The technology of lap siding was known to our ancestors many centuries ago. True, in those days it was called much simpler - covering external walls with unedged or edged boards. Currently, lumber manufacturing technologies have significantly improved, special impregnations have appeared to protect wood from pests and putrefactive processes, and varnishes and paints with unique performance properties are used to finish external surfaces. The performance characteristics and appearance of the boards have improved significantly, which makes it possible to give facades a new look.

How to install lap siding (in this case, fiber cement)

Overlapping vinyl siding

Lap siding

Traditional wood shiplap siding

The main feature of the technology is that each subsequent horizontal row of boards slightly overhangs the previous one. Today you can find “American” not only made of natural wood, but also of plastic and metal, but we will focus on traditional material.

Wood siding prices

Wood siding

Sheathing a house with overlapping boards

The example uses this sort of working template. Two vertical logs have already been installed

Step 1. Preparatory work. Overlapping siding can be done on walls made of any building materials, from natural wood to aerated concrete slabs. There is no point in leveling surfaces to perfection; the boards are fixed to a special load-bearing sheathing. But it is highly recommended to do additional insulation of external walls. This will not only increase the comfort of living in the building, but will also greatly reduce financial losses during the heating season.

Perfect leveling of the base is not required in this case.

Important! It is better to use pressed mineral wool as insulation. As a last resort, you can use non-flammable foam. Just remember that existing legislation prohibits the use of any type of foam plastic for insulation of buildings that are more than one floor in height. Do not violate this requirement, do not expose the building and your life to additional risks.

The thickness of the insulation layer depends on the climatic zone of the location of the building, but in all cases it should be more than 10 cm. A smaller thickness of the insulation will save a small amount of money on the purchase of material, but the thermal protection will be so low that there is no need to talk about the overall effectiveness of the insulation. The insulation technology is common, there is no point in dwelling on it. The only thing worth mentioning is the quality of the sheathing. Vertical posts must be strictly perpendicular and must lie in the same plane. Check their position before starting work.

Calculation of insulation thickness for siding

Mineral wool for insulation

Step 2. Calculate the quantity and range of materials. Find out the area of the walls minus window and door openings. It is not recommended to overlap the basement part of the building; keep this in mind when purchasing boards. Additionally, lumber will be needed for finishing internal and external corners, slopes and trims of windows and doors, and lining the overhanging rafter system.

Preparation of material

Practical advice! Always increase the amount of materials by 5-8%; any construction work cannot be done without waste. It is better to have a small supply than to stop work due to a shortage of boards.

For fixing, it is better to use ordinary nails; it is much cheaper and faster than fastening with self-tapping screws. At the same time, the reliability of fixation is no different. The length of the nails depends on the thickness of the lumber, but one rule always applies - two-thirds of the length of the nails should be included in the load-bearing elements. For example, if the thickness of the board is 25 mm, then the length of the nail must be at least 70 mm.

After cutting the boards, the ends must be impregnated with mastics; purchase them as well. Even if the boards are factory-impregnated, the cut ends should still be finished.

Colorless water-based wood impregnation for exterior use

Prices for wood preservatives

Impregnation for wood

Step 3: Prepare your tools. For sheathing, you will need a handheld portable electric saw, a builder's level, a water or laser level, a tape measure and a pencil. If you have a small stationary saw, great, the work will go much faster. You can, of course, use ordinary hacksaws, but they are difficult to work with, and the cut is not very even, especially for beginners.

Preparing everything you need

Hammer and building level

Step 4. Check the condition of the sheathing, correct problem areas if necessary. There are two ways to fix uprights.

- Using a nail puller, slightly tear the slats away from the wall, place wooden wedges in the right places and nail them again.

- Fix thin slats on top of the old ones, changing their thickness to level the position.

Both methods are equivalent; the specific choice depends on the magnitude of the deviations. If the deviations are significant, then it is better to use the second method. The maximum difference in the position of the slats should not exceed 0.5 cm per linear meter, otherwise the bending of the outer skin will be noticeable. If you missed this point, then correct the error already during the covering. In places where the sheathing bends, nail the boards loosely. As soon as you see that they begin to bend, stop. If you didn’t have time to react in time, it’s okay. Pull the nail out a little and straighten the board.

