Some owners of country houses and dachas use houses for residence only in the warm season, organizing an appropriate autonomous water supply from a well or well. After the end of their stay with the onset of cold weather, many homeowners are faced with the question of how to drain the water from the water supply system for the winter.

Not only the external and internal pipelines, but also the automatic elements of the electric pump and pumping equipment will have to be freed from water masses. The task is not so simple due to the presence in the house of a large number of plumbing and household electrical appliances, the operation of which is related to water consumption and residual water can be stored in these devices for a long time.

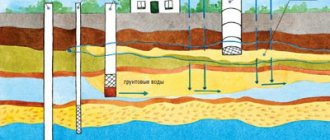

Rice. 1 Draining water from a house into a well - an example of a diagram of how to drain water from a water supply system for the winter

Preparing the cottage for winter: draining the water

All properly designed water supply systems in country houses for seasonal residence, regardless of the material of the pipes, shut-off valves, operating pressure and location of the pump, are basically the same:

- The pipes have a slight slope towards the well or well.

- The pipe through which water enters the house has a check valve (in the well or in the house, next to the accumulator). In operating mode, it prevents water from draining.

To drain all the water from the water supply, the owner of the dacha must stop the operation of this valve, then the water will return back to the well, or, if a well is used, it will drain into a special drain. Therefore, a drain valve is installed on the pipe between the check valve and the hydraulic accumulator (a valve with a long handle is placed in the well so that it can be opened and closed from the surface of the ground).

When the check valve is installed on a pipe in the house, next to the accumulator, the drain valve is installed on a parallel pipe.

Sometimes the system is not installed quite correctly, and there is no parallel pipe with a drain valve. There is no other way out - all that remains is to disassemble the water supply unit and drain it manually.

When draining water from the system using a drain tap, you need to ensure that all mixer taps are in the open position at this time.

After draining the water, you need to disassemble all the filters that are installed in the system in front of and behind the hydraulic accumulator, remove the cartridges and send them for storage.

Air purging technique

Air has high compressibility, unlike liquid, in which this property is much less pronounced. Thanks to this characteristic, it is successfully used in shock absorbers. Excellent compressibility indicators also explain the fact that effective blowing requires a powerful compressor, which cannot be said about the machine version. When blowing out a long pipe, there is a rapid drop in air flow pressure, which makes it impossible to blow out the remaining volume of water.

Purge of the water supply system must be carried out taking into account the permissible pressure and air consumption. You should not use too strong compressors, since the pipes with which the internal wiring is equipped can withstand a maximum pressure of 8-10 atmospheres. The process of purging a complex and long plumbing system, which is equipped with multi-story buildings, can require a very large air flow.

How to drain water from a pump for the winter

The next important part of the system is the pumping station. If it is installed in the house, be sure to empty the water from it. If it’s in a well or borehole, then, theoretically, you don’t have to do anything at all - the freezing depth in the Moscow region is 1.5 meters, and pumps are installed deeper.

Sanych1415 Member FORUMHOUSE

The main thing is that the hose can withstand temperature changes. If it holds up, then there is no problem.

But in practice, when using a well or well seasonally, FORUMHOUSE participants, at the end of the summer season, pull out the pumps and take them to the city so that the equipment can winter in a warm room.

Andrey 203 FORUMHOUSE Administrator

At the end of the season I sort everything out. The pump and automation are stored at home at positive temperatures.

To drain water from the pumping station, you need to turn off the power and unscrew the drain plug, which is located in the lower part of the pump housing. The pump should be tilted towards draining the water, and to ensure complete drainage, turn it upside down.

Areas of application for purging

It is important to know the applications of the compressor in which the blower is a necessary equipment.

More than one water supply needs preparation for the winter period, the cleaning process of which is a common activity, especially for its internal part.

The temperature in the room is always higher than in the outside space, which means that the occurrence of negative temperatures inside the house is a very rare phenomenon.

The most common cases of damage include problems in the following systems:

- in external automatic watering;

- in a pipeline located inside rooms that are not heated;

- in the external (street) water supply;

- in pet feeders;

- in the water supply connected to the pool;

- pumps and pumps

The systems listed above also require pre-purge using a compressor.

How to drain water from a water heater

Having dealt with the pump, we move on to water heaters: storage heaters are usually installed in summer cottages, and on the eve of winter, the water from them must be completely drained. The heater is not intended for operation at subzero temperatures, and if even a little water remains in the device, it will not survive the winter.

Unfortunately, dacha owners often make mistakes when draining water in heaters and leave some water inside the device.

This is what happened to a user of our portal with the nickname megakino: he has a storage heater under the sink in his dacha. The instrument panel did not survive the first winter - it was squeezed out, and after the second, frozen water tore the entire hull.

