02.11.2020

The thickness of aerated block walls directly affects the warmth in the house. The thicker the aerated concrete walls, the more comfortable the room will be in winter. It would seem that it could be simpler: make the wall wider and forget about the cold. But there is also the other side of the coin: a large width of aerated concrete wall means the use of a large amount of building materials, which means increased costs.

It is necessary to decide what thickness of aerated block masonry should be at the stage of designing a home, when its main parameters are laid down. In this case, it is important to focus on the criteria on which the thermal conductivity of the walls depends.

Thermal insulation characteristics of aerated concrete

Aerated concrete blocks are included in the category of cellular concrete. They have low thermal conductivity compared to most other wall materials. This level is a guarantee that the room will be warm in winter and comfortable in summer.

Low thermal conductivity of aerated concrete blocks is due to their porous structure. During the production process of the material, gas bubbles are evenly distributed inside, thereby reducing its ability to transfer heat.

The porous structure, on the one hand, gives aerated blocks advantages, but on the other hand, it impairs their strength. The compressive strength of aerated concrete, depending on the brand, is 15–50 kg/cm2. Low density blocks, such as D200, have minimal thermal conductivity. However, such a gas block cannot be used for load-bearing walls due to the limited load-bearing load: as a rule, it is used as insulation.

When choosing the size of a suitable aerated concrete block for laying the walls of a house, attention is paid to both thermal conductivity and compressive strength.

When calculating the optimal thickness of the walls of an aerated concrete building, it is important to remember the effect of moisture on thermal conductivity. Wet blocks retain heat less well, so you need to protect them from precipitation with facade materials: brick, siding, plaster.

How thick should a wall made of aerated concrete be?

Aerated concrete is the most popular building material due to its thermal characteristics, low cost and high speed of wall construction.

One of the most important questions when building a house is the following: “how thick should a wall made of aerated concrete be?” After all, the issue of saving money on heating is more relevant than ever. To answer quickly, the thicker the wall, the stronger it is, and the better it retains heat. But not everything is so simple; economic feasibility is important.

In addition to its thickness, the thermal engineering of a wall is also influenced by the density of aerated concrete. The lower the density, the better the heat is retained. Most likely, you would just like to know how thick the aerated concrete wall should be, but in addition to all of the above, the choice of wall thickness is also influenced by the region in which you live, since the difference in temperatures between Siberia and Sochi is huge.

For central Russia, it is believed that the wall’s resistance to heat transfer (according to SNIP) should be about 3.2 W/m•C°. For colder regions of the country, this figure should be higher. Please note that for private construction, it is not necessary to comply with these standards.

Such thermal protection (3.2 m2 C°/W) is provided by the following options for single-layer aerated concrete walls.

- D300 – 300 mm.

- D400 – 400 mm.

- D500 – 500 mm.

It is worth noting that the overall thermal efficiency of a building is affected not only by the walls, but also by the insulation of the floor, roof, ceilings, reinforced belts, lintels, and windows. It follows from this that the heat loss of the building through the walls ranges from 30 to 40%. That is, making walls that are too thick is not rational. We need some balance between the costs of wall thickness and heating the house.

If we are talking about a permanent residence, then at current heating costs, the optimal thickness of a single-layer aerated concrete wall is: D400 - 400 mm, D500 - 500 mm.

For a country house that is visited quite rarely, a wall with a thickness of 250-300 mm made of D400 aerated concrete will be sufficient.

Fire resistance

The fire hazard of building materials is determined by the following fire-technical characteristics: flammability, flammability, flame spread over the surface, smoke-generating ability and toxicity.

The fire resistance of a building structure is the time from the beginning of the thermal effect on the structure until the moment when it loses the ability to maintain its properties.

The fire resistance indicator is the fire resistance limit of a structure, which is established by the time (in minutes) of the onset of one or sequentially several, normalized for a given structure, signs of limit states: loss of load-bearing capacity (R); loss of integrity (E); loss of thermal insulation ability (I).

Autoclaved aerated concrete is an inorganic material belonging to the category of non-combustible building materials (NG), capable of withstanding one-sided exposure to fire for 3–7 hours and protecting metal structures from direct exposure to fire.

