Cooking, unfortunately, takes a lot of effort and time. Often, the duration of cooking depends not so much on the complexity of the dish, but on the power of the gas stove: with a nominally weak technique, everything takes longer to cook and fry. Finding ways to increase the power of a gas burner is so relevant because spending a free evening on yourself is much more pleasant than standing at the stove.

But are these modernization methods really safe? And are gas games worth the time savings? We will consider these pressing issues in detail in this material, providing it with visual photos and useful videos.

The best gas stoves according to buyers

Stove GEFEST 1200С7 K8 on Yandex Market

Stove GEFEST 900 on Yandex Market

Stove GEFEST 5100-02 0010 on Yandex Market

Gorenje GI 62 CLB stove on Yandex Market

Electrolux EKG 95010 CW stove on Yandex Market

Latest articles:

- Safety when working with power tools Safety precautions when working with power tools The following safety measures when working with power tools are universal and are suitable…

- Fire safety of a private home Every person at least once in his life has had to break some rules - cross the road when it is red...

- How to hang a sink on drywall? Installing a sink on drywall in three ways Introduction Most bathroom sinks are wall-mounted. Enough…

- Provence hood Types of hoods and their photos in the interior The correctly chosen hood in the kitchen interior works great when…

Briefly about the power of the stove and heater

The total power of the working surface depends on the number of burners and their direct power, indicated in the equipment passport. On average, 2-2.5 kW per burner. With decent gas quality and normal line pressure, this value is quite sufficient for comfortable and relatively quick heat treatment of products. In this case, the maximum burner power is determined by turning the knob to the limit and with full gas supply.

Manufacturers often offer home stoves with different wattages:

- on small ones - 0.7-1.2 kW;

- on average - 1.3-1.8 kW;

- on large ones - up to 4 kW and above.

This technological solution is quite logical and convenient - there is no point in brewing coffee in a Turk on a powerful WOK burner or trying to boil a large amount of water on a small one. Choosing different wattages allows you to save gas, and if the room temperature is maintained using an air conditioner, you can also save electricity.

When using powerful burners, the air heats up more due to heat transfer, so climate control equipment will require more resources for cooling

Therefore, the acceptable parameters for the calorific value of the gas used by a mid-price range hob, consisting of 4 burners, are 8-10 kW. Cheaper models usually have a total power of 5-7 kW.

High calorific value cooktops may require a separate chimney or heavy-duty hood installation to operate safely. However, for home use, purchasing such models is not always inappropriate.

Gas stoves with two- and three-circuit burners are especially popular. The so-called double or triple “crown” is a powerful burner in which the flame is emitted not in one row, but in several circles. This device allows you to cook faster and heat food more evenly.

Oven

Gas stove ovens are:

- gas;

- electrical;

- combined (with electric grill).

The optimal choice of the last two types of ovens, since they distribute heat evenly. However, with this choice, you must definitely consult with an electrician to see if the wiring can withstand the resulting load.

Gas ovens can be of 2 types:

- without convection;

- with forced air circulation.

The best choice is a gas oven with forced air circulation, since in this case the likelihood of cooking food that is not cooked through or that is burnt on one side is minimal.

Self-modification of the nozzle

If you determine that the equipment has unsuitable nozzles and there are no replacements, then you can find many recommendations for modifications on the Internet. They explain in detail how this can be done using a soldering iron, solder, sandpaper and sewing needles. It is recommended to check the performance of the resulting product experimentally.

But please note, this is very dangerous! The result of such an experiment may be a leak. You should not expose your life and health to such danger. Better to buy a new part

Better to buy a new part

You should not expose your life and health to such danger. It's better to buy a new part.

Gas burner selection parameters

Once the type of device and its functional features, as well as the operating conditions, have been determined, it is necessary to carefully study its characteristics and compare it with the closest analogues

You need to pay attention to the following technical points

Battery type

All of the above burner models operate on liquefied gas - propane or butane, which, in turn, can be supplied in completely different containers.

The most compact and portable burners, used for domestic and tourist purposes, use compact collet gas cartridges as a battery. Some devices have a separate compartment for such a can, others are fixed on top of it.

Classic tourist burners with one or two burners operate from five-liter gas cylinders connected through a special reducer. Such devices are widely used for both cooking and heating;

! Preference should be given to models that allow the use of several power sources with equal efficiency, and also have the ability to connect to a stationary gas pipeline.

Gas used to power the burner

- Isobutane mixture is the most common and versatile type of fuel. Provides clean combustion without large amounts of emissions and high heat transfer;

- Propane is a gas that is prone to clean combustion and does not tend to emit harmful substances during the combustion process. It is less common on sale than isobutane mixture;

- Butane is similar in properties to propane, but its combustion process is less clean, and it is also quite unstable in the cold season.

How to choose the power of a gas burner

The power of a gas burner is a parameter that reflects its operating efficiency and efficiency. It is impossible to achieve one hundred percent effect from gas combustion, however, many modern models have an efficiency rate of 80-90%. Power is traditionally measured in kilowatts and indicated in the technical specifications. In field conditions, the power of the burner is calculated quite simply - one kilowatt of energy is enough to cook one liter of food. For example, for a company of four people it is necessary to prepare about 2-2.5 liters of food, and therefore the most suitable burner will be capable of producing a power of 2.5-3 kilowatts. The same principle is used to determine the power of a gas burner used for other needs - heating a tent, water heating.

Ignition type

- Inexpensive gas burners in this regard are deprived of all conveniences - the valve opens the gas supply to the nozzles, and ignition is carried out using matches or a lighter. This principle is both reliable and not - there are no mechanical elements that can fail, but matches tend to get damp, and a lighter tends to fail at the most inopportune moment;

- Piezo ignition is used in advanced devices. It is a compact piezoelectric element that produces a spark and ignites the gas-air mixture when the button is pressed. It should be remembered that such ignition requires careful handling and periodic maintenance, and also that it may not work at altitudes above 4 kilometers. Even if your burner is equipped with piezo ignition, matches will never be superfluous;

Which one should I do?

Low-power gas burners for everyday life and small private production are classified according to performance indicators as follows. way:

- High-temperature – for precision soldering and welding, jewelry and glassblowing. Efficiency is not important, you need to achieve the maximum flame temperature for a given fuel.

- Technological – for metalworking and forging work. The flame temperature is highly desirable not lower than 1200 degrees, and subject to this condition the burner is brought to maximum efficiency.

- Heating and roofing systems achieve the best efficiency. The flame temperature is usually up to 1100 degrees or lower.

Regarding the method of burning fuel, a gas burner can be made according to one of the following. schemes:

- Free-atmospheric.

- Atmospheric ejection.

- Supercharged.

Ejection

In ejection burners, at least 40% of the air required for fuel combustion is sucked in by the gas flow from the injector. Ejection burners are structurally simple and make it possible to obtain a flame with a temperature of up to 1500 degrees with an efficiency of over 95%, therefore they are used most widely, but cannot be made modulated, see below. According to the use of air, ejection burners are divided into:

- Single-circuit - all the necessary air is sucked in at once. With a properly profiled gas channel at a power of more than 10 kW they show an efficiency of over 99%. Can't be repeated with your own hands.

- Double circuit - approx. 50% of the air is sucked in by the injector, the rest into the combustion chamber and/or afterburner. They allow you to get either a flame of 1300-1500 degrees, or a CPL of over 95% and a flame of up to 1200 degrees. Used in any of the ways listed above. Structurally they are quite complex, but repeatable on their own.

