- Carbon fiber reinforcement.

A canvas made of this modern composite material, glued in several layers, allows you to very efficiently solve the problem of how to strengthen a wooden floor beam. The carbon fiber is glued with epoxy glue, covering the joints of the strips with transverse layers. After the glue hardens, it turns into a strong and rigid frame, almost as good as metal and perfectly resistant to loads.

The advantage of this method is its ease of installation and the absence of the need for installation tools.

This method is more suitable for cases where the ends of the beams are damaged, which often occurs when they are poorly waterproofed in the support sockets. They are replaced with prostheses made from paired trusses made of steel reinforcement with a cross-section of at least 10 mm.

Before strengthening the ceiling in a house with wooden floors, a temporary support is installed under the damaged beam and the floors are dismantled from the bottom and top 1.5 meters from the wall.

The rotted end is cut off, and the prosthesis is inserted vertically into the opening. Then it is unfolded, placed in a horizontal position and pushed onto the beam, after which the free end is pushed into the support socket in the wall. The prosthesis is secured to the beam with nails.

- Electric heated floor

Installation of ventilation systems

Load redistribution

You can reduce the load on load-bearing joists by installing supports under them or by installing additional beams under the ceiling.

- Installation of intermediate supports or struts.

With this method, the load is partially transferred through the supports to the underlying floors or side walls, so you must first make sure that they can withstand it. It is rarely used to strengthen the floors of the second floor, since the racks and struts are difficult to fit into the interior of the first floor, and they also create inconvenience for movement around the room. But this is the best solution to strengthen the floor joists from sagging in a wooden house.

The larger the lags on which the ceiling lies, the less load falls on each of them. By installing additional beams of a suitable cross-section between the existing ones, you can not only remove excess load from them, but also increase the total weight of the floor. Which consists of the weight of insulation, floor and ceiling coverings, furniture, equipment and people on the floor.

Strengthening wooden floors - ways to strengthen the ceilings and beams of the second floor

The main element of attic and interfloor floors in many private houses is a wooden beam. The service life of wood floors is limited due to the properties of the wood, especially if it has been poorly processed or has been subjected to stress and moisture.

As a result of such factors, the beam ceases to cope with the function assigned to it (sagging, deflection, curvature is possible) and reinforcement of the wooden floor beams will be required.

In addition to damage and loss of load-bearing capacity of floor and ceiling beams (joists, purlins), strengthening may be dictated by an increase in the load on the floor.

Glued laminated timber

To increase the strength or size of solid beams, they are fastened together manually during installation of the floors. For the same purposes, laminated veneer lumber manufactured at enterprises is used. It consists of several bars connected to each other. The thickness of an individual element is regulated by the number of products glued together. Glued laminated timber is produced at the factory by pressing, its length reaches 12 m.

Finished products retain the characteristics of solid lumber and can be nailed without loss of strength or cut into pieces of the required size. The only drawback of such structures is their high cost. It is necessary to carefully calculate everything before installing the first floor ceiling on wooden beams.

Note! Glued laminated timber is often used in construction for the installation of arched ceilings.

When to strengthen wooden floor beams

- poor condition of the beam structure. The result is wood damage. High humidity, temperature changes, the activity of various pests (bark beetles), cracking - all this leads to deformation of the floor beam;

- reduction in load-bearing capacity. Under their own weight, constant and variable load, floor beams can bend. According to the standards, if the deflection is within 1:300, then there is nothing to worry about. For example, if a beam is 2500 mm long. bent by 10 mm. this corresponds to the normal deflection value. If the deflection is greater, it should be strengthened;

- the need to increase the load-bearing capacity of the beam. Associated, for example, with the reconstruction of an attic into an attic or living space. Such a restructuring will lead to an increase in constant and variable loads on the floors of the second floor, which automatically requires a change in the cross-section of the installed wooden beams.

Within the article, several common methods of strengthening the ceiling (repair, reconstruction) will be given. But only a professional can accurately answer the question of how to strengthen wooden floor beams and only after analyzing the condition of the structure. After all, in each case the decision will be individual.

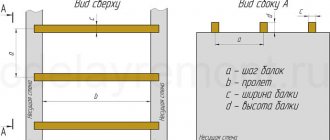

Using the table, you can get an idea of what cross-section a beam should have under a certain load.