Numerous tests have shown that when the temperature rises to 400°C, the strength of autoclaved aerated concrete increases by 85%; with a further increase in temperature to 700°C, the strength decreases to its original value. The structure of a building made of autoclaved aerated concrete remains unchanged after a fire, and to eliminate the consequences of the fire, only updating the surface coatings and interior decoration is required.

Autoclaved aerated concrete structures meet the requirements of DIN 4102 for fire resistance.

Fire walls (firewalls) made of autoclaved aerated concrete have the following fire resistance limits for different thicknesses:

| Purpose of the wall | Thickness of a fire-resistant wall made of autoclaved aerated concrete, mm | ||

| 100 | 150 | 200 – 400 | |

| Fireproof curtain wall | EI 120 | EI 240 | EI 240 |

| Fire-resistant load-bearing wall | – | REI 120 | REI 240 |

| Load-bearing wall inside a fire compartment | – | R 120 | R 240 |

- R—bearing capacity;

- E - structural integrity;

- I - thermal insulation ability.

Monolithic autoclaved aerated concrete walls and building structures (in conjunction with steel structures or as cladding) have high fire resistance and are therefore ideal for fire walls (firewalls), ventilation and elevator shafts. Due to its low thermal conductivity, a wall made of autoclaved aerated concrete heats up slightly, even when in contact with an open fire, so fireplaces and stoves can be adjacent to such walls, and smoke and ventilation ducts can be laid inside the walls.

Let us summarize the advantages of autoclaved aerated concrete:

- Low heating rate

- No smoke or toxic emissions

Thickness of aerated concrete with insulation

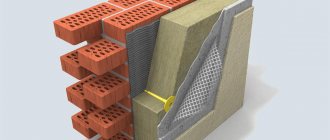

Now as for multi-layer walls, that is, insulated. Stone wool, polystyrene foam and low-density aerated concrete are usually used as insulation materials.

By using insulation, the thickness of load-bearing walls can be reduced, achieving a certain value of thermal resistance. That is, the cost of aerated concrete will decrease, but the cost of insulation will increase. Thus, you need to look for a balance between the thickness of aerated concrete and the cost of materials for insulation.

To make it easier for you to decide on the thickness of aerated concrete and insulation, we have found tables on the thermal parameters of wall materials.

Heat transfer resistance (R0) of aerated concrete depending on the thickness of the masonry.

The higher the value, the better.

Table (thermal conductivity coefficient of aerated concrete)

The lower the value, the better.

For greater clarity, let's make calculations.

For example, you want to build a house in the Moscow region. The required value for thermal resistance in Moscow is R=3.28 . Your house is made of autoclaved aerated concrete D500 with a thickness of 300 mm, and you need to decide on the thickness of the insulation.

The thickness of the aerated concrete wall (0.3 m) is divided by the thermal conductivity coefficient of aerated concrete D500 (0.14).

Thermal resistance of the wall R = 0.3/0.14 = 2.14 m2 °C/W.

Next, we subtract the resulting thermal resistance R (2.14) from the required value R(3.28).

This means the thermal resistance of the insulation should be 1.14 m2 °C/W.

Thermal conductivity coefficient of mineral wool = 0.04.

Multiply 1.14 by 0.04 = 0.0456 meters, that is, 45 mm.

That is, the required insulation thickness was 50 mm.

Thus, you can calculate the required insulation for any wall.

Block classification

Aerated concrete is a porous building material. It contains: cement, lime, aluminum powder, quartz sand and water. During the process of mixing and making blocks, a reaction occurs that produces hydrogen. The mixture is then subjected to vibration and hardens. Blocks of the required size are cut out of a large solidified mass. Their width can be from 7.5 to 50 centimeters. Length from 60 to 62.5 centimeters. Height from 20 to 25 cm.

When choosing sizes, it is necessary to take into account the purpose and size of the building, seasonality of use, service life and monetary costs. And only after this should you choose the thickness of the blocks, since this will determine the heat, sound insulation and much more.

