Fiberglass (another name is gossamer) combines the best characteristics of glass and non-woven material. To attach it, special adhesive compositions are used. They can be in the form of ready-made solutions or powder for self-preparation. What kind of glue for fiberglass is better to choose and how to work with it will be discussed in the article.

Properties of fiberglass

Painting fiberglass outwardly creates the impression of an absolutely fragile material that can tear with careless movements. However, when glued, it creates an excellent reinforcing layer that prevents existing cracks from spreading and prevents the formation of new ones.

Given the different densities of the material, it is divided into certain classes. Accordingly, the cost of such a web is based on thickness. For gluing to the ceiling, a thickness of 26 g/m2 is sufficient. This will create a light but durable reinforcing layer.

In addition, the material has a number of advantages:

- thanks to the use of natural raw materials, fiberglass is environmentally friendly;

- high breathability helps maintain an optimal microclimate;

- the composition of the material does not contribute to the formation of fungi and mold;

- perfectly amenable to wet cleaning;

- the strength of the material prevents the formation of microcracks;

- being absolutely non-flammable, the material does not emit harmful fumes when in contact with fire;

- The fiberglass ceiling can be glued to any materials, including natural and polymers.

Thanks to the interesting weave pattern, the fiberglass-covered ceiling looks original.

Cobweb to strengthen the ceiling

Rating of the best wallpaper adhesives

| Photo | Name | Rating | Price | |||

| TOP 3 adhesives for non-woven wallpaper | ||||||

| #1 | Moment Interlining | ⭐ 4.85 / 5 | Find out the price | |||

| #2 | Metylan Interlining Express Premium | ⭐ 4.7 / 5 1 - voice | Find out the price | |||

| #3 | Quelyd Special interlining | ⭐ 4.6 / 5 1 - voice | Find out the price | |||

| TOP 3 adhesives for paper wallpaper | ||||||

| #1 | Lakra Universal Builder | ⭐ 4.9 / 5 | Find out the price | |||

| #2 | TITAN WILD Universal | ⭐ 4.8 / 5 | Find out the price | |||

| #3 | KLEO TOTAL Universal | ⭐ 4.65 / 5 | Find out the price | |||

| TOP 3 adhesives for vinyl wallpaper | ||||||

| #1 | Quelyd Vinyl indicator | ⭐ 4.95 / 5 | Find out the price | |||

| #2 | PUFAS EURO 3000 Vinyl with indicator | ⭐ 4.8 / 5 | Find out the price | |||

| #3 | Metylan Vinyl Premium with indicator | ⭐ 4.6 / 5 | Find out the price | |||

| TOP 3 adhesives for glass wallpaper | ||||||

| #1 | PUFAS Glutolin GTX Rubin | ⭐ 5 / 5 | Find out the price | |||

| #2 | KLEO ULTRA for glass wallpaper | ⭐ 4.9 / 5 | Find out the price | |||

| #3 | Oscar for fiberglass wallpaper | ⭐ 4.75 / 5 | Find out the price | |||

Which glue would you choose or recommend?

Take the survey

Application area

Gossamer is a decorative reinforcing material widely used in construction to strengthen and level ceilings. In rooms finished with plasterboard or plastered, smooth fiberglass is used, which can replace finishing putty. It can also be used to reinforce external surfaces prone to cracking. If it is not possible to create suspended structures, the ceilings can be leveled with cobwebs.

To create a relief pattern on ceilings and walls, it is not necessary to purchase expensive wallpaper. It is enough to cover the surfaces with fiberglass, which can serve as an effective strength barrier. It is fixed with a special glue, after which it is primed, covered with putty and painted. Thanks to the reinforcing properties of the material, the service life of the coating, which is subject to numerous repaintings, is significantly extended.

Composition requirements

Fiberglass is a dense material made from the finest strands of fiberglass, which are interconnected with a synthetic polymer composition, similar to felt. It is used as a reinforcing material, a leveling layer for walls and ceilings, or as a coating for surfaces to be painted.

The glue for the web (glass host) must hold not only its weight on horizontal and vertical surfaces for a long time, but also the weight of the finishing material (wallpaper, paint, plaster, plaster). To reliably strengthen the mounting material, ordinary wallpaper glue or PVA is not suitable.

