Construction of houses from laminated veneer lumber > Houses and cottages from laminated veneer lumber > Houses from laminated veneer lumber

The construction of country houses from laminated veneer lumber is very popular in the modern housing construction market. In addition to their aesthetic appearance, houses made of laminated veneer lumber have high performance qualities.

Filters

Popular articles

October 1, 2021

Operation of the Holz House representative office in Turkey. Foreign projects and representative offices of the Holtz House company

March 22, 2021

Windows in a wooden house: selection and installation of windows in a wooden house

June 21, 2021

How to choose a good house, features of design and construction of private houses, house designs from Holz House

View all articles

Popularity

Glued laminated timber is gaining popularity among owners of suburban areas. Before choosing this material as a construction material, you need to carefully study the design features, advantages and disadvantages.

At woodworking factories, strong and reliable wall structures, furniture, and floor beams are created by gluing lamellas of coniferous wood. Such products have high load-bearing capacity, excellent moisture resistance and strength. Houses made from laminated veneer lumber are non-shrinking, with a beautiful and aesthetic exterior. The operation of such buildings exceeds 50 years.

Now technology allows you to make it yourself, so many artisanal companies make it in the garage. If the owner of a future home wants to build a reliable and strong structure, then experienced builders recommend buying timber from manufacturers who have been producing it for 10 years or more.

Formation of cracks

Time inevitably ages any wood material. If, during the production of wood, the timber has been prepared in accordance with technological standards of drying, gluing and other treatments, then the process of crack formation will be minimal.

In addition, it is important to consider the color property. The darker the walls, the more intense the cracks will appear, especially on the south side of the house.

Assembling laminated veneer lumber with your own hands

One of the main advantages of this material is the ability to assemble a house with your own hands without experience in construction. After the project has been developed and the foundation has been poured, they begin laying the timber. The construction of walls from this material consists of the following stages:

- Laying the first crown. The foundation is waterproofed and the first row is laid out. For it, material is taken from coniferous trees with a large cross-section.

- Treat the timber with antiseptics three times.

- Secure with anchors and metal crutches.

- After installing the first row, the subsequent ones are laid. Between the rows, heat-insulating material is laid - jute or flax, felt.

Glued laminated timber is connected in one of five ways:

- on the root spine. A tenon is created at the end of the beam, and a groove is made in the adjacent one;

- on an insert tenon. This is the simplest method that builders use most often;

- half a tree. This is the name for the method of laying a row because part of the wood is removed from the ends and placed on the adjacent log. The result is a perfectly even angle;

- in the paw. The method is similar to the previous one with the difference of cutting out the ends;

- end to end. Builders rarely use this method of laying crowns. The resulting corner is considered the least blown.

Experienced builders say that you only need to build walls yourself if you have experience in building houses. In any other case, it is better to entrust the assembly of the house to professionals.

If the owner decides not to bother with building a house from laminated veneer lumber and raises the walls from brick, but loved ones are disappointed, then now it has become possible to hide the brick walls under imitation timber.

Imitation

A cottage with imitation laminated timber is no different from a house built from natural wooden material. For finishing, linings with a width of 65 to 200 mm and a length of up to 4 meters are used. This material is easy to cover complex building facades and trim corners.

Panels are available in natural colors and all colors of the rainbow at the client’s request. When purchasing lining with a color different from natural, you should take into account the conditions of its use:

- in the southern zone it is not recommended to use dark colors of cladding material due to the fact that they heat up in the sun;

- in the northern regions, on the contrary, dark colors are welcome. It will attract the sun's rays and warm up the house faster.

Lining is used for finishing external and internal walls. It is selected according to the length of the walls; grooves and latches are used for connection. Experienced builders recommend applying antiseptic agents once every two years to the walls after construction and twice during finishing. This way they protect the material from warping and pests.

Manufacturers still recommend using real profiled laminated timber, since this material is environmentally friendly.

Video description

About the advantages of laminated veneer lumber in the following video:

Northern forest harvesting Source rubankom.com

Correct Techniques

- Sawing . It not only sets the shape of the lamellas (thickness and length). Proper cutting eliminates wood tension, which is caused by different humidity and density of material layers (both external and internal, in annual rings). When drying, the wood will not deform.