Main types

The requirements for blocks in terms of strength and thermal insulation may be different and they depend on what kind of room will be built. If this is a non-residential building, then it is necessary that the walls are simply strong, but when constructing a residential building, it is important to take everything into account. There are several types of aerated concrete block:

- Thermal insulation . The density of such a block is 300-500 kg/m3. This type is suitable for the construction of self-supporting walls or it can be used as additional insulation.

- Structural . Density - from 1000 to 1200 kg/m3. It is light in weight, so it is used for the construction of large objects.

- Structural and thermal insulation . Density - from 500 to 900 kg/m3. This type is suitable for the construction of low buildings. It is considered a warm and durable material.

This building material, when used correctly, has a lot of advantages. The main thing is to take into account its main characteristics and coordinate it with the conditions and location of construction.

Material Density

The density of a block is determined by its weight and is designated by the Latin letter D, and the numbers indicate the width. For example, grade D 500 represents a block with a width of 50 cm. There are several grades of density (D):

Related article: How to cover the walls of a bathhouse inside

- D 50, D 100, D 250 - have a minimum density, so they are best used for laying interior walls without loads.

- D 300, D 400 - used for the construction of load-bearing walls. This brand can be recommended for the construction of two-story houses.

- D 500, D 600 - are highly resistant to frost, their price is much higher than previous brands. Suitable for laying facade walls of a three-story house.

- Grades from D 600 and above are recommended for the construction of durable special structures.

Density must be taken into account first of all when calculating the load on the foundation of a building at the initial stage of work.

Soundproofing

Airborne noise is propagated by sound waves, which, when encountering a building envelope (for example, walls or ceilings), are partially reflected, partially absorbed and partially pass through it.

Sound insulation is a reduction in sound pressure level when a wave passes through an obstacle. The effectiveness of the enclosing structure is assessed by the airborne noise insulation index Rw (averaged in the range of the most typical frequencies for housing - from 100 to 3000 Hz), and of floors - by the index of reduced impact noise under the floor Lnw. The more Rw and the less Lnw, the better the sound insulation. Both quantities are measured in dB.

The sound insulation ability of the enclosing structure depends both on the material (density, porosity and elastic modulus) and on the design solution used.

Sound-absorbing materials have a porous structure. In this case, when a sound wave passes through the thickness of the material, it causes the air enclosed in its pores to vibrate; small pores create greater resistance to the air flow than large ones. The movement of air in them is slowed down, and as a result of friction, part of the mechanical energy of the sound wave turns into heat and it weakens.

The sound-absorbing property of a material is characterized by the sound absorption coefficient (α), which is the ratio of the absorbed sound energy to the total energy incident on the material.

Sound absorption coefficient of some materials:

| Construction material/structure | Sound absorption coefficient (α) at a frequency of 1000 Hz |

| Open window | 1,0 |

| Autoclaved aerated concrete | 0,2 |

| Tree | 0,1 |

| Brick | 0,05 |

| Concrete | 0,02 |

Regulatory Requirements

In order to understand what thickness a wall made of aerated concrete should be, first of all you should familiarize yourself with the regulatory requirements for the use of aerated concrete blocks, which are regulated by the document STO 501−52−01−2007. This document contains all the necessary recommendations:

- Height of buildings. For a load-bearing wall, the maximum height is 20 meters. And for self-supporting ones - no more than 30 meters.

- The strength of the blocks must be at least B3.5 during the construction of a house with five floors, and a mortar of class M100 is used. For a three-story building - B2.5 with M75 mortar. And for a two-story building, the strength class of the block should be B2 using M50 mortar.

Based on these requirements, the main indicators of the designed structure are calculated.

Optimal wall thickness

You can build anything from aerated concrete, but when constructing residential buildings, important recommendations must be taken into account. When constructing low-rise buildings, the main purpose of which is living in the summer, you must adhere to certain rules:

- When building a one-story house in warm areas, the thickness of aerated concrete blocks should be at least 20 cm.

- For high-rise buildings, a gas silicate block 30 cm thick is required.

