Slate

This was once the most popular and cheapest of all types of roofing materials. Its properties and characteristics are such that today it is everywhere being replaced by new coatings. Slate sheets are made from an asbestos-cement mixture (85% cement, 15% asbestos). There are several varieties, differing in thickness, number and height of waves, as well as sheet sizes. As standard, corrugated slate sheets weigh 10 - 15 kg. Their length is 1750 mm, width is 980 - 1130 mm. He has waves - 6, 7 and 8.

Modern industry produces slate in various colors.

The positive qualities of this material include: low cost and waterproofness, as well as a long service life, up to 40 years. It has more negative properties: asbestos is harmful to health, the sheets are very fragile and break with little impact, the material has a high specific gravity. In addition, during use, moss may appear on the sheets in shaded areas.

What is a roof

The roof is the top element in the structure of the house, performing the main protective and decorative function. It not only protects the house from all external influences and prevents heat loss, but also ensures the attractiveness of the building due to its shape, dimensions and roofing. The roof is also called the fifth facade, implying its aesthetic parameters, ideally corresponding to the chosen architectural style. Sometimes it is the roof that “stretches out” a boring typical box, for example, due to height, disproportionate slopes or elongated overhangs.

As for the difference between a roof and a roof, then structurally, a roof is a complex, prefabricated system of various elements.

And the roof is precisely the finishing covering of the roof with protective and decorative functions. And, as already mentioned, in everyday life these concepts are interchangeable. But if a roof without a roof under a temporary covering (banners, roofing felt, films, etc.) can stand if necessary, then a full-fledged roof separately from the roof is impossible in principle.

Most roofing materials are universal and suitable for almost all types of roofs; only the complexity of the work and the amount of waste will vary, that is, the price of the issue. However, there are also coatings that require a special design included in the project, so in any case, the best option is when the type of roof is determined immediately, at the design stage, especially when it comes to large houses and complex roofs.

In practice, houses are still often built without a design, “out of the blue,” let alone roofs, but with this approach the risk of getting unfinished buildings of varying degrees of readiness increases. Moreover, with the current abundance of specialized graphic editors and online calculators, even not the most advanced user is able to perform at least a primitive sketch and calculate the loads, if desired.

How to complain about poor work or failure to carry out repairs

Residents of an apartment building have the right to file a claim if the housing management company does not fulfill its direct duties or performs them improperly. The norm is established by the Federal Law “On the Protection of Consumer Rights” and Article 161 of the Housing Code of the Russian Federation.

Submission order:

- higher authority;

- body Rospotrebsoyuz;

- city administration or housing inspection;

- prosecutorial supervision body;

- Judicial authority.

Any documents confirming the violations committed by the Criminal Code can be attached to the complaint. For example, copies of collective appeals, decisions of homeowners, photographs.

Main types of roofs

All roofs can be divided into two main types:

- flat;

- pitched.

Flat roofs

Multilayer horizontal structures with virtually no slope, 1-2⁰ (up to 4⁰) required for precipitation removal are visually almost invisible. They are divided into exploited and non-exploited, relevant for houses in a modern and minimalist style. Despite the apparent simplicity of the design, the complexity of implementation is due to increased requirements for waterproofing.

Pitched roofs

Within the categories, they are divided into several varieties, differing in the number and geometric shape of the slopes and the level of complexity of implementation.

- A pitched roof is the most simplified subtype in the original version, represented by one inclined plane supported by load-bearing walls located at different height levels. The slope angle of the slope varies in the range from 10 to 60⁰; the optimal slope of a pitched roof is 30-35⁰. To increase the decorative effect of a pitched roof, the design is made more complex by slightly rounding, bending the plane or combining orientation.

- A gable (gable) roof is one of the most common structures; it consists of two inclined planes separated by a ridge (rib). In this type of construction, pediments appear - the side parts of walls in the form of triangles, formed from the main wall materials or other than them. Depending on the architectural design, the slopes can be either identical, forming an isosceles triangle in diameter, or with different angles of inclination and overhang length. The minimum permissible angle of inclination of the slopes is 20⁰, the optimal is 40-60⁰.

The remaining subtypes, with the exception of non-standard designs, are a derivative of the gable roof.

Pil18Super-Moderator FORUMHOUSE

Hip-slope (hip or hipped) roofs are formed from gable roofs. Their pediments are cut off by inclined planes to their full height. The triangular slopes of hipped roofs are called hips. Semi-hip roofs differ from hip roofs in that only part of the gables are cut off by inclined planes. Four-gable roofs are formed from the connection of four gable planes.

If it is not an attic that is planned under the roof, but a living space for seasonal or year-round use (heated), an attic-type roof is built. It can be either a simplified gable, or a hip, or half-hip; its feature is not the shape of the slopes, but the presence of thermal insulation in the roofing pie. Often, if there is a lack of living space, a cold attic is converted into an attic or a major reconstruction is carried out, adding an attic roof with a larger square footage.