How to choose a window sill?Installation of PVC windows

- Covering the drain hole with your own hands

A simple solution

Probably the most popular option should be the simplest option for strengthening the attic floor, namely, installing a pillar supporting the problem beam. This simple method solves the issue of accepting loads with a vertical support. The work, in this case, is reduced only to the installation of the pole. As a result, the main problem disappears, but two others appear in its place.

One drawback is the formation of a point load acting on the floor. The second is related to the aesthetic side of the issue. The fact is that a pole installed in the middle of the room will look ridiculous. But if you decorate it in an original way, the support can turn into an interesting decorative element, and also functional.

There is another way to strengthen the attic floor. But its use is effective only in cases where the ceiling beams do not have deformations. The load-bearing capacity of the structure is increased by installing additional purlins with mandatory winding of their ends with roofing material. Protective measures avoid mechanical damage and help resist moisture.

Ways to strengthen wooden floor beams

The main types and methods of strengthening wooden floors are given in order of increasing labor costs and duration of work.

Type of amplification without changing operating conditions

Reinforcement with wooden overlays

The method is used when the tree is damaged. The pads are installed on both sides of the timber beam (on the sides or top and bottom), as tightly as possible to it and are fastened (tightened) through with a bolt. It is important to treat the damaged area and pads with an antifungal solution. In critical cases, if the area is severely damaged, it is better to remove it. To strengthen the beam, you need to attach an overlay along its entire length.

Reinforcement of spans with metal plates (plates) or rod prostheses

Steel plates are used instead of the wooden ones described above. The metal also needs to be treated with an anti-corrosion solution. The device diagram is shown in the figure.

Reinforcement of flooring with carbon fiber (carbon fiber reinforced plastic)

Modern reinforcement technology (carbon fiber reinforcement). Carbon fiber (strips, sheets, plates, threads, fabric) is glued in several layers until the required beam stiffness is achieved. The ease of use and lightness of the material lead to the fact that carbon fiber is gaining popularity as an effective means for restoring beams and building structures.

Below is a diagram of reinforcement (strengthening) of floor beams with carbon fiber.

- How to lay flexible tiles on the roof?

How to properly lay a vapor barrier on the ceiling?

- Is it possible to glue wallpaper on whitewashed walls?

Reinforcement at the ends with wooden or metal prostheses

The technology allows you to strengthen the beam at the junction with the load-bearing wall. This is exactly the place where, due to temperature changes, wood damage occurs faster.

Installation of a rod prosthesis

The bar prosthesis of the Deidbekov system is made of two paired trusses, which are made from scraps of reinforcing steel with a cross-section (diameter) of 10-25 mm. The length of the prosthesis should be 10% greater than twice the length of the rotted end of the beam, but not more than 1.2 m.

- Install temporary supports under the ceiling at a distance of 1-1.5 m from the load-bearing wall, consisting of racks and purlins.

- Disassemble the ceiling from below to a width of 75 cm and from above - 1.5 m from the wall.

- Cut off the damaged section of the beam (0.5 m)

- Insert the prosthesis blank vertically into the interfloor ceiling and turn it to a horizontal position, first pushing it onto the beam, then pushing it into the wall niche in the opposite direction.

- Move and nail the sliding strip.

Reinforcing beams with truss ties

Strengthening wooden floors using these methods requires a significant restructuring of the supporting structure of the beam spans.

Changing operating conditions of structures

Changing the work pattern

If it is not possible to strengthen the wooden floor beams, you can try to unload them, i.e., distribute the load from the existing beams to additionally installed elements.

Strengthening floors by installing supports under load-bearing beams

Supports supporting beams from below are a good way to redistribute the load from the beam to the support.

Strengthening floors by installing additional beams

If the existing logs are intact and intact, their load-bearing capacity can be increased by increasing their number. Installing additional wooden beams will increase the load on the structure. When installing new logs, it is imperative to protect their ends with roofing felt to avoid damage.

We hope that from the above methods of strengthening wooden floor beams, you will choose the one that will solve your problem in the best way and at minimal cost.