- One-and-a-half-circuit, often also called double-circuit - the primary air is sucked in by the flow from the injector, and the secondary air freely enters a limited volume (for example, the furnace firebox), in which the fuel burns out. Only single-mode (see below), but structurally simple, therefore they are widely used for temporarily starting heating stoves and gas boilers.

Supercharged

In pressurized burners, all air, both primary and secondary, is forced into the fuel combustion zone. The simplest supercharged microburner for benchtop soldering, jewelry and glass work can be made independently (see below), but the manufacture of a supercharged heating burner requires a solid production base. But it is the supercharged burners that allow you to realize all the possibilities of controlling the combustion mode; according to the terms of use they are divided into:

- Single-mode;

- Dual mode;

- Modulated.

Troubleshooting color changes

The most common mistake that users of gas equipment often make is purchasing the wrong equipment.

Some products are only suitable for one type of gas, but may be used for another. Then it is also possible to change the color of the flame.

In everyday life, propane stoves are often used, which require a slightly different ratio of gas and air. If they are connected to the main gas supply system, the color of the flame will changeFor example, a household appliance may run on propane. It requires a slightly different proportion of gas and air than natural gas.

Therefore, before purchasing a stove, it is important to ask whether it is intended for the gas mixture that you will use.

So, if the color of the gas flame has changed to yellow, orange or red, first of all, it is necessary to recognize the presence of danger. Many begin to blame everything on low-quality gas or problems with the supplier, but most often the reason is in the burners themselves.

It is important to find the source of the color change and troubleshoot it. If you cannot do this yourself, it is recommended to contact the company with which you have an agreement for the maintenance of gas equipment

They will carry out diagnostics and repair the device if necessary.

Most often, the problem is solved by simply cleaning your gas equipment. Sometimes it may be necessary to replace burner nozzles or take other steps to fine-tune the supply of air-fuel mixture to the burner

It is also important to take preventive measures. Most often, gas changes color due to the fact that the burners inside become clogged with household dust and food debris

If you use the stove more carefully and do regular cleaning, you can avoid unnecessary objects getting inside the burner. This is an effort that absolutely every user can make.

Cleaning can be done using special detergents. This should be done when the burners have cooled completely.

Try to follow these cleaning rules:

- Clean enamel and metal surfaces without using abrasive cleaners;

- do not use chlorine-containing cleaners;

- Clean glass ceramic surfaces with soapy water;

- For the holes themselves, use a stiff-bristled brush.

Finally, wipe the cleaned stove with a dry cloth, wait until it dries, and try to light the gas.

If cleaning the burners does not correct the situation, and the gas is still orange, then there is only one way out. You should immediately contact a specialized service center that repairs gas equipment.

The burners must be kept clean after absolutely every food preparation. Use available products and high-quality detergents to achieve the desired effect.

If you don't know how to disassemble and clean them, you can look at the instructions for your gas stove. There should be descriptions of how to clean these mechanisms

In addition, it is important to keep the entire stove clean, even the parts furthest from the fire. Indeed, in some cases, contaminants from those places can be accidentally transferred and fall under the damper

Most of the recommendations described above may seem elementary and frivolous at first glance. Many people think that they handle their stove normally and are in control of the situation. In fact, completely different processes can occur inside the slab.

The dust that you did not remove immediately ends up inside the burner, where it melts and chars. And in this case it becomes very difficult to clean it. And if the household appliance continues to be used in this spirit, its condition will deteriorate more and more. Ultimately, this will lead to complete failure.

Do not delay contacting gas services and specialists. If the stove systematically malfunctions, it needs repair. Preventive examinations from specialists will also be useful.

In addition, you should not neglect the rules for the safe operation of gas equipment, because even the slightest mistake can lead to dire consequences.

Technical parameters of blue fuel

- Flame temperature at different modes

- Dependence of temperature on fuel type

- Determination of flame temperature

Flame temperature at different modes

The gas mixture begins to ignite at 640–700 degrees, depending on the quality and composition of the gas, and the combustion process begins only at 800–900 degrees. This temperature is quite enough for cooking and heating water in a gas water heater. Gas boilers intended for home heating also operate in the same temperature range.

However, the temperature of the flame in different parts of it is not the same. The heterogeneity of the flame can be clearly seen upon closer examination.

The highest temperature is observed in the upper part of the flame, where it reaches a value of 1400 degrees. The maximum combustion temperature of the gas is 2043 degrees. However, such figures can only be obtained with powerful industrial equipment. On a kitchen stove, the flame is limited to a maximum of 1500 degrees.

In addition to the quality of the gas mixture, the temperature of the burner depends on the intensity of the fire, which is regulated by rotary knobs located on the gas stove or regulators on the boiler. Turning the tap at a small angle increases or decreases the fuel supply to the burner, thereby increasing or decreasing the heat transfer of the flame.

In addition, using the regulators you can increase or decrease the distance between the bottom of the pan and the flame, which is extremely important. The significance of this procedure lies in the fact that when the fire comes into contact with the cold surface of the cookware, incomplete combustion of the gas occurs, accompanied by the release of a large amount of harmful impurities.

Therefore, when placing a kettle with cold water on the stove, the burner must be adjusted so that the flame barely reaches the bottom, but in no case wraps around the sides of the kettle.

Dependence of temperature on fuel type

For domestic needs, two types of gas are used: natural and liquefied. Both of them are a transparent, explosive substance without color or odor. Therefore, to increase safety and the possibility of instant leak detection, ethyl mercaptan is added to the gas - a substance whose tart smell is felt by a person when he opens the gas tap. According to its chemical composition, natural gas consists of 98% methane and 2% of impurities that are represented sulfur, nitrogen and carbon dioxide.

In private homes, dachas and in areas not equipped with a main gas pipeline, liquefied bottled gas is used. For this, two types of mixture are used: propane-butane with a ratio of 65/35 and butane-propane prepared in a ratio of 85/15. The flame temperature of bottled gas is slightly lower than that of natural gas, and never exceeds 1000 degrees.

Due to the difference in temperatures, each gas has its own gas equipment. However, many manufacturers of gas stoves running on natural gas equip them with jets and reducers necessary to convert the stove to bottled gas. If the stove is connected to a cylinder without these important devices, the burner will begin to emit a huge amount of soot and constantly go out.

In this case, you will need to immediately contact the gas service and under no circumstances switch the stove to another type of gas yourself.

Determination of flame temperature

If the stove in the kitchen has a thermometer or a remote sensor with an indicator that displays temperature values on the screen, then determining the temperature does not cause any difficulties.

In addition, many modern units are equipped with a thermostat that maintains a certain temperature in the oven, as well as a thermostat that allows you to turn on the burner to the desired value.

However, most older home stoves are equipped only with an oven thermometer, and the fire temperature of the burners is not determined. This can be extremely inconvenient when preparing complex dishes that require precise adherence to temperature conditions.

How to light a fire

If you have never encountered gas stoves before, then the question of how to light a gas stove may be very relevant. To do this, you need to adhere to a certain algorithm. First of all, you need to ventilate the room. The following steps should be followed step by step:

- Open the tap on the pipe or valve if using a gas cylinder.

- Light the burner.

This process occurs differently depending on the type of stove and the source of fire. The stove can be lit in the following ways:

- from an open source of fire - matches;

- using an electric or silicon lighter;

- electric ignition

Modern models of gas stoves are equipped with a built-in electric ignition system. This function can be displayed on a separate button, or it can be built into the burner tap. This is the only case when turning the stove tap can simultaneously light the burner. In other models, you must first provide a fire (spark), and then open the burner valve. The tap opens clockwise when slightly pressed inward. Read about how to light a gas stove oven here.