- For the base and basements from 30 to 40 cm, but for these purposes it is better to choose another material, since aerated concrete is afraid of moisture.

- Interior partitions should be at least 15 cm, and between apartments - from 20 to 30 cm.

The thickness of the aerated block for a house that will be built for permanent residence depends on the climatic conditions of the area. With the correct calculation, you don’t even need to use insulation. And to make it easier, experts have already calculated the heat transfer resistance for some regions: Astrakhan region - 2.1, Altai - 3.5, Volgograd region - 2.8, Moscow region - 3.29, Chukotka - 4.9, St. Petersburg - 3.29, Krasnodar Territory - 3.5.

These indicators are calculated for the construction of buildings without the use of insulation. But if you still plan to make walls with insulating material, then calculating the thickness of aerated concrete blocks for external walls is even easier. In this case, only the quality and density of the material can be taken into account.

The thickness of aerated concrete walls - the best options

Aerated concrete block products differ from conventional concrete in their low thermal conductivity. This quality is achieved by the presence of aluminum powder in the feedstock. Hydrogen bubbles spread throughout the hardening mass, which allows aerated concrete to transfer less heat than concrete. But this advantage is fraught with a decrease in strength, which is relevant when comparing blocks with concrete analogues. Based on this, the thickness of aerated concrete walls is determined taking into account the required level of thermal insulation and structural strength. And here there is another important feature - full compliance with the existing budget.

Load-bearing wall thickness

The construction of any object is preceded by strength calculations. It is not always possible to perform such actions on your own; for this reason, it is allowed to use parameters that determine strength.

The thickness of the load-bearing wall is determined taking into account these data.

Another important factor is the purpose of the facility being built. If the house is low-rise and is intended to be used during the summer season, it is recommended to comply with a number of simple requirements:

- when constructing a one-story building in an area with a warm climate, a garage and other outbuildings, aerated concrete 250 mm thick is used;

- for two- or three-story buildings this parameter increases to 300 mm;

- when constructing basements or ground floors, the recommended wall thickness is from 30 to 40 cm. But remember that aerated concrete is afraid of abundant moisture, so it is necessary to use other materials.

If the construction of a facility intended for year-round living is meant, the strength indicator is not enough. In this case, the thermal conductivity of the material is taken into account. Using calculations, the minimum thickness of an aerated concrete wall is determined, or the same parameters remain as for summer houses, but the external walls are additionally insulated. In this case, the calculation is carried out according to the available money - a more profitable option is determined. Either the thickness of the load-bearing aerated concrete wall is increased, or insulation is used.

When determining the cost of insulation material, do not forget about fasteners and the cost of specialist services.

Construction: with your own hands or with the help of professionals?

Gas silicate blocks are very light and almost perfectly smooth. They are easy to install yourself. They are attached using ready-made special solutions, using which even a non-professional can achieve a very narrow seam. Therefore, construction can be carried out independently.

To simplify the process, it is recommended to purchase blocks with special recesses on the end side. They allow you to align a number of blocks and improve their joining. Thanks to this feature, the connection line looks professional with a minimum of effort.

Thickness of partition walls

This parameter is selected taking into account certain factors, the load-bearing capacity is calculated and the height of the partition is taken into account.

When choosing blocks for such walls, you should pay close attention to the height value:

- if it does not exceed the three-meter mark, then the optimal wall thickness is 10 cm;

- when the height increases to five meters, it is recommended to use blocks whose thickness is 20 cm.

If there is a need to obtain accurate information without performing calculations, you can use standard values, which take into account connections with the upper floors and the lengths of the walls being erected. Particular attention is paid to the following tips:

- when determining the operational load on the internal wall, it becomes possible to select optimal materials;

- for load-bearing partitions, it is recommended to use D 500 or D 600 blocks, the length of which reaches 62.5 cm, the width varies from 7.5 to 20 cm;

- the installation of conventional partitions involves the use of blocks with a density index of D 350 - 400, which makes it possible to improve standard sound insulation parameters;

- The sound insulation indicator fully depends on the thickness of the block and its density. The higher it is, the better soundproofing properties the material has.

