Every year, an increasing number of apartment and private house owners are abandoning the usual “compact” and monoblock toilets. They are being replaced by an aristocrat among plumbing fixtures - an installation. This is an easy-to-use sanitary product with an excellent design, yet affordable to the middle class. An additional bonus to the advantages of a wall-hung toilet is the need to install a false wall made of plasterboard, with the help of which the utility lines of the toilet or combined bathroom are hidden.

Despite the fact that installing the installation is much more complicated than installing monoblocks or compact toilets, many homeowners take on this work, performing all the operations on their own, without the involvement of specialists. Such independence is fraught with negative consequences during the operation of the toilet.

Knowing all the nuances of installing an installation will help you complete the work efficiently, without unpleasant surprises in the future. The editors of the StroyGuru portal decided to help the craftsmen and analyze in detail how to install a wall-hung toilet with a do-it-yourself installation with a selection of photo and video materials.

Niche preparation

Installing a wall-hung toilet involves using a niche to place the frame.

As already mentioned, a certain strength of the walls is required for fastening. The installation design can withstand a weight of up to 400 kg, part of the load from which is transferred to the wall. This issue must be approached with special care. In order to place the installation, you need to prepare a niche. It should be as follows:

- Height – 1 m;

- Width – 0.6 m;

- Depth - up to 0.2 m.

In some cases, creating such depth is problematic. In such cases, it is necessary to go deeper into the possible value, and hide the remaining elements with plasterboard panels.

By hiding the main part of the device, certain opportunities for decorating and improving the interior open up. It’s not worth just placing the installation near the wall and sheathing it with plasterboard, because... placing a toilet with a conventional layout will be cheaper and easier. In addition, it will take up less space.

Installation installation

Do-it-yourself toilet installation on a special frame fixed to the wall is a more expensive process, but faster and more reliable. The installation will be fastened to the floor and a solid wall.

The technological sequence is as follows:

1. Fastening the metal frame. It has corresponding holes with which it is fixed to surfaces with dowels. Two points for fixing to the floor and two to the wall. Sewer and water pipes are supplied to the installation site. The installed frame must be checked for levelness using a building level. It is necessary to maintain exact parallelism to the wall being installed, because even minor distortions can lead to interruptions in operation and even breakdowns. Horizontal adjustment is carried out using mounts in the wall, which change their position.

This stage also involves setting the height of the wall-hung toilet. It will depend on the height of the residents, usually 0.4 m. The height of the bowl can be adjusted in the future.

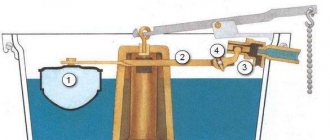

2. Supplying water to the drain tank. You can use a flexible or rigid system. Professionals often use hard, because... it can last longer. You can also use flexible hoses, but if they break down, you won’t be able to get to them and replace them quickly. During the installation of the liner, the valve tap of the tank, as well as the drain from it, must be closed.

After connection, you should check the reliability of the connections. To do this, open the water supply and start filling the tank. If there are leaks, they are eliminated. Water may remain in the tank.

3. Connection to sewerage. The toilet drain hole must be inserted into the sewer pipe outlet using the appropriate corrugation, but some models can be connected without using it. Upon completion of the connection, the tightness of the system should be checked by test drains. To do this you will need to temporarily screw the bowl to the frame. After this, remove it again, it will be installed at the end of the installation.

The correct installation of the sewer pipe must be completed before the installation begins. Pipe diameter – 100 mm. It must be laid with an appropriate slope. You can read about it in the corresponding article.

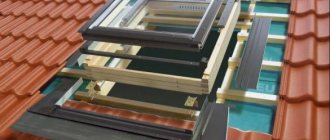

4. Covering with plasterboard sheets. The installation of a wall-hung toilet must be accompanied by decorative finishing of the functional elements. To finish bathrooms, it is necessary to purchase waterproof double plasterboard. It is more durable than the usual one. The sheets must be mounted to metal profiles and directly to the toilet frame. The installation instructions must contain the necessary information on the cutting method, indicating the points for cutting holes.