The special adhesion composition must include the following components:

- The polymer base is polyvinyl acetate (PVA). This is the main adhesive component;

- Plasticizing additives – provide optimal viscosity and elasticity of the adhesive joint, prevent the formation of cracks after drying;

- Modified starch – increases adhesion characteristics when working with glass host;

- Fungicides – prevent the formation of mold and fungal deposits;

- Polyvinyl alcohol – speeds up drying and prevents delamination.

Strengthening ceilings with fiberglass

Gluing fiberglass helps strengthen the base of the ceiling, eliminating the formation of cracks. The work is carried out at a temperature of no lower than 18 and no higher than 25 degrees, provided there is a complete absence of drafts.

Surface preparation

Preparing the ceiling surface

The main requirements for finishing work include surface preparation. Remains of old coatings: wallpaper, whitewash, plaster, paint need to be carefully removed. Experts say that the web can be glued to a whitewashed ceiling containing no more than 3 layers of lime. But, to be on the safe side, it is advisable to wash it off with a wet cloth or clean it off with a spatula. When cleaning, there is a possibility of the formation of potholes and chips, which will have to be primed and puttied.

Prime the base

After making sure that the top layer of putty has set, it is treated with a primer. The composition should be applied in large quantities so that it takes at least 20 minutes to dry. This will significantly improve the adhesion of the surface to the glue and, therefore, to the material. For work, it is better to choose not a simple primer, but a deep impregnation one.

We dilute the glue

When the primer has dried, proceed to direct gluing, using special compounds intended for fiberglass. True, out of despair, you can use products containing PVA. Although there are no problems with the “original” mixtures, they can be purchased at all construction supply stores, where they are presented in the form of a powder or a ready-made composition packaged in buckets. The first option is more economical, since from a 300-gram package diluted with cold water, you will get 11 liters of high-quality glue, which is enough to glue 50 m2 of fiberglass cloth.

Covering the stream with fiberglass

Smoothing when pasting should be thorough, but as careful as possible

Attention! It should be remembered that during operation the material must be protected from direct sunlight.

Having measured the required dimensions, pieces are cut from the roll with a small margin. The adhesive composition should be applied to the ceiling with a roller or wide brush. The area of impregnation must correspond to the width of the fiberglass. The web is pressed to the coated surface and smoothed like wallpaper, from the middle to the edges. The procedure is performed using a plastic spatula.

Considering that the fiberglass material is too vulnerable at this point, it is quite easy to tear. Therefore, actions should be performed without fanaticism, without pressing too hard.

In a similar sequence, the entire surface of the ceiling is sealed, cutting off the excess length of the material. The final step is to apply glue on top of the web. After the canvases have completely dried, which occurs after 24 hours, you will receive a reliable reinforcing layer that will allow you to forget about repairs for a long time.

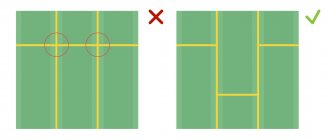

Attention! If the side of the fiberglass is torn, you will have to glue the next piece overlapping, making an overlap of about 4 cm. To do this, in addition to the next section, the part of the piece on which the material will be applied is coated with glue. To avoid the formation of a noticeable protrusion, serrated incisions are made at the application sites. After removing the excess layer from each canvas, the joint is smoothed using a spatula.

Covering the ceiling with overlapping fiberglass

Types of mixtures

In construction stores you can find ready-made solutions for steklohost or dry mixtures for dilution. In addition, there is also fiberglass fabric already impregnated with glue, you just need to wet it.

Ready-made mixtures for fiberglass

To speed up finishing work with fiberglass, ready-made solutions are used. They can be applied directly from the packaging to the installation material. Usually sold in containers from 0.5 to 5 liters. When using them, the reliability of adhesion depends on the quality of the mixture.

Check the expiration date and integrity of the packaging.

Once opened, finished formulations are stored for no more than 10 days. When purchasing, choose the smallest size. The approximate material consumption is indicated by the manufacturer on the packaging.

Dry powder for fiberglass

Its advantage is that it can be diluted and used in portions. You can independently choose the volume of powder for preparing the solution. Dry mixtures are diluted with water; manufacturers indicate the proportions on the packaging. Strictly follow the recommendations for preparing the composition.

