Gas equipment is an unsafe device. Therefore, it is necessary to know the signs of various breakdowns in order to quickly eliminate them. The most common cause in gas equipment is a change in the color of the gas combustion. Normally it should be blue. But if you notice that the color has turned red, orange or yellow, and an unpleasant odor has appeared and black soot is falling, then most likely the fire is smoking. If injection is disrupted, orange or yellow colors appear on the flames. This indicates a lack of air.

In our article we will talk in detail about gas combustion and the signs of poor performance of gas equipment.

What color should the gas flame be when it burns?

Proper combustion of natural gas with a blue tint. When the equipment is in good working order and there is enough fresh air in the room, then there will be no questions about why the gas burns with a red flame on the stove - the work will be excellent.

Gas needs air to burn. With an optimal amount of oxygen in the burner, the mixing process begins, allowing for a high heat release. When the gas does not burn completely, carbon begins to be released, which turns the flame yellow.

In this case, the fuel is consumed incorrectly, starting to smoke the dishes and slowly heat them up. Also, released sulfur compounds can be absorbed into food.

Conclusions and useful video on the topic

It is not always possible to figure out how to clean a gas burner from scale and dirt the first time. The video below offers detailed instructions on how to do this:

So, the normal color of a gas flame is blue. If your burners burn differently, this is a reason to clean them or call a specialist for a more complete diagnosis. You shouldn’t delay this issue, because it’s not just the color of the flame that changes, but the composition of the combustion products.

The accumulation of carbon monoxide can lead to undesirable consequences. Therefore, gas safety issues must be addressed first.

Have you ever experienced a change in flame color? How did you act in such a situation? Leave your comments, share your experience, ask questions - the contact block is located under the article.

Rules of operation to prevent repeated violations

Basically, a change in the color of the flame to orange-yellow, green, or red occurs due to insufficient cleaning and design errors.

Therefore, be careful when purchasing equipment.

- Before going to the store, find out what gas is used in the house/apartment.

- After that, ask the sellers which models are designed for your type of gas.

These simple steps will minimize gas discoloration.

You can also eliminate the occurrence of defects by replacing equipment with specialists (they can do the replacement themselves or supervise you). Regular diagnostics of the condition by gas workers will extend the service life and prevent malfunctions. For independent control, you can take a regulator; it will reflect the state of the gas-air mixture. You can also contact professionals for refilling gas cylinders, if you use them - https://ballonis.ru/s-geliem

Following instructions

Household appliances must be used according to the instructions, and a gas stove is no exception. By studying and following the manufacturer's recommendations, you make operation safe and extend the life of the equipment.

Proper care of equipment

Below is the cleaning sequence when incorrect colors appear in the gas.

| 1. | Do not use products containing chlorine |

| 2. | Glass ceramics can be cleaned with soap and water and a sponge. |

| 3. | The surfaces of enamel or metal plates must not be washed with detergents. |

| 4. | To clean the burner openings, use a stiff brush; for the rest of the surface, a simple sponge will do. |

Before turning on the appliance, the surface of the stove must be wiped dry.

To thoroughly clean the equipment, you can look at the structure in the instructions. In addition to the diagram, it describes cleaning options that will allow you to organize everything efficiently.

Dust and food debris that are not immediately removed begin to melt and char, making subsequent cleaning difficult. With each switching on, the work may deteriorate and the equipment may be completely broken. Cleaning the burners daily will prevent them from becoming clogged from the inside.

There is also no need to be shy about contacting gas companies. They will be able to eliminate systematic failures, give advice on operation and extending service life.

What to do in such a situation

Once the color of the flame turns orange, red or yellow, you should understand that this indicates danger. Therefore, it is necessary to find the problem and fix it. Once you notice a change in the color of the flame, you should contact a qualified specialist to diagnose and repair the gas device.

It may be necessary to clean the gas equipment, replace the burner nozzles and adjust the air seal in the boiler. You can adjust the air-fuel mixture yourself. This does not require the help of a specialist.

The main requirement before installing gas equipment is the installation of carbon monoxide detection sensors.

It will not be difficult for qualified specialists to eliminate flame smoke. This does not require special tools. If you have the slightest suspicion of a carbon monoxide leak, immediately contact a specialist.

