Hi all! The range of thermal insulation materials is constantly expanding. At the same time, new developments appear that are noticeably superior to their predecessors, as well as competitors. New insulators include Tepofol insulation.

I would like to talk about what kind of material this is, what its features are, as well as how it is produced and in what industries it is used.

We will also touch on the topic of tepofol or penofol - which is better, since both materials are often compared with each other.

Composition and principle of operation of the material

Penofol insulation is obtained by foaming polyethylene with propane-butane or approved phenols in an extruder at high pressure.

The gas expands, a bubble is formed, which cools sharply and hardens at the exit from the nozzle.

The result is a material with a porous closed cell. By adjusting the pressure and temperature of the mixture in the extruder, a material of different porosity, thickness and density is obtained.

A layer of polished aluminum foil is applied on top of the polyethylene, whose heat reflection coefficient reaches 95-97%. If, in addition to thermal insulation, the material is used for waterproofing, two layers of foil are applied to the surface of the polyethylene film using the heat welding method.

Insulation from the inside

- A frame is made from slats or a metal profile, which allows for a ventilation gap.

- Penofol is laid on the frame and secured with a construction stapler or special glue.

- The resulting gaps are filled with sealant or foam, and the joints are sealed with aluminum tape.

- Another frame is built on top of the thermal insulation material for decorative finishing.

Material advantages

A versatile, lightweight, durable material is widely used as insulation and waterproofing material indoors and outdoors.

- Penofol is used for insulating facades, floors, walls, and roofs. It has low vapor permeability, so when using it, an additional layer of vapor barrier is not required.

- High sound insulation and vibration protective properties.

- Light and thin material is easy to install and does not require special tools or skills to carry out the work. It is produced in rolls, sold in meters, which simplifies its transportation to the installation site. Easily cut into pieces of the required length with ordinary scissors.

- Does not emit harmful and toxic substances.

- The material retains heat in winter and serves as a barrier to solar and ultraviolet radiation in summer.

- Protects against electromagnetic radiation.

- Durable and undamaged by insects, mold and mildew.

- Penofol 4 mm thick replaces 8 cm of mineral wool, 2 cm of wood and 3 cm of styrofoam in terms of its functions.

The disadvantages of the material include its high cost compared to other materials; it is not used as insulation under a layer of plaster or wallpaper.

Why choose Tepofol: customer opinions

“Tepofol”, reviews of experts about which you can read in the article, can be used in heated buildings and houses without heating. Thanks to the opinions of professionals, we can conclude that the material is characterized by high thermal insulation properties. And the foamed structure of polyethylene increases the sound insulation ability, which is expressed in noise absorption of 32 dB. Due to the fact that the water absorption of the product described is only two percent, this makes it possible to use it as thermal insulation and a waterproofing layer.

Among other things, if you insulate surfaces, they will not lose their ability to breathe. Also for this reason, according to buyers, this thermal insulation can act as a vapor barrier. If you do the calculations, it turns out that the consumer saves three times. The use of Tepofol has a positive effect on the internal microclimate of the room. The optimal temperature is maintained in the building, a person does not experience the effect of suffocation, because the penetrating ability of the material is quite high. "Tepofol" foil has a small thickness. That is why he is not able to take away the volume of the room. Due to the thermal insulation properties, the thickness of the wall can be reduced and the costs of work can be reduced.

Technical parameters of penofol

The thickness of the polyethylene foam base is from 2 to 10 mm, the thicker version is up to 30 mm, for areas with cold climates they produce 50 mm. The thickness of aluminum foil is 12-30 microns.

Use temperature range from -400 C to +1000 C, heat reflection coefficient 97%, thermal conductivity from 0.37 to 0.51 W/(m K), water absorption capacity depends on the class of material and varies from 0.35 to 0.7 %.

Foiled penofol has a sound-absorbing capacity of up to 32 dB and is used for soundproofing cabins of lifting equipment, cars, operator rooms in boiler rooms, and smelting shops.

They are used for insulation of refrigeration equipment, freezers, in air conditioners, ventilation systems, for insulation of car interiors, refrigerators, and wagons.

Areas of use

Penofol is often used as packaging material for industrial products for civil and military purposes. It is used in the production of printing products, advertising materials, refrigeration chambers and refrigerators, railway cars, and in the oil and gas industries.

In everyday life, self-adhesive foil penofol is used for:

- waterproofing basements, attics, roofs, attics, basements;

- insulation of communications (water, heating, sewer pipes);

- heat, noise and vapor barrier of residential premises (balconies, loggias, floors, ceilings in rooms);

- thermal insulation equipment for engines and car interiors;

- sound insulation of walls, floors, interior partitions;

- sealing door panels, window frames.

Penofol sections can be placed in residential areas behind heating radiators. The material will direct heat into the room and prevent its loss.

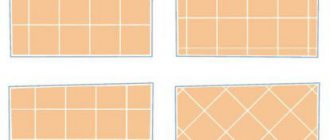

Types of insulation

The type of product depends on the manufacturing features, thickness, number of layers of foil coating and surface topography.

- A - one-sided aluminum coating, used as an additional, starting layer of heat, sound and vapor barrier, attached directly in front of the layer of foam plastic or foam polystyrene.

- B – polyethylene is covered with foil on both sides, the material is used as an independent type of insulation. An ideal option for floor insulation, which will protect against the penetration of cold and retain heat.