Pasting the ceiling for painting

Considering that the work is carried out indoors, the use of interior paints will be the best design option. They are able to favorably highlight the structure of the material, dry quickly, and also do not have any foul odors.

The best result when painting fiberglass is achieved using a medium-pile roller, well soaked in paint. To ensure that all bulges and depressions are evenly covered with paint, the roller is passed alternately in the horizontal and then vertical directions. To achieve a durable and especially beautiful surface, the next layer of paint should be applied to the dried layer.

Voting: the best wallpaper glue

Which glue would you choose or recommend?

Moment Interlining

0.00 % ( 0 )

Metylan Interlining Express Premium

50.00 % ( 1 )

Quelyd Special interlining

50.00 % ( 1 )

Lakra Universal Builder

0.00 % ( 0 )

TITAN WILD Universal

0.00 % ( 0 )

KLEO TOTAL Universal

0.00 % ( 0 )

Quelyd Vinyl indicator

0.00 % ( 0 )

PUFAS EURO 3000 Vinyl with indicator

0.00 % ( 0 )

Metylan Vinyl Premium with indicator

0.00 % ( 0 )

PUFAS Glutolin GTX Rubin

0.00 % ( 0 )

KLEO ULTRA for glass wallpaper

0.00 % ( 0 )

We cover the plasterboard ceiling with fiberglass

Today, plasterboard structures are a fairly common phenomenon. Fiberglass fabric on them is also successfully used as a reinforcing coating. It is recommended to use it regardless of the use of serpyanka at joints, since the web can protect the drywall from deformation. The sequence of gluing fiberglass as an intermediate layer separating the drywall from the final finish is reminiscent of the previous methods, but the surface preparation differs in certain nuances. Therefore, before gluing fiberglass you should:

- putty the tile seams and cavities from self-tapping screws;

- treat the ceiling surface with glue, which acts as a primer, and wait for it to dry completely;

- Now you can glue the fiberglass.

Structure of fiberglass for painting

Useful tips

To avoid errors in work and save time on rework, follow these recommendations:

- You should start gluing the fiberglass from the corner. Glass material is fragile, so it does not need to be wrapped at the corners, but placed end-to-end;

- When reinforcing the ceiling, cut the strips no more than two meters. Otherwise, they will be very difficult to stick;

- During work and until complete drying, there should be no drafts in the room, otherwise the material may move away from the base;

- The joints of the strips of reinforcing fabric should not be combined with the seams of plasterboard panels;

- When diluting the dry mixture, a reaction may begin, releasing heat and solvent vapors. Mixing and further work should be carried out using personal protective equipment;

- Fiberglass web has a front and back side. Usually the front part is smoother and directed towards the inside of the roll;

- Before the final coating, the bases are primed in two layers.

The difference between fiberglass canvas and glass wallpaper

Many people incorrectly believe that fiberglass wallpaper with a painting web are identical materials. Indeed, they have a common origin, numerous quality characteristics, and the ability to strengthen surfaces. This ends their similarities and begins their significant differences.

- The web can be repainted an unlimited number of times, and glass wallpaper can withstand no more than 25 color changes.

- Unlike wallpaper, fiberglass fabric is not a woven material, and has a smooth structure, while wallpaper has a textured structure.

- Wallpaper is a material intended for finishing, and cobwebs are used as an intermediate reinforcing layer.

- There is a significant difference in density and weight between these materials.

- The cost of cobwebs is significantly lower than wallpaper.

Due to the fact that the material is not able to absorb dust, its maintenance is greatly facilitated by wiping the pasted surface with a damp cloth. When choosing fiberglass to strengthen ceilings, you should pay attention to reviews from consumers who have tried the products. Direct gluing of ceilings is not particularly difficult, as it seems at first glance. Every hardworking owner, even one completely unfamiliar with construction, is capable of mastering such work.

Popular manufacturers

Today, we can distinguish the following brands of adhesives for fiberglass, which are widely used due to the predictable and high-quality results of their use:

- Oscar. Designed for gluing painting fiberglass, glass wallpaper in dry rooms on concrete, gypsum bases and drywall. It is economical in consumption. Contains antifungal components. Produced as a ready-made solution in containers of 0.45 kg. and dry powder in packs of 0.2 kg. a package of ready-made glue is enough for 50 m², dry for 25 m². Cost from 170 rub.