The flame should be a distinct blue color and evenly distributed around the burner. If it slips in, close the tap and re-ignite the burner. The optimal flame height should not exceed 2-2.5 cm and is adjusted by turning the valve handle. If there is a draft in the room, the flame will tend to break away from the burner, which is dangerous from a fire safety point of view. If there is too much air, you need to close the window. If there is a lack of air, the color of the flame will clearly change from blue to yellow, and carbon monoxide will be released, which is dangerous to human health.

Features of installation of the accounting device

Installation of the meter must be carried out exclusively by specialists with appropriate qualifications; compliance with the required installation standards and requirements is mandatory. As for the cost of installation work, it depends on a number of individual features, including the specific model of the device, the location of gas pipelines and gas-powered equipment.

Which gas stove to install

When installing the stove, you should know that the main gas is supplied to the apartments at a pressure of 1.5 kPa (15 mbar) and the stove itself is set to the specified value, and the liquefied gas tank reducer is usually set to the gas boiler pressure of approximately 2.3-5 kPa (23-50 mbar). Because of this, increased pressure occurs, which can be judged by the red flame (normally blue) coming out of the burners of the gas stove, and the black “marks” of soot that appear on the bottom of the pans. There are two ways to solve this problem: install a lowering pressure stabilizer or purchase a stove that matches the gas pressure.

The production facility produces professional gas stoves of various modifications. Industrial gas stoves "Vulcan-Heidebrenner" are designed for use in catering establishments, in the kitchens of large and small restaurants and cafes, in canteens of preschool and school institutions, sanatoriums and hospitals. The main advantage of using gas stoves is significant savings in money, since today gas is the cheapest source of energy.

All Vulcan-Heidebrenner gas stoves are equipped with a piezo ignition system for all burners and a safety system against gas leaks (gas control).

Large control handles of the taps have a fuse against breakage of the tap (and, accordingly, gas leakage): if the load on the gas tap is exceeded, the fuse is triggered, which avoids breakage of the tap and gas leakage.

Massive cast iron burners securely hold and allow you to safely move heavy cookware across the surface, and the most powerful gas burners cook large volumes of food in a minimum amount of time.

Our series includes 2, 4, 6, 8 or even 10 burner models with or without one or two ovens.

The edges of the protruding internal elements are specially processed, which protects your hands from cuts and scratches during operation.

Upon request, the stove can be configured to operate on natural gas from the city gas network or liquefied gas from cylinders.

You can expand the functionality of the professional Vulcan-Heidebrenner stove by installing a kebab grill on a lava stone or a lava grill instead of one of the open burners on the table.

Hidden fastening elements on the body provide a more aesthetic appearance.

If your kitchen has narrow doors, then by unscrewing the adjustable feet, you can carry the stove into a standard doorway 80 cm wide.

We care about the convenience and safety of our consumers!

A few words about the internal structure of gas burners

Gas is blown into the burner cavity through an injector, which is often called a nozzle. But this is not where we need to start.

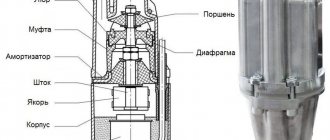

In modern kitchen appliances, burners consist of several parts:

- the divider is a flanged bushing with teeth, thanks to which the gas is distributed in a circle and forms a uniform flame;

- divider cover - this thing complements the design and is located in the upper part of the burner. In modern stoves, the lids can be made of different materials, but most often it is stainless steel.

In more sophisticated devices, all this is complemented by an electric spark plug, which is placed on the side. If you remove the divider and cover, you can see the jet. Essentially, it is a small bolt with a tiny through hole, made of brass or bronze. The hole has numbers stamped on it indicating its diameter. Passing through its cap, the fuel enters the divider and burns. When the stove smokes, the hole is too large.

Therefore, it makes sense to check whether the type of nozzles matches the raw materials used. Most gas stoves use jets designed for city main gas - methane. Here the pressure is less and the hole should be larger. And vice versa, in a propane tank the pressure is higher, which means the hole in the nozzle should be smaller.

Externally, nozzles operating from mains or liquefied gas are no different. The only difference is the holes. If upon inspection it is clear that the nozzle is not correct, it should be replaced. I note that the jets must match the specific stove model, otherwise they will not work correctly or you will not be able to install them at all. In addition, an incorrectly installed unit is a direct path to a gas leak and explosion.

Design examples

Understanding the designs of gas burners, we will take the path of increasing power, this will allow us to better understand the material. And from the very beginning we will get acquainted with such an important circumstance as supercharging.

Mini from a spray can

Mini gas burner device powered by a spray can for refilling lighters

Pressurization - from an aquarium compressor. Since without the resistance of the sprayer under water it gives a noticeably pulsating flow, you need a receiver made of 5 liters of eggplant. Soda is not produced in these, so the receiver plug will need to be additionally sealed with raw rubber, silicone or just plasticine.

The stumbling blocks when repeating this design are, firstly, adjusting the gas supply. There are no problems with air - its supply is set by the standard compressor regulator. But adjusting the gas by bending the hose is very rough, and the regulator from the dropper quickly breaks down, since it is also disposable. Secondly, pairing the burner with the can - in order for its valve to open, you need to press on the filling fitting

The first thing that will help solve the problem is the node shown in pos. B; they make it from the same pair of needles. First, you need to select a piece of tube for the sleeve that fits onto the canister fitting with a little effort, and then, also with a little effort, push it into the needle cannula; it may need to be drilled out a bit. But the sleeve should not hang either on the fitting or in the cannula separately.

Then we make a clip for the canister with an adjusting screw (pos. B), insert the canister, put the regulator on the fitting according to pos. B, and tighten the screw until the required gas supply is obtained. The adjustment is very precise, literally microscopic.

Soldering torches

The easiest way to make a soldering torch is approx. by 0.5-1 kW, if you have any gas valve available: oxygen series VK, from an old autogen (the acetylene barrel is plugged), etc. One of the design options for a soldering torch based on a gas valve is shown in Fig.

Simple gas torch for soldering

Its peculiarity is the minimum number of turned parts, and even those can be selected ready-made, and quite wide possibilities for adjusting the flame by moving the nozzle 11. The material of parts 7-12 is quite heat-resistant steel; in this case, the relatively inexpensive St45 is suitable, because the flame temperature, due to the complete lack of profiling of the gas channel and ejector windows (which do not exist as such), will not exceed 800-900 degrees. Also, due to the fact that this burner is single-circuit, it is quite voracious.

How to achieve safety

Here the matter is in the so-called. Reynolds number Re, showing the relationship between flow speed, density, viscosity of the flowing medium and the characteristic size of the region in which it moves, for example. cross-sectional diameter of the pipe. From Re one can judge the presence of turbulence in the flow and its nature. If, for example, the pipe is not round and both of its characteristic sizes are greater than a certain critical value, then vortices of the 2nd and higher orders will appear.

Not all homemade gas burners are accurately calculated according to the laws of gas dynamics. But, if you arbitrarily change the dimensions of the parts of a successful design, then the Re of fuel or sucked air may jump beyond the limits that it adhered to in the author’s product, and the burner will become, at best, smoky and voracious, and, quite possibly, dangerous.

Injector diameter

The determining parameter for the quality of a gas burner is the cross-sectional diameter of its fuel injector (gas nozzle, nozzle, nozzle - synonyms). For propane-butane burners at normal temperatures (1000-1300 degrees), it can be approximately taken as follows:

- For thermal power up to 100 W – 0.15-0.2 mm.

- For a power of 100-300 W - 0.25-0.35 mm.

- For a power of 300-500 W - 0.35-0.45 mm.

- For a power of 500-1000 W - 0.45-0.6 mm.