Sheathing can be done in two ways: over the entire area of the wall or only along the installation plane. The second method involves the formation of a small shelf above the bowl, which can be used to place necessary items.

Subsequently, the installed barrier is finished with tiles or panels along with the rest of the room.

5. Finally, it is necessary to install the toilet on the installation, namely the bowl. It should be hung in the appropriate place using two fasteners.

6. The last, easiest step is to install the flush button. They are pneumatic and mechanical. The process is not complicated, because... everything should already be connected to the required opening in the wall. The mechanical button is installed using special pins and then adjusted. For the pneumatic one, you just need to connect the appropriate tubes and everything is ready.

During the activity, it is necessary to especially control the installation process of the installation frame, because The course of further installation will depend on the correctness. Figuring out how to install a toilet installation is actually not difficult. It is enough to follow the recommendations of the installation instructions, and in addition watch the corresponding video about the process, and everything will work out.

Hanging plumbing fixtures are gradually gaining popularity, especially among owners of small bathrooms. However, not everyone likes wall-hung toilets - outwardly they seem unstable and unreliable. This impression is deceptive, because it is carried out using an installation system that is hidden behind the finishing material of the wall. Let's take a closer look at the advantages of hanging plumbing fixtures and read the instructions for installing them.

System health check

When all installation activities are completed and the installation elements are connected to the main communications, you need to make sure that there are no malfunctions in the system. To do this, first turn the water tap valve and monitor the flow of water into the tank.

As soon as the tank is full, press the drain button and repeat this action several times. Then they carefully inspect all parts of the system.

If the structure works correctly, and water does not ooze from the pipes and connecting parts, proceed to decorative finishing. Detected dampness or droplets of water clearly indicate a problem that needs to be corrected before tiling work begins.

The most common causes of problems:

- Water is leaking from the tank - perhaps the sealing gaskets were not installed correctly or moved out of place during the installation process. You need to turn off the water supply, unscrew the connecting bolts, check the location of the gaskets and correct them or replace them if necessary.

- The toilet bowl is wobbly - you need to look at the fasteners of the toilet itself and the connecting elements of the installation, and then carefully tighten them so that the position of the plumbing fixtures is clearly fixed. It is advisable to act very carefully, otherwise there is a risk of breaking the threads of the reinforcement fasteners or even splitting the ceramics.

- Water stagnates in the toilet - a clear indication of improper placement of the drain pipe. To resolve the issue, you will have to dismantle the plumbing, install the drain strictly at 45 degrees, and only then return the toilet back.

- Dampness on the floor and around the base of the toilet - most often this phenomenon is associated with poor sealing of the connecting corrugation. To eliminate a leak, just cover the joints with another layer of sealant and let it dry well.

All these problems are not very difficult and can be easily fixed with your own hands at home. If the owner does not have the desire or time to carry out repairs, you can call a professional plumber, and he will quickly fix the problems that have arisen.

Selecting and purchasing a toilet with installation

The main condition for purchasing the installation is that it must match the model of the toilet you have chosen. Often, wall-hung toilets are equipped with an installation system initially; it is best to prefer this option.

Take measurements of the niche where the installation will be installed

The installation must match the size of the niche in which it will be placed.

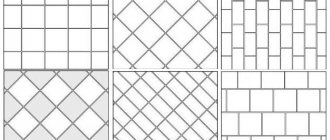

There are two types of installations

Block

– is attached to the wall using conventional anchor bolts, which are the main support of the entire structure.

Framework

– is a frame on legs, thanks to which the height of the toilet is adjusted. The frame is attached in four places. An option is possible when all four fasteners are fixed on the wall - this installation method can only be used in the case of solid walls.

If the wall is not stable enough, choose an installation with two fastenings on the wall and two on the floor. The last two fasteners bear the main load.

- Provide a service hatch just below the drain button. This will make it much easier if necessary.

- Use modern flush buttons that save water. These can be two separate buttons, one of which drains the full volume of water in the tank, and the other half. Another option is to have Start and Stop buttons.

- Consider the location of the drain button relative to the tile elements. Design the button either strictly between two tiles, or in the center of one of them.