- Gluing . With a properly organized process, the lamella from the core part (with a denser structure) is located on the outside of the beam, reducing the likelihood of cracking. Parts of the timber are glued together with alternating fiber directions, which gives special strength to the product.

- Milling . High-precision equipment allows you to obtain locking connections with precise geometric parameters. Such locks connect structural elements, eliminating the appearance of cracks.

The unusual design was made possible thanks to bent timber Source sledcomspb.ru

See also: Catalog of companies that specialize in the construction of turnkey laminated timber country houses.

Materials: types and classification

Manufacturers produce various types of laminated veneer lumber, which can be sorted according to several criteria:

- Appearance . The market offers a regular and profiled version of the product. Profiled parts can have locks, grooves or ridges, making installation quick and neat.

- Dimensions . The timber is produced in standard sizes and profiles, within which you can order products of any dimensions (length).

- Bonding technologies . There are horizontal beams (two boards are glued together in a horizontal plane), vertical (a harder board forms the outer surface) and salon (includes 4 to 8 layers). The material is often combined: larch or cedar is used for the front slats, pine or spruce is used for the internal slats.

Beams of non-standard sizes for the implementation of design projects Source cafe-ayo.ru

Business

Today, the production of profiled timber has been established in Russia, and the material is in demand. Our manufacturers prefer coniferous species - spruce and pine.

During the production of material for building houses, defective areas are removed from the wood and strength is increased. The material is distinguished by high load-bearing capacity and dimensional stability.

To produce timber, expensive equipment is required:

- automatic glue application machine;

- compression presses;

- end processing machines;

- drying chamber.

The main difficulty in production is the search for wood that meets GOST standards.

- GOST 8486 - softwood lumber for the production of laminated veneer lumber;

- GOST 21779 - maximum deviations of linear dimensions of laminated veneer lumber;

- GOST 19414 - serrated adhesive joints when gluing timber along the length;

- GOST 8486 - quality of lumber for the manufacture of glued load-bearing and enclosing beams;

- GOST 17005 - degree of water resistance of adhesives;

- GOST 15613.1 - strength of adhesive joints;

- GOST 14192-96 - transport marking;

- GOST 19041 - formation of packages.

For gluing boards, we use waterproof adhesives that are safe for nature and humans. We use the following adhesives:

- resorcinol;

- melamine;

- polyurethane.

From glue manufacturing companies: Clayborit, Concept Smart of Japanese origin from the Oshika Corporation.

Producing the material is half the battle. The main thing is to find sales. The scope of application of timber lies not only in raising houses for suburban areas. It is used for the manufacture of bathhouses, benches, tables, floors and interior ceilings. Both legal entities and individuals purchase the material.

If you are interested in the production of laminated veneer lumber, you want to cooperate with us, follow the link and leave a request: .

What does the concept mean?

Durability of residential buildings refers to the lifespan of the building. The service life of residential buildings is the period of time between the moment when the house began to be used and the first major repair. The technical condition of the house is determined by the level of its physical wear and tear. Structural elements and engineering equipment wear out over the years and gradually become unusable. When a building partially or completely loses its operational qualities, we can talk about the end of its service life. The legal limit for physical wear and tear of a house is 70%. The service life of a particular home is influenced by many factors, so the terms may vary.

Glued laminated timber manufacturing technology

The production of laminated veneer lumber consists of the following stages:

- wood sorting. The required wood for processing is selected from the assortment. Classified by variety, type, size;

- the selected wood is sent for drying. The material enters the drying chambers and remains there until it reaches certain values that comply with GOST standards;

- after drying, blanks are formed. First, the wood is sent to machines to remove defects, irregularities, and cut into lamellas, which are spliced along the length on a CNC machine;

- in an installation with a press, the lamellas are coated with an adhesive composition and sent under high pressure from the press;

- the finished timber is planed and cut. The material is then sent to machines where the locking elements are cut out;

- then it is protected by covering it with an antiseptic composition and packaged.

Now let's see what the finished timber looks like.

How to buy quality timber?

One of the most important questions is how to purchase guaranteed quality materials for construction? After all, this will determine how warm the house will be, as well as the overall durability of the building.

A beam glued together from five lamellas.