Related article: How to attach a wooden block to a concrete wall

If the length of the partition is eight meters or more, and its height is four meters or more, then in order to increase the strength of the entire structure, the frame base is reinforced with a reinforced concrete reinforcing belt. In addition, the required strength of the partition can be achieved by using the adhesive composition used for laying.

Reinforcement of reinforced concrete monolithic belt

Reinforcement is placed in a monolithic belt.

| Reinforcement of a monolithic reinforced concrete belt |

To reinforce the belt, working reinforcement with a diameter of 10-12 mm is used. The reinforcement bars are connected (anchored) along their length, placing the ends on top of each other over a length of 40-50 bar diameters.

To fasten the roof Mauerlat, anchors are embedded into the concrete of the belt. It is also possible to secure the Mauerlat to the belt using spacer dowels.

Wall thickness for different regions

The optimal option for designing an object is complete calculations of strength and thermal conductivity, but not every person is capable of such a task. And there is no desire to pay money for the services provided. In such cases, you should focus on the approximate strength and thickness of aerated concrete blocks for external walls.

Compared to other materials, aerated concrete has a significantly smaller thickness with the same energy efficiency.

Such advice is considered to be recommendations of an average nature, compiled mainly on the basis of statistical data on the use of aerated concrete material in the construction industry and recommendations of manufacturers.

If construction is to be done in a region with warm climatic conditions, then the thickness of the walls should be from 20 cm. But the value is advisory, and many developers opt for 30 cm.

What thickness should be the walls of objects being built in other regions of Russia? Here everything depends on the average daily temperature. For example, for Siberia, the thickness of an aerated concrete wall should be greater than in the southern regions.

UDK

Rating: 4.8

The largest manufacturer of aerated concrete blocks in Ukraine is the UDK company. The company focuses on producing premium products. The manufacturer produces building blocks using autoclaved aerated concrete technology. Masa AG equipment is installed in the factory workshops, which has a positive effect on the geometry. The main raw material base is natural materials such as Portland cement, crushed quartz sand, and quicklime. A distinctive feature of the brand is a scholarship program for students that financially supports high-achieving students.

The manufacturer occupies third place in the rating for its precise geometry, affordability and care for the younger generation. The disadvantages include large waste and low strength.

GOST requirements

Construction work using cellular concrete material is regulated by special requirements. The main recommendations for using blocks are as follows:

- regulatory documents require that the maximum height of the wall be determined by calculation;

- building heights are limited. It is allowed to build five-story buildings with a height of two dozen meters from blocks that have undergone autoclave processing. Self-supporting walls in nine-story buildings should not exceed thirty meters. Foam block material is used in the construction of a three-story building, the maximum height of which does not exceed ten meters;

- The standard defines strength indicators taking into account the number of floors. Block B 3.5 is used for the construction of a five-story building, and for three- and two-story buildings, B 2.5 and B 2 are used, respectively;

- For self-supporting walls, block material B 2 - 2.5 is used.

Builder reviews

How thick should the walls be?

Aerated concrete is considered an effective material for heat preservation, and is explained by its cellular structure.

To accurately determine what thickness of aerated block to choose, you must follow the following useful recommendations:

- In construction work, a special masonry mortar is used, which is applied to the block surface in a thin layer. This especially applies to people who constantly work with cement mortars. Thick seams will begin to let in cold, which will negatively affect the thermal insulation characteristics of the block;

- if construction is carried out in areas with cold climatic conditions, then the aerated concrete wall is insulated on both sides;

- strength calculations must take into account the additional mass created by thermal insulation materials.

In addition to official calculations, builders determine additional factors that help determine the thickness:

- Duration of use at home. If the option is a country house, then the thickness of the walls can be twenty centimeters. They will be able to withstand the weight of the roofing and protect from spring and autumn coolness. If you plan to stay all year, the thickness indicator doubles.

- Load-bearing walls should be ten to fifteen centimeters greater than the thickness of the internal walls made of aerated concrete.

- When increasing the height of the object, more durable gas blocks are used. If the object is one-story, then the wall can be from 25 cm, and in the case of multi-story construction this value reaches 300 - 400 mm.