The original roofs include round ones (dome, conical) - they are erected mainly on round-shaped houses, as well as over turrets, on houses with “castle” architecture. They differ from ordinary pitched ones not only in shape, but in the special structure of the rafter system.

Corrugated roofing: inexpensive, durable, but noisy

Roofing made from corrugated sheets is lightweight and affordable. In addition, it is resistant to wind, snow and hail. A wide variety of colors allows you to choose the option that suits the style of your house.

Pros:

- Ease. A sheet of corrugated roofing with a thickness of 0.4–0.8 mm weighs 3–7 kg.

- Ease of installation. The profiled sheet does not require a clearly adjusted sheathing pitch, because it does not have waves.

- The corrugated sheet is easy to repair: cover up minor damage with mastic or replace the entire sheet.

Minuses:

- Lack of sound insulation.

- A corrugated roof needs insulation and waterproofing, because due to the large number of fasteners, the material cannot be called absolutely airtight.

This roofing can be installed on a pitched roof, just like metal tiles. The corrugated sheeting is mounted in places where the lower part of the wave adjoins the sheathing using self-tapping screws.

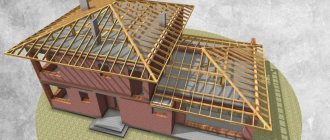

Roof construction

The roof is a multi-layer prefabricated structure, even if it is a single-pitch type. With rare exceptions, when the base of a flat roof in use is a reinforced concrete floor slab, it consists of the following basic elements.

- Mauerlat - necessary for rigidly fixing the roof to the base and uniformly distributing point loads from structural elements to the walls. It is a load-bearing frame located along the upper contour of the load-bearing walls. In wooden and timber houses, the upper crown serves as a mauerlat; in frame houses, the upper frame is used; in the rest, an antiseptic wooden beam with a cross-section of 100x150 mm, 150x150 mm is used. It is also permissible to use a double board (50×150 mm) as a Mauerlat.

- The rafter system is a supporting load-bearing frame that determines the shape of the roof, formed from inclined beams (joists), vertical posts and struts. It is assembled both from individual parts on site and from ready-made trusses, factory-made or home-made. In private houses, the rafter system is predominantly wooden, with the exception of metal frame structures (LSFK). The most important parameter of the rafter system is the distance between the rafters (pitch).

Pil18

The installation step of the rafters depends on the cross-section of the board (timber) used and the length of the rafter element, as well as the calculated load value for a given region. The data presented in the table does not replace a full calculation of the load-bearing capacity of the rafter system; they can be considered as recommendations for fairly simple roofs. The table gives values corresponding to the possible maximum loads on the truss structure for the Central European zone. Also, these tables have been prepared taking into account the range of lumber produced by Russian enterprises, in accordance with GOST 24454-80 (Raw wood).

| Rafter installation pitch (mm) | Length of rafter legs (mm) | ||||||

| 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | 6000 | |

| 600 | 40×150 | 40×175 | 50×150 | 50×150 | 50×175 | 50×200 | 50×200 |

| 900 | 50×150 | 50×175 | 50×200 | 75×175 | 75×175 | 75×200 | 75×200 |

| 1100 | 75×125 | 75×150 | 75×175 | 75×175 | 75×200 | 75×200 | 100×200 |

| 1400 | 75×150 | 75×175 | 75×200 | 75×200 | 75×200 | 100×200 | 100×200 |

| 1750 | 75×150 | 75×200 | 75×200 | 100×200 | 100×200 | 100×250 | 100×250 |

| 2150 | 100×150 | 100×175 | 100×200 | 100×200 | 100×250 | 100×250 | — |

GOST is valid, the last changes were made on September 12, 2018, now called “Softwood lumber. Dimensions".

- Lathing is a frame structure made of boards or timber, laid on the rafters at an angle of 90⁰, taking on the loads from the roofing and precipitation. Depending on the type of roofing, sparse or continuous lathing is used. Some finishing materials may require a combination of sparse sheathing and moisture-resistant slabs (soft tiles, roll roofing).

- Roofing covering is a finishing protective and decorative sealing layer fixed to the sheathing or slab base.

In addition to the main elements, when constructing a roof, protective membranes (vapor barrier, waterproofing) are used, and if the roof is of the attic type, then specialized thermal insulation materials. Most often these are slab varieties, laid between the rafters or in two layers, with overlapping joints.

If the attic is planned to be of a cold type, then it is not the slopes that are insulated, but the ceiling, thus ensuring thermal protection of the building.

Features of DIY construction

The rafter system is treated with chemicals against the effects of moisture, insects and fungi.