Sheathing a house with overlapping boards

Step 5. Covering the corners. Prepare the boards and use a saw to cut them to width and length. Remove the edges at an angle of 45°. Connect two boards at a 45° angle and fasten with self-tapping screws. Fix securely; the boards may warp during use. Recess the heads of the screws and seal the holes with wood putty. Sand the joint area with sandpaper. To improve the quality of sanding, it is better to fix the sandpaper with a stapler to a flat square or rectangular block. Be sure to soak the cut ends of the boards with any antiseptic or special primer.

Corner cladding scheme

Practical advice! Finishing the corners can be done using a different method - first sheathe the walls, and attach the ends of the siding boards end to end. After finishing the sheathing, nail even boards in the corners and close the ends. This method simplifies the installation process - there is no need to accurately adjust each board to length. But it also has a drawback - snow blows into the cracks in winter. It is necessary to take measures to seal large gaps, otherwise the insulation may get wet. Wet glass wool is a big problem for all wooden structures. In addition, the efficiency of insulation is significantly reduced.

Step 6: Secure the formed corners under the dividing board. A dividing board separates the lower part of the foundation from the main one. We have already mentioned that it is better to sheathe this area with waterproof materials, but the use of wooden siding is also allowed. Fix the corners with nails, make sure that the boards do not crack.

Professional advice! Never drive nails into boards at right angles; this position increases the likelihood of cracking. The nail should enter the wood at an angle of approximately 30°; due to this position, it simultaneously penetrates several layers of wood, and this prevents cracking.

During fixation, constantly check the vertical position of the corners, do not allow even the slightest deviation. If this condition is not met, then each siding board will have to be adjusted to length, and an oblique cut will also have to be made. Even experienced builders find it difficult to avoid gaps at the joints when making oblique cuts.

The window sill must be tilted so that water drains from it

Step 7. Set the starting bottom bar. For these purposes, an ordinary edged board is taken and placed in a horizontal position. If you don't have an expensive laser level, then use a water level. It is much cheaper, and the accuracy is no lower than that of a laser.

Setting the lower starting bar

The ventilation gap is maintained

Step 8. Install gutters on the bottom boards surrounding the bottom boards. They can be purchased metal or homemade wooden. The gutter drains rainwater from the lower rim board. Another purpose is to level the first row of siding.

Step 9. Take measurements between the drain and the top point of the wall, calculate the number of rows of siding, taking into account the width of the boards and the amount of overlap. The overlap is done within 2-3 cm. Mark the position of the boards; for this it is better to use a template. It is made very simply.

- On one side of the straight slats, apply marks corresponding to the width of the boards. Do this very accurately, errors are completely eliminated. Indicate in any way that this is the front side of the template.

- On the other side of the template, make marks along the width of the boards, but offset by the amount of overlap of the lower edges. We have already mentioned that the overlap is done within 2-3 cm.

Step 10. Place the template against the corner and transfer the marks from the front side of the template, then turn it over and transfer the marks from the back. At each corner you should have two rows of marks, one indicating the top edge position of the first board and the second indicating the bottom position of the next covering board. Repeat the same operation on all corners of the building.

Step 11. Proceed to fix the siding boards. Place the first one along the lower marks and secure it with nails. Then the next one on top of it, pay attention to the two marks taking into account the height of the overlap.

The first board is fixed (here it is already used, since a small working template is being sheathed)

Practical advice! If the boards are long, you should call an assistant. If this is not possible, use various stops to fix the selected position of the board.

American overlapping cladding

Boards are fastened with nails

To prevent the edge of the board from sagging during installation, you can use a support like this (if you work alone)

The wall is ready

The same thing, but from a different angle

According to the specified algorithm, continue sheathing the wall to the very top. Next you need to finish the soffit.

Lining the roof overhang with wooden clapboard or board

Step 1. Select the material that will be used for the cladding. When covering a house with natural boards, we do not recommend using various plastics. The soffit can be finished with an ordinary edged board or covered with overlapping wall siding. Make your own decision based on your own needs.

Soffit

Prices for different types of spotlights

Roof soffits

Step 2. Start covering the soffits with markings; the lines can be marked with a rope and blue or make pencil marks along the rafters. Boards will be nailed along the lines.

Step 3. Nail the first board; its position must be checked several times. If there is a non-parallelism between the line of the rafters and the wall, then an individual decision should be made in each specific case. If there is a slight parallelism within 2-3 cm, it can be eliminated by gradually moving the boards. A non-parallelism of 2-3 mm is completely unnoticeable; multiply this value by the number of rows of siding and find out whether this method can be used. If there are large discrepancies, you will have to trim the first and last boards with a wedge. Unfortunately, such an operation will not go unnoticed.