Peculiarities

Today, the following main types of floors are used in construction:

reinforced concrete slabs;

metal constructions;

Klein overlaps.

They all differ in the methods of reinforcement and the material with which the work will be carried out.

Most often, damaged areas of floors are very difficult to detect. As a rule, bases made of different materials are located under decorative plaster or covered with suspended ceilings and painted.

That is why reinforcement of floors has to be carried out not quite in a timely manner, when obvious problems with the building structure begin.

There are several reasons why floors should be strengthened to prevent slabs from cracking, rotting or sagging.

- First of all, the reason may be a violation of the process of installing floors during the construction of a house.

- Another reason is often the use of low quality materials.

- In the case of metal elements, accelerated corrosion is possible.

- Most often, reinforcement of floor beams is carried out if they are made of wood. Their deterioration occurs mainly as a result of natural influences, for example, with sudden changes in air humidity or temperature.

- Reinforcement of reinforced concrete floors is carried out due to an increase in the load on the supporting structure, the appearance of cracks, defects during installation or further operation.

- There may be a need to complete a floor of a house. As a result of an increase in load, a redistribution of the impact force occurs on all components of the base. This is also one of the reasons that requires measures to strengthen the load-bearing structures of the house.

Repair of ceilings involves replacing some elements in case of minor defects or strengthening the entire area in case of a critical situation.

The process of strengthening the ceiling is a rather complex undertaking, since all work must be carried out in a confined space (inside the building), and it is not possible to mechanize certain operations.

Preparatory work takes a lot of time.

To carry out the entire process, mounting supports are erected under the structure that will be strengthened. They are placed vertically. The supporting elements are made of logs or steel pipes and fixed with spacers or pads. After this, the surface that is going to be reinforced is cleaned. Remove paint, whitewash, peeling concrete, and rotten parts of beams. That is, they create optimal conditions for the convenience and safety of moving under the ceilings.

Before starting the preparatory and then the main stages of work, you should have a specific plan for strengthening the foundations (technological map). It is necessary to know the magnitude of the existing loads and calculate the number of mechanisms and materials for carrying out measures for the restoration of existing beams.

It is best to consult experienced builders or entrust the work of strengthening the floor beams to a team of specialists.

Strengthening wooden floor beams with your own hands: basic methods and techniques

Wooden beams are most often used in roof construction. This is not surprising: installation is relatively simple, the weight is quite tolerable, the elements are affordable, they can withstand significant loads, and the walls do not deform. In addition, the aesthetic side of the issue is not left aside: subject to installation rules and some, not too expensive, finishing, wooden beams can be left in the public domain: they will only add a certain charm to the room. Chalet or half-timbered styles will never lose their popularity. However, there is a certain difficulty: with large dimensions of the structure, reinforcement of wooden floor beams is required. The span width should not exceed 5-6 meters, otherwise the elements begin to sag over time, which threatens the roof collapse.

In principle, you can do without strengthening wooden floor beams: the reliability of the structure is ensured by installing additional supports or increasing the cross-section of the wooden beams themselves. However, such steps lead not only to excessive consumption of materials (and therefore to the cost of construction), but also to the loss of usable area of the room. Watch the video:

Installation of an attic floor with a false ceiling

When constructing roofs from trusses, skull blocks are nailed to the lower chords of the truss, and floor panels are placed on them or false ceilings are made.

Scheme of the installation of an attic floor with a false ceiling: 1 top frame, 2 front board, 3 asbestos-cement corrugated sheets, 4 sheathing, 5 truss, 6 insulation made of mineral wool boards, 7 polyethylene film, 8 ceiling boards, 9 solid fiber boards, 10 lath, 11 external wall panel, 12 window block.

After installing attic floors, the ceilings of houses are lined with solid fiberboards or plasterboard sheets.

When installing an attic floor from panels, they are laid on the top frame of the walls and secured to each other and to the frame with nails.

The joints between the panels are carefully insulated and covered with strips. The panels are moved into the design position by a crane, and it is necessary to strictly ensure that the ends of the panels rest on the frame equally on both sides of the walls. On the ceiling side, there should be no ledges larger than 1 mm between adjacent panels.