- For a power of 1-3 kW - 0.6-0.7 mm.

- For a power of 3-7 kW - 0.7-0.9 mm.

- For power 7-10 kW – 0.9-1.1 mm.

Power

Under no circumstances should you make a gas burner with a power exceeding 10 kW. Why? Let's say the burner efficiency is 95%; for an amateur design this is a very good indicator. If the burner power is 1 kW, then it will take 50 W to self-heat the burner. A 50 W soldering iron can get burned, but it does not threaten an accident. But if you make a 20 kW burner, then 1 kW will be superfluous; this is an iron or electric stove left unattended.

Armature

The third factor that determines the safety of the burner is the composition of its fittings and the procedure for using it. In general the scheme is as follows:

- Under no circumstances should the burner be extinguished using the control valve; the fuel supply is stopped using the valve on the cylinder;

- For burners with a power of up to 500-700 W and high-temperature ones (with a narrow injector, excluding the transition of Re gas flow beyond the critical value), powered by propane or isobutane from a cylinder up to 5 liters at an external temperature of up to 30 degrees, it is permissible to combine control and shut-off valves in one - standard on the cylinder;

- In burners with a power of more than 3 kW (with a wide injector), or powered from a cylinder of more than 5 liters, the probability of “overshooting” Re beyond 2000 is very high. Therefore, in such burners, between the shut-off and control valves, a reducer is required to maintain the pressure in the supply gas pipeline within certain limits.

Example of calculating gas consumption

Let's consider the consumption of blue fuel by the Gefest PG 6500-03 0045 stove. The device has 4 burners on the work surface and a gas oven.

Burner power in kilowatts:

We take the efficiency at 45%. We select the specific heat of combustion of household gas for two different cases: normal – 9.3 kW·h/m³ and maximum – 11 kW·h/m³. In the first calculation we will use the standard one.

The image shows a Gefest PG 6500-03 0045 stove, designed for a nominal pressure of 13, 20 and 30 mbar, and with a useful oven volume of 52 liters

We use the formula Q / (q × efficiency / 100%) = Vhour. We get 12.6 kW / (9.3 kW·h/m³ × 45% / 100%) = 3.01 m³/h.

For complete clarity of the calculation, we will do it in 3 stages: 12.6 kW / (9.3 kW h / m³ × 45% / 100%) = 12.6 m³ / (9.3 hour × 0.45) = 12, 6 m³ / 4.185 hour = 3.01 m³/hour.

Calculation in steps and only with numbers:

- 12,6 / (9,3 × 45 / 100).

- 12,6 / (9,3 × 0,45).

- 12,6 / 4,185.

- 3,01.

Gefest PG 6500-03 0045 is not the most efficient stove, but it has 2 burners in the oven, which is why the maximum consumption is so high.

The Hi-Light electric stove burner consumes the same amount as the average Gefest PG 6500-03 0045 burner, but heats up in just 5 seconds and has high efficiency

Let's calculate fuel consumption with maximum specific heat of combustion (11 kW·h/m³):

12.6 kW / (11 kWh/m³ × 45% / 100%) = 2.55 m³/hour.

To make calculations, it is enough to have burner power indicators and know the average values for other parameters.

As you can see, there is nothing complicated about calculating the gas consumption of a stove. You just need to devote a little time to this.

We also suggest reading our other article, where we talked in detail about how to calculate gas consumption for heating a house.

Gas stove burner design

To understand how you can increase the flame in a household gas stove, it is worth familiarizing yourself with the structure of the burner itself, the principle of gas supply and combustion.

The first thing worth remembering once and for all: what burns in the stove is not just pure gas, but a gas-air mixture. It is its final composition, the ratio of gas and air, that largely determines the size and efficiency of the fire that the consumer receives from the burner.

Burners in burners, depending on the method of air intake, are of three types:

- Diffusion ones are usually used in ovens. There is no air leakage in such structures; mixing with gas occurs naturally.

- Kinetic burners use line pressure to capture the right amount of air to create the right fuel mixture.

- Combination burners successfully use both methods of adding air to gas. These are the devices used in most household gas stoves.

The design of the burner itself has a simple, but precisely calibrated configuration.

The pipeline ends at a tip into which a nozzle is mounted. Its passage hole has a certain calculated diameter. It is through this that gas is supplied to the mixer, in which fuel is mixed with air. From the mixer, the flammable composition enters the burner, in which a flame is produced.

It is worth paying attention to the area between the jet and the mixer. While the gas overcomes this segment, exactly the amount of air that is necessary to obtain the optimal combination of fuel and oxygen is mixed into it

This distance is also strictly calculated, so that the gas burns completely and with the highest possible efficiency.

Burn, burn, my stove.

(review of the gas stove market)

- Issue: No. 4 (72) April 2004

- Material prepared by: Boris Bezel

“And we have gas in our apartment. ” – not so long ago, this children’s rhyme was perceived by many residents of the USSR with understandable envy. In fact, in the land of stoves and primus stoves, gas stoves were an unattainable luxury for many, much more desirable than the notorious “view of Red Square.”

In developed countries, gas heating of kitchen fires has been successfully used in everyday life for more than a century. To this day, gas stoves are widespread - especially in Russia, where in Moscow alone there are about 2 million gasified apartments. There are many reasons for this popularity. Gas stoves and built-in hobs are reliable and simple in design; they can last for decades without the need for any repairs. In addition, the use of gas in Russia (at least today) is economically beneficial, since it is cheaper than electricity. Gas stoves, when turned on, do not require time to warm up the massive burners, and after work, they do not need time to cool down. Finally, many cooks prefer to work with a gas stove out of habit - they believe that cooking with gas is more convenient.

Rules for using gas at home

- Carry out unauthorized gasification of a house or apartment, rearrangement, replacement and repair of gas appliances, cylinders and shut-off valves.

- Carry out redevelopment of the premises where gas appliances are installed, change the area of heated premises without coordination with the local government.

- Make changes to the design of gas appliances. Change the design of smoke and ventilation ducts; seal ventilation ducts, brick up and seal “pockets” and hatches intended for cleaning chimneys.

- Disable automatic safety and regulation. Use gas if gas appliances, safety automatics, shut-off devices (taps) and gas cylinders are faulty, especially if a gas leak is detected.

- Use gas if the integrity and density of masonry, plaster (if cracks appear) of gasified stoves and their chimneys are damaged.

- Install and use a valve (gate) on the smoke channel, chimney, chimney. If there is a valve (gate) in the furnace design, ensure that it is removed and sealed from the outside of the wall of the smoke channel of the resulting hole (crack).

- Use and install gasified stoves in apartment buildings.

- Use gas appliances when there is no draft in the smoke and ventilation ducts, closed vents (transoms), or the closed position of the louvre grille on the ventilation duct. In this case, at the bottom of the door or wall opening into the adjacent room, it is necessary to provide a grille or a gap between the door and the floor, as well as special air supply devices in external walls or windows.

- Use forced ventilation devices (hood, fan) when gas boilers or water heaters are running.

- Leave operating gas appliances unattended (except for appliances designed for continuous operation and having appropriate safety automatics for this purpose).

- Allow preschool children and persons who do not control their actions and do not know the rules for using these appliances to use gas appliances.

- Use gas and gas appliances for purposes other than their intended purpose. Use gas stoves for space heating.

- Use rooms where gas appliances are installed for sleep and rest.

- Dry clothes over or near a gas stove.

- Check the operation of ventilation ducts and the tightness of connections of gas equipment using open flame sources, including matches, lighters, candles and others.