- QUELYD for glass media. Dry mixture with enhanced adhesion. Can be used for finishing before painting. Mix without lumps for 15 minutes. After drying, it does not leave stains or streaks. Available in 0.45 kg packs. One pack is enough for 35 m². Costs from 375 rubles.

- Kiilto Master Pro. Liquid adhesive for dry rooms. Has fungicidal additives. Used for finishing for painting. Painting is possible after complete drying within 24 hours. After dilution, the time to use the mixture is 30 minutes. Sold in 5 liter containers. Packaging consumption per 25 m². Price from 950 rub.

- Nortex for fiberglass. Dry mixture for cobwebs, can be used for painting. Complete drying within 36 hours. In addition to fiberglass, it can be used for non-woven and vinyl coverings. Solution preparation time 10 minutes. Packs 300 gr. enough for 30 m². Price from 220 rub.

- Tex universal for fiberglass. Liquid adhesive for finishing for painting. Contains antifungal components. The time for adjusting the canvas when gluing is 10 minutes. Dries within 24 hours. It has medium density and does not leave stains after drying. Packaging 3 l. enough for 12 m². Price from 650 rub.

- Bolars FiberFix for fiberglass. The finished solution is not intended for further coloring. Fiberglass adjustment time is up to 15 minutes. Complete drying within 24 hours. It has increased adhesion to concrete and plasterboard, and can be used for particularly heavy coatings. Available in 5 liter containers. Consumption 0.15 kg/m². Price from 670 rub.

- PUFAS Security for fiberglass – waterproof dry composition. Can be used for finishing wet rooms. Mixture preparation time 15 minutes. Complete drying within 36 hours. Consumption 0.2 kg/m². The powder does not contain solvents and does not leave dark marks after drying. Packaging 0.5 kg. costs from 580 rub.

Fiberglass: what are they?

Broadly speaking, the product is called fiberglass wallpaper. This is a coating that has a structure similar to fiberglass fabric. The material used is special glass. So, at a special temperature, fibers are drawn out of it. Then specialists form the yarn, and after that the material is created. Beautiful patterns are woven to create products.

It is important to choose the right glue for glass wallpaper: there are several variations of the substance. The better the composition, the easier it will be to glue the material, and the longer it will last on the walls.

How to choose the right one

Wallpaper is selected based on density and the thickness of the rolls themselves. It should be remembered that manufacturers can use more impregnation for this. It compacts the roll itself, but does not provide any texture, and the design turns out inexpressive. If the manufacturer uses loose threads for textured patterns, then after squeezing out the air with a spatula, the pattern becomes flat.

To avoid getting into an unpleasant situation, you can choose glass wallpaper in the following ways.

- Take a small piece of canvas and stick it on the wall. Then you need to paint the surface and treat it with a spatula. If the material on the wall is not flattened, it means the product is of high quality and you can work with it.

- If you can’t experiment, choose well-known brands. Companies value their reputation, which means the gluing result should be strong, textured, and durable.

Manufacturers

Among manufacturers, it is better to trust world-famous names. This applies to the Swedish company Johns Manville and its Oscar, Welton, Tassoglas series. Glass wallpaper from the Vitrulan series from the German manufacturer Vitrulan Textilglas GmbH is in demand. Such wallpaper can withstand serious mechanical loads, even if the surface itself is wet.

The quality of the roll can be checked by touch, but after gluing it to the wall it may not be as dense. This is due not only to loose threads, which makes the result flat, but also to the addition of starch to the composition. The latter option gets wet upon contact with liquid glue, and the wallpaper itself becomes loose.

The density of good wallpaper should be at least 145 g/m2. m. If the indicator is not in the characteristics, take rolls with a large weight. According to the marking, choose first-grade glass wallpaper. There may be black stripes on the roll. This indicates a defect, for example, places with crooked or fallen threads. Then another 50 cm of canvas is added to the standard length.