Necessary clarifications

For all its positive qualities, wood still has a number of negative parameters. Of the most basic:

- relatively low endurance of both the floor beams and the entire structure as a whole. The maximum load is 500 kg/m2, and in most cases it does not exceed 200-300 kg/m2. Therefore, deflection is very likely;

- low sound insulation performance, which is typical for all wooden floors. They transmit the entire range of sounds, from airborne noise (conversation, music, murmur of water) to percussion, which occurs during repairs, moving furniture and even steps;

- fire hazard, to combat which it becomes necessary to treat wooden beams with special compounds;

- defenselessness against bioattacks. Wood is susceptible to rotting and woodworm damage, so wooden beams need additional impregnation not only from fire, but also from natural enemies.

Despite all the shortcomings, wooden structures do not lose their position. Even when strengthening the floors is considered vital. And this need may arise for various reasons. Watch the video:

Structural resistance parameters

To determine the durability parameters of a structure made of solid wood (for example, coniferous), the burnout rate of this wood is taken equal to 0.8 mm/min. When calculating floors based on open wooden beams 24 cm high with a span width of 5.8 m or 5.85 m, the width of the beams increases to 120 mm or more. Thus, taking into account fire resistance in this case, it is necessary to choose beams whose cross-section is 11 cm x 24 cm.

Drawing a conclusion from all of the above, we can say that there are still quite a lot of questions regarding the reliability of fire safety and sound insulation of house floors that will have to be resolved in the coming years by the joint efforts of designers, scientists, manufacturers of building materials, designers, and builders.

Reinforcement of floor beams: when it is necessary

The basis of any construction is accurate and scrupulous calculation. It guarantees consistently successful operation of the building, the longest service life of any wooden, metal and concrete elements, and comfortable living within the walls of the house for its inhabitants. But life, as we know, is unpredictable and likes to make its own adjustments to our plans. As a result, we are faced with the fact that it becomes urgently necessary to strengthen the floors. The following points are recognized as the most common reasons for such a step.

- The wooden structure of the floor has lost its quality. Simply put, it's worn out. The humidity turned out to be unexpected, a lot of time had passed, pests showed increased activity, walls and other components were subject to unexpected temperature changes - there can be many options. A special case is the initially low-quality wood used to make beams. Unfortunately, this option is not that rare. The result is the same: the load-bearing capacity of the structure is reduced, and the structure needs to be reinforced with wooden floor beams. Checking for the urgency of manipulation is simple: if a beam with a length of 2.5 meters bends under its own weight by 1 centimeter, this is the norm. If the deflection exceeds this indicator, the structural element must be strengthened.

- A timber beam needs reinforcement according to “personal” requirements. For example, you decided to make an attic or even a full-fledged living room from the attic. The loads on the ceiling of the second floor will certainly increase. This means that a change in the cross-section of the wooden beams holding it is required.

Separately, we note: even if redevelopment is not in your immediate plans, you need to check the condition of all load-bearing wood structures in the house annually. And floors should be the first item on this list. Unless, of course, you agree that someday the top floor will simply collapse onto the bottom.

Strengthening a beam structure can be done in different ways. Let's get acquainted with the most common ones.

General information

A beam is a structural element, which is a rod that is subject to forces in a direction perpendicular to its axis. Under the influence of these forces, any beams, including wooden ones, are deformed.

A slight deflection is completely acceptable. For example, when walking on a wooden floor, we often feel how it springs slightly. But if the deflection exceeds the permissible values, this can lead to breakage of the part.

Acceptable deformation is one that meets the following requirements:

- Does not exceed the calculated values.

- Does not interfere with comfortable use of the home.

To find out how much a part will deform in a given case, it is necessary to perform some calculations for rigidity and strength. It should be noted that such work is usually carried out by civil engineers. However, in private construction, after familiarizing yourself with some formulas, you can perform them yourself.

Minor deflection of floors is allowed

It must be said that calculating the deflection of a wooden beam is a very responsible job, because any building must meet certain strength requirements. Therefore, beams must have a certain stability and rigidity so that the structure can withstand the planned loads with a certain safety margin.

"Little blood"

Most homeowners will prefer to reinforce the floors in such a way that it remains possible to live within the walls of the building. In most cases this is indeed possible. If the wood of the load-bearing beam is damaged, but it has not yet crumbled into dust and retains its main characteristics, some kind of prosthetics can be installed on the element. And from different materials.