Gas stove cleaners

How do you like the article?

Recommendations

Compliance with several rules will protect the unit from premature wear, and will also help prevent the occurrence of adverse reactions from improper operation.

- Installation and connection should only be carried out by gas service employees. They must register new equipment and also provide a guarantee that all connections are made without errors.

- It is recommended to ventilate the room well and turn on the hood when cooking. This will reduce the level of humidity and prevent oxidation of contacts and the formation of rust on elements.

- When installing the cylinder, carefully study the contents and follow all safety rules. Do not buy from unverified suppliers.

- Keep children away from the stove. They can reset the settings, leave the burner open, fill the burner openings with liquid, or damage the handles. In order to prevent such incidents, some manufacturers have included a child lock function in the device.

- Avoid mechanical damage.

- To extend the service life, once every six months, invite an engineer to carry out a preventive inspection.

If the above recommendations do not help and the stove fails, contact the service center. Our technicians will quickly perform diagnostics, find the cause of the defect and quickly eliminate it. All work and installed parts are guaranteed.

Expert advice

Experts say that the likelihood of carbon monoxide poisoning if you follow the rules for operating the equipment is minimal.

What to consider:

- installation and transfer of equipment is carried out by gas company specialists;

- poor-quality ventilation can lead to poisoning;

- regularly check the draft of gas-consuming appliances;

- Do not turn off the automation in devices yourself;

- when working with the stove, open a window for ventilation;

- simultaneous operation of the panel and the hood above it with the window closed disrupts the removal of combustion products;

- Gas stoves cannot be used for heating premises.

Operating principle

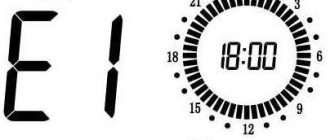

So, gas control of burners: what is it? This is a reliable system designed to control the gas supply and prevent gas leaks. If for some reason the fire on the hob goes out, the system shuts off the fuel supply.

Most often, a gas leak occurs due to liquid getting on the burner or an accidental gust of air (draft in the apartment)

This mechanism is quite simple. Each burner is equipped with a burner and a flame sensor. The main elements of the sensor are a thermocouple, a solenoid valve and a wire.

A thermocouple is two wires made of different metals and fused together in a certain way. The place where the wires are fused is a round element that perceives temperature changes. When the element is heated to a certain level, an electrical signal appears at the other end of the thermocouple, which is supplied to the solenoid valve. The thermocouple is installed so that the fused end (heating element) is always at the flame boundary.

Gas control device diagram

The solenoid valve, in turn, is responsible for the fuel supply. It is connected to a thermocouple and a tap of the gas burner mechanism. When there is a signal from the thermocouple, the valve presses on the burner tap and keeps it open. If the flame goes out, the thermocouple heating element cools down, the signal is not generated, the valve closes the gas valve and the fuel supply is stopped.

After the gas control mechanism is activated, the stove must be re-ignited. The thermocouple element takes time to heat up. Depending on the stove model, the ignition process can take from 1-5 to 10-20 seconds.

Ignition time may increase as the stove is used

Calcium

Calcium is an element of the 4th period and PA group of the Periodic Table, serial number 20. Electronic formula of the atom is 4s2, oxidation states +2 and 0. Refers to alkaline earth metals. It has low electronegativity (1.04) and exhibits metallic (basic) properties. Forms (as a cation) numerous salts and binary compounds. Many calcium salts are slightly soluble in water. In nature, it is the sixth most abundant chemical element (the third among metals) and is found in a bound form. A vital element for all organisms. The lack of calcium in the soil is compensated by applying lime fertilizers (CaCO3, CaO, calcium cyanamide CaCN2, etc.). Calcium, calcium cation and its compounds color the flame of a gas burner dark orange (qualitative detection).

Calcium Ca

Silvery-white metal, soft, ductile. In humid air it fades and becomes covered with a film of CaO and Ca(OH)2. Very reactive; ignites when heated in air, reacts with hydrogen, chlorine, sulfur and graphite:

Reduces other metals from their oxides (an industrially important method is calcium thermia):

Production of calcium in industry:

Calcium is used to remove non-metal impurities from metal alloys, as a component of light and anti-friction alloys, and to separate rare metals from their oxides.