- Store empty and filled liquefied gas cylinders in rooms and basements. Unauthorizedly, without special instructions, replace empty cylinders with filled gas cylinders and connect them.

- Have in a gasified room more than one cylinder with a capacity of more than 5 liters, not connected to a gas stove.

- Place cylinders at a distance of less than 0.5 m from a gas stove, 1 m from heating appliances, 2 m from stove burners, less than 1 m from an electric meter, switches and other electrical appliances and equipment.

- Expose liquefied gas cylinders to sunlight and heat.

- Allow damage to gas equipment and theft of gas.

- Twist, crush, bend, stretch or clamp gas hoses connecting gas equipment to the gas pipeline.

Equipment setup

The open chamber is a fairly simple combustion device. It looks like this: above the burner there is a heat exchanger in the form of a coil of thin copper tubes. Thanks to the open design, the air required for the combustion reaction is supplied to the point of ignition of the gas from the environment.

As a rule, there is enough air from the room (provided good ventilation is organized). But there are wall-mounted models with air intake from outside, for which a special hole is mounted in the wall. Open combustion chambers require a chimney.

Most often it is installed for models of floor-standing gas boilers, and was also used to complete an old-style boiler (in this case, ignition was carried out by a pilot burner).

Combustion chamber design diagrams

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

If the jet needs to be replaced

Here you can also do something yourself. To work, you will need a set of keys and a Phillips screwdriver: if the nozzles for bottled gas are 8 mm, for burners - 14 mm, for pipelines - 17 mm. Don't forget to turn off the tap.

In old-style plates, the jets are hidden deep down. To begin with, remove the dividers, burners, and table top. The type of fastenings depends on the type of stove, however, in most cases you need to unscrew a couple of screws. Here you can see traverses - metal strips on which the burners are fixed. All of them are made in the same design and differ only in the length of the aluminum pipeline connecting the nozzle and the divider. There is one metal frame for every two burners. The body of each burner is rigidly fixed to the traverse, and the pipes are fastened in pairs with ears inside the body.

As I said, at the end of each pipeline there is a nozzle where the gas is supplied. Then, through a hole in the nozzle, it comes out to the burner and is fed to the divider. To replace the plates in older models, you need to release the tip with the nozzle by bending the special lock. In the new ones, everything is done much simpler, you don’t need to bend anything. When you have found something to replace, you can start repairing. Assembly is carried out in reverse order.

Tips for saving gas

Follow these simple tips to reduce gas consumption when cooking on the stove.

- Use only the heat that is sufficient for the cooking, frying or stewing process, and do not exceed the heat.

- After the water or broth boils, the flame can be pressed to a minimum.

- The fire heats the bottom of the pan faster and more efficiently if it touches it lightly, rather than covering it from all sides. It has been proven that the highest burner temperature is at the top point of the flame.

- When the container is placed on the burner, close it with a lid. The boiling and cooking process then goes faster. Some food is cooked only with the lid open, but heating water to a boil or heating the dishes initially with the lid closed will not harm the dish itself.

- Make sure that there is no draft in the room where the cooking appliance is located, in which part of the thermal energy is directed to the side and wasted.

- Close the valve when the dish is already cooked. Or press immediately as soon as the water boils.

- Do not heat the contents in a container with a flame turned on. In this case, the walls of the containers give off heat faster, and gas consumption reaches 10–15%.

- Try to cook small dishes in the oven less often. Warming it up takes a lot of resources.

If you have a gas water heater installed in your apartment, you should save water that needs heating. Fill the sink with water when washing dishes, and use running water for rinsing. It has been noticed that if you take a shower rather than a bath, much less hot water is consumed. To save money, special nozzles for shower heads are sold.

If there is individual heating, the largest amount of gas is spent on heating the home. Insulate the house, install a boiler with an automatic thermostat. Reduce the temperature 2 degrees below comfortable. If possible, use a solid fuel boiler, as it is more economical than a gas one.

It would be useful for any utility user to know the fuel consumption and power of their gas stove, boiler, or water heater. Then monthly invoices will not surprise you with their numbers. The ability to independently make calculations will help you compare the maximum and minimum consumption of gas devices and choose the right meter in accordance with the parameters.

When purchasing a metering device, do not destroy the technical documentation for it; it may be useful when installing or replacing them. For old-style gas stoves, the documents for which have been lost, you can take average indicators.

The gas consumption test is shown in the following video.

Rules of operation and repair

The serviceability of equipment and your personal safety largely depend on how you treat the equipment. This includes correct installation, careful operation, regular maintenance and replacement of parts that have a limited service life.

Here are the basic rules for using a gas stove:

- regularly clean the grate, stove surface, burners, control knobs;

- keep in touch with representatives of Gorgaz and regularly carry out maintenance of equipment;

- ventilate the room, even if you use a hood;

- in case of prolonged absence, close the shut-off valve;

- Make sure that the knobs are in the “off” position while the hob is not in use.

You also need to be careful when using the oven. It, like any equipment, requires cleanliness and serviceability of all parts.

It is not recommended to use the oven as an ordinary cabinet for storing dishes, especially cluttering it with easily flammable or melting objects.

Only “working” accessories should be inside the oven: baking sheets, racks, grill equipment and utensils or molds, if they are involved in cooking

If the ventilation is faulty and it is not possible to open a vent or window, it is prohibited to use gas equipment.

If a specific smell of gas appears, it is necessary to open the fuel supply valve, open the windows and call the emergency service. During the waiting period, you should not turn on electrical appliances, light a flame, or better yet leave the room altogether. It is recommended to even make a call from the landing or from the street.

Repair of gas equipment should be carried out either by invited specialists from the service organization, or by employees of a specialized service center.

Nozzle and handle - manufacturing options

If you look from the outside, the handle and nozzle are, in fact, the entire unit .

The rest is pipes and valves supplying gas. For the nozzle, you can purchase a brass nozzle from gas appliances. They sell without problems and cost pennies.

If you need a special design, you can proceed as follows.

We clamp a suitable workpiece with a vice.

To avoid crushing the thread when clamping the part in a vice, first use a regular wooden clothespin.

Carefully drill a hole with a drill of a suitable diameter, not reaching the end about a millimeter. We grind down the remaining metal until the point left by the very tip of the drill appears.

After this, using a thin drill or a hardened awl, we punch a hole of the required diameter from the inside.

Any suitable object can be used as a handle. A handle from an old soldering iron, a piece of thick-walled hose, or a drilled piece of wood will do.

To fix parts and hoses, we use clamp clamps and hot glue gun.

The burner flame is adjusted and adjusted in the following ways:

- gas control valve - current;

- moving the nozzle (nozzle) along the axis of the injection chamber, changing its opening.

- changing the size and shape of the supply window through which atmospheric air enters.

The last two methods are used when setting up . They do not need to be changed during operation. However, if you are not sure of the accuracy of the design calculations, you should take care of the possibility of adjusting them.

How to increase the power of a gas burner in a gas stove? Example.

How to increase the power of a gas burner in a gas stove?

A woman came to us, a big fan of hiking and all kinds of river rafting. She brought with her a small tourist single-burner stove PGT1 model 802 and asked “Is it possible to increase the power of the burner in such a stove”?

Let's take two Hephaestus burners assembled and consider these two designs.

When assembled it looks like this:

A pipeline that ends with a tip into which a nozzle with a through hole of a certain diameter is screwed, directing the gas flow into a mixer installed on the burner body.

It is worth noting the following:

— the distance from the nozzle to the entrance to the burner mixer tube is approximately the same, about 14 mm, — the holes in the nozzles are different (small burner 0.5 mm, medium burner 0.75 mm nozzle hole diameter, i.e. 25% more gas is supplied to medium burner than small)

Do you know, for example, that in order to take and burn 1 cubic meter of natural gas, we need to mix it with and burn 10 cubic meters of air? Standard formula.