So, today timber can be purchased on the construction market, or you can order it from a trusted manufacturer directly from a woodworking company.

Purchasing building materials on the market from an unverified seller is a very risky proposition. It is quite easy to be deceived and buy insufficiently high-quality material. Moreover, there are several common options for deceiving buyers.

- For example, glued or solid timber of a certain size is ordered, and, as a rule, the seller offers delivery of the material to the site. Upon delivery, it may turn out that the length or cross-section of the timber is slightly smaller than what was ordered. This means that the buyer has already overpaid the manufacturer a certain amount, regardless of the quality of the products. Therefore, it would be advisable to find out when and where the material will be loaded before delivery, so that you can come personally to check the quality of the products - take a tape measure and measure the timber.

- It is imperative to be present when loading the material for the reason that among the quality timber, an unscrupulous seller may well place defective products.

- To check the material for evenness, it is necessary to examine each product for bending in all planes, and immediately select the bent beam. It must be abandoned on the spot, as it will be extremely difficult to work with.

- In addition, it is necessary to inspect the products for uneven cuts and cuts, bark residues and insufficient grinding - all these flaws can be attributed to defects and require replacement of individual products. After all, you're spending your money and placing an order when you see quality samples, so demand the same quality for the entire batch you purchase.

The consequences of using insufficiently well-dried timber to build a house, which arose after the material shrinked.

- The most unpleasant moment may be the manufacturer’s dishonesty in indicating the percentage of wood moisture content, or in non-compliance with the technology for drying it. There are cases of using low-quality, cheapest glue in the production of laminated veneer lumber. If you use such material to build a house, then after a short time you may encounter problems when parts begin to come apart and bend.

- High-quality laminated veneer lumber consists of at least 5÷8 lamellas. Low-quality ones are assembled “quickly” from 3÷4 boards. Therefore, you need to pay special attention to this when purchasing.

The gluing of timber at the ends is the result of a violation or inadmissible simplification of production technology.

- If circumstances still force you to purchase laminated veneer lumber on the construction market, then you can conduct your own “examination” to determine the quality of the material. To do this, you need to ask to cut off a small section of the timber - if necessary, you can even buy it. The wood must then be weighed and the resulting value remembered or recorded. Next, the material must be boiled in water for two hours. Weighing will show what percentage of moisture the wood has absorbed. Then the fragment is dried to its original value (again, the recorded value of its mass will help to check). If after drying the cut returns to its original state, then the material is glued together with high quality. If the boards of the timber begin to come apart, it means that its production was carried out in violation of technological standards.

- You should not purchase timber packaged in plastic film without opening the packaging and checking its quality, as it is also often poorly processed or behaved poorly.

The optimal solution is to purchase high-quality timber directly from a manufacturer that has a high quality rating for its products.

The difference between the quality of timber ordered from a large manufacturer and purchased on the market is due to several important points, which include the following:

- Availability of normal conditions and necessary equipment for the production of quality products and for storing finished products.

- The presence of qualified specialists who manufacture products, carry out sorting and ensure proper control over their quality.

- Large specialized enterprises value their authority, and therefore not only produce high-quality products, but also try to organize careful shipment and delivery of them to the consumer.

It should be noted that in almost every region you can find a reputable manufacturer of both laminated veneer lumber and solid timber. Therefore, experts recommend turning to trusted manufacturers - only in this case you don’t have to worry about the quality of the material.

And, finally, a video filmed at the request of one of the leading Russian manufacturers of profiled timber -. It tells in detail, without embellishment, the secrets of choosing the right quality building material of this type.

What does it look like

The material comes in different colors, with or without fine-toothed profile cutting. LVL is used to build houses. You will not find a perfectly pure one-color material unless it is dyed. The color of natural timber will shimmer from dark to light horizontally and vertically. It all depends on how the lamellas were glued together.

For example, pine wood gives the walls gray, pinkish shades. If you look at laminated larch timber, you will find the material has a light greenish tint or bright burgundy.

We’ll talk further about what colors this building material comes in and what LVL timber is.

Grey

Gray color is often used in architecture. Thanks to the neutrality of the shades, it matches with all the colors that will be present nearby. Houses in this style will always look trendy and beautiful.