Step 4. Cover the joints between the soffit and the wall sheathing with decorative strips. Don't forget to leave vents for natural ventilation. The end facade walls do not have a roof overhang; they should be treated differently. As the sheathing proceeds, the boards are trimmed to size using a wedge, and the joints are subsequently closed with decorative end strips. If you wish, you can additionally nail wide boards to the slats, which will help hide the unevenness of the cuts.

Roof siding

Another example of a binder

On a note! We have given a description of the universal overlap siding technology, but everyone can change it a little. Use various finishing elements for corners, joints, etc. The combination of wooden boards with plastic decorative elements gives an original look.

This is how water drains if the siding is overlapped

Laying technology

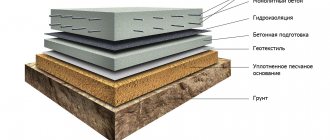

Installation of siding begins with the creation of sheathing, laying insulation, and vapor barrier. The pitch between the vertical bars is maintained at 50–65 cm. The horizontal bars are calculated based on the size of the material.

If the rules are followed, the seams are difficult to notice

Stage 1. Sequence of actions

- The starting bar is placed above the ebb/foundation. Fixation is done with self-tapping screws in the center of the fasteners. The screws do not tighten flush, leaving free play for the material to expand.

- If there are complex/internal corners, start working from these places, installing the corner profile, corner elements to hold the panels. A special overlay will be used for external corners.

- The issue with the direction of the lining is being resolved, that is, move towards the seam: first, the lower bar covering it.

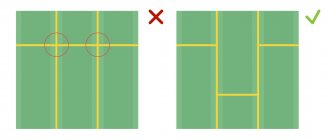

- The alternation of joints is determined. Calculate so that the offset is made through two panels.

- To perform proper alternation, some elements will be trimmed to length.

- Checkerboard docking must be performed symmetrically.

- The fastening lock is cut to the depth of the joint. The front part is not affected.

The principle of installing overlapping siding

Stage 2. Installation of the first panel

The process of attaching siding begins with installing the starting profile. Next, the lower part of the first panel is inserted into the profile, and the upper edge is fixed to the sheathing with screws/nails. Start fastening from the middle, gradually moving towards the edges.

In the place of fastening with fittings, leave 6 mm for “walking/expansion” of the material. If work is carried out during the cold period, the gap should be larger (10–12 mm).

Temperature clearances are calculated when installing fasteners/starter molding

Stage 3. Installation of the attachment part

The overlay panel is aligned horizontally, adjusted to match the cutouts and attached over the first plank with an overlap.

Reinforce under long sections to eliminate sagging. Nail a piece of block/board in the right place directly to the wall.

Carry out the fastening slowly, carefully adjusting each part, then the joints will be less noticeable. The finishing strip is installed before installing the last row

Stage 4. After installation

A sealant will help prevent the penetration of dust/moisture in the areas of the linings. Choose a special type of siding; it is elastic and absorbs the “walking” of the planks by 50%, for example Tytan, Weather Master.

Seal the panel seams with sealant.

Imitation siding with overlap

Very beautiful and reliable casing. In appearance it is impossible to distinguish it from the traditional method described above, but in all its indicators it is much superior to it. The effect is achieved due to the unique profile of the boards. They also have a wedge-shaped geometry, but the side edges are locking. Due to this structure, the front plane is located at an angle to the wall, and the back plane is parallel to it. To improve ventilation, special grooves can be made on the reverse side.

The process of finishing walls with such siding is almost no different from ordinary clapboard cladding, but as a result, the owners receive a completely new design of facade walls.

Imitation siding with overlap

Types of material

There are many types of siding made from different materials and for different purposes:

- from artificial materials - vinyl, acrylic, PVC;

- made of wood - lining (traditional or euro), “American”, planken;

- made of metal - aluminum, galvanized steel, anodized or coated with polyester, pural;

- from cement - fiber cement and asbestos cement.

The first two types of materials are used for cladding walls; metal and cement types of siding are universal - they can successfully withstand increased loads in the basement of buildings and are used for cladding facades and interiors.

There is no single standard for the sizes of lamellas, as well as a method of fastening. Each manufacturer has its own size range, type and design of supporting profiles and guides.