- The top edge of the toilet should be no higher than 45 cm from the floor and no lower than 40 cm.

- The thickness of the wall hiding the installation system should not be more than 7 cm.

- The standard distance between the mounting holes of the toilet is 18 or 23 cm.

- Monitor the correct installation at all stages of work. This will help to avoid gross errors during installation and problems during the operation of plumbing equipment.

A toilet installed in accordance with all the rules can withstand a load of up to 400 kg!

If you doubt that you can carry out all the work correctly and efficiently, we advise you to seek the help of qualified specialists. Well, self-installation of the installation system will certainly help you save your budget. Feel free to use technological and design know-how to create an original and practical interior.

103583

Common Difficulties

The main problems arise due to the limited size of most bathrooms. This is especially true for strictly residential buildings, when in addition to the small “dimensions” there is added poor geometry of the room - the absence of right angles and parallels in the enclosing surfaces. In this case, even the slope of the wall is checked before installation. And leveling the walls further reduces the room for “maneuver” when installing the installation under the toilet.

The correct choice of type and model of installation, as well as the accuracy of markings, frame location and adherence to the installation diagram will help you avoid mistakes and alterations.

And the main condition is careful handling of mechanisms and sanitaryware. Even “tightening” the fastenings of the intake and exhaust valves or the hinged bowl can lead to a violation of the tightness of the connections or damage to the device itself.

What is important to know. It is necessary to buy installations and plumbing from reputable brands. It is better to do this with dealers or trading companies that have appropriate agreements with service centers and provide a guarantee for the purchased product. In addition, if necessary, you can buy additional accessories or a repair kit for the selected installation model from such sellers.

Installation of a toilet without installation, on a concrete base

Sometimes people are interested in how to install a wall-hung toilet without installation. Of course, installing a toilet on a frame can be replaced with a cheaper option - installing it on a self-made concrete base.

A metal structure with special devices designed to secure plumbing equipment is called installation

. It is used for installing bidets, sinks, and toilets. Plumbing fixtures attached to the wall help save space and create a feeling of lightness. In addition, installation of the installation helps to hide all communications and pipes that are located in the wall, allowing you to achieve an attractive appearance of the room and hygiene.

We install it ourselves

When installing a toilet installation with your own hands, a person can use previously acquired skills, instructions included with the design, and video clips from the Internet. There is enough information to get an idea of what the design should look like in the end, and how to achieve the desired result. But, if you have doubts about your strengths, it is better to seek the help of professionals. Using modern tools, they will quickly cope with this task and in the near future will provide a decent result of the work.

If you think there is not enough information, you can always supplement it and express your opinion in the form below “Your opinion”.

Recently, conventional floor-standing toilets are increasingly being replaced by wall-hung structures. They require placement in a smaller area and also have a more modern appearance. Therefore, the process of displacement of traditional models by them is quite natural. However, following modern trends has its negative sides - more complex installation, longer and more expensive. However, you can successfully get out of this situation if you learn how to install a wall-hung toilet with a do-it-yourself installation.

Types of toilet installations

Today, there are 2 types of installations that have their own design features.

Block structures

They are mounted only on main walls and consist of a plastic tank with fittings. A set of fastenings is additionally included with the toilet. This type of installation for toilets is installed in a pre-prepared niche and is completely hidden in the wall. The main advantage of this design is accessibility, but if there are no solid walls in the bathroom, then installation is impossible.

After purchasing a toilet, many decide to install it themselves. The procedure is very simple and does not require special skills. Increasingly, people are buying in order to save space; there is an additional design - an installation, which ensures that the toilet is attached to the wall. In such cases, installing a toilet installation yourself can raise a number of questions. To provide a complete picture of the work process itself, there is a special toilet installation instruction that will help in acquiring all the necessary knowledge.

Let's take a closer look at the entire sequence of work that must be done when installing a wall-hung toilet.

Before starting work, you need to check that you have all the tools that may be needed during the work process. This is a tape measure, a pencil or marker, a hammer drill with drills for concrete, a building level, spanners and open-end wrenches.

Now you should unpack the box with fasteners and see if everything is available. Manufacturers try to complete their products as much as possible so that a person does not have to buy additional fasteners. Therefore, it is enough to compare the equipment available with the one specified in the instructions. Let’s begin the work process.