Advantages and disadvantages of cobwebs

Fiberglass is not without strengths and weaknesses in the same way as other colleague materials. Traditionally, people talk about the benefits first, so let’s move straight to their impressive list. Cobweb:

- it is considered environmentally friendly, absolutely safe, since it does not contain any harmful or suspicious components;

- sometimes it makes it possible to get by with only the starting putty, without the participation of the finishing type of this coating;

- is not noticed in the accumulation of static electricity, so dust ignores it;

- not afraid of high temperatures, temperature changes, or high humidity;

- durable, it is not afraid of mechanical stress, fire, corrosion;

- makes it possible to carry out work indoors and outdoors;

- it is vapor permeable, which means that mold does not threaten surfaces;

- and the adhesive composition for it do not provoke allergies;

- has no sharp unpleasant odors;

- does not require serious care.

The material can be safely glued to any surface - wood, concrete, brick, plasterboard, ceilings or walls.

There are also disadvantages, these include:

- The ability to “attack” low-quality, inexpensive material with a short service life. Such products will disappoint due to the inconvenience of working with them, inelasticity, and fragility.

- Impossibility of using first grade fiberglass in premises. It contains phenols and formaldehyde resins, which are undesirable components.

- The ineffectiveness of the material if there is a need to hide serious defects - large cracks, chips, potholes. They will have to be sealed in advance.

- The need for protection (gloves, glasses, masks, or better yet, a respirator) when working due to small glass particles.

- Difficult to dismantle the coating.

- High consumption of glue.

One cannot but agree that the disadvantages are still relative, since most of them relate to low-quality products. Therefore, in the “battle” of advantages and disadvantages, the first ones emerge as winners.

Characteristic

The fiberglass material is a kind of web, fiberglass threads that are connected in an indefinite order. This structure allows you to create an ideal surface that will combine both visual and internal characteristics, that is, the characteristics of strength and density.

There is a special glue for fiberglass. The composition of such glue usually includes: modified starch, vinyl acetate polymer, a plasticizer that increases the elasticity of the fabric, as well as other bactericidal additives. The glue is produced in special packaging - in plastic boxes, which are secured with a tight lid.

Glue for fiberglass

Advantages of Oscar glue

There are a number of positive characteristics that Oscar glue for fiberglass has:

- no harm to the human body;

- economical - for 10 liters of water you need only 0.5 kg of dry powder;

- ease and speed of preparing the solution: the existing powder is poured into a container with cold water and is ready for use after 8-10 minutes;

- saving on product consumption: only 0.25 kg of ready-made glue mixture is enough for 1 sq.m of coating;

- a fairly long shelf life of the prepared mixture: it can be stored for up to 2 months, but only in closed packaging;

- You can easily move the glue in a closed container.

Before you begin the process of gluing the material onto the finished surface, you need to carry out the main stages of preparatory work. Is it possible to glue fiberglass without preparation? Of course not, otherwise he won’t stick around. The surface should be cleaned of all dirt and dust, and cracks that are visible to the naked eye should be treated initially. Working with glue makes the task much easier than gluing wallpaper to the wall, because the glue is applied only to the surface itself, as shown in the video.

Features of Wellton glue

Glue for fiberglass canvas Gossamer is created specifically for working with fiberglass canvases. It is able to firmly fix the canvas on any base, even if it is not perfectly smooth. The advanced features of this glue provide such characteristics as:

- high solubility of the product;

- obtaining a uniform and homogeneous mixture;

- effective adhesive ability;

- saving money;

- safety and preliminary protection of the development of bacteria or fungi during operation.

For work you will need:

- roller;

- construction stationery knife with replaceable blades;

- spatula 35 cm, spatula 10 cm;

- respirator, gloves (recommended)

Worth knowing! When working with the material, you should wear clothing that will protect fiberglass from dust (special clothing, or just long sleeves) and use a respirator. Sharp fiber particles can get on your skin and cause irritation.

Preparing the surface for gluing

Before gluing, you need to make sure that the surface is intact (check if the plaster is falling off, etc.). If there are large cracks, they must be repaired.

Fiberglass wallpaper on the ceiling, how to glue: all cracks on the walls need to be repaired

This can be done using starting putty or cement-sand mortar (depending on the old coating). Small cracks are eliminated using serpyanka mesh and putty.

Serpyanka (fiberglass mesh) is used to seal cracks

Next, you need to putty the entire ceiling with a putty mixture. After drying, the surface must be sanded with sandpaper or a special mesh.

The prepared surface must be coated with a deep penetration primer. This is necessary to improve adhesion and bonding of construction dust.

We recommend watching the video: “What material to choose”

How to stick: seal the seams