Effective and reliable materials for thermal insulation of loggia floors include loose expanded clay and tile extruded polystyrene foam Penoplex. They are installed under any floor covering: concrete screed, wooden floor, parquet, linoleum, ceramic tiles, carpet, laminate.

These insulation materials have low thermal conductivity, are easy and quick to install, and have an affordable price. The only thing that distinguishes them is the method of installation on the loggia floor: expanded clay is placed in bulk in the spaces between the sheathing, and Penoplex is attached to the base with panels of different thicknesses.

What is the best way to insulate a floor under a screed? We understand the choice of optimal material

Since about 30% of all heat loss occurs through the floor, it needs insulation in the same way as other structural elements of the room - walls and ceiling.

The main method of thermal insulation is insulating the floor under the screed. When insulating under a screed, it is very important to choose the right thermal insulator. Insulation materials such as expanded clay, polystyrene foam, mineral wool, penoplex and polyurethane foam are most often used as insulation for installing a heat-insulating layer under screed. You can also install a floor heating system, which can be infrared, electric or water.

Insulation with mineral wool

Mineral wool has high sound insulation properties. Due to the high hygroscopicity of the insulation, the mineral wool thermal insulation layer must be completely isolated from contact with moisture.

Technology of floor insulation with mineral wool mats

Before installing mineral wool mats, it is necessary to remove the old floor covering

Before installing mineral wool mats, it is necessary to remove the old floor covering, clean the floor from existing contaminants, cover cracks and crevices, then lay a waterproofing film, mineral wool mats and a vapor barrier membrane. Clamps are installed on top of the structure in order to provide the necessary ventilation gap, and a reinforcing mesh of 3 mm wire is mounted on top of the clamps.

A leveling concrete screed is applied on top of the reinforcing mesh. If significant static and dynamic loads will not act on the floor, then the concrete screed can be lightened by adding expanded clay to it.

Penoplex screed - what kind of technology is it?

Penoplex boards have good density and strength; they are not afraid of high loads. Both sand and cement screed and self-leveling mixtures fit well on their flat surface.

Its homogeneous structure is similar to a whole arsenal of small cells measuring 0.2 mm in size. Unlike other insulation materials, it has virtually no vapor permeability and does not absorb moisture. Penoplex is produced by industry mainly in the form of rectangular slabs of different lengths, widths, and thicknesses.

For insulation, you can use not only slabs, but also polystyrene granules, which are sold in bags. Granules are added to the concrete solution to produce polystyrene concrete. But it is more convenient to use penoplex in slabs under floor screed for insulation.

An uninsulated floor leads to increased humidity in the house, which results in the appearance of fungal mold. The room loses up to 20% of heat through cold floors. People suffer from colds and leg joints suffer.

Before insulating floors with foam boards, you need to prepare the base. The concrete base is freed from dirt, potholes and irregularities are repaired. The earthen base is first covered with a sand cushion, and before screeding it is compacted and leveled.

Pros and cons of floor insulation under screed

Compared to other insulation materials, the manufacturing technology of tile penoplex is aimed at protecting the material from moisture absorption. Its closed cell structure gives the material frost resistance and compressive strength.

Penoplex on the floor under the screed has the following advantages:

- Expanded polystyrene boards are not subject to combustion, do not emit toxic fumes, are not afraid of high humidity, and do not wear out or rot for a long time. Their service life is determined to be 50 years.

- The material is endowed with a high thermal conductivity coefficient. Its value is 0.030 W/(m*C), which indicates its good thermal insulation properties. The vapor permeability coefficient is 0.007-0.008 mg/(m*hour*Pa). Its low vapor permeability is comparable to roofing felt.

- The high strength of the material allows you to place heavy pieces of furniture on it without fear of squeezing.

- The slabs are well cut to the required dimensions and are easy to install.

- The porous structure of penoplex gives the slabs light weight.

- Weather conditions do not interfere with working with the material.

Important! Penoplex panels do not lose their thermal insulation and other qualities throughout their entire service life.

The disadvantages of penoplex products include their high price, strong smoke during smoldering, and the fact that they are destroyed under the influence of chemical solvents and high temperatures.

How to choose floor insulation: a comparative review of 10 different options

The question “Which insulation is better for the floor?” are asked by everyone who loves comfort. It's always nice to walk barefoot without fear that your limbs will freeze. And this is especially true in the off-season, when central heating (if any) is not yet turned on, and in winter, when the temperature outside is sub-zero. It is then that people often turn their attention to floor insulation. We will tell you how to choose the material and how to lay it correctly. After all, a well-insulated floor is one of the components of heat preservation in a living space

When choosing insulation materials, it is important to take into account the climate zone (how cold it can be in winter), the characteristics of the room and its purpose, the type of existing or planned floor covering. For example, floor insulation in an apartment and in a wooden house will differ significantly

Dry screed with expanded clay

- If the subfloor is made of concrete, it must be insulated from moisture. To do this, lay a thick plastic film, preferably in one piece; but if its width is not enough, overlap the strips by 20 cm and glue the joints with tape. The film sides should rise along the perimeter of the walls. Their height should exceed the total thickness of the screed and floor covering.