- Deflection of beams can be eliminated by applying wooden prostheses. The pads are fixed as tightly as possible on both sides of the damaged element, either on both sides, or on top and bottom. Maximum strengthening of floor beams is achieved by fastening the lining along its entire length. In this case, it is important to treat both the prosthesis and the element being strengthened with an antifungal compound.

- Reliable reinforcement of the overlap can be achieved using metal overlays or rod prostheses. Steel plates are used on the same principle as wood linings, only they are treated not with antibacterial, but with anti-corrosion agents.

- Reinforcing floor beams with carbon fiber has recently become much more popular than wooden overlays and metal prostheses. Carbon fiber is available in the form of tapes, fabrics, plates and strands, so it is not difficult to choose the option that is most convenient to work with in specific conditions. The material is glued in several layers until the desired degree of reinforcement is achieved. Working with carbon fiber is simple: it is light, plastic, attached with glue, which greatly facilitates installation, and is non-flammable, which increases the fire resistance characteristics of wooden beams and other structural elements made of wood. Carbon fiber becomes especially relevant in cramped spaces where there is not much freedom of movement.

Note that strengthening floor beams using the listed methods only makes sense if the deflection of structural elements is not accompanied by significant deformations. Strengthening beams that have significant mechanical damage in this way is only suitable as a temporary measure.

Other solutions

Before strengthening the logs of the second floor, you can check whether it is possible to unload them, that is, distribute the load to other elements.

For example, you can use supports or install additional logs. The first option, however, is not always possible to implement. The fact is that the supports will take up space and can create inconvenience when moving around the room. But some craftsmen turn them into a decorative element of the interior.

As for the installation of additional logs, as mentioned above, this is not always possible due to the design features of the building. If conditions allow, then it is better to add several elements to the ceiling. This is especially true when the existing joists are not damaged. In this case, the ends of the new elements must be protected with roofing felt before installation.

Additional supports

If the floor beams are in generally good condition but have cracked - for example, due to heavy snowfall - the best option to strengthen them and restore their functionality is to install supports on either side of the fracture. Of course, if we are talking about the attic and other utility rooms. However, a beam equipped with additional support may well fit into a living space if it is designed in a designer manner. The support can be installed either wooden or metal.

The procedure for strengthening work can be reduced to the following points.

- Bringing together the ends of the damaged beam. You will need an analogue of a jack, which will allow you to connect the fragments. Or the coordinated and leisurely work of a team of three or four people.

- Fault fastening. You can use any option of prostheses and onlays: until the supports are installed, they will hold the split part.

- Calculation of the location of the support. It is likely that they will become places of schism. But it may happen that two supports are needed, in those places where the maximum load falls on the wooden beam. This is especially likely if the beam has a large cross-section.

The rest is a matter of technique. The only thing that is required from the repairman is to clearly check the perpendicularity of the support, otherwise strengthening the ceiling will definitely not be possible.

How to strengthen wooden floor beams

Damaged wooden beams, worn out by loads and time, or not strong enough initially “according to the design” are the first reason for the weakening of the load-bearing capacity of the floors, the appearance of vibrations and creaking floors on the upper floors of the house. Let's figure out how to strengthen wooden beams and make the structural elements of the floor stronger.

- Reasons for weakening beams

- Increasing the cross-sectional area of a beam

- Rod prostheses

- Reinforcement of beams with carbon fiber

- What to do if strengthening beams is impossible

Permissible load

The most important indicator when choosing building materials for load-bearing structures is the permissible load on the wooden floor beam. This parameter shows what operational load the elements can withstand without losing their functional properties.

Permissible load ratings vary depending on the location of the beams. If they are used as an attic floor, then the constant load on the elements will be small - within 50 kg/m2. In this case, the operating load will be 90 kg/m2. For buildings where beams serve as the floor for the second floor, the load is 150 - 250 kg/m2.

However, these are only average indicators that cannot be used as objective data. Each structure requires a professional calculation that takes into account all load parameters and other influencing factors.

Reasons for weakening beams

The need to strengthen beams may arise in a number of cases:

- natural wear and tear of a correctly installed product;

- damage to the beam due to errors in manufacturing and installation;

- change in the purpose of the room associated with increased load on the floors.

