Soft roofing is a term that combines a number of flexible roofing materials with good consumer properties. Its piece and roll varieties perfectly protect the house from fire and effectively decorate the exterior. They weigh little, do not require effort in cutting and fastening. Among the advantages is the ability to lay the coating yourself.

For an ideal result, it is not necessary to have the skills of a roofer. You need skill, patience, tools and information about how the technology of laying soft roofs differs from other methods.

No. 1. Composition of flexible tiles

The material called flexible tiles is also popularly called soft tiles, bituminous shingles, roofing tiles, shingles and even shingles, named after the main domestic manufacturer of the material. It is sold in the form of small flat sheets of various shapes and colors. High performance qualities are due to production technology.

Soft tiles consist of the following layers:

- the base is fiberglass, much less often organic cellulose. Fiberglass is obtained from a molten mass of inorganic glass; the fibers are bonded together thanks to special additives. Fiberglass canvas today produce wet and dry methods. The first involves strong grinding of raw materials, foaming of the mass on a molded canvas, on top of which a binder and film are applied. The dry method involves squeezing molten glass through dies and molding fibers that are woven together to form a web. After processing the canvas with binders, drying occurs;

- layers of bitumen with polymer additives (often one or two). Bitumen is a resin-like organic substance of natural origin, with which fiberglass is impregnated to give the future product properties such as flexibility, strength, and resistance to critical temperatures. To improve the performance qualities of flexible tiles, bitumen is modified with polymer additives ;

- the top decorative layer is made of basalt granulate, silicon or shale chips. It gives the product the required color, brings it closer in aesthetics to natural tiles, and also plays the role of additional protection from mechanical damage, moisture, ultraviolet rays, and protects the bitumen layer from melting under the influence of high temperatures. The topping also increases strength and durability. Basalt is the most preferred and common coating option. Its particles fit tightly to each other and are better fixed on the surface. Slate has the property of absorbing oils contained in bitumen and changing color;

- bitumen-polymer layer with a self-adhesive base ;

- film to protect the previous layer.

Polymer additives that modify bitumen deserve special attention . The properties of soft tiles depend on them. The following are usually used as additives:

- styrene-butadiene-styrene (SBS), also known as artificial rubber or thermoplastic, makes bitumen more elastic, resistant to frost and high temperatures. Excellent for use in regions with cold climates and sudden temperature changes, so in domestic conditions this is the best option;

- atactic polypropylene (APP) allows bitumen to withstand very high temperatures, makes it resistant to sunlight, but does not protect against frost - an option for regions with hot climates.

There is also oxidized bitumen , which is produced by treating bitumen with oxygen, starting the process of artificial aging. Due to this treatment, service life and resistance to low and high temperatures are increased. In terms of elasticity, such bitumen is inferior to SBS-modified, but is cheaper and is fully applicable in domestic conditions.

The type of bitumen used can be determined by external inspection of soft tiles. It is enough to pull the corner of the top layer, and if the bitumen stretches, we see its modified version; if it breaks, it is oxidized.

Insulation

If it is necessary to insulate a room or attic, insulation for flexible tiles is used. The material recommended by experts for insulation is mineral wool based on basalt or glass wool. They are easy to install and are even suitable for installation in hard-to-reach places. At the same time, they do not form cold bridges and protect well from temperature changes.

CAREFULLY!

The minimum thickness of the material is 150 mm , and for regions with severe frosts - 200 mm or more .

No. 2. Advantages and disadvantages of flexible tiles

The peculiarities of the production of soft tiles determine their excellent performance qualities, which, in turn, create great demand. Among the main advantages of flexible tiles:

- ease of installation and transportation due to low weight and compact dimensions. There will be no need to construct a reinforced rafter system, and this is a significant saving;

- possibility of use for organization of roofs of complex shapes, even domed, and there will be minimal waste;

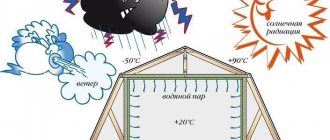

- resistance to all negative environmental factors , however, it is necessary to choose soft tiles of the appropriate composition. The material is not afraid of sunlight, moisture, ice, frost, corrosion, mold, and therefore boasts high durability (about 50 years), and manufacturers give a multi-year guarantee for their products;

- the material does not fade in the sun and does not change its color over time;

- excellent heat and sound insulation, allowing you to maintain an optimal microclimate in the house and not suffer from noise during rain;

- beautiful appearance , a huge selection of colors and shapes, the ability to imitate natural tiles;

- health safety;

- soft tiles are dielectric , so there is no need for a lightning rod;

- resistance to fire, since combustible bitumen is covered with stone particles on top.

