The gutter solves the important problem of draining rain and melt water from the roof. If you build it hastily, without taking into account the features of the roof, or completely abandon drain gutters and pipes, then water will flow from the slopes chaotically, flooding the foundation and moistening the walls. Therefore, when starting roofing work, you should take care of choosing the right drain, which can be metal or plastic.

The material of manufacture is the main difference on the basis of which you can make your choice. So, which gutter is better: plastic or metal? Let's compare these two types of gutters, examining in detail their characteristics and functional features.

Plastic gutters

Plastic drainage systems are made from durable vinyl and stabilizers that make it resistant to ultraviolet radiation and thermal effects.

They are characterized by excellent performance properties, last an average of 10-20 years, are available in a wide color palette, and are inexpensive. Installing a drain is reminiscent of assembling a construction kit with connecting many accessories together without cutting or soldering. The variety of parts allows you to install a polyvinyl chloride gutter on an eaves overhang of any complexity, length, or shape. The components are connected using adhesive or, more often, glueless (using high-quality rubber seals) method. Due to the fact that PVC cannot withstand heavy loads, gutter brackets should be installed at a distance of 0.5 m from each other.

Plastic gutters can have any color scheme on the RAL scale, so matching them to the shade of the roofing will not be difficult. Brown, white and graphite drainage systems are in greatest demand among buyers. They look most organic with bitumen and ceramic tiles, but they will go well with any modern coatings.

Resistance to mechanical loads ↑

- Metal drains are easy to scratch. As a result, the polymer layer is damaged, causing corrosion.

Advice

If you discover a violation of the coating, even the slightest, it is recommended to immediately paint this area. This will help extend its service life.

- To make gutters, thin metal is used that can bend under mechanical stress.

- But plastic gutters are completely devoid of these disadvantages: pipes, like gutters, made of this material are not afraid of scratches or rust. Since they do not have a polymer coating, they also do not need to be painted.

- Plastic storm drains do not bend under the influence of sensitive mechanical loads, but they can break if excessive force is applied.

Metal gutters

Metal drainage systems continue to enjoy constant popularity, most of them having a longer service life compared to their plastic counterparts. They also go well with almost all modern roofing coverings. Various metals are used for the production of drainage systems , the quality of which determines their beauty, reliability and cost.

Galvanized gutters do not lose their functional properties for 10-15 years and are cheap. But any scratches or damage to them lead to the formation of rust. And they don't look very attractive. For these reasons, galvanized steel drains are considered obsolete.

A more modern option is drainage systems with colored polymer coatings . Thanks to this combination of plastic and metal, the service life of products increases to 50-60 years. The coating of the drain is responsible not only for decorative functions, but also protects it from corrosion, because moisture simply does not reach the galvanized steel surface. The quality and cost of a metal-plastic product depends on the polymer used. Polyester is most often applied to 0.5 mm steel; it is prone to mechanical damage and scratches. Plastisol and polyurethane are sprayed onto both sides of the metal with a thickness of 0.55-0.6 mm, which provides significantly greater protection against rust formation. At the same time, the cost of galvanized products with a polymer layer is not much higher than that of analogues without it.

Aluminum-zinc drainage systems are made from steel sheets coated on top with a layer of AluZinc , consisting of an aluminum and zinc alloy. This coating increases the resistance of products to corrosion and ultraviolet radiation. Gutter systems are available in a wide range of colors that do not fade or darken over time.

Copper drainage systems belong to the elite class and are expensive. They are not affected by moisture, cold, ultraviolet radiation, or corrosion, so they last at least 100 years. The metal oxidizes over time, becoming covered with a patina of a reddish or greenish tint, highlighting the nobility of the material and increasing its wear resistance.

Drains made of aluminum weigh little, due to which they allow increasing the thickness of the walls of gutters and pipes to 1-1.6 mm (for steel - 0.5-0.7 mm) without loading the fastening. Thanks to this, the products can easily withstand high loads and do not deform. Aluminum has excellent anti-corrosion properties, because... Contact with air masses forms an oxide film on it, which prevents rust from forming. Moreover, it is capable of self-healing when damaged. Aluminum gutters are painted on both sides with polymer powder paint, which also protects against corrosion.