Our user does not understand what happened: it seems that he drained the water according to all the rules and left the taps open for the winter.

Here's how FORUMHOUSE participants explained this mystery: the water from the heater was not completely drained; it was prevented by the check valve installed on the water supply. To accurately drain ALL the water from the water heater, you need to blow it out. The main thing here is not to confuse the cold and hot water inputs:

- open the cold water drain and supply hot air into the hot water pipe. The cold water inlet is located low, and when blowing into it, all the water can be displaced without any residue.

Jackson FORUMHOUSE User

If you do the opposite, you will get nothing but bubbles in the heater volume.

You can do it easier and install a water heater drain tap.

This is how the heater drain is equipped for our participant with the nickname Liftanuty.

What equipment is needed to blow out pipes?

Plumbing compressors come in a variety of varieties, and their use is not limited to purging pipelines. Below we will tell you in detail about existing compressors, and then you can make the right choice.

Scroll compressors

These devices are primarily characterized by their high reliability and long service life. They are so called because the main element of the installation is a special spiral, which is perfectly balanced, so vibrations are practically not felt during operation.

There are few moving elements in the installation of a scroll compressor, so no extraneous pulsations are observed when the pressure increases. This compressor differs from the piston compressor in its increased volume.

Diaphragm compressors

In such devices, air compression occurs under the influence of a membrane. In this installation, it performs a reciprocating motion, and thus performs the same functions as a piston.

Diaphragm compressors differ:

- stable long-term work;

- long service life;

- ease of use;

- corrosion resistance;

- safety to use.

Inside such a compressor there is a dense rubber chamber; it plays the role of the main air storage device. Therefore, a membrane-type compressor does not rust, which is why it lasts much longer.

Piston compressors

The operating principle of this compressor can be compared to the combustion chamber of an engine in a car. After all, air is also compressed here as in cylinders. Although the design of a piston compressor is quite simple, therefore these models are inexpensive and anyone can purchase them.

Negative aspects of the unit: short operation, high noise level.

Screw compressors

A pressure screw is installed in the design of this device. Almost all models are sheathed on the outside with sound-insulating material, so screw compressors operate almost silently.

The screw compressor needs to be lubricated once every 3 months, but this is only in case of active use. It is this feature that makes this compressor an indispensable assistant in the country when blowing pipes.

How to drain water from a washing machine and dishwasher

If a washing machine and dishwasher are left to spend the winter at the dacha, then they will also need to be dehydrated. There can be difficulties with dishwashers, as our users say, “they have real labyrinths for water inside.” Therefore, if the manufacturer’s instructions do not directly indicate that the device can be wintered in an unheated room, and the preparation steps for such wintering are not outlined, it is better not to take risks.

With washing machines everything is simpler. To drain the water from the washing machine, you need to:

- Disconnect the machine from the water supply and sewerage. Place the ends of both hoses into a low basin. Turn on the "drain" mode. Wait for the work to finish.

- Disconnect the machine from electricity. Place a flat container like a cat litter box and unscrew the drain pump cover.

- To be completely sure, you can turn the washing machine upside down and leave it to winter in this position.

But some models of washing machines have containers inside in which water may remain, and if not, access to them is possible only through partial disassembly.

Disadvantages and advantages of compressors

Cleaning pipes before winter is mandatory. Advantages of using compressors for purging water pipes:

- easy connection. It is necessary to prepare an adapter fitting to connect the outlet hose of the compressor unit to the pipe;

- free movement to the water intake point due to the compactness of the device;

- little noise during operation (except for piston models).

The disadvantage of compressors is the possible contamination of compressed air with lubricants. To avoid this, the receiver is equipped with filters to purify the water supply at the dacha for the winter. Another disadvantage is that many devices have a complex design. Therefore, if they break down, it is impossible to repair them yourself - you have to look for a specialist.

How to bleed the water supply system at your dacha

To be completely sure that there is no water left anywhere, the dacha water supply system will have to be purged. Even a small amount of water in winter, turning into ice, can burst a pipe.

Jackson FORUMHOUSE Member

For the winter, I always blow all the pipes with air step by step, along different lines, because when simply draining, “bags” of water still remain.

Blowing is done with a valve to which a car compressor is connected. It is screwed to the ends of pipes or flexible hoses unscrewed from the water heater.

During blowing, the faucet taps should be closed and the drain taps should be open. After blowing, it is necessary to open all the taps, both drain and mixer taps, and leave them in this position until spring.

Here's why this is done: almost always, the shut-off valves in country water supply systems are ball valves, and in their design there is a cavity where water can remain. For the same reason, you need to unscrew the shower head, shake the water out of it and put it into storage.