White

Spruce gives white color to laminated timber. Such houses have a beautiful and aesthetic appearance. They look noble. The same wood is used to make window frames from laminated veneer lumber.

LVL

LVL abbreviation comes from the English abbreviation LVL. LVL stands for Laminated Veneer Lumber. Its manufacturing technology differs from the usual one:

- Remove bark from coniferous tree logs.

- Soak the wood for three days.

- Prepared wood is cut into logs and veneer is made with a size of 3 mm.

- The veneer is sorted and dried.

- The veneer layers are glued together, the resulting timber is pressed, cut, and labeled.

This is how LVL timber is obtained. It is used:

- As beams for interfloor floors;

- rafter legs;

- ridge beams;

- creating large spans;

- in power formwork systems.

LVL is only one of the varieties of laminated veneer lumber. There are many types and subtypes of building materials.

Kinds

Companies produce insulated and regular laminated veneer lumber. The first option is cheaper. Houses are built from it in the southern regions, where the freezing of walls in winter is not so strong as to create double insulation for the walls. A house made of such material has to be caulked for a long time so that the walls are not blown through.

Insulated

Insulated timber consists of heat-insulating material inserted into the grooves of the wood. Owners who have built a house using this material will save up to 40 percent on heating costs in winter. In summer, the rooms in the house remain cool and comfortable to live in, because the special material achieves high vapor and breathability. And for building a house, a shallow foundation will be enough, because the timber is light.

Finnish laminated timber

Finnish timber differs from others in the crown cups that connect the lamellas. The direction of the arcs of the annual rings towards the center when gluing gives the material strength and durability. Reduces internal tension. When creating Finnish timber, the manufacturer does not mix coniferous species, which ensures a uniform tone.

The use of wide lamellas in Finnish production gives the wood the ability to breathe. Because the glue impregnates only the upper part necessary for strong gluing of wood to each other.

The technology of vertical gluing every three meters gives the material a beautiful appearance and the inconspicuousness of the gluing seam.

Dark

Dark laminated veneer lumber is obtained from larch, oak or using stain. By dyeing, any shade of the material of the house can be achieved.

Oak laminated timber

Oak wood is used to produce reliable and durable building material. It is resistant to shrinkage; cracks do not form in the lamellas for ten or fifteen years, provided that the gluing is good.

The oak species does not absorb water. This means that in humid areas the wood will not swell. Compressive strength is 57 MPa, and bending strength is 107 MPa. These are quite high values.

The coastal type of oak wood has a white color. Trees that grow far from lakes and rivers produce darker-colored wood after treatment. In this way, different colors of the material made from the species of this tree are achieved.

Coniferous

Glued laminated timber made from softwood has gained great demand on the market. Let's see what this material is famous for and why it is so popular among the people.

From larch

Hardwood timber is resistant to adverse external factors. The only disadvantage of material made from this breed will be the high price. Therefore, most often only interior furniture and crossbars are made from larch, rather than wall beams.

From cedar

Cedar wood contains essential oils that are beneficial to humans. A favorable microclimate will always reign in a house built from cedar laminated timber. Wood tolerates unfavorable environmental conditions well. It is durable and has antibacterial properties.

Pine and spruce

The material is made of spruce with a yellowish tint. It has soundproofing properties and high strength. Pine produces timber with an affordable price, high strength and aesthetic appearance.

Application

The building material is used for the construction of house walls, extensions, furniture, floor beams, and roofs. It is distinguished by its earthquake resistance, resistance to high humidity, and lightness.

Houses and cottages made of laminated veneer lumber

Houses and cottages made from this material can be adapted to suit any taste and lifestyle. They are distinguished by environmental friendliness, harmony, unity with nature. Strict geometric shapes will delight those who love order and comfort.

Life time

Houses and cottages are durable and reliable. With proper and regular care, the timber will last fifty years or more without cracking or rotting. Since the material is earthquake-resistant, when building a strong foundation, the walls will withstand slight vibrations of the earth, without the formation of shrinkage and cracks.

Roof

Rafters made from laminated veneer lumber have a high load-bearing capacity. They are characterized by ideal geometry and its preservation for twenty or more years.