Titanium-zinc roof gutters are quite expensive, but they last about 100-120 years. It consists of zinc (99%), titanium, which is responsible for protection against rust, and a small amount of copper, which increases the ductility of the material. The flexibility of the products allows them to be installed on facades of any shape. A patina film naturally appears on the surface of drains over time, so there is no need for additional protective coating. First they become matte gray, and then anthracite. The only drawback of titanium-zinc material is its susceptibility to electrocorrosion upon contact with iron and copper, so the contact of these metals is unacceptable.

Where to stop?

The final choice must be made taking into account the entire complex of evaluation criteria.

- First of all, it is assumed that the drainage system has its direct functions, and first of all must cope with them. The rest is, to a certain extent, secondary. In addition, it does not determine the facade appearance of the building, but, on the contrary, it is matched to the existing (planned) roof and wall design.

Naturally, gutters and pipes should not be in harmony with the overall exterior decoration and style of the building.

- You should immediately carry out all the necessary calculations to determine the list and quantity of necessary components. This will allow you to find out prices in local stores and assess your financial capabilities in terms of purchasing a particular system.

How is a roof drainage system designed?

There is a special algorithm that allows you to select the correct cross-section of gutters and pipe diameters, “arrange” funnels and reinforcement currents, and calculate the number of necessary components. This is described in detail in the article on our portal dedicated to self-installation of drainage systems .

- In regions with difficult operating conditions (high probability of ice, heavy snow, severe frosts, etc.), preference should still be given to high-quality metal systems. But on the sea coast, plastic will still be better.

- For a roof made of corrugated sheets or metal tiles, a metal drain with a corresponding harmonious color would be most appropriate. For soft roofing coverings, on the contrary, plastic system options suggest themselves.

- A copper drainage system on some “poor” roof will look absolutely ridiculous. And vice versa - copper roofing in combination with galvanized gutters. That is, one must intuitively understand the difference between harmony and obvious kitsch, “dust in the eyes.”

As for the rest, rely on your taste and, of course, financial capabilities. In this case, it is best to pay attention to the products of proven, reputable manufacturers who accompany their products with a good quality guarantee. These include the German, French “Nicoll”, British “Hunter”, and, of course, the domestic “Alta-Profile”, “Aquasystem”, “Grand Line”, “Metal Profile”, “Marley”.

One of the leaders in the Russian market of polymer products, and in particular drainage systems:

At the end of the publication, there is a video that also gives advice on choosing drainage systems:

How should you choose gutters?

The choice between installing a plastic or metal drainage system depends on many factors, because... the design must be organically combined with the roof covering and the entire external design of the building. A practical option is considered to be one in which the service life of the drain and the roof will be the same . In this case, they can be replaced simultaneously.

When choosing a drainage system, you should focus on:

- The area of the roof slopes.

- Climate in the region (amount of precipitation, temperature).

- Architectural design of the building.

- Selected roof covering.

- Material well-being.

For regions with frosty winters, where ice often forms, it is better to give preference to metal drainage systems. If metal tiles or corrugated sheets are chosen as roof covering, you can safely purchase a steel drainage system with a polymer layer. Thanks to a wide palette of colors, you can easily choose gutters and components to match the color of the roof.

Plastic gutters will go well with flexible tiles or any other soft type of roofing. The same applies to slate roofs.

Snow check ↑

Structures made from both materials can withstand significant snow loads. Although metal options can take a more significant load, since their fastening, as noted above, is more durable

However, there is a small “but” - in the event of an avalanche, any storm drain can become unusable, which is why the installation of snow holders in snowy areas is considered mandatory.

Video material

An objective comparison of metal and plastic drainage systems and expert opinion on the choice.

Comparison of metal and plastic drainage systems Which drainage system is better - plastic or metal?

Ease of installation and maintenance

Installation of both systems is not particularly difficult.

- A plastic drain is a little easier to install. It is lighter, and most systems have ready-made funnels integrated into a small section of the gutter. And even adjusting the length of gutters and pipes is faster. But you have to install support hooks more often - the distance between them should not exceed 60 cm.