- A damper tape is laid along the perimeter of the walls. It is used to compensate for the expansion of materials, preventing arbitrary opening of the floor and their deformation due to increased air temperature.

- In order to spread expanded clay in an even layer, beacons are used. It should be noted that beacons that are used under concrete mixture are not suitable, since they are not high enough. Usually take guides at least 3 cm high and attach them to the floor with mortar. Expanded clay is poured between the guides and the surface is leveled with a wooden rule. As a standard installation of a new expanded clay floor, the floor rises by 6-8 cm. This value includes the height of all materials, including the top slabs.

How to cover expanded clay?

The bulk material is covered with slabs of plywood, chipboard, OSB, gypsum fiber board. Of these, the most popular are gypsum fiber sheets (GVL). They are laid in 2 layers. The reverse side is first coated with special glue for gypsum plasterboard. A good option if the sheets have folds along the edge of the perimeter. They allow you to join them tightly, without gaps. The folds are also coated with glue.

Laying the slabs begins from the corner near the window and moves towards the door. At the same time, make sure that the seams of each next row are spaced apart from the adjacent ones. It resembles brickwork. Upon completion of work, any finishing coating is laid.

Forced insulation of a finished wooden floor

A cold floor in a room does not leave a pleasant impression and sometimes you have to insulate it.

To do this you need:

- Remove the baseboards around the perimeter of the room.

- Carefully, without damaging, remove the finishing boards. Number them in order of location, remove the nails.

- Remove the subfloor.

- If necessary, add expanded clay just above the bottom level of the joists, carefully level it and tamp it down.

- Cut penoplex plates according to the distance between the joists and along the length of the room.

- Lay the first layer, seal the joints with tape.

- Lay the second layer in the same way, ensuring that the joints overlap. Tape the joints.

- Restore the subfloor.

- Lay the finishing coating, installing the boards according to the numbering in reverse order.

- Nail the baseboards.

In this case, we recommend using plates with a minimum thickness of 20 mm in two layers. This is enough to successfully resolve the issue.

Useful article? Add to your bookmarks!

Options for thermal insulation materials

The result of the work depends, first of all, on the quality of the materials. When assessing the positive qualities of thermal insulation and the thermal conductivity coefficient of different materials, one should not forget that natural and synthetic materials have different technical characteristics, on which the quality of work and the quality of the thermal insulation itself depend. Among the most popular materials today, it is worth highlighting insulation made from natural materials - mineral wool, expanded clay, glass wool. And artificial materials - polystyrene foam, extruded polystyrene foam, polyurethane foam. These insulation materials are quite widely represented on the market, however, in order to select the right material you need to know the basic characteristics of the material.

Expanded polystyrene

Expanded polystyrene or polystyrene foam consists of granules bonded together during the manufacturing process. Density is a qualitative indicator of a material. The higher the density of expanded polystyrene, the higher its thermal insulation qualities. Expanded polystyrene is produced in slabs with a thickness of 20 to 50 mm. The main application is thermal insulation of buildings and communications. The material is lightweight and does not absorb water. However, among the disadvantages it is worth noting that mice often settle in the thickness of the foam. It is flammable, so you need to be careful when installing. To insulate the floor on the ground, material with a high density is used, low density is used for installation on walls and ceilings. For the floor, slabs with locking joints at the ends are used.

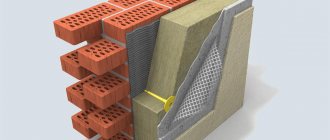

Walls

Insulation of external walls is extremely rarely carried out separately. After all, it will then lead to improper distribution of heat throughout the material. The walls, floor and ceiling will warm up first, and only then will the air temperature begin to rise. This, of course, is not at all what is expected from a quality bath.

Formally, there is no need for a counter-lattice. But any experienced craftsmen install it to make it easier and faster to create a ventilation duct. The wood must be impregnated with an antiseptic. If installation is on a brick wall, it is advisable to use dowels; they compensate for the excessive rigidity of the structure and speed up installation. Foamed glass is technically perfect, but it turns out to be too expensive to use.

Penoplex

Penoplex, which is often called extruded polystyrene foam, has high strength, resistance to deformation and rotting, water resistance, environmentally friendly composition and the absence of toxic substances. Using penoplex as insulation can significantly reduce energy costs and save on the purchase of additional heating devices.

With high-quality installation, penoplex can provide ideal thermal insulation properties.