To fasten lightweight panels - vinyl, acrylic, wood - wooden beams are most often used, although manufacturers often have special profiles. Metal siding and heavier panels made of fiber and asbestos cement are mounted on metal profiles.

All types of siding cope with the main task - protecting walls from bad weather, they differ only in durability: if cheap types of vinyl siding will last 3-7 years without changing color, and the lining will have to be dismantled after 2-5 years for impregnation with an antiseptic and protective painting, then metal , fiber cement and expensive types of acrylic panels can last up to 25 years.

Questions and answers

Let's look at frequently asked questions regarding shiplap siding.

How big should the overlap be?

One of the advantages of this method of wall finishing is that each master chooses the amount of overlap individually. Due to this, you can accurately adjust the position of the rows according to the height of the window openings; there is no need to cut them to width. Any trimming worsens the appearance of wall surfaces. But the amount of overlap must be selected not only according to this parameter - much depends on the method of fixing the boards. If you want to make the carnations invisible, then two conditions must be met.

- The nail heads of the previous row should be covered by the next board.

- The fastening should keep the lumber from warping.

Based on such requirements, practice shows that the boards should overlap by about a third of the width; one nail holds two at once. But an increase in overlap automatically leads to an increase in material consumption, and accordingly, the cost of work increases.

The amount of overlap is selected individually

On a note! There is one more important point. If you have an “American” one, then increasing the overlap does not affect the angle; if the board is flat, then the greater the overlap, the farther the second end goes from the wall.

How to attach nails - in a row or in a checkerboard pattern?

A very difficult question with no clear answer. Each method has its own advantages and disadvantages. But practitioners still advise driving nails across the entire width of the boards in a checkerboard pattern. In this case, one row of hardware will be noticeable, but the likelihood of warping is almost completely eliminated. For the visible row, studs made of stainless alloys are used, and for the closed row, ordinary ones can be used.

It is recommended to drive nails across the entire width of the boards in a checkerboard pattern.

Is it possible to close internal and external corners without gaps?

It is possible, but not always advisable. Why?

- It is very difficult. Each board should be placed against the end of the lamellas and their locations should be accurately recorded; the pattern will be in the form of a herringbone. Subsequently, excess material is carefully removed, the position is checked and final adjustment is carried out. The cut areas must be sanded and impregnated with antiseptics at least twice. The same manipulations should be done with the second board. As practice shows, the time to finish one corner increases several times.

- The gaps between the decorative corners and horizontal boards serve as additional ventilation holes. For all lumber, optimal relative humidity levels are very important - wet structures are quickly damaged by various diseases and rot.

Siding installation

Which corner finishing is better - close to the boards or corner boards covering the slats?

We prefer the second option for several reasons.

- Work becomes much easier. Deviations in length of a few centimeters do not create problems during finishing decorative finishing. The boards can be cut not individually, but in batches, which greatly speeds up the sheathing process. In addition, there is no need to carry the board to the machine several times for accurate measurements and final adjustments.

- The ends of the boards are well blown with air - the risk of rot is reduced, the elements do not need to be treated with antiseptics.

Sheathing a house with overlapping siding

How to replace a damaged board?

For example, let's look at the most difficult option - the boards are fixed with two rows of nails. To do the job, you need a nail puller that has a flat blade on one side.

- Insert the flat end of the nail puller into the gap between the intact and damaged boards; the tool should be located as close to the nail as possible.

- Gently press down on the tool until the head protrudes a few millimeters above the surface of the board. Take out the nail puller and tap the board near the nail with a hammer, this will make it easier for the head to come out.

- Grab the head with the opposite curved side of the nail puller and pull it out. These manipulations must be done on the damaged boards covering it. To avoid damaging the surfaces, be sure to place wooden spacers between the nail puller and the sheathing boards.

Replacing a damaged board is not difficult

Visible nails are pulled out in this way. As for the invisible ones, you will have to bite them with wire cutters. Lift the entire board until there is a gap wide enough to allow the pliers to get to the nail. Depending on the circumstances, it may be necessary to undermine two or more entire boards - this will make it possible to increase the gap without the risk of cracking entire lamellas.

What to consider

You have decided to buy yourself vinyl siding, the texture of which is made to resemble wood, stone or other material. And you are interested in seamless siding, installed with an overlap.