- Metal drain funnels must be cut into the gutter (if it is not a separate drainage funnel at the valley), and such an operation complicates the installation of the system. But the gutters themselves can be attached to the front board less frequently - the maximum step is 90 cm.

System maintenance takes place at the same frequency. The cleaning methods and tools for this are the same. Although the polymer coating of a metal drain must be handled very carefully.

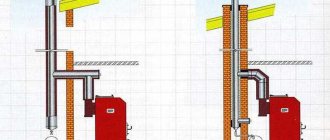

Design features of drainage systems for different types of roofing

The system includes many main and auxiliary elements. The first type includes gutters, pipes, funnels. For the second - fasteners and plugs. However, such structures are placed in different ways. The order of work depends on the type of roof. In one case, an external drainage system is provided, in the other - an internal one.

The design of ebb tides depends on the characteristics of the roof

Gable roof

A gable roof is characterized by an external drainage system, which requires the installation of all elements outside the building. It includes:

- gutter. Used to collect rainwater from roof slopes. Consists of individual elements, the length of which can vary over a wide range;

- receiving funnels. The water previously collected in the gutter is received and discharged further through the system;

- gutters. Moisture is removed outside the house into special receiving wells;

- auxiliary elements: connecting inserts, end caps, mounting brackets and other elements used during installation work.

Flat roof

Buildings with a flat roof usually have an internal flashing installed. The roofing material is laid in such a way that the water that gets on the surface flows down the roof and falls into a special funnel. Then the collected liquid flows into a pipe located in the wall of the house or inside a special technical channel.

For a flat roof, the elements are located inside

Common mistakes to avoid

Consequences of installation errors

In any case, no matter which drainage system is chosen, it is necessary to avoid mistakes that are often made by non-professionals:

- Small number of funnels. The system will not cope with the incoming volume of water, and it will overflow through the gutters.

- Large distance between brackets. The gutters will bend and the water will not reach the funnels.

- Incorrect calculations.

- Savings on components and quality of materials.

- Unorganized water drainage. Water pouring directly onto the blind area will sooner or later damage both the blind area and the foundation.

- Poor quality paint may fade or fall off.

Calculation of ebb tides for the roof ↑

When analyzing how to make ebb tides on the roof, it should be noted that the work actually begins with planning. One of the important aspects is the correct calculation of the components included in the system. This is done quite simply.

- To calculate the length of the gutter, it is enough to sum up the lengths of the slopes and gables. The result must be taken with some reserve. Their number is calculated based on the length of the drains. Funnels are installed in increments of 8–10 m. The same number of drainpipes is needed as funnels. For one side, one funnel is enough, but funnels installed in the corners look much more aesthetically pleasing.

- The mounting brackets are calculated based on the following conditions: the installation pitch is 50–60 cm and a couple more for the funnel. For example, for a gable roof with a slope of 6 by 8 m, their number will be 36 pieces.

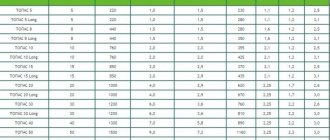

- The diameter of the product is of particular interest, since an inaccurate calculation can lead to an overflow of water, and it will fall from the edge of the gutter onto the walls. The main parameter influencing the choice of diameter is the roof area. The smallest possible cross-section is 1.5 cm2 for each m2 of roof surface.

- The area of the already indicated slope is 24 m2, so it turns out that the cross-section of the tray cannot be less than 35 cm2. In practice, the dimensions of flashings for a roof with these parameters are 7–20 cm. The diameter of a round drain, the size of which is 7 cm, is 76 m2, which is quite consistent with our assumptions.

- The slope must be directed towards the drainage pipe. In private construction, it is customary to choose 20–30 mm for every 10 m. As a rule, such an inclination is sufficient to ensure the operability of the system. It is logical to assume that drains with a greater slope will drain water more efficiently. But then they won’t really fit into the overall appearance of the building.