This is the idea

The gas from the nozzle in a thin stream hits the inside of the mixer (burner) tube in a straight line 14 mm long, sucking in or taking with it, as you wish, a certain amount of air, where in this tube, or rather its outlet, mixing of gas and air occurs (hence we have The factory name of the burner is the name of the mixer).

What is the secret meaning?

The distance of 14 mm was not taken by chance by the factory!

1 . If you start to increase this distance, then there will be an excess of air and the combustion power of the resulting gas-air mixture will drop.

2. And if we reduce this distance, we will get an excess of gas, and the air will not have time to mix in the required amount. We get a red flame, soot that the kettle cannot be washed, but the power, of course, will increase by some amount.

3. And the distance between the nozzle and the entrance to the mixer tube cannot be increased indefinitely either, since the gas stream simply breaking into the air will not enter the mixer tube at all.

Based on the data obtained, we see that simply increasing the diameter of the nozzle in order to increase the burner power will not be entirely correct. But we did just that, although to be fair, we would also have to increase the diameter of the burner so that there would be more mixture. But the housing did not allow inserting a mixer of higher power.

As a result, we gave the lady two types of nozzles with a diameter of 0.85 and 0.95 mm M6 pitch 0.75. According to the state, the tile has a jet with a diameter of 0.75 mm. Haven't called yet. Usually, if they don’t call us, then everything is fine)))

Below is a burner and nozzles to increase power for PGT 1 (gas tourist)

Source

Choosing a torch for soldering

Soldering or cutting cannot be done using ordinary gas torches. For this purpose, powerful and productive devices are needed, equipped with an air blower or an injector. By adjusting the composition of the supplied mixture, you can achieve the flame of the required strength and perform the necessary work related to soldering metals or other materials. Professional torches used for soldering are expensive, and therefore they are needed by a narrow circle of specialists. The power of such devices is 10-15 kW.

Attention! This material is the subjective opinion of the authors of the project and is not a guide to purchase

How to clean injectors

First, turn off the gas and check if the stove has cooled down. To clear the blockage, you need to remove the cover and dispenser. As I said, there is a small hole inside. Take a sewing needle and carefully clean it. There is no need to crush and put pressure on him. Simply insert the tip and gently rotate the needle between your fingers.

Care and operation of gas stoves

At the same time, if there is dirt, it is useful to clean the divider itself and the cover. You can use a toothbrush, dish soap and a stream of warm water. You cannot pick with wire or nails. Modern burners are not the same as those used 50 years ago. They won't stand such vandalism. Then you wipe the whole thing dry, dry it for half an hour or a little longer, assemble it and put it in place. When assembling, make sure that the grooves and projections of the burner match. The lid should be in place exactly, without displacements or distortions.

Use cookware with a heat exchanger element

When heating water in ordinary flat-bottomed pots, a large amount of heat is spent simply heating the air around it. Fuel is used especially inefficiently if the shape and dimensions of the burner burner do not match the dimensions of the bottom of the cookware. Heat exchange elements are designed to capture the heat that radiates away from the burner and return it to heat the boiler. Heat exchangers can reduce gas consumption and cooking time by up to 50%, as well as reduce the harmful effects of wind on the boiler flame. The higher price of such utensils is very quickly compensated by the reduction in the cost of gas cylinders.

Gas stove burner design

To understand how you can increase the flame in a household gas stove, it is worth familiarizing yourself with the structure of the burner itself, the principle of gas supply and combustion.

The first thing worth remembering once and for all: what burns in the stove is not just pure gas, but a gas-air mixture. It is its final composition, the ratio of gas and air, that largely determines the size and efficiency of the fire that the consumer receives from the burner.

Evidence that the optimal amount of air is added to the gas is a blue color, the absence of soot and obvious yellow “flies”

Burners in burners, depending on the method of air intake, are of three types:

- Diffusion ones are usually used in ovens. There is no air leakage in such structures; mixing with gas occurs naturally.

- Kinetic burners use line pressure to capture the right amount of air to create the right fuel mixture.

- Combination burners successfully use both methods of adding air to gas. These are the devices used in most household gas stoves.

The design of the burner itself has a simple, but precisely calibrated configuration.

The diagram shows the structure of a gas burner. Only at first glance the design seems simple. However, a failure in any unit can affect the quality and composition of the gas-air mixture and reduce the efficiency of the stove

The pipeline ends at a tip into which a nozzle is mounted. Its passage hole has a certain calculated diameter. It is through this that gas is supplied to the mixer, in which fuel is mixed with air. From the mixer, the flammable composition enters the burner, in which a flame is produced.

It is worth paying attention to the area between the jet and the mixer. While the gas overcomes this segment, exactly the amount of air that is necessary to obtain the optimal combination of fuel and oxygen is mixed into it

This distance is also strictly calculated, so that the gas burns completely and with the highest possible efficiency.

GOST indicators

The power of a gas stove's burners is measured in kilowatts (kW). According to the requirements of GOST 10798-85, this household appliance must meet the following technical characteristics:

- have several burners - from 2 to 4, each of which must ensure normal maintenance of a flame that is resistant to air flows;

- have reduced (0.6 kW), increased (2.6 kW) and normal (1.7 kW) thermal power;

- have a power of the main burner per oven unit of 0.08 kW/dm³, of the oven fry burner - 3 kW.

Typically, the parameters of burners are indicated in product data sheets and differ depending on the model and country of manufacture. On average, the total power of all burners is 10 kW. GOST standards apply to all household gas stoves, except for tourist stoves and those that discharge combustion products into the chimney.

The burner burns weakly or goes out

The burner of the table or oven burns weakly when the tap is open fully and the oven is cold. If there are problems with only one burner (the rest are working fine), then the reason is that the nozzle of the corresponding burner is clogged. The repair is simple. It is necessary to clean the nozzle (nozzle, injector). This is done with a thin wire or needle. First, you can try cleaning the nozzle without removing it. The nozzles of the table burners are installed under the burners (Fig. 1. A). The oven burner nozzle is installed on the side of the stove (Fig. 2. A). Getting to the oven nozzle is not always easy. Then you need to remove the bottom wall of the oven, unscrew and remove the burner (it is secured there with one or two screws). The nozzle will be accessible from the oven.

If you cannot clean the nozzle without removing it, you can easily unscrew it with a suitable key.

If all the burners burn weakly, then the reason is low gas pressure. The burner of an oven with a thermostat should be checked when the oven is cold. Otherwise, the thermostat may reduce the gas supply when a certain temperature is reached. This is, in fact, its standard function.

LOW GAS PRESSURE

Quite often, owners of gas stoves complain about low gas pressure. In this case, it is very important to immediately establish the cause of this phenomenon. invites you to diagnose gas equipment and, if necessary, eliminate the malfunction. We have been working in the field of servicing gas appliances for many years, we have extensive experience and an impeccable reputation. By contacting us, you can rest assured that your stove is in good hands.

Main causes of the problem

Gas stoves are one of the most common types of household appliances. And the quality of the prepared food depends on their serviceability. This is why low gas pressure is a serious problem and causes a lot of inconvenience. Poor gas supply can result in:

- changes in the color of the flame in the burners;

-reducing flame intensity;

- complete loss of fire in the burners.

There are two reasons for this phenomenon:

- weak gas pressure in the pipeline itself;

- contamination of the burner dividers or the nozzles themselves.