Among the shortcomings we note:

- relatively high price . Compared to metal tiles or slate, roofing tiles are, of course, more expensive, and compared to natural tiles, the material seems to be a budget option. In any case, the cost of purchasing bitumen shingles is offset by its durability and minimal waste;

- the need to construct a solid base on which the material will be installed. The base is made from edged boards (an expensive option), plywood, but its performance is not the best, or OSB boards. The latter are considered the optimal solution;

- installation cannot be carried out at sub-zero temperatures, but there is a trick here too. If before laying the tiles you keep them in a warm room and warm them up with a hairdryer, then installation can be carried out down to a temperature of -150C.

Soft tiles are a universal material for covering the roofs of private houses, public and commercial buildings, and industrial buildings. Roofing tiles are installed on roofs with a slope of more than 12 degrees, and if the slope is more than 45 degrees, then each element will have to be reinforced with 2-4 nails.

Installation features

The quality, strength, efficiency and practicality of the roof depend on how correct the installation process was. It consists of the following stages:

- The very first step of installation is the preliminary preparation of the sheathing, laid in a solid ball . To make it, you can use wood board or moisture-resistant plywood. The sheathing must be smooth and uniform.

- Arrangement of underlay carpet . It is mounted over the entire roof area parallel to the direction of the cornice. The strips are laid with an overlap, the width of which is at least 10 cm.

- Sealing seams . This is necessary for the integrity of the layer and its tightness. For this you can use a special mastic.

- Installation of cornices . Thanks to this, it will be possible to strengthen the roof overhangs and protect them from the harmful effects of precipitation. Installation is carried out using roofing nails, which are attached at a distance of 12 to 15 cm.

- Installation of tiles . It is carried out from the center of the roof to the middle. It is additionally recommended to use nails for fastening.

A private house, the roof of which is equipped using flexible tiles in compliance with all the rules, will be not only attractive, but also durable.

No. 3. Why are flexible tiles better than their competitors?

Among the main competitors of flexible tiles are roofing coverings such as ondulin, slate, metal tiles and natural tiles. Soft tiles are more expensive than the first three analogues, but buyers often prefer them, because they are superior to slate and ondulin in aesthetic qualities, durability, amount of waste and ease of installation. Metal tiles can compete in appearance, but their downside is a lot of noise during rain and the possibility of corrosion when the protective layer is deformed. Flexible tiles are quiet and are not afraid of rust.

All that remains is natural tiles , which can boast record durability, neutrality and excellent appearance, which manufacturers of soft tiles are so eager to repeat in their collections. However, the natural analogue is much more expensive, requires reinforcement of the rafter system, is difficult to install and requires periodic monitoring of the condition of the roof and replacement of damaged elements.

Liquid roofing: a durable shell for the house

Spray roofing is also soft of its kind; it easily bends around any obstacles on the roof. This roof has a special application technology, which requires skills and knowledge. The difficulty is that proper preparation of the base for applying the composition is necessary.

Unfortunately, it is difficult to do this manually if you do not have the proper experience or at least consultation. But the result will definitely please you:

Liquid roofing, or as it is also called, liquid rubber for roofing, comes in different types depending on the composition used:

For example, liquid rubber based on rubber literally hardens within a day into an elastic, fairly thick film of the chosen color. This is the same spraying that is actively used today for waterproofing swimming pools. In a word, this coating has excellent water-repellent properties.

That is why this type of soft roofing is becoming more popular day by day and is actively used for insulating flat roofs. After all, the result is a uniform anti-slip coating, which, thanks to its chemical properties, is not afraid of either ice or snow:

No. 4. Types of flexible tiles according to the method of cutting sheets and color

Roofing material is usually evaluated based on a variety of parameters, with appearance being taken into account first. Aesthetics depends not only on the color, but also on the shape of the element. Today, manufacturers of soft tiles offer us the following options for cutting sheets:

- shingles;

- rhombus;

- rectangle;

- oval;

- hexagon;

- "brick";

- "beaver tail";

- "dragon tooth"

Some of them are designed to imitate natural materials, for example, ceramic tiles, while others are designed to give the roof an original look. Almost every manufacturer strives to present these standard names in their own way in order to distinguish the product from analogues from competitors. In addition, in the collections of companies engaged in the production of soft tiles, you can find products of other shapes.

The variety of colors is even greater. Tiles in red-brown, green and blue shades are popular, but the choice is not limited to this. Manufacturers have learned to create not only monochromatic products, but also with a transition from one color to another, and the capabilities of modern technology make it possible to paint in almost any shade, and with a 3D effect. Changing the color of the topping and base, the shape of the sheet and the pattern on it, as well as the glossiness and dullness parameters allows you to achieve original effects or complete resemblance to clay or wooden tiles.