For the rafter system, LVL timber is used. Manufactured using the special technology described above, it shows a high tensile strength of up to 48 MPa and the ability to create a maximum span of up to 38 meters without the use of supports.

Maintenance of a house made of laminated veneer lumber

Maintenance of a house made of laminated veneer lumber is an essential part of caring for it. For example, without regular antiseptic coating, wood becomes darker and easily susceptible to mold and destruction by bark beetles. Additionally, the shrinkage of the foundation, cracks in timber, and the sealing of windows and doors are checked.

Steps for maintaining a laminated timber cottage:

- The first inspection is carried out a month after the project is completed.

- The second check is after six months.

- Third – after 12 months.

After the third maintenance, similar checks are carried out once a year. The studs on the crowns, the jacks of the support beams are checked, the fasteners of stairs, doors, and windows are adjusted. The building's electrical system is being inspected.

The building is painted regularly - once a year.

Shrinkage

Shrinkage occurs in any structure, no matter if it is made of brick or wood. It is not recommended to save on raw materials when building your own house or buying a turnkey building. In the latter case, builders may ignore building codes, and you will find out about this only two years later, when the floors and windows are corroded as a result of shrinkage.

Therefore, it is better to assemble the house yourself or turn to professionals. The main thing is to control the use of insulation yourself and the fit of the crown links of the log house.

Stages and terms of construction

Stages and terms of construction:

- Raising the foundation – 1 month.

- Construction of walls and roof - 2 months.

- Interior finishing and installation of communications – 3 months.

In total, building a house from profiled timber takes from six months to 9 months.

Combined (for example, timber and stone)

Combined houses combine construction from wood and brick. For example, the walls of the first floor are built from stone or brick, and the second floor, where the bedrooms and children's rooms are located, is built from laminated veneer lumber. Such houses turn out to be beautiful and aesthetically pleasing.

Country houses

Recently, those who like to relax outside the city have begun to build country houses from laminated veneer lumber. Firstly, they save time on construction and can raise the walls themselves without contacting companies. Secondly, houses made of laminated timber in the country differ from neighboring brick ones in their beauty and cleanliness.

Half-timbered

Half-timbered buildings are durable and can withstand sudden changes in weather. They can be seen especially often in countries with a sharply continental climate. The houses combine a solid stone foundation and bright wall elements of natural wood.

For permanent residence

Houses made of laminated veneer lumber do not require the use of good insulation. Walls made of wood with a cross-section of 180 mm will retain heat even at an outside temperature of minus forty degrees. Houses for permanent residence made of timber show high sound-proofing and heat-insulating properties. You can live in them all year round, without fear that the walls will begin to mold or become covered with fungus.

With terrace

The terrace in the house offers panoramic views of the countryside. The technology and layout of the manufacture of terraces and laminated timber can be made fireproof. A gazebo on a suburban area is no longer needed, as it is completely replaced by a terrace. This means that you can save extra square meters for your garden.

With bath or sauna

Glued laminated timber allows you to make any frame for a bathhouse. It can be made round, like a barrel, or square, triangular. Such baths and saunas are environmentally friendly. They retain heat for quite a long time inside the building, so they do not require a large amount of firewood for kindling. Such baths also have a positive effect on health.

With garage

Houses with a garage will allow the owner's car to always be in a dry and clean room. The car does not have to be warmed up in winter, and it is not exposed to negative environmental influences.

Winter option

In houses for winter living it is necessary to minimize heat loss. Therefore, experienced builders advise choosing timber with a thickness of 150 mm or more for buildings where winter with frost lasts more than two months. It is advisable that the tree be harvested in the cold season. Then you can avoid the appearance of rot and the attack of timber by parasitic bugs.

With swimming pool

Houses with a swimming pool take no more than 6 months to build. The material retains heat and moisture at the level necessary for humans better than brick. Therefore, it will always be comfortable for pool visitors to come for a swim and just relax near the water when winter is raging outside the walls.

With a second light

Houses made of laminated veneer lumber with second light look aesthetically pleasing and beautiful. Usually this is a spacious building with a high ceiling that can accommodate a swimming pool and home theater. It is recommended to leave the roof beams open.