How to eliminate weak gas pressure

If the cause of the problem is that there is low gas pressure in the gas main itself, then you need to contact the gas service at your place of residence. In Moscow it is Mosgaz, in the region it is Mosoblgaz. They will check the line and fix the problem. However, much more often the reason is different.

If the problem concerns only one burner, then there may be problems directly with the stove. In this case, it recommends not to try to eliminate them yourself. It should be remembered that gas stoves are potentially dangerous equipment, and work with them can only be carried out if you have the appropriate certificate.

If your stove needs repair, call us. A qualified technician will come to you as soon as possible and determine the cause of the malfunction. Then he will clean the required gas equipment unit or replace it. Using only original spare parts significantly improves the quality of repairs. Entrust the repair of your equipment to us, and your stove will serve you for many years to come.

Conclusions and useful video on the topic

It is not always possible to figure out how to clean a gas burner from scale and dirt the first time. The video below offers detailed instructions on how to do this:

So, the normal color of a gas flame is blue. If your burners burn differently, this is a reason to clean them or call a specialist for a more complete diagnosis. You shouldn’t delay this issue, because it’s not just the color of the flame that changes, but the composition of the combustion products.

The accumulation of carbon monoxide can lead to undesirable consequences. Therefore, gas safety issues must be addressed first.

Have you ever experienced a change in flame color? How did you act in such a situation? Leave your comments, share your experience, ask questions - the contact block is located under the article.

Gas burns reddish

Carbon monoxide is a byproduct of the combustion of any fuel.

Gas water heaters, which have a blue flame when burning gas, emit a safe level of CO. An orange or red flame indicates an increased presence of CO emissions. The symptoms of carbon monoxide poisoning are identical to those of the flu, headache, dizziness and nausea.

Carbon monoxide is called the “silent killer”; it fatally poisons the unsuspecting user, while having no aroma or color. Therefore, if the gas burns reddish and the gas heater goes out, you should take care of professional cleaning.

Several decades ago, due to the lack of a gas control system, gas water heaters killed up to a hundred people a year, poisoning them with carbon monoxide. We, as a company engaged in the repair and sale of gas equipment, advise you not to let things get to this point, but to call a professional technician at the first sign of a malfunction of the gas water heaters.

Inadmissible actions during operation

In addition to all of the above operating requirements, you should also know the list of actions that are strictly unacceptable when using the stove. So, IT IS PROHIBITED:

- drying clothes over the stove - there is a high risk of fire;

- leaving the stove turned on unattended is also likely to cause accidental ignition, for example, of a nearby towel, or a gas leak resulting from the fire dying out when the tap is open;

- allow preschool children to use the gas stove;

- heat the premises using the burners turned on;

- independently install and change gas equipment, including a kitchen stove - in this case, in addition to the above risks, punishment is provided for by the gas service and administrative authorities.

Despite the numerous advantages of a gas stove over its electric counterparts, it causes greater harm to the health of household members and requires increased caution during operation. The use of natural gas makes it more economical, although modern models of induction and electric furnaces of class A+ and A++ allow optimizing electricity costs, keeping them to a minimum. Therefore, taking into account the desires of the surrounding world for environmental friendliness and energy saving, when choosing a stove, you need to analyze all the pros and cons of each type, and adhere to safety requirements during operation

Therefore, taking into account the desires of the surrounding world for environmental friendliness and energy saving, when choosing a stove, you need to analyze all the pros and cons of each type, and adhere to safety requirements during operation.

Adjusting the flame of the hob burners

The normal operation of the burner must be adjusted in cases where the flame loses efficiency and quality. The creation of a gas stove should also be done by a specialist. But understanding the algorithm of this process will be useful to any user.

First, you need to figure out what a properly burning stove flame looks like. The fire should be blue. An intense bright blue glow is a sure sign that the stove is working properly and you do not need to debug it. A yellow, orange or red flame indicates an incorrect fuel mixture. In this case, there is clearly not enough air; its flow needs to be increased.

Sparks and flames are another sign of insufficient air in the burner mixture. The composition is corrected using a special screw.

To change the gas-air mixture entering the burner, it is necessary to adjust the operation of the air dampers, which are usually located near each burner.

The direct setting is as follows:

- after disconnecting the stove from the gas system, it is necessary to gain access to the adjustment mechanisms under a special partition or in the gas regulator handle;

- the stove is reconnected to the electrical network, gas is supplied to each burner in turn;

- the volume of air entering the mixer is regulated by turning a special screw;

- Once the flame in each burner is the correct color, you can turn off the stove again, reassemble it and connect it to the mains.

When adjusting the stove, it may be necessary to work with the gas control valve and its thermocouple. If the flame regularly goes out when the fuel level is low, the problem may be with the gas regulator. The operating principle of this option is based on a special sensor that reacts to the energy released during the combustion process. If the flame suddenly goes out, the thermocouple sensor cools, signaling that the gas supply has stopped.

Simply using a small sensor can prevent severe consequences. Therefore, the stove top and its parts must be kept clean.

However, oxidation processes and a decrease in the sensitivity of the sensor due to the ingress of liquids or the formation of plaque from food deposits can cause the gas to close incorrectly outside of an emergency situation. Therefore, both the stove and this unit must be kept clean, and if necessary, call a professional for cleaning.

If you encounter unusually noisy burner operation, we recommend that you find out the cause of the burner noise and how to eliminate it.

The nozzle is clogged with dirt

Another popular reason why one or all burners do not light is a nozzle clogged with dirt. It is a small nozzle through which gas is supplied. To clean it, you should follow strict recommendations so as not to worsen the situation and not expose yourself to danger:

- remove the burner and clean it if necessary;

- we find a small hole - a nozzle;

- Using a needle, a straightened paper clip, or wire, carefully clean it and turn the tool in one direction or the other. The item used must pass through the channel without obstruction! If there is an obstacle, be sure to contact the appropriate service, do not break through it yourself;

- We assemble the burner and check the operation.

You cannot run gas directly through a nozzle that is not covered with a disk - a burner!

Systematically clean the stove thoroughly, making sure that dirt does not collect on the surface. Proper care is the best preventative measure in such a situation.

Gas oven design and operating principles

A gas oven is a heat-insulated chamber built into the body of a gas stove or located separately with burners inside.

The oven in the Hephaestus gas stove models currently presented by the industry has two burners - the main one, for preparing traditional dishes and baking, and a grill burner for roasting meat dishes.

The oven is equipped with a baking tray, a roasting pan for collecting juice and fat, and a wire rack for placing baked meat, vegetables, and fish on it.

The operating principle of an oven in a gas stove is to heat the air as a result of the combustion of liquefied fuel or natural gas. Gaseous fuel is supplied to the burner and combustion chamber from the network or a gas cylinder.

The TUPA valve regulates the gas supply. It passes through the nozzle and mixes with air, then leaves the nozzle and ignites.

Ignition can be done manually, using matches and an electric lighter, or using an electric ignition built into the design of the gas stove

GEFEST cookers are also equipped with a timer, pleasant lighting in the oven, and a gas control function. This same gas control serves to interrupt the gas supply if it fades. The last function is simply irreplaceable if a draft blows out a weak flame or the fire is flooded by liquid running from the pan.

What is a TUP faucet and how does it work?

The TUP tap is a safety thermostatic device, which is a capillary tube containing a kerosene mixture. There is a small canister on one side of the tube. When heated, kerosene liquid expands and closes the gas path to the burner, and when the temperature drops, it opens it.

The TUP tap has a start button that opens gas access to the oven burner. There are models that have a faucet installed without a button

The TUPA mechanism is hidden behind the stove panel and is controlled by a tap handle, which simultaneously controls the operation of the oven and grill, maintaining the set temperature.