How window companies deceive you or how to choose the right quality plastic windows

So you have decided to replace your old windows with new plastic ones. You went around and called a huge number of window companies, but the questions only grew. You don’t see how one window company differs from another and how the plastic windows offered by one company differ from the windows offered by another company, and if there is no difference, then why pay more?

And here you make the most common mistake - you start looking for a company that can offer the minimum price for plastic windows.

There is no need to rush, now we will figure out how windows differ and what window companies are trying to hide from you .

Profile

When it comes to PVC plastic windows, the most common question that is asked is “what profile are your windows made of?” At the moment, there are more than 40 profile manufacturers on the market and each manufacturer has a large number of different profile lines in its arsenal.

All European manufacturers offer a high-quality product (KBE, Gealan, Veka, Rehau, SCHUCO, etc.) - the guarantee for such a profile is at least 40 years, such a profile does not crack or turn yellow. A slightly different picture with the Turkish and Chinese profile systems. Without going into unnecessary details, I will say that a European manufacturer is preferable, and we simply forget about the rest, especially since there is practically no difference in price.

As we have already said, each manufacturer offers not just one, but a whole line of profiles for windows. Different profiles and profile systems differ from each other in thickness, number of sealing contours, design, number of air chambers.

As for the design, as they say, it comes down to taste and color...

The number of sealing circuits does not affect the blowing in any way and it is definitely not worth overpaying for it, but the thickness of the profile is not an unimportant factor. For the middle zone, the recommended profile has a thickness of 58 mm - 60 mm, but in practice, at low temperatures in the places where the hinges are attached, a cold bridge occurs and freezing and ice formation occurs, i.e. the structure freezes.

We advise you to choose a profile for windows from 68 to 84 mm, and a thicker glass unit can be installed in such a profile. Such systems are produced by companies such as Rehau, KBE and Veka. The difference in price with a thinner profile is insignificant, but the rigidity and heat efficiency of such windows is much higher, so the choice is obvious.

System Operation

During operation of a structure for this purpose, it is necessary to take into account its features:

- The drainage system does not require careful maintenance, but there is a need to clean the trays 2-3 times a year due to accumulated dirt, deposits and fallen leaves. To facilitate the process, you can install filters that are fixed along the entire length of the roof slope. They are designed to prevent debris from getting into your gutters.

- Due to the fact that the galvanized steel from which the drainage system is made darkens over time and rust forms in some areas, it must be treated with anti-corrosion compounds.

- Painted flashings require periodic inspection and painting of scratches and chips.

Some practical tips

- Craftsmen recommend installing gutter covers before starting installation work.

- Water will flow smoothly into the funnel if you bend the edge of the gutter down.

- If it is necessary to bend plastic, it must first be heated with a match; metal is bent using pliers.

- Cut the ebbs using a hacksaw.

- Burrs at the joints are cleaned with a knife (plastic products), a file - metal ones.

- On galvanized parts, cuts are protected from corrosion with a protective compound.

Video: How to install, secure.

https://youtube.com/watch?v=JTuJCFlOwwM%3F

2021 stylekrov.ru

Features of wall roof gutter

Before installing a drainage system, it is necessary to calculate the required diameter of the product. The result of the work—the removal of any liquid from the roofing surface—depends on this parameter. If the gutter has a small width or height, the water flow will flow over the edges, the liquid will fall on the walls and base of the building. The calculation is based on the total area of the flat roof covering and the distance between the storm drain and the turning points of the gutters.

The cross-section of the elements completely depends on the roof area of the building: if the roof area is 150 sq. m, then for the drainage design it is enough to use gutters with a diameter of 10 cm. When calculating the cross-section of the gutter, it is also necessary to take into account the atmospheric conditions, climate, and average precipitation rate.

To prevent the formation of dangerous hanging ice and frost on the edges of the roof during thaws, it is recommended to install a special heating electric cable:

- Along the edge of the roof;

- In the gutters of the system;

- In drainage pipes.

Gutters have a practical fastening

It is not for nothing that the wall gutter is called an integral part of the structure. A high-quality drainage system is the key to the durability of the repair and the aesthetics of the structure. The drainage system from professionals will function in accordance with GOST and the norms specified by law.