When constructing a pitched roof with your own hands, it is necessary to take into account all the nuances at each stage of this process.

- Work with high-quality and sharp tools. This is the only way to create clear parts shapes and reliable connecting nodes. Using sharp saws will avoid the appearance of cracks in load-bearing elements.

- Cutting accuracy. If a mistake is made, it is better to replace the defective element and make a new one than to risk the entire rafter system.

- Preparing wood for installation. You need to cut off the bark from the workpieces and remove areas affected by fungus and insects. After this, the timber and boards should be treated with an antiseptic and fire retardant.

- Maintaining alignment, vertical, horizontal and slope angle of each part. Violation of the geometry leads to weakening of the frame and disruption of its stability.

- Insulation of metal parts used for fastening. When the temperature changes, the hardware becomes covered with condensation, which is absorbed into the wood and causes it to rot.

- Compliance with the rules for laying roofing materials. The formation of cracks, distortions, and holes is not allowed. If necessary, sealants, sealants and mastics should be used.

It is necessary to approach the design of overhangs correctly. They need to be hemmed in such a way as to ensure a presentable appearance while maintaining free air circulation.

Nuances of choosing a roof

In most cases, the most important parameter when choosing a roof type is the price of the issue - the more complex the design, the more expensive it will be. The most budget-friendly in all respects is considered to be a simple gable roof, the angle of inclination of the slopes of which does not go beyond 25-30⁰. It can be either cold or attic type; with this design, there is enough space inside.

The climatic conditions in the region of construction are no less important, so flat and gently sloping roofs are not the best choice in areas with heavy rain and snow loads. And where you can count the windless days on your fingers in a month, you should think a hundred times before making steep slopes. As for decorativeness, the key to a spectacular look is not so much the pretentious shape and elite roofing material, but harmony. The roof must correspond not only to the architectural style of the house and wall materials, but also to the surrounding reality.

Advantages and disadvantages of ceramic roofing

Natural tiles are made from clay using high-temperature firing technology (1000º). Service life - up to 150 years, warranty - 30. Roof slope from 30º (for some models from 22).

Pros:

- aesthetics, respectable appearance;

- strength;

- good noise/heat insulation;

- water resistance, chemical resistance;

- temperature resistance;

- color fastness: does not fade even over time;

- Fire safety;

- high maintainability.

Minuses:

- the heaviest weight among all coatings, increased load on supporting structures;

- highest price.

When installing, pay attention to the quality of the tiles: if there is a crack, the tile will break if water gets in and freezes.

See our work on installation of roofs made of natural tiles in the “our work” category.

Conclusion

To ensure that the result does not disappoint, the roof must be designed simultaneously with the house, optimally the shape, parameters of the rafter system, and type of roofing. Another thing is that the project can be standard or made independently using computer programs and regulatory tables. It is very convenient that modern technologies allow you to “try on” roofs of different types and “see” in advance whether it is worth bothering with a hip or whether the house looks good with a gable roof. And if you can’t decide on your own, you can always ask for help on the forum, in the profile section.

On the topic - the interesting roof of Sudeikin, designed by an outstanding Russian architect in the last century, but which has not lost its relevance today. And if you don’t want a roof like everyone else’s, pay attention to porcelain tiles - an interesting look and an affordable budget in tandem. The video is about a stone house with a flat roof.

Subscribe to our Telegram channel Exclusive posts every week

How to submit an application for roof repair and where to submit it. Sample

If signs of a leak are detected, you should submit a claim to have it fixed. It is written in any form in compliance with the rules of clerical work.

In the upper right corner of the application it is indicated:

- name of the management company or housing office, its legal address;

- personal data of the head of the organization;

- personal and passport details of the applicant, place of registration, contact mobile or home phone number.

In the center of the sheet, after indenting one line, write the name of the document. It must contain the basis of the motive for the action - a detailed description of the essence of the problem that has arisen. At the end, the date of application and the signature of the applicant are affixed.

The application is submitted to the organization that has assumed obligations to maintain this apartment building. It must be registered in the incoming information book with a number assigned. Notification of the decision is sent to the applicant in writing.

Advantages and disadvantages of seam roofing

Seam roofing is flat sheets or metal in rolls. Separate blanks (pictures) are connected to each other by folds. Additionally, the folds serve as stiffening ribs. Service life depends on the material: galvanized steel - 30 years, aluminum - 80, copper and zinc-titanium - 100. Roof slope - from 7º.

Pros:

- with high-quality installation, the seam fastening is sealed and eliminates leaks;

- flexible sheets allow installation on curved roofs;

- if you have the tools – simple and quick installation;

- minimum waste.

Minuses:

- poor sound/thermal insulation;

- good electrical conductivity, lightning protection is required.

I wrote more about the nuances of installing a seam roof here.