On sale you can find three-layer soft tiles , which differ from the usual two-layer tiles not only in price and even better performance, but also in appearance. The third layer is applied with a slight offset, which allows you to achieve the effect of volume and relief, and this has a positive effect on the aesthetics of the coating.

Installation of valleys, cornices and end parts

When figuring out how to lay shingles, it is important not to forget about reinforcing the roof overhangs with metal eaves and end strips on top of the underlayment layer. These strips must be laid overlapping and secured with roofing nails. The step is no more than 12 centimeters. Self-adhesive tiles are laid along the eaves line butted against the metal strip.

Initially, you need to remove the protective film from this tile, after which each of its elements is attached to the base with nails. A special carpet called a valley must be laid in the valleys. All insulating materials must be secured with nails and treated with the same bitumen-based mastic. Sometimes a valley top is also installed, which serves more of an aesthetic appeal.

No. 5. Types of soft tiles by modification

Installation of a roof made of bitumen shingles requires the use of elements of different modifications:

- row tiles are those that form rows and make up the main part of the roof covering;

- ridge tiles are used to arrange the joints of roof slopes and the ridge, giving the roof a finished look;

- eaves tiles are intended for arranging eaves, that part of the roof that takes on the greatest load in the autumn-spring period, being exposed to melt water and ice. The elements of such tiles have increased thickness;

- ridge-eaves tiles combines the characteristics of the two previous types and is universal.

Installation of underlay carpet

This roof element carries the function of protecting against possible leaks of the roof structure.

When laying a coating such as bitumen shingles, the technology requires mandatory compliance with existing installation standards (more details: “Flexible tiles: installation technology”). According to them, if the roof slope is more than 18 degrees, an additional layer of rolled insulation, for example, roofing felt, should be laid at a minimum width of 40 centimeters from the edge along the ends and edges of the roof eaves, which are potentially the most likely areas for water penetration . The best solution would be to drain the material to the façade surface. The roof ridge also needs to be covered with an insulating layer so that on each side the material is at least 25 centimeters long.

No. 6. What to consider during an external inspection?

Sometimes a visual inspection will tell you much more about the quality of soft tiles, rather than the manufacturer’s description of the technical characteristics. To choose high-quality flexible tiles, when purchasing, pay attention to the following points:

- flexibility . A high-quality product must be flexible and elastic - this is the key to its durability and practicality. To check the flexibility, just try to bend the material, not fold it in half, but bend it a little. A high-quality product will bend without problems and then return to its previous state;

- There should be no smell of bitumen , because this is the first sign that it is actively evaporating, and this threatens to lose its elasticity in the near future;

- The coating of stone chips should be uniform and dense and not crumble. If more than 2 g of chips fall from one shingle, it is a poor quality product;

- the presence of a self-adhesive surface greatly facilitates the installation of flexible tiles, but it is important that no more than 6 months have passed since the production of the product, otherwise you will have to deal with a construction hair dryer;

- single ply shingle thickness should not be less than 4 mm. Multilayer elements will be somewhat thicker, they have increased resistance to moisture and wind.

Soft tiles are sold in packs of 22 elements, which approximately corresponds to 3 square meters. m of finished coating. Packaging weight ranges from 5-8 kg for single-layer products and up to 20 kg for multi-layer products. Experts recommend using elements from different packages during installation - this guarantees that the roof will be aesthetically pleasing, even if the color of the material in different packages is slightly different. The quality and durability of a roof made of soft tiles depends on the preparation of the base - violation of the technology can lead to a significant reduction in service life.

Comparison table of characteristics

Below are brief parameters of the considered models, namely:

| Model | Layers, pcs. | Density, kg/m² | Size, mm |

| Onduvilla | 1 | 4 | 1060x400x3 |

| Dock Europa | 1 | 3.2 | 1000x318x2.8 |

| TechnoNIKOL Shinglas Classic | 1 | 2.9 | 980x310x3 |

| Rulfex Runa | 1 | 4.3 | 1020x300x3.2 |

| Icopal Plano Natur | 2 | 8.9 | 1000x320x3 |

| Cartain Teed Belmont | 3 | 12.47 | 914x457x12 |

| Siplast Toisite | 2 | 17.5 | 500x300x6 |

Required tools:

Before starting work, you need to ensure that you acquire the necessary tools. You may need:

Roofing knife - for cutting single-layer tiles.

A special mechanical or pneumatic cutter for cutting multi-layer bitumen shingles.

Metal scissors - for cutting metal strips or reinforcing profiles.

Stapler - for fixing roofing films.

Guide bar - for even cutting of shingles in valleys, on ridges or junctions.

Hammer, saw, drill, screwdriver - for installing the rafter system and fastening various elements.

Construction hair dryer - for heating bitumen shingles or components (valleys, ridges) in the cold season.