Calcium oxide CaO

Basic oxide. Technical name: quicklime. White, very hygroscopic. It has an ionic structure Ca2+ O2-. Refractory, thermally stable, volatile when ignited. Absorbs moisture and carbon dioxide from the air. Reacts vigorously with water (with a high exo-effect), forms a strongly alkaline solution (hydroxide precipitate is possible), a process called lime slaking. Reacts with acids, metal and non-metal oxides. It is used for the synthesis of other calcium compounds, in the production of Ca(OH)2, CaC2 and mineral fertilizers, as a flux in metallurgy, a catalyst in organic synthesis, and a component of binding materials in construction.

Equations of the most important reactions:

Production of CaO in industry - limestone roasting (900-1200 °C):

CaCO3 = CaO + CO2

Calcium hydroxide Ca(OH)2

Basic hydroxide. Technical name is slaked lime. White, hygroscopic. It has an ionic structure: Ca2+(OH–)2. Decomposes when heated moderately. Absorbs moisture and carbon dioxide from the air. Slightly soluble in cold water (an alkaline solution is formed), and even less soluble in boiling water. A clear solution (lime water) quickly becomes cloudy due to the precipitation of hydroxide precipitate (the suspension is called milk of lime). A qualitative reaction to the Ca2+ ion is the passage of carbon dioxide through lime water with the appearance of a CaCO3 precipitate and its transition into solution. Reacts with acids and acid oxides, enters into ion exchange reactions. It is used in the production of glass, bleaching lime, lime mineral fertilizers, for causticizing soda and softening fresh water, as well as for preparing lime mortars - dough-like mixtures (sand + slaked lime + water), serving as a binding material for stone and brickwork, finishing ( plastering) walls and other construction purposes. The hardening (“setting”) of such solutions is due to the absorption of carbon dioxide from the air.

Equations of the most important reactions:

Production of Ca(OH)2 in industry - slaking of lime CaO (see above).

How to clean injectors

First, turn off the gas and check if the stove has cooled down. To clear the blockage, you need to remove the cover and dispenser. As I said, there is a small hole inside. Take a sewing needle and carefully clean it. There is no need to crush and put pressure on him. Simply insert the tip and gently rotate the needle between your fingers.

At the same time, if there is dirt, it is useful to clean the divider itself and the cover. You can use a toothbrush, dish soap and a stream of warm water. You cannot pick with wire or nails. Modern burners are not the same as those used 50 years ago. They won't stand such vandalism. Then you wipe the whole thing dry, dry it for half an hour or a little longer, assemble it and put it in place. When assembling, make sure that the grooves and projections of the burner match. The lid should be in place exactly, without displacements or distortions.

Carburizing view of welding flame

If the oxygen to acetylene ratio in the welding torch is less than 1, a carburizing welding flame is formed. The core of such a flame does not have a sharp contour, and the top of the core is colored green, which indicates an excess amount of acetylene.

The reduction zone in such a flame is lighter than in a normal flame, and the torch is yellow in color. There is no clear boundary between the zones. Excess acetylene breaks down into carbon and hydrogen. Carbon easily passes into the weld pool, therefore, a carburizing flame is used if there is a need to carburize the weld metal or to replenish carbon if it is burned out during welding. This flame is well suited for gas welding of cast iron.

Studying fire in our own kitchen

Kitchen gas stoves operate on two types of fuel:

- Trunk natural gas methane.

- Propane-butane liquefied mixture from cylinders and gas holders.

The chemical composition of the fuel determines the fire temperature of a gas stove. Methane, when burned, forms a fire with a power of 900 degrees at the top point.

Combustion of the liquefied mixture produces heat up to 1950°.

An attentive observer will note the uneven coloring of the burner reeds of a gas stove. Inside the fire torch there is a division into three zones:

- Dark area located near the burner: there is no combustion here due to lack of oxygen, and the temperature of the zone is 350°.

- A bright area lying in the center of the torch: the burning gas heats up to 700°, but the fuel does not burn completely due to a lack of oxidizer.

- Translucent upper section: reaches a temperature of 900°, and gas combustion is complete.

The figures for the temperature zones of the fire torch are given for methane.