Let's consider these reasons in more detail. So, the beam can become unsatisfactory due to the influence of various factors, including increased levels of humidity, sudden temperature changes, as a result of pest activity, as well as simple physical wear and tear with the further appearance of cracks.

The dishonesty or incompetence of builders should not be discounted. The owner of the house is not able to check the quality and correct installation of hidden installation elements. Problems are identified later - already during the operation of the premises, when walking on the upper floor, the floors vibrate or creak.

The main errors at the stage of manufacturing and installation of beams include the following:

- using insufficient or incorrectly dried wood. After such beams dry, they become covered with cracks;

- using too thin timber, which leads to vibration of the beams;

- too large spans between beams;

- assembly of beams from several parts.

If we are talking about changing the purpose of the room - for example, the attic is planned to be turned into an attic or a residential unit, then in this case the load on the floor will increase. Obviously, this will require increasing the load-bearing capacity of the beams.

A non-specialist can determine the need to strengthen beams. The main indicator in this case, in addition to the mentioned vibrations or visible damage, is the level of deflection that occurs both under load and under the beam’s own weight. The deflection may increase after increasing the load - installing parquet on the top floor or after importing furniture. In this case, the beams begin to sag, which not only causes vibration of the floors, but can also threaten their collapse.

The maximum permissible deflection of a beam is easy to calculate independently. The simplest method is to calculate the indicator depending on the length of the beam. In particular, the level of deflection should not exceed approximately one three-hundredth of the length of the product. For example, if the deflection is 8–10 millimeters with a beam length of 2.5 meters, this is normal. If it turns out to be large, then it’s time to strengthen or replace the beam.

Decrease step

In this case, new ones are installed between the existing beams. But the method does not provide such effectiveness as the previous one. When calculating the bearing capacity, the span is taken in the second degree (according to the first group of limit states), and the step is taken only in the first. Reducing the span by half increases the load-bearing capacity by 4, and the step by 2.

The depth of support of the beams is prescribed from 200 mm. New and existing elements are treated with an antiseptic. If desired, you can use fire retardants that increase fire resistance. In places where materials of different properties come into contact (wood with metal, brick or concrete), waterproofing is laid: Technolelast, roofing felt, Linocrom, etc.

Increasing the cross-sectional area of a beam

One of the most popular ways to strengthen floor beams is to increase their cross-section by installing additional wooden overlays. This method is mainly used in cases where the material of the beams becomes loose due to natural aging or as a result of the activity of wood-boring beetles.

An increase in the cross-sectional area is achieved by installing wood overlays with a thickness of at least 50 mm on the weakened or damaged area. Some experts argue that it only makes sense to increase the section along the horizontal sides, that is, at the top and bottom of the beam, and increasing the thickness of the product along the width does not give a useful effect.

Before installing the overlays, as in the case of other work on strengthening beams, weakened areas should be treated with antifungal agents. After antifungal treatment, it is necessary to reduce the level of deflection to a minimum using jacks. It is more efficient to directly install the linings along the entire length of the beam. Attachment is carried out using bolts or studs through and through.

Not only wood, but also metal can be used as a reinforcing element. In this case, channels or metal strips are used. The latter are less reliable than the channel and can only be used to strengthen small areas of damaged beams.

Reinforcing the span of a beam with the help of metal overlays is carried out according to the same algorithm as in the case of wooden overlays, but it has some peculiarities. In particular, before installation, metal linings are treated with an anti-corrosion compound. In addition, a waterproofing layer should be installed between the metal and wooden parts.

Peeling and deterioration of the plaster layer

The first thing you need to do when you plan to repair a wooden ceiling is to inspect and tap the entire ceiling in order to identify all the voids and the density of the ceiling. If the ceiling is strong, then the old plaster can simply be soaked with a paint roller and cleaned off with a spatula.

But the most common problem in old Stalinist houses is the peeling and destruction of the old layer of plaster. 30-40 years ago, builders used clay for this task, which cracks and crumbles very much, so if this process has already begun, in order to make a quality repair, removing the entire layer is necessary. This can most easily be done using a hammer drill or drill with an impact function.