- C is a self-adhesive type of insulation covered with foil on one side and a layer of polyurethane or polystyrene glue on the other. A protective film of polyethylene is applied on top of the adhesive composition, which is removed before installation on the surface. When using, you do not need to purchase special mounting adhesive. Self-adhesive penofol is cut into strips of the required length, the protective film is removed gradually as it is applied to the surface. Convenient for processing hard-to-reach areas, corners, and ceilings.

- R – modification of type A material with perforation on the foil layer. Convenient when using arranging an insulating pie if an air gap is required. It is also used as a finishing material in premises, underground structures, production workshops and warehouses.

- ALP is a type of penofol type A in which the polyethylene bubble base is additionally covered with a polyethylene film that creates a water and vapor barrier. Widely used in agriculture, livestock farms, incubators.

- NET – designed to retain heat on heating mains, during the installation of chimneys, and laying pipelines.

- AIR - used in frame construction, a characteristic feature is through holes (perforation), which increases vapor permeability and prevents moisture condensation on the surface of the insulation.

A little about the manufacturer

When talking about Tepofol insulation, it is generally correct to capitalize the name. After all, this is not the name of the material, but of the company that produces it. The situation with penofol is similar, since we are talking about a trademark.

The Tepofol brand was registered by the company of the same name, Tepofol LLC. This happened in 2004.

The company's production began with the design and practical use of a laminator for applying a reflective layer to a surface based on polyethylene foam.

Tepofol became the founder of a completely new category of thermal insulation materials. It uses non-crosslinked polyethylene foam, as well as seamless insulation technology.

Now Tepofol is not just the first, but the leading manufacturer in Russia, engaged in the segment of roll insulation materials with patented interlocking technology. Moreover, in this regard, the company is the only one in Russia.

Speaking of Penofol. Unlike the Penofol company, the manufacturer Tepofol deals exclusively with foamed polyethylene, as well as products based on it.

Features and stages of working with the material

Before starting work, the insulated surface is cleaned of dirt and dust, and the floor is leveled with a cement screed. Select the appropriate type of material; for type A, buy polymer glue.

- Type B is mounted on a prepared sheathing with a beam thickness of 1-2 cm.

- The aluminum layer should be located towards the heat source.

Important! Aluminum is highly electrically conductive; before starting work, it is necessary to insulate the cable connections.

The insulation is laid with an overlap of at least 5 cm, the edges of the connection are carefully fixed with mounting tape.

Penofol insulation requires careful installation. Bends, tears, poorly fastened joints, holes worsen the thermal insulation properties and lead to significant heat losses, especially in strong winds.

Using foil insulation you will retain heat and provide protection from cold, solar energy and electromagnetic radiation.

Life time

Since foil insulation appeared relatively recently, it is not yet possible to determine the exact expiration date. However, after conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the adhesive used. If the adhesive composition has passed its expiration date, then you can re-install it with the same heat insulator.

There are a lot of insulation materials on the construction market. The choice is so wide that the question arises, which is better. To answer, you need to compare the characteristics of the thermal insulation material and the scope of application - street, living room, garage or agricultural building.

Photo of foil penofol

Useful video

Various building materials are used to insulate residential and non-residential buildings. Penofol is also used as insulation. Let's consider what this material is, what its advantages and disadvantages are.

How to lay penofol with your own hands

The best insulation effect is achieved if you adhere to the following rules:

- Between the structural element and the insulation itself, you need to leave some distance for the sake of ventilation, no more than a couple of centimeters.

- If you install one-sided penofol, the layer with foil should be directed in the direction where the heat will come from.

- It is better to connect sheets of material joint to joint, which gives uniformity in heat reflection. But if, for example, a loggia is insulated, joining using the overlapping method to a width of up to 10 cm is also acceptable.

- When sealing joints between sheets of materials, tape, also foil, should be used.

It is very important to remember that this material must be attached taking into account the fact that the reflective aluminum foil conducts current. Therefore, if there is wiring nearby, it is necessary to insulate the wires well.

An example of using penofol for insulating walls and floors

Once a material suitable for the operational requirements has been selected, additional waterproofing, protection from steam or heat can no longer be used. It will also be possible to save on the installation process and materials necessary for high-quality insulation and insulation of surfaces. You can also watch several videos on this topic.

What to glue it with?

A correctly selected adhesive solution for foil material does not yet guarantee a successful installation. For a quality connection of materials, it is necessary that the surface to be glued be carefully prepared. All defects, irregularities, and various debris must be eliminated.

To improve adhesion, materials made of metal, concrete and wood can be treated with a special primer solution.

Concrete floors and walls are leveled, cracks are sealed, and metal products are treated with an anti-corrosion agent.

Adhesive for foil insulation can be either specialized or universal. You can also use liquid nails, double-sided tape, or a thin layer of foam. The choice of glue depends entirely on the purpose of the surface and its further use.

The adhesive composition must correspond to the performance indicators of the insulating material:

- permission for indoor use;

- the toxicity of the solution should be 0;

- high resistance to adhesion;

- the glue must withstand temperatures in the range of -60 to +100 degrees.

If insulation is carried out externally, then the adhesive solution must be resistant to water vapor and liquid.

In order for penofol to be reliably glued to the surface, the glue must be applied to the side that does not have a foil layer. The adhesive solution is applied evenly, without gaps. The edges of the panel are carefully coated with glue so that the foil material does not come off during operation.

Before you start fixing the penofol, you need to wait 5-60 seconds for the glue to dry slightly. This ensures better adhesion to the products. Penofol is pressed to the surface, holding it, and smoothed out with special care.

If the insulation is glued in pieces, then the joints are additionally glued.