

| Ariston washing machine | from 850 ₽ |

| Washing machine Candy | from 900 ₽ |

| Electrolux washing machine | from 900 ₽ |

| Washing machine Zanussi | from 1000 ₽ |

| Miele washing machine | from 1350 ₽ |

| Whirlpool washing machine | from 1150 ₽ |

| BEKO washing machine | from 850 ₽ |

| Washing machine Siemens | from 950 ₽ |

| Washing machine Ardo | from 950 ₽ |

| Washing machine AEG | from 1200 ₽ |

| Brandt washing machine | from 1050 ₽ |

| Washing machine Atlant | from 950 ₽ |

| Washing machine Gorenje | from 1050 ₽ |

| Hotpoint Ariston washing machine | from 1000 ₽ |

| Other brand | from 800 ₽ |

How to increase blood pressure?

Low pressure in the water supply is not a death sentence. You can connect a special booster pump and thus increase the water pressure to the required value.

Another thing is that these are additional costs. To get a clearer idea of booster pumps and their cost, let's give a short overview of such units.

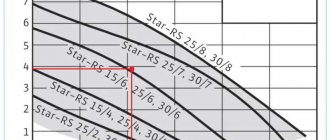

- Pressure increasing pump WILO PB-088 EA. A relatively inexpensive pump with good characteristics, which is suitable not only for a washing machine, but also for a shower cabin, jacuzzi and other things. Pressure – 9.5 m, temperature – from 0 to +60, power – 0.09 kW. The price is about 60 dollars.

- Pump for increasing pressure GRUNDFOS UPA 15-90. A slightly less powerful unit, but it is still more than enough to ensure the normal operation of an automatic washing machine. Pressure – 8 m, power – 118 W, operates absolutely silently. The price is about 90 dollars.

- Gilex Jumbo 60/35 P-24. This booster pump model is for those who need a unit to supply several consumers at once. For example, a shower cabin, a dishwasher and a washing machine. The pump gives a maximum head of 35 m, with a power consumption of 600 W. The price is about 107 dollars.

- Marina Cam 80/22. This is already a full-fledged pumping station with appropriate dimensions. Pressure 32 m, water intake depth up to 8 m, power 800 W. Average cost: $170.

The choice of pumps that increase the pressure in the water supply system is quite large, and their quality is at the same level. Take the model that has the best characteristics and price.

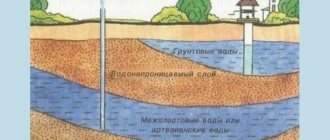

Washing machines operating without running water

In the vastness of the CIS countries, it happens that there is nominally a running water supply, but there is no water in it. Under such conditions, no pumping station will help. If the main source of water for your rural home is a standpipe or, especially, a well in the yard, there is a reason to get an automatic washing machine that does not need a connection to the water supply. There are few such cars, to be precise, only three models of one brand - Gorenje.

Self-contained Gorenje washing machines do not need a water supply connection, since a fairly large tank is attached to the side of them, into which water is poured. To start the wash, you just need to connect the washing machine to the power supply, pour water into the tank and that’s it – you can wash without worry. Moreover, the tank of the Gorenje washing machine is so capacious that its volume can be enough for 2-3 washes.

By the way, you can order a larger-volume tank that can hold enough water for 6 washes.

In addition to the inlet valve, autonomous Gorenje brand washing machines have a pressure pump. So water passes through the inlet valve of such a machine with quite a lot of pressure, washing the powder into the tank without any problems. The washing quality is very high. You can learn more about this technique by reading the article Washing machines with a water tank.

To summarize, we note that in order for an automatic washing machine to work properly, it is necessary that the water pressure in the water supply reaches the minimum that is programmed in its control module and sensed by the inlet valve. If the pressure in the water supply is below the minimum, the machine will not work. There is a way out of the situation - install a booster pump, and if you have the opportunity to choose a washing machine, you can take a model that can work autonomously. Good luck!

Interesting:

- Review of Gorenje washing machine for rural areas

- Washing machines for cottages without running water

- Miele dishwasher errors

- Washing machine for rural areas or cottages

- Installing a washing machine without running water

- The water in the dishwasher does not heat up

readers

- 11/18/2017 at 07:23 pm

Nata:

I bought an Atlant machine for the village, and now I’m thinking about which pumping station to get to make it work. We don't have running water.

Answer

- 02/01/2018 at 17:33

Anonymous:

Washer manufacturers, plumbers and pump manufacturers have probably agreed. Some make machines with difficult water supply, others reduce the pressure in the water supply, and others produce pumping stations. They divide the proceeds among themselves. Kidding. But in every joke...

Answer

- 03.12.2018 at 09:56

Tim:

Why are pumps in dollars, do we live in America? We have our own ruble, we live in Russia, so we need to write in rubles, and not rack our brains, translate!

Answer

- 01/06/2021 at 03:09

Vova:

Because the pump is sold for dollars - that's it. The price in rubles will be different in different years. That's two. And thirdly, people watch videos even where there are no rubles, but there are dollars.

Answer

- 01/01/2019 at 08:25

Ivan:

We bought a Gorenje washing machine, one tank is only enough for 1-2 washes