To summarize, preparing a country water supply system for winter includes the following mandatory steps:

- draining water from the system through the drain valve;

- draining water from the pump;

- draining water from the water heater;

- draining water from the washing machine and dishwasher.

- gradual purging of all pipes.

Now all that remains is to remove water from the most dangerous elements of the drainage system: disassemble the siphons under the sinks, drain the water from the toilet tank and drain the water seal (for example, with a rubber bulb). In winter, instead of water, the water seal is filled with antifreeze - this way, unpleasant odors from the septic tank will not enter the house.

All that remains is to prepare the water supply and septic tank for wintering.

Do-it-yourself septic tank conservation

In year-round country houses, the septic tank does not freeze, but when the owners leave for the whole winter, work on its insulation cannot be neglected.

To preserve a septic tank for the winter, you need to:

- disconnect it from electricity;

- disconnect pumps and air compressors;

- pump out the liquid from the septic tank by ¾ (or add water, but the septic tank should be a quarter full!).

- pour bacteria into the septic tank (this will get rid of unpleasant odors after re-opening)

- insulate the septic tank lid and pipeline with any insulation.

This is the neck liner for insulating a septic tank made by our participant with the nickname Ice9avalon.

If there are still concerns that the walls of the septic tank may freeze, throw a five-liter bottle half filled with water into each section.

Then the ice, expanding, will compress the plastic of the bottle, and not the plastic of the septic tank.

Having completed all this work, you can leave the dacha with a clear conscience until spring - in spring the autonomous water supply and sewerage systems will work like new.

How to mothball a well

The well is preserved for the winter so that in the spring it is completely ready for use. This means that throughout the winter we will not be able to use it; access to water will be completely blocked. We have already done the main work: we drained the water from the pipeline, heater and plumbing fixtures, and removed the pump.

Now the well is not in danger, the main thing is to close the wellhead correctly: screw on the head, which will protect sheets, etc. from rain, snow, and seal it with film.

In a water supply system arranged according to all the rules, a caisson is made - it deepens the well below the freezing point, protecting it from rain and groundwater. A well with a caisson will survive any frost, the only thing is that this device is not cheap.

A FORUMHOUSE user with the nickname Lesha-Samurai has a fairly standard situation: there is a well 75 meters deep (self-flowing 10-15 m3 per hour), which will not be used in winter, and a categorical reluctance to install an expensive caisson.

According to FORUMHOUSE administrator Andrey 203, a caisson is the only reliable option in a leshy case.

Andrey 203

A caisson is needed to move the wellhead below the freezing depth of the soil.

However, a successful method of caisson-free well conservation has yet been found. Using this technology, Lesha-Samurai and his friend have been preparing their well for winter for several years now.

The algorithm is like this:

- Take 6-7 soda bottles (there should be some drink left in each bottle), shake each bottle to create pressure in them.

- Remove the head of the well and insert bottles into it.

- Put the head back.

- Pump air into the well using a car compressor through the nipple (pump for about 10 minutes). This will ensure that the water level in the well is reduced to the level of soil freezing.

- Shut off the air outlet from the well with a ball valve.

Lesha-Samurai

You can take a plug for 1, use a drill to make a hole of a suitable diameter in it and insert a nipple into it with oil.

Even if air leaves the well through elements of such a structure and the water level rises, the bottles will prevent its expansion.

But the dispute arose about the check valve.

We are simple people; we don’t need theories; at the far end there is a valve; the sellers also weaved different things about as close to the pump as possible, I listened to them carefully and did as I saw fit. Why did I put it at the far end? because flooding an open suction line with water during a spring start-up is an activity for very diligent citizens; I don’t consider myself one of those people - I’m forgiven for filling a pipe and hose locked at the far end; the procedure takes about five minutes, and I don’t strain myself; an inquisitive reader will ask, how do I air the system for the winter, if the valve is deep under water? I just release the pressure and pull out the tail of the hose with a cable, open the check valve and drown this happiness back in the spring - I pull it out again and lock the valve; the procedure, as we can guess, is not very stressful and there are no hemorrhoids with the spring start

There is another opinion. In response to my question about where to install the check valve, at the top or right next to the pump, one specialist said the following. It turns out that centrifugal pumps for wells are extremely sensitive to the reverse spin-up of the turbines when the water flows back. And the slightest dirt that gets inside the pump through a far from ideal intake filter easily gets into the gap between the pump body and the blades. The gap is very small, a fraction of a millimeter, and “catching the wedge” is quite easy. If the engine power is enough to turn the turbine “with sand,” then the gap simply increases, and the efficiency of the pump falls catastrophically.