Gas control function in household stoves

Gas control is a useful feature that significantly increases the safety of gas cooking equipment during its operation.

At the same time, it is precisely this that makes it difficult to ignite the stove, and in the event of a breakdown, it makes it completely impossible to use the equipment.

Operating a gas stove with a faulty and poorly functioning gas control system is unacceptable! If a breakdown is detected, you must contact a specialist

Oven taps with built-in gas control differ in different stove models in the number of thermocouples connected to them. A faucet with two thermocouples controls the burners of the oven and grill, while a faucet with one thermocouple controls and starts only the oven.

Thermocouple using the example of a gas burner. For a thermocouple to work, it must heat up for a certain amount of time. Until it warms up, you need to keep the burner tap pressed so that the valve does not interrupt the gas supply

Popular articles Technology for effective foundation insulation with penoplex

A thermocouple is two wires made of different materials that are fused together in such a way that the junction forms a small ball. When the temperature rises to a predetermined temperature in the work area of the part, a small electrical signal appears.

This weak electrical charge is transferred to the solenoid valve, which as a result opens the gas supply path. If the flame goes out, the thermocouple cools down. Due to a drop in temperature, the signal stops flowing to the valve, which closes the blue fuel supply channel.

Ways to increase burner power

Depending on the design features of the burner, several methods are popular for increasing the power of the stove. But is it worth checking them on your own experience?

It is worth remembering that independent repair of gas appliances is also prohibited, and even remodeling equipment at home is an event bordering on dangerous and even fatal sabotage.

A common cause of emergency gas leaks is very often the neglect of household appliances by users. The end of such incidents is often tragic

Unfortunately, explosions and carbon monoxide poisoning are tragedies that shock the public with the frequency and number of deaths. Therefore, there is absolutely no point in altering the burner for convenience. And the methods described below are more useful for understanding the theory than for practical application.

Method No. 1 – boredom or jet replacement

The throttle is one of the main regulators of the volume of gas that gradually enters the burner. To increase the power of the stove, you need to carefully pierce the nozzle or replace it with a part with a wider supply hole.

For boring, you can use a sharp knitting needle with a diameter of up to 3 mm. But don’t get too carried away: uncontrolled enlargement of the hole or replacement of the nozzle is fraught with extremely unpleasant consequences.

it is impossible to increase gas consumption without calculation errors, since the burner itself must be able to process it. Excess gas will cause the flame to separate from the burner. The fire will change color to red, soot will appear, which is almost impossible to remove from the cookware. The problem can be solved by installing a larger diameter burner.

In fact, drilling the nozzle leads to the creation of an emergency situation and a fire hazard. The fleeting ability to increase the power of a burner is almost guaranteed to lead to undesirable consequences

However, replacing the burner is not always possible due to the design of the furnace body itself. Even if you do replace the burner, the new volume of gas passing through the nozzle may not be enough. This threatens even greater problems - the flame can slip and burn near the nozzle itself.

But the extinguished flame and soot in this case are the lesser of the evils. Falling into a flame indicates incomplete combustion of the gas, which releases combustion products dangerous to life and health: soot and carbon dioxide.

Method #2: Reduce the length of the jet mixer

Fortunately, this method is not as popular as tips on how to increase the power of a gas stove. The method is more dangerous than the previous one, since it involves even greater interference in the burner design, is less effective and can even lead to negative consequences.

The size of the area referred to in the description of the burner device also affects the power of the flame created. If this zone is reduced, gas will enter the burner faster and the burner power will increase slightly.

However, some of the air necessary for normal combustion simply does not have time to mix with the incoming gas. As a result, the upgrader will get the same red flame with soot that will most likely come off the burner.

A gas burner is an important and clearly designed unit by engineers, where every part has optimal characteristics and is in its place

Method #3: Remove the splitter

You can try to increase the burner power without compromising the operation of the nozzle. The partition covering the burner evenly divides the flow of the gas-air mixture, distributing the flame into separate bundles. Removing the diffuser increases the contact area between the flame and the cookware. The column of fire becomes higher and higher, and the heat treatment itself proceeds faster.

However, this is an extremely temporary measure and is not suitable for all dishes. For this type of cooking it is necessary to use high cauldrons or special WOK frying pans. Uncontrolled fire from the partition also becomes quite dangerous.

It will also be useful to regularly clean the holes in the partition, which may become clogged with combustion products or burnt-on food debris.

Method #4: Increase Gas Pressure

The pressurization method is only suitable for stoves connected to gas cylinders. The standard cylinder pressure for home use is approximately 1.6 MPa. But this value is not constant: the force of gas pressure on the walls of the vessel can be influenced by both the degree of filling of the cylinder itself, and the temperature in the room, the composition of the gas, etc.

The higher the temperature of the gas, the more it expands, pressing against the walls of the container. Consequently, the cylinders are not completely filled, but approximately 85%. Moreover, the less gas remains in the vessel, the weaker its flow into the burner.

you need to try to increase the pressure of the gas entering the furnace using a reducer, the so-called “frog”. Tampering with the assembly is unsafe and, fortunately, most modern gearboxes cannot be disassembled. However, replacing the part may solve the problem. Supplying gas at higher pressure will cause increased air leakage, causing the burner flame to increase significantly.

But do not forget about safety precautions and monitor the gas supply even with the burner regulator closed. Too much pressure can cause gas cutting even if the burners are not lit.

The cylinder is an important element of the gas system. Gas cylinders must be subjected to periodic inspection and maintenance, during which the tightness of the joint will be checked, and if necessary, the valve will be replaced

Based on all of the above, you can understand that when choosing one of the methods of increasing potency, you should be extremely careful and not overdo it.

The only safe and economical way to increase the power of your burners is to buy a new hob or stove. It is necessary to initially select gas equipment that meets the needs of the family. Any attempt to change the parameters of the burner passport by an inexperienced technician at home will inevitably lead to serious problems.

Ignition produces a spark, but the burner does not ignite

If a spark occurs when turned on, but no fire occurs, the reason is the thermocouple. It is necessary to intercede if repair is impossible. Updating the solenoid valve also gives a positive result. After this, the stove works stably.

Advice! Check the picture of the ignition unit - if it is in order, but a spark does not occur, the problem lies in the unit or power supply wire.

If there is a spark, the dust burns, but goes out quickly, press the button to supply gas for a long time. Perhaps the sensors responsible for supplying the flame do not have time to warm up.

How to determine the flame temperature?

First of all, these parameters can be found in the instructions for the gas stove. If the equipment was purchased quite a long time ago, then the documentation may not have been preserved, but it is necessary to know the basic parameters of the equipment’s operation. There is a list of average indicators that are found in most models. For example, the operation of a gas oven is assessed according to the following parameters:

- Maximum temperature 280 degrees.

- With medium heating, the temperature is about 220 degrees.

- With a minimum gas supply - 160 degrees.

In order to check exactly what temperature a gas stove operates at, you need basic knowledge of physics. That is, information that relates to the boiling of various liquids. The main parameters include:

- simple clean water will begin to boil at 100 degrees;

This method of determining the combustion temperature of a flame in a gas stove is suitable only for older models. Since new and modern equipment is equipped with ultra-sensitive thermometers and special sensors that measure temperature as accurately as possible.

At first glance, the flame of a gas burner does not represent a large torch in which high temperatures can rage, but in fact the temperature in individual parts of the torch can reach 2000 degrees or more. Much depends on the composition of the gas or its type. The highest temperatures occur in the center of the plume, in its brightest part. The lowest temperatures occur at the base of the flame.

Read also: Get vaccinated in Moscow for an adult