Chalet

Chalets are buildings with a high foundation. Such houses are built mainly from coniferous trees. They are equipped with a gable roof and a large number of small windows with shutters. The chalet can easily protect you from the violence of the elements; it is distinguished by its good quality and massiveness.

Two-story

Two-story houses are light and aesthetically pleasing. To build them, you do not need to pour a massive foundation, and the second floor can be made in any shape from semicircular to square. The material is made in the form of various shapes, so such blocks speed up construction.

Single-story

One-story houses include spacious buildings and small square footage. They do not need interior or exterior finishing. Experienced builders recommend using comb-shaped timber. It retains heat and protects from wind and drafts.

Luxury "Premium" class houses

Elite houses are built from coniferous wood from the northern forest, which is twice as dense as wood in central Russia. For gluing the lamellas, formaldehyde-free glue is used. The walls of the house breathe and do not allow cold and moisture to pass through.

With bay window

The ability to produce material of any shape from laminated veneer lumber allows you to build houses from it with protrusions or, as in construction, it is called a bay window. Such buildings look original and provide additional living space. Panoramic windows are inserted into the walls.

Modern style

Glued laminated timber looks laconic and aesthetically pleasing, so it fits perfectly into the modern style. Many owners of suburban areas build houses in this style. They are distinguished by a large area, a spacious terrace, and minimalism.

High tech

Features of high-tech buildings made from laminated veneer lumber include:

- big windows;

- shades of strict, cold tones in the colors of the rooms and the exterior of the house;

- adaptation of laminated veneer lumber as part of the design and decor;

- minimal lack of decorative elements.

Glued timber lamellas make it possible to fulfill all of the above conditions in an ideal manner.

Reviews

Mikhail Andreevich Sosnovsky, 26 years old, Tomsk

I ordered the construction of a house from this company three years ago. I was pleased with the work done. I liked that the team approached the construction competently. When I tried to put in my two cents, they explained everything to me and explained why this should not be done. The house is warm in winter, cool in summer. The result is quality. Thank you

Klinko Andrey Viktorovich, 20 years old, Vladivostok

I ordered a house from them for my parents. My grandfather loves everything the old fashioned way without any modern frills. The team did everything as grandfather ordered. A former designer, my grandfather reviewed the drawings twice and could not find a single mistake. This may have saddened him because he likes to argue, but I was glad that my parents liked it.

More reviews.

Glued laminated timber board

Glued laminated timber panels are used to make furniture: tables, cabinets, beds. The result is durable and beautiful things. They are practical and can be repaired if something breaks.

Casing made of laminated veneer lumber

The casing is needed to strengthen the walls and maintain the geometry of the window sizes during the shrinkage of the house. It is installed in all wooden houses. It is recommended to trust the manufacture of casing only to professionals in their field, so as not to have to restore the whole house later.

Doors made of laminated veneer lumber

Interior doors made from laminated solid wood are durable and rigid panels that will last more than 30 years if you regularly care for them. They are environmentally friendly and attractive in appearance. The likelihood of cracks and deformation of wood is negligible compared to other materials.

Hotel or guest house made of laminated veneer lumber

Features of a hotel made of glued timber:

- optimal price;

- quick construction of walls;

- stylish design in natural shades.

Inside, the rooms can be decorated in a cozy home style, which will attract more visitors.

Garage made of laminated veneer lumber

A garage made of laminated veneer lumber will keep your car warm and cozy. You will be able to spend more time repairing or tuning your car in the lamp atmosphere of such a building.

Window

Windows made from laminated veneer lumber are not inferior in functionality to conventional wooden or PVC windows. They have minimal shrinkage, so they retain their original dimensions throughout the entire operation of the product. They do not crack and are not susceptible to the effects of fungal microflora or mold.

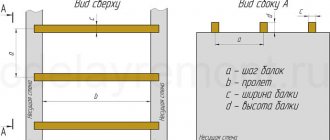

For floors

Laminated profile floor beams are made from coniferous wood: pine and spruce. They are durable. Oak, maple and some other species are also used. But in this case, the technology is followed: the percentage of wood moisture content should not exceed 14 percent.

Furniture

You can build furniture of any size and design from timber. It will become the highlight of the interior of a room or home. The material allows you to create fairly ergonomic furniture that can be repaired at any time if it breaks. It is universal in stylistic and color direction.