The following instructions are not for dummies, but rather for people with some experience. First, I advise you to try the classic fastening technology. After this, practice editing in the American way.

Before we talk about how the panel is joined, a few more words. This technology allows you to do without an H profile, that is, without a connecting strip. Siding is mounted on a wooden frame and metal sheathing. Suitable for vertical siding as well. You can make mistakes here if you don't follow the rules. Therefore, before doing the work, practice.

Starting profile: install it correctly

Siding installation consists of several stages and includes the installation of many components, including starting and corner profiles, moldings and much more. This process occurs along the lines of walls, windows and roofing.

Installation of Deke siding consists of several key points:

- Choice of technology;

- Setting up a starting profile;

- Installation of external and internal corners;

- Covering corners other than rectangular.

How to choose the right technology?

First, determine the type of base (Fig. 15). It can be sunken, protruding and even. The first is that the base “sinks” into the wall, which slightly overhangs it. The second - the wall is narrower, the third - they have the same width. Facade cladding with a flat and sinking base is carried out using the same technology, with a protruding base - using a slightly different one.

Sometimes the base can change its appearance, turning from protruding to sinking. This transformation is possible due to the thickness of the sheathing. If you have retained the protruding plinth, then you need to install a vinyl molding under the starting panel. In this case, the base can be left untouched and covered with base siding.

Rice. 15. Types of socles: a - sinking; b - smooth; c - protruding (aligned with the wall by the sheathing); g - protruding with ebb along the top of the sheathing; 1 - wall; 2 - sheathing; 3 - base; 4 – vinyl deck; 5 - cement screed

Docke siding starter profiles are used not only along the bottom of the wall of a building. Starter strips successfully cover the roof gable, which is especially important with an attic covered with siding and open facades. They are ideal for installation on roof gables and at the beginning of subsequent floors when a design or engineering project requires a visual separation of the cladding. Installation is carried out along the bottom line of the wall.

Why use the overlap method

The overlay is economical since an H-profile is not needed

Advantages

There are several reasons to use overlay siding:

- Saving. In order to reduce material costs, an overlap is used - a direct connection. You avoid large-scale trimming, as happens when working with an H-profile.

- Aesthetics. The exterior of the walls forms a single covering without dividing strips. This result is obtained with precise docking, in compliance with the rules.

- Non-standard walls for which the length of the canvas is not enough.

- Easy installation. This method is easier and you can do the house cladding yourself. There is no need to adjust each panel to the required length, and there is no need to install a joining strip. Hired workers take all these nuances into account and significantly increase the payment rate.

- Color spectrum. Using the overlay method, it is easier for you to choose the desired color scheme for the cladding, since components of the desired shade are often not on sale. Therefore, the connection is made without the use of auxiliary decorative strips.

If the correct installation technology is followed, the joint lines are not noticeable

Flaws

There are disadvantages to installing PVC lining with an overlap:

- The work must be done carefully; this is a waste of time.

- The effect of a continuous surface is not observed from all viewing points. The overlay is visible when viewed from the overlay side.

- The cracks become more noticeable with seasonal weather fluctuations.

- If the technological installation rules are not followed, the joints will bulge.

- Violation of tightness. Overlapping areas may be affected by wind. Dirt and dust accumulate in the cracks.

When choosing an overlap method, I recommend weighing the pros and cons, calculating your strengths and only then making a decision.

As the building shrinks and the soil shifts seasonally, the gap may become more noticeable

Preparing the base from OSB (OSB)

In theory, siding installation technology allows for fastening elements without sheathing to a flat base. Often, without a supporting structure, frame houses are finished, sheathed with OSB (OSB) boards, which have sufficient moisture resistance and the necessary strength. This is possible if there are no significant irregularities on the surface.

A prerequisite is the presence of waterproofing. A vapor-permeable polypropylene membrane (“Izospan A” and others) is suitable for this, which will protect the interior from moisture penetration. It is laid with an overlap of 15 cm on adjacent canvases

Particular attention is paid to places near door and window openings, as well as at points of intersection with other structures

Attention! It is important not to mix up the side of the waterproofing when installing. There should be a smooth surface of the material outside

For better moisture removal and ventilation of the space under the cladding, a sheathing is made of 20x40 mm bars. The planks are placed on top of the protective membrane in the areas of the supporting pillars of the building. The presence of such a gap is stated in SP 31-105-2002 in paragraph 10.1 on the general requirements for the design of external walls.