In this case, the plaster is removed down to a layer of shingles - lathing made of thin slats, which served as the basis for plaster in Stalin-style houses. Before doing this, you need to take care of protecting your eyes and respiratory organs - during this process, the room is filled with dust. You can use goggles and a respirator for this.

After removing the plaster, the shingles are removed using a crowbar, pry bar and other available tools.

The next step will be leveling the ceiling and sealing cracks. The cracks are widened using a spatula, and then coated inside with a deep penetration soil solution or PVA glue. After sealing the cracks, you must wait until the primer is completely dry before the next stage of work.

Before puttying, you can use a reinforcing plaster mesh made of metal to protect against the appearance of cracks.

Next, thoroughly putty the ceiling and apply the final leveling layer, after which the rough work can be considered completed and you can begin finishing with the selected materials.

Rod prostheses

In cases of severe damage to sections of beams, it is practiced to remove such areas and install bar prostheses made from steel reinforcement in their place. This method is used mostly when replacing end elements, which most often become unusable.

The role of prostheses is played by scraps of reinforcement with a cross-section from 10 to 25 mm. The length of the prosthesis is selected with the expectation that it should be 10% greater than the double length of the damaged section of the beam. There is also a limitation on the length of the prosthesis - it can be no more than 1.2 m.

Before performing work, you should support the area that will be strengthened with a stand to prevent possible collapse of the structure. The racks and support run are placed at a distance of one to one and a half meters from the load-bearing wall. After such temporary strengthening, the ceiling is dismantled, and the rotted section of the beam is cut down.

The prosthesis blank is inserted vertically into the ceiling and then rotated to a horizontal position. The structure is first slid onto the beam and then into the wall niche. It should be taken into account that beams restored with the use of prostheses will last for a long time, however, the strength of the updated structure will certainly be lower than in the case of a new beam. Therefore, the restored beams should be loaded to a minimum.

Prefabricated monolithic options

The installation process does not require special equipment for lifting structural elements due to their low weight.

There are two traditional options: a prefabricated floor made of hollow-core slabs or a monolithic floor

The algorithm of events provides:

- Place support beams at intervals of 60-80 cm.

- Installation of polystyrene concrete or expanded clay blocks on the beam shelves to form the formwork.

- Installation of reinforcing mesh.

- Pouring with concrete mortar.

- Hardening of the monolithic base.

- Insulation using expanded clay, basalt wool and other materials for thermal insulation.

Where would you prefer to live: in a private house or apartment?

Definitely an apartment! Comfort, coziness and warmth, surrounded by people and infrastructure

754 ( 7.48 % )

Only a private house! There is silence, peace, a lot of space and few people around!

4588 ( 45.52 % )

Why choose just one? There is an apartment in the city, and a private house outside the city.

4307 ( 42.73 % )

I am a free Citizen of Planet Earth! I don't need a man-made cell!

431 ( 4.28 % )

Back

Design advantages:

- increased vapor and sound insulation;

- increased strength;

- the ability to perform installation work without the use of special equipment.

Reinforcement of beams with carbon fiber

In addition to traditional technologies, innovative solutions are widely used when strengthening beams, one of which is the reinforcement of structures with carbon fiber reinforced plastics. Attention: this method is the only possible way to strengthen beams if, due to extreme cramped spaces or for some other reason, increasing the cross-section of structures is impossible or extremely difficult.

The undoubted advantage of carbon fiber reinforcing elements is the absence of the need to operate with large and heavy metal or wooden components, as well as the minimal labor intensity of the work in general. Modern carbon fiber reinforced plastics, like any composite materials, are characterized by high strength and low weight. Carbon fiber reinforcements cope well with significant mechanical loads. They are available in different modifications - in the form of tapes, fabric, threads, plates or sheets.

Reinforcement of a beam with composites is carried out by gluing carbon fiber onto it in several layers. The attached layers of carbon fiber are applied to the surface of the beam, one above the other and along its entire length. The edges of the glued strips must be covered with transverse layers. The reinforcing components are glued until the reinforced beam becomes rigid enough to withstand the loads. Installation is carried out using epoxy glue. After hardening, the layer’s strength characteristics are sometimes not inferior to metal.