To lay penoplex, the soil is leveled with gravel, thoroughly compacted and covered with a layer of compacted sand. Then a rough base is created from reinforced concrete, which is left to dry for a week, after which a waterproofing layer is laid on it, and penoplex is placed on it. Penoplex is covered with another layer of waterproofing and filled with concrete screed.

We do the insulation of a bathhouse from the inside with our own hands: what and how, different bathhouses need to be insulated differently

Home page » What is the best material to build a bathhouse from » Insulation of a bathhouse » We do the insulation of a bathhouse from the inside with our own hands: what and how, different bathhouses need to be insulated differently

Insulation may be required either by a new, just built bathhouse, or by an already used one, but requiring modernization or repair.

You can contact a specialized company that provides such services, paying for both materials and installation services. Or you can insulate the bathhouse from the inside with your own hands, thereby saving on the cost of services. But our article is intended to help and understand all the intricacies and intricacies.

Semi-dry and dry screed

Dry screed gets its name due to the fact that liquid cement-sand mixtures are not used at all in its construction.

In essence, the creation of such a screed is the filling of expanded clay as insulation and filler between the joists of the subfloor.

The technology for laying dry screed consists of laying waterproofing, damper tape and backfilling the expanded clay itself. The base of the subfloor is laid on top of the dry screed. GVL sheets are most often used as such.

Dry expanded clay screed can be covered only with materials that can withstand moisture, withstand severe mechanical loads and not crumble. Therefore, the use of chipboard, plywood, etc. is strongly not recommended.

A semi-dry screed is a cross between a regular cement-sand screed and a dry expanded clay screed. The meaning of this option is to pour expanded clay onto a rough base (as in the case of a dry screed), followed by pouring concrete.

This solution is convenient due to the absence of the need for thorough preparation of the subfloor and lower consumption of central fiber. However, it is worth considering that in terms of its ability to withstand loads, a semi-dry expanded clay screed is much inferior to the “wet” version.

How much does Penoplen cost?

Extruded polystyrene foam XPS PENOPLEX FOUNDATION 1185x585x50 mm buy at a price of 289.0 rub.

Interesting materials:

How to calculate the remaining vacation days upon dismissal? How to calculate lighting in the kitchen? How to calculate vacation of 28 calendar days? How to calculate vacation for a part-time working month? How to calculate vacation? How to calculate vacation calendar days? How to calculate vacation pay with a minimum wage? How to calculate the fall of the Lena River? How to calculate penalties for 1,300 refinancing rates? How to calculate inventory turnover period?

When to choose expanded clay

The range of heat-insulating materials on the modern market is so large that it can be difficult to settle on just one. However, it is worth learning the full range of properties of this unique material in order to understand that there is no better option than to insulate the floor with expanded clay.

A list of properties that make this simple material a leader among its competitors:

- Low thermal conductivity - the porous material contains air bubbles, which provide high-quality thermal insulation. A 10 cm layer of expanded clay exceeds the thermal conductivity parameters of a similar wooden surface by 3 times, and brickwork by 10 times.

- Sound insulation is a property that is in demand in apartments of multi-storey buildings; the expanded clay floor will serve as a reliable barrier to the penetration of noise from neighbors below, while simultaneously preventing the spread of sounds in the opposite direction.

- The strength of the material allows it to be used in the bottom layer of the floor pie without additional supporting structures (expanded clay is available in different grades of strength from 250 to 600).

- Resistance to rot and fungi, mold (unlike wood-based materials) increases the service life of the floor and its durability.

- Chemical inertness - expanded clay is a natural material, does not release any substances into the environment, and is also resistant to chemicals.

- Heat resistance - quality is important in terms of fire safety.

- Frost resistance - expanded clay does not lose its properties at extremely low temperatures.

- Light weight - allows you to insulate the floor with expanded clay under a screed in houses where a large load on the floors is undesirable (read: “Insulating the floor under a screed - practical tips”).

- The granular fraction of the material makes it easy to work with - one person who does not have construction skills can handle the backfill.

- Low cost is an additional bonus for a material that has a range of excellent qualities.

The only disadvantage of expanded clay is its ability to retain moisture for a long time. This drawback can be easily mitigated by following the technology of installing a floor with expanded clay and carefully gluing the waterproofing layer.

Screed in the apartment.

Dear REPAIRERS, please tell me how best to make a screed in an apartment, beat off the horizontal with a water level without taking into account the tiles and glue, the result is 12 cm, you can simply fill it with sand concrete solution, hiding all the electrics, or you can put 5 cm of red penoplex, secure it with fungi, lay out the wiring, throw cellophane around the edges of the damper tape and fill in 7 cm of screed. And another question is penoplex for soundproofing the floor, is it normal?

Masters online: 381 Orders per week: 1,214 Offers per day: 542

I like the second option better