The first step is to start applying markings that will indicate the mounting location. The location of the sewer drains must be taken into account to ensure the installation procedure is as simple as possible. Typically, the installation system should be located at a distance of 14 mm from the wall.

Now you should mark the attachment points of the cistern; usually it is located at a height of 1 meter from the floor level. It is also necessary to mark the mounting points of the installation elements on the wall and floor. After applying the markings, you need to use a hammer drill to make holes in the wall and floor where the installation fasteners will be located, and insert dowels into the holes. Regardless of the type and features of the installation, it will require horizontal and vertical fastening. It is necessary to install mounting anchors into the holes with installed dowels; with their help, the installation will be attached to a vertical plane. When installing, it is important to follow the sequence so that in the future there is no need to adjust the vertical level. Now you can install the installation structure itself and attach it to the levels. It is very important to install the housing in a level position relative to the vertical and horizontal levels. Only after the installation is installed correctly can all fasteners and bolts be tightened, firmly fixing the structure. Now comes the stage at which the sewerage system is connected to the installation and secured. The design is initially equipped with special plastic clamps, this will significantly facilitate the work and speed up its implementation.

After all the work is completed, you need to once again make sure that the installation is securely fastened, that the bolts are properly tightened, and that the structure complies with the levels. At this stage of control, you should be extremely careful; any inaccuracy or poor fixation of the structure can lead to breakdown in the future.

How to properly carry out preliminary marking?

To make markings, take a simple pencil or marker, a tape measure and a building level. All measurements are taken taking into account the dimensions of the installation itself. To ensure that subsequent installation is correct, first determine the location of the central axis of the structure and mark it with a straight line.

Then, using a tape measure, measure the distance from the conditional edge of the installation to the wall - it should not be less than 13.5 mm. Mark with strokes on the wall the area where the drain tank is expected to be located and mark on the floor and walls the places for the fastening mechanisms of the equipment.

When marking, be sure to use a level. It will help align the system vertically and horizontally, which will ensure its subsequent correct operation.

Correctly made markings make it possible to install the installation exactly where it will not clutter up the space and interfere with the entrance and exit to the bathroom.

We study installation installation on video

Installation can be done in several ways. For example, to provide structures with higher reliability, people buy special brackets. But the manufacturer of the pendant does not provide for such a design, so the brackets are not included in the package and are not mentioned in the instructions.

Therefore, to understand how the work will differ, you can visit the Internet and watch the corresponding video, which shows all the intricacies of the work process. In the video clip, each stage will be described in as much detail as possible, so that even a person who has no idea about this procedure can cope with the work quickly and efficiently.

The result is a strong and reliable fastening of the toilet installation that will last for a long time.

Connecting communications

To connect to the water supply, the installation kit includes an inlet valve with an external outlet for a ½-inch pipe and an angle shut-off valve inside the installation.

For toilet installations with a bidet function, an additional tube is provided for the intimate hygiene fitting. And to ensure a comfortable temperature, such models are also connected to the electrical network to heat the water that is used for washing. And for this purpose, fastenings are provided for mounting the protective tube of the electrical wiring.

Design Features

Before proceeding directly with installation, you should understand the design. Installing a wall-hung toilet will become much easier when you know its structure and operating principle. It will immediately become clear how to act correctly and what is necessary.

The main feature of the product is that only the bowl remains visible.

The basis of the entire structure is a durable metal frame. The visible part is directly attached to it. It is from this element that all installation work starts. The frame must be firmly attached to the wall and firmly placed on the floor. As a result, it should be able to support an adult without any problems. Based on this, we can say that it will not be possible to fix the frame to a weak wall.

The frame has an element that allows you to change the height of the bowl, which is secured using special pins. They are the main fasteners when installing a toilet installation.

A common option is to attach two installations at once - a toilet and a bidet.

The second element is a plastic drain tank. He is also hiding in the wall. It has a specific shape, because must fit in limited space. The tank is also installed in a metal frame and insulated with a special material that prevents the formation of condensation. There is a cutout on the front wall of the tank for mounting a drain button. Modern models, including floor-mounted ones, have a dosed water discharge - 3 or 6 liters.