Therefore: 1. if the valve is located directly next to the pump, then it, the valve, is locked properly by this very pillar, and possible air leaks or leaks will not lead to reverse current and spin-up. 2. if the valve is at the top, then the deeper the water surface, the greater the vacuum the water can create in the supply pipe, trying to flow back into the well (or well). And, one way or another, an air plug forms plus reverse spin.

How to insulate a well

Modern wells are made from reinforced concrete rings. This is a material with high thermal conductivity, and it will freeze. There is a particularly high risk of freezing in shallow wells, with a water level no higher than 1.1 - 1.2 meters, and in wells located in cold regions.

In regions with a temperate climate, it is enough to simply close the well tightly for the winter, or make a reliable house on top without cracks - the cold penetrates through the cracks, falls down and thus freezes the shaft.

Protasevich Consultant FORUMHOUSE

In a tightly closed well, the rings in frost are approximately 0.5-0.7 meters below ground level. The concrete rings themselves will not “conduct” the cold to the bottom.

But insulation of wells is also welcomed in the Moscow region. Frozen water in a well can damage pumping equipment, displacement of rings, and discrepancies in the joints between them.

Wells that are not insulated for the winter are more likely to need repairs.

If you have a blind area, you can insulate it too.

You can buy a ready-made “shell” for insulating wells, or you can insulate the structure with polystyrene foam or extruded polystyrene foam (these options are used by FORUMHOUSE members more often than others.

Recommendations

It makes sense to leave the devices open for a while and let the moisture dry out. This can be done indoors where there is no wind and dust does not fly. This requirement is especially significant for equipment that is sensitive to solid particles. Breakage will not happen, but the abrasive will damage the mechanical components.

It is necessary to drain any water from flexible hoses that may remain in the kinks. To do this, the hose must be lifted sequentially until liquid stops flowing from the end hole. There is nothing complicated. The main thing is to show a little attention, and the spring mood will not be overshadowed by anything.

Recommended insulation for a well made of concrete rings

| Type of insulation | Features of the material | Installation technology |

| Styrofoam | Inexpensive, has good thermal conductivity, does not deform, and does not absorb water. Not resistant to rodents and insects. Sold in the form of ready-made elements corresponding to the sizes of reinforced concrete rings. | The walls of the well are cleaned of debris, façade glue is applied tightly, without gaps. Styrofoam is attached. If the foam does not adhere well, you can secure it with concrete dowel nails. Any barrier insulation material is laid on the foam. The trench is filled with earth and compacted. |

| Extruded polystyrene foam | Resistant to low temperatures, aggressive environments, and withstands loads well. Approximately 20% more expensive than polystyrene foam, produced in the form of slabs. | Installation is no different from installing foam plastic. The joints are sealed with polyurethane foam. The insulation is wrapped with rolled waterproofing material. |

We invite you to see how a member of our portal with the nickname pdp000 insulated his well

The insulation of the blind area is made of EPS, the walls of the ring are insulated with expanded clay. An insulated lid-liner is also made.

You can insulate a well with a little blood. Here are a few methods tested on FORUMHOUSE.

- Our user with the nickname Accurate covers the concrete ring of the ring with plastic film. Since then, the water supply pipe has not frozen even once - it was heated by well water, and the water did not freeze because the film did not allow the cold to pass through.

- Our participant with the nickname Hodok has been insulating a well from the inside for 40 years. Attach two frames made of thick wire in the form of inverted letters P to the last ring at a distance of 25 cm from each other. They descend to ground level. On them, Walker places two semicircles cut out of iron - this creates a flooring on which a plastic film is placed. He covers all the cracks with the same film, puts old clothes inside and leaves the well until spring. But this needs to be done when stable frosts arrive, so that the improvised insulation does not get wet from the fumes from the well.

Looking for energy efficient solutions?

Pay attention to FORUMHOUSE geothermal heat pumps

Ground source heat pump EU (start/stop)

Geothermal heat pump IQ (pseudo-inverter)

IQ ground source heat pump (inverter)

The summer season ends, and the house is left to spend the winter - without people, without heating, without supervision. Winter is a difficult test for all elements of an unheated country house, and in this article we will look at how to prepare utility lines for cold weather - this part of the country house is most vulnerable to low temperatures. We have prepared step-by-step instructions for you, a checklist, following which you can easily prepare your dacha engineer for frost and safely leave it until spring.

- How to organize drainage of water from the water supply in the country for the winter.

- How to drain water from the pump for the winter.

- How to drain the water from the heater and washing machine.

- How to preserve a well for the winter with your own hands.

- How to preserve a septic tank.