Hozblok

A utility block made of laminated wood is a popular and functional building on a country plot. You can build its walls yourself, thanks to the ease of installation of the material. The results are fireproof and beautiful buildings.

Tabletops

Tabletops made from laminated wood are durable and moisture-resistant products. They look presentable and are highly wear-resistant. The countertops are suitable for any kitchen interior.

Glued laminated timber gazebos

Glued solid wood is a convenient material for making a gazebo. It does not crack or rot, even if it stands in the open air with a stretched mosquito net instead of a roof. There is a closure of the building, especially for winter recreation. They retain heat perfectly and can serve as temporary housing for humans.

Laminated timber canopy

A canopy can solve your summer vacation problem forever. It is also erected to store the car from precipitation in the summer. The canopy can be either attached to the house or made as an independent object. Glued solid wood allows you to build it quickly and without any problems. You only need a screwdriver and a hacksaw.

How to increase the service life of a wooden house

Despite the appearance on the construction market of new materials for private housing construction, wood does not lose its popularity. Cleanliness, environmental friendliness, good operating characteristics, external superiority and beauty do not allow wooden buildings to remain unclaimed. In order for a wooden cottage to serve you as long as possible, it is worth knowing several conditions for its operation.

1. Factors influencing the service life of a wooden house

Let's talk in more detail about the indicators that affect the service life of a wooden cottage.

The main ones:

- a mandatory point is the permanent residence of people; without heating, the house quickly loses its characteristics;

- quality of construction, experience and qualifications of the construction team;

- mandatory availability of a project and its implementation during construction;

- the climate in the place of construction, frequent and sudden temperature changes have a negative effect on the tree;

- quality of raw materials for construction;

- technical ability to repair and replace individual elements;

- the use of antiseptic impregnations with a special composition;

- desire and ability to care for the building and make its repairs.

If these conditions are met, a wooden house will last no less than its “brother” made of brick.

A properly developed construction project will play a big role in the future fate of the constructed building, since all the main mechanical loads are calculated in it. And following the rules of care will extend the life of your home and keep it in good condition for many years.

Bathhouse made of laminated veneer lumber

A bathhouse made of laminated veneer lumber means savings on the foundation during construction and on heat during operation. The structure is resistant to fire, damage by insects and fungi. In addition, it has a pleasant interior and exterior. The walls of the bathhouse do not need to be finished with additional material, because the laminated wood itself already creates an aesthetic appeal.

Two-story

Two-story baths allow you to save space on the site, since the relaxation room is located on the top floor. It can also be equipped not only for relaxation, but also for a gym or bedroom. Glued solids make beautiful and durable buildings that do not shrink. The owner will be able to save on heat in the winter without additional wall cladding.

With barbecue

Today baths are made with a terrace. A barbecue oven is placed on it. This creates a place to rest after the bath, protected from the sun. It is easy to build walls from laminated wood not only for a bathhouse, but also to equip a terrace with a barbecue oven. A stone stove will contrast perfectly with wood.

With terrace

A sauna made of laminated timber with a terrace will save money and give you the opportunity to enjoy the mesmerizing aroma of wood from the inside and warm up your body. And outside - you can relax, enjoying the beautiful view of your site. If you make a closed terrace, then in winter you can relax after steaming in a cool room, admiring the snow-covered landscape.

With swimming pool

In a timber bathhouse you can install one of two types of pools:

- stationary. These are reliable and durable structures;

- collapsible. Such devices are lightweight and can be transported from place to place. Considered a cheaper option.

If a bathhouse made of laminated timber looks spacious, then you can install a swimming pool with hydromassage.

With panoramic window

Panoramic windows in the relaxation room of the bathhouse made from laminated veneer lumber make the building look more impressive and elegant. For the owner, such windows offer a view of the site, river or lake, which is located nearby. A person here relaxes not only with his body, but also with his soul.

Pros and cons of laminated timber baths

Advantages of baths made of laminated veneer lumber:

- beautiful view;

- ease of installation;

- savings on heat and wall construction;

- captivating aroma of wood.

Disadvantages of laminated wood baths:

- when purchasing timber, it is impossible to determine what type of wood it is made from;

- additional insulation with flax will be required during construction;

- the use of low-quality impregnation leads to a fire hazard.