- The duration of the cold season and the average daily temperature directly affect the strength of the walls. For Siberian regions this value is always higher.

- If you plan to use insulating materials, the thickness of the blocks can be reduced.

How to prepare glue?

Aerated concrete masonry is made using an adhesive joint, which is created from a dry mortar with special characteristics, and consists of sand, cement and various kinds of water-retaining, plasticizing and hydrophobic additives. The minimum joint thickness should be 2-5 millimeters, but masonry on such a mass is possible with a joint thickness of 8-10 millimeters. Aerated concrete can also be laid on sand-cement mortar with an average horizontal joint thickness of 12 millimeters and a vertical joint thickness of 10 millimeters.

The creation of an adhesive solution for the construction of wall partitions made of aerated concrete should begin immediately before work.

Moreover, the preparation work must be done clearly according to the instructions:

First, you should pour a certain amount of water, indicated on the packet with the mixture, into a plastic bucket. Now carefully pour the dry solution there in the required proportion, stirring constantly. It must be left for 10-15 minutes and stirred again. During the laying process, it is necessary to stir the mixture several times so that its consistency remains at the desired level. To carry out masonry in cold periods, it is better to use an adhesive solution that contains anti-frost additives.

Pros and cons of block material

The thickness of the walls is considered the main disadvantage of the material in question. For example, the minimum value in the Moscow region is 53.5 cm. At the same time, great importance is given to cold bridges, which further reduce the overall level of protection by ten percent.

Reinforcement and lintels must be installed on the walls above openings for windows and doors, which also negatively affects thermal insulation. Ultimately, the thickness of the wall under construction must be at least 65 cm.

Blocks made of aerated concrete material are used quite often today. It should not be forgotten that the material is hygroscopic, and this is its main negative feature.

But there are also positive aspects. The geometric parameters of the material are accurate and impressive in size. This allows construction to be carried out at good speed and with minor deviations. The costs of finishing external walls are reduced, and if you use blocks with tongue-and-groove joints, the formation of cold bridges and cracks is eliminated.

The material is fire resistant, easy to process, and lightweight.

Optimal thickness of aerated concrete walls

Due to their light weight compared to silicate or red brick, good heat and sound insulating properties, frost and fire resistance, ease of mechanical processing and installation, aerated concrete blocks are used in the construction of load-bearing elements and partitions of residential buildings, garages, and country cottages. Many people make the wrong thickness of the wall from aerated concrete, which, if its thickness is low, does not prevent the penetration of cold and requires additional installation of insulation, and if it is large, it leads to wasteful waste of excess material, and therefore money. In order to avoid such a situation, it is necessary to understand what influences this indicator and what it should be according to standards and depending on external factors.

Related article: How to make a semicircular wall from plasterboard

Depending on the density in kg/m3, this material comes in several types:

Lightweight blocks with low density and excellent thermal insulation properties. They are mainly used as insulation.

Unlike the previous ones, they have sufficient strength, weigh more and conduct heat a little better. Perfectly suitable as the main material for the construction of walls.

Heavy aerated blocks with the highest density for the construction of buildings requiring structural strength.

Internal partitions.

No matter what modern design of partitions you decide to use in your home (for example, partitions made of metal profiles and gypsum fiber or plasterboard sheets), you will still have to make some kind of sandwich system using insulation in order to achieve a satisfactory level of sound insulation. And any sandwich system is labor intensive and more expensive than block masonry.

Blocks with a thickness of 75 and 100 mm are suitable for the manufacture of internal partitions. with a density of 500. The wall turns out to be quite strong, sound and heat insulated and at the same time light.

The use of a sandwich system (metal profile, plasterboard, insulation) is not required, which ultimately results in a cheaper cost of constructing the partition.

How thick should an aerated concrete wall be?