The next element is the toilet bowl. The only part that is visible and in active use. It has a traditional shape, but some designer models have original configurations.

The delivery set contains all the necessary parts and accessories. The attached instructions can also show the entire installation sequence of the toilet installation.

Advantages and disadvantages

Installation toilets have the following advantages:

- Attractiveness and aesthetics;

- Minimum dimensions allowing maximum free space to be used in small rooms;

- The missing legs and support simplifies the cleaning process;

- Versatility of design, providing a choice according to taste and budget;

- Failures rarely occur, and if they do occur, repairs are not complicated.

The disadvantages include high cost. Taking into account the installation features with the need for additional work, the installation price can exceed up to 2 times the price of placing a floor-standing analogue.

But given the growing popularity, manufacturers have organized the release of relatively inexpensive models that are becoming available to a wider range of consumers.

Another disadvantage is the presence of hidden elements that are not very accessible for maintenance and repair.

Installation technology

Installing a wall-hung toilet using a special frame installed in the wall is more expensive, but more reliable and faster.

The installation must be mounted to the floor and main wall

Installation steps:

- Installation of a steel frame - through special holes it is attached to the main wall and floor using dowels. Sewer and water pipes are installed at the installation site. The frame (installation) should be checked for evenness using a level. It must be clearly parallel to the wall to which it is attached. At this stage, the installation height of the wall-hung toilet is also set - 40-43 cm. It depends on the height of the apartment owners.

The height of the toilet bowl is adjustable during installation

- Water supply to the tank. It can be flexible or rigid. Experts insist on the hard version, as it lasts much longer. While the liner is being installed, the valve in the tank is closed.

During work, the water drain from the tank should be shut off.

- Connecting the toilet to the sewerage system. The toilet outlet is inserted into the sewer outlet and the connection is secured using corrugations. After installation, it is necessary to test the system - do a test drain. To do this, the toilet bowl is temporarily completely screwed to the frame. It is then removed again, as it is usually installed at the final stage.

Many installation kits are connected to a sewer pipe without the use of corrugations

- Covering the work area with sheets of plasterboard. For the plumbing unit, choose sheets of waterproof double plasterboard, which is stronger than regular plasterboard. The panels are mounted to a frame and a metal profile, which is mounted on the wall. The instructions included with the product contain a detailed cutting diagram of the material with locations for cutting the necessary holes. There can be two options for covering: for the entire wall area or just to cover the installation. In the second case, an improvised shelf will appear above the toilet bowl.

An improvised shelf above the toilet and bidet can be used for decoration or necessary things

- Facing the partition with ceramic tiles or panels similar to the finishing material of the bathroom.

The wall cladding behind the toilet should be in harmony with the rest of the room’s decoration

- The final stage is the installation of a wall-mounted toilet, specifically its bowl. It is hung on a designated part of the steel frame using two pins.

Sheets of plasterboard with lining cover the installation and the flush cistern, leaving the toilet bowl and flush button

Particular attention should be paid to the correct installation of the installation, since the correct execution of subsequent work depends on it

Sewage supply

Supplying water to the toilet installation does not cause any difficulties. And for any connection of the tank (from the side or from above), you can always lay a half-inch rigid or flexible pipe. With connection to the sewerage system the situation is more complicated. The diagram for the installation shows two types of connections:

- the knee goes down at a right angle;

- the knee is rotated 45° in the plane of the frame.

In most cases, the connection of the installation to the sewer system is based on these options.

The first option, for example, is used for direct connection to the drain, when the frame stands in the same niche as it. The second option is used when laying a drain pipe to the riser along the wall.

But there are cases when both options are not suitable due to limited space and the unique geometry of the bathroom - the large diameter of rigid pipes and fixed elbow angles prevent this from being done correctly. And to solve the problem of how to turn the sewer elbow away from the installation and provide the required slope angle, corrugated adapters are used. For example, corrugation D 90/110 MM FLEXI from ALCAPLAST. But in this case, it is necessary to check the slope of the corrugation.