Sauna chalet

The most pleasant style for arranging a bathhouse is considered to be a chalet. Glued laminated timber is ideal as a material for raising walls. Such a bathhouse returns a person to childhood, a fairy tale. Modern notes can also be woven into this style.

Video description

About the disadvantages of laminated veneer lumber in the following video:

Finnish house made of timber with tinting in natural colors Source yandex.ru

- Possibility of defects . Despite the manufacturability of production, laminated veneer lumber remains wood (for which it is valued). Like any wooden product, it is not guaranteed against cracks and shrinkage, only such troubles occur in a tenfold smaller volume.

- Possibility of purchasing counterfeit goods . Here you are not insured against anything. The result can be significant shrinkage of the house (in artisanal conditions it is difficult to ensure proper drying), changes in geometry, discrepancies in size and harm to health (no one can vouch for the quality of the glue).

- Glue . Glued laminated timber with a vertical orientation may contain 4-5 layers of glue. And although high-quality glue is close in its properties to tree resin (the basis is natural substances), it disrupts natural air circulation. In this case, only the inner surface of the wall can regulate the humidity in the room. An option would be to use horizontally oriented material.

- Flammability . The wood is treated with a fire retardant, which inhibits the spread of fire for 20-30 minutes, which is enough to evacuate people and call rescue services.

Modern project with elements of ethnic style Source realtor.if.ua

Characteristics

The following are the technical characteristics of the beams. Here are all the parameters to choose the right size, quantity and suitable material for thermal conductivity.

Dimensions

Beam dimensions:

- 100x100x6000mm;

- 100x150x6000mm;

- 100x200x6000mm;

- 100x250x6000mm;

- 125x125x6000mm;

- 200x200x6000mm;

- 200x250x6000mm;

- 250x250x6000mm.

Weight and quantity of laminated timber per 1m3

Weight of material in kg:

- 100x100x6000 (mm) – 31.2;

- 100x150x6000 (mm) – 46.8;

- 100x200x6000 (mm) – 62.4;

- 100x250x6000 (mm) – 78;

- 125x125x6000 (mm) – 48.75;

- 200x200x6000 (mm) – 124.8;

- 200x250x6000 (mm) – 156;

- 250x250x6000 (mm) – 195.

Thermal conductivity

Table of thermal conductivity in relation to other materials

| Material | Thermal conductivity coefficient, W/m*C |

| Glued laminated timber | 0,1 |

| Dry wood | 0,09–0,18 |

| Pine, spruce across/along the grain | 0,09/0,18 |

| Oak across/along the grain | 0,1/0,23 |

| Profiled timber | 0,18 |

| Foam concrete | 0,08–0,47 |

FAQ

Below are answers to frequently asked questions from users.

How to treat laminated veneer lumber?

Glued laminated timber is treated with various antiseptics to protect against rot and parasites. They use wax impregnations, primers - OSG 3180, DD113, end coatings called Log And Seal.

How much laminated veneer lumber is needed for a house?

If the beam measures 20*20*600 cm, then multiply it by 0.2*0.2*6 m, and the volume is 0.24 cubic meters. To find out how many units of timber are in one cubic meter, divide the unit by the volume of one piece: 1/0.24 = 4.167, round to 4.

You need to find out the area of the wall that can be built from one cubic meter of material with a beam thickness of 200 mm. We convert it into meters: 200 m = 0.2 m. Divide the cubic unit by this value: 1/0.2 = 5 sq.m. Find out the square footage of the walls of your house and multiply by the resulting value.

What is better: laminated veneer lumber or rounded logs?

Rounded logs are cheaper, but will require annual caulking and sealing of the house. Houses made from rounded timber will have parasites and fungal infections because it does not undergo optimal drying.

Glued laminated timber or frame house, which is better?

Houses made of laminated veneer lumber are warmer, stronger and more durable. It is erected faster than frame.

Is it necessary to insulate a house made of laminated veneer lumber?

If the walls are constructed correctly, there is no need to insulate a house made of laminated veneer lumber.

What is better timber or laminated timber?

Unlike regular timber, laminated timber is much stronger and more durable.