The power value is calculated depending on the following factors:

According to the requirements of such standards as SNiP 23-02-2003, the minimum thickness (H) is calculated using the following formula: H = Rreq × λ, where:

- Rreq – structural resistance to heat transfer, calculated for each region;

- λ – thermal conductivity coefficient of gas blocks, (W/m∙°C) depends on the brand and humidity.

| Brand of aerated concrete blocks | Thermal conductivity coefficient, W/m∙°С | |

| Dry | At 4% humidity | |

| D300 | 0,072 | 0,084 |

| D400 | 0,096 | 0,113 |

| D500 | 0,12 | 0,141 |

| D600 | 0,14 | 0,16 |

| D700 | 0,165 | 0,192 |

| D800 | 0,182 | 0,215 |

| D1000 | 0,23 | 0,29 |

The lower the value of λ, the better its thermal insulation properties - accordingly, walls made of aerated concrete grade D300 have the best indicator, and D1000 has the worst indicator. Due to the presence of water in the cavities, wet material has a higher thermal conductivity than dry material.

The value of Rreq characterizes the resistance of the material to the passage through it of the total amount of heat accumulated indoors, and is equal to the product of the degree-day (D) of the heating period by the correction factor a and adding the constant b to the resulting result: Rreq = (D×a)+b.

The value of D is equal to the product of the difference in indoor temperatures during the heating period and the average daily outdoor temperature by its duration in days: D=(tin.room-toutdoor)×Rot.period.

So, for example, for Moscow this indicator for 214 days with an average indoor and outdoor air temperature of -3.1 and +20°C is equal to 4943 degree days; the southern regions have the lowest D value, for example, in the Rostov region it is only 3523 °C*day, and in the northern regions - Siberia, Magadan, the Urals - it is the highest. The values of the variables a and b depend on the type of building used and for the walls of residential buildings, garages and cottages, they are equal to 0.00035 and 1.4, respectively.

Using reference materials for the degree-day value of the heating period, the above coefficients and the thermal conductivity of block brands, you can calculate what thickness according to the standards should be for aerated concrete walls in the largest cities of various parts of Russia and the adjacent regions.

Calculation of the power of structures made of cellular concrete for various zones of the Russian Federation:

| Cities | D,°C*day | Capacity of fencing depending on the brand of aerated blocks, cm | ||||||

| 300 | 400 | 500 | 600 | 700 | 800 | 1000 | ||

| Moscow | 3934 | 20 | 25 | 35 | 40 | 50 | 55 | 65 |

| Saint Petersburg | 4796 | 25 | 30 | 40 | 45 | 55 | 60 | 75 |

| Novosibirsk | 6601 | 30 | 35 | 45 | 55 | 65 | 70 | 90 |

| Ekaterinburg | 5980 | 30 | 30 | 45 | 50 | 60 | 65 | 85 |

| Rostov-on-Don | 3523 | 20 | 25 | 35 | 40 | 45 | 50 | 65 |

| Ufa | 5517 | 25 | 30 | 40 | 50 | 55 | 65 | 80 |

| Krasnoyarsk | 6341 | 30 | 35 | 45 | 55 | 60 | 70 | 85 |

| Khabarovsk | 6475 | 30 | 35 | 45 | 55 | 65 | 70 | 85 |

| Murmansk | 6380 | 30 | 35 | 45 | 55 | 60 | 70 | 85 |

| Yakutsk | 10394 | 40 | 45 | 65 | 75 | 85 | 95 | 120 |

| Average | 5994 | 30 | 30 | 45 | 50 | 60 | 65 | 85 |

Graph of changes in the thickness of wall structures depending on the region and brand of gas silicate blocks:

Walls made of aerated concrete grades D300-D400 are characterized by the best thermal insulation properties. Their thickness ranges from 20 to 40-45 cm, despite this, these materials contain a lot of pores with air and little load-bearing frozen mortar. The highest strength, but at the same time large wall thickness (up to 100 cm or more), necessary to preserve heat inside the room, is distinguished by gas blocks of the D800, D1000 brands. Most often they are used in the construction of public buildings, shopping pavilions and other structures with heavy loads and additional insulation.

The “golden mean” and the most optimal strength-thermal conductivity ratio are characterized by D500-D600 blocks, most often used in the construction of residential buildings and cottages, as well as other buildings.