Attaching the finishing strip

To install the last siding panel, use a finishing strip. Most often it is used at the top of the wall under the eaves. The plank, prepared to size, is attached to the sheathing with self-tapping screws (leaving a gap of 1-2 mm). After this, the top part of the siding is placed under the bend of the finishing strip. The last panel may need to be trimmed. To secure the trimmed panel in the finishing strip, make new hooks using a punch.

To install the last siding panel, use the finishing strip (photo No. 10)

What types of lathing are there?

The classic of the genre is wooden sheathing. Not much has changed about this since siding was first invented. Then, for greater accuracy, they began to use metal guides for the sheathing. And now polymer lathing has appeared - it is, of course, more expensive than the classic one, and it is more difficult to get. So the benefits of purchasing it are not yet obvious.

Photo camburg.ru

Installation of siding panels on gables

Let's look at the gable trim in more detail. When covering inclined eaves elements with siding, in addition to the vertical supporting frame, you will need to fasten the bars along the slope and on the eaves overhang. If the pediment is separated from the rest of the facade by a cornice or other protruding element, we attach a plinth strip at the bottom, a J-shaped strip along the slope of the roof, and an internal corner strip along the junction of the pediment and the roof overhang.

The roof overhang is covered with panel scraps, inserting them, on the one hand, into a J-shaped strip, and on the other into a corner profile. For more reliable fastening, the pitch of the screws is reduced to 10–15 cm.

Having measured the angle of the roof, the siding panels are cut on both sides in accordance with this angle. The first panel is snapped into the fold of the plinth strip, inserted on the sides into the corner profile, and secured with self-tapping screws into the frame posts.

How to avoid mistakes: 7 rules

Direct connection of panels, without a connecting strip, has its own characteristics. A guarantee of a good result is provided by following certain rules:

Installation is carried out only at positive air temperatures, not lower than 10 °C.

Otherwise, large gaps will be difficult to set correctly.

The overlap of panels must be strictly observed in the interval of 20–30 mm.

The top panel must be clearly aligned horizontally, achieving a single continuation of the bottom part.

Trimming of nail strips/panel locks is mandatory.

As a result, the required distance is formed, allowing for an even overlay and compensation for expansion moments.

The staggered arrangement helps to level out the overlap areas.

A stop is placed under the end of the interior siding panel.

A timber or board is stuffed, eliminating the possibility of deflection.

To reduce the visibility of the seam, no physical effort should be made.

Bending the end, pressing, or pulling on the lock will damage the material.

Try to remove joints from doors and corners. Start laying from these areas, this way the overlay will be placed at a certain distance

This is especially important in areas of doorways, where the wall vibrates when slammed shut.

Selecting the necessary tools

You will learn how to attach siding to a wall from the outside and what tools you will need for this:

Construction tape.

The length of the finishing panels is 3 meters or more (there are panels measuring 3.10 and 3.66 meters). If you install the planks yourself, you will need a tape measure of the appropriate length (for example, 5 meters);

Building level.

How to fasten siding so that it does not break or deform? To do this, you need to install the sheathing and secure the panels strictly level. It is advisable to have two levels: for short areas use a tool 70-100 cm long, for long surfaces - from 150 cm. Measure the vertical and horizontal accuracy of laying;

Screwdriver.

You will have to tighten a lot of screws, so it is better to avoid using a screwdriver. To install the panels on a wooden sheathing, you can use nails, then instead of a screwdriver you will need a hammer;

To attach the siding to the frame, a screwdriver is most often used (photo No. 3)

Drill.

If the walls of the house are made of brick, concrete or foam blocks, to install the sheathing you will need to drill holes and install dowels in them;

Hacksaw for metal.

Vinyl and acrylic siding can be easily cut with a hacksaw. For these purposes, a jigsaw with a metal blade is also used;

Cutter knife.

To give the planks the desired shape, use a knife-cutter or a stationery knife with a thick blade (a thin blade can break). A figured cutout can also be made with a jigsaw.

Punch.

The trim and window trim often have to be trimmed. Cut off the part on which the mounting hooks are located. To make new holds, professional installers use a punch.

To make new hooks on the bar, installers use a punch (photo No. 4)

Ladder.

For installation on the upper floors and on the gable, you will need a ladder. You can use an extension or folding ladder. To avoid damage to the sheathing, do not lean the ladder against vinyl or acrylic siding.