A mini tractor is a universal medium-sized agricultural unit equipped with an internal combustion engine with an output of up to 40 horsepower.

Technicians consider it an intermediate link between a walk-behind tractor for plowing a garden and a full-fledged heavy-duty tractor. Most often, such agricultural machinery does not have a cabin, although even with this drawback, the working process on a mini tractor seems much more comfortable than for a conventional walk-behind tractor: the operator gets the opportunity to sit down and control the machine with levers.

Many inexperienced users believe that the terms “mini tractor” and “motor tractor” are identical and interchangeable concepts. In reality, everything is not so: a motorized tractor is a tractor adapted from a walk-behind tractor. Even the best motorized tractor cannot technically compare with a real mini tractor.

The leading unit of such units is a walk-behind motor, the force of which is in the range of 10-25 hp. They also have a walk-behind transmission, a weak wheel frame, and only one cylinder, while all mini tractors are characterized by a three-cylinder design.

So that such confusion does not arise, and the need to choose this technique is based on clear knowledge and not on guesswork, we will try to shed light on this topic and answer the most frequently asked questions from users.

What is a snow removal attachment for a walk-behind tractor?

A universal device for removing snow mass over large areas is called a snow blower. The design is created in such a way as to collect, sweep and throw away snow. The main function of the snow removal attachment is to automate manual labor and save time. Snow blower features:

- works in tandem with a walk-behind tractor;

- attached to the front;

- easy to maintain.

Nozzle for snow removal

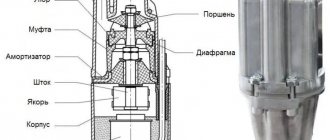

The body of the nozzle is made of metal, less often – plastic. Inside the box there is a shaft on which steel blades of complex shape are attached. The shaft rotates due to bearings installed in it. Disc knives are welded onto the shaft in a spiral. They consist of two halves, which converge in turns towards the central part.

When the shaft moves, the snow cover is captured by the blades and directed to the center. A thin stream transfers snow to a screw conveyor (auger). The snow and ice mass, moving along the augers, is destroyed and falls on the rotor blades. After this, being sucked in by a fan, it is thrown out through the outlet pipe (sleeve) in a given direction and at a certain distance.

DIY mini-tractor based on an MTZ walk-behind tractor

There is a rather original way to convert a mini-tractor from an MTZ walk-behind tractor. This walk-behind tractor is equipped with a two-cylinder diesel engine, so during operation the center of gravity shifts to the front. This significantly complicates the workflow. You can fix the problem as follows:

- The walk-behind tractor is switched to operating mode with a mower.

- The front platform is completely dismantled.

- In its place, using bolts, the front wheel from the motorcycle is installed, along with the steering wheel.

- In the niche for installing the steering rod, it is located in the upper part of the frame, an adjusting rod is attached. This gives the structure additional rigidity.

- The mount under the driver's seat is welded to the platform using electric welding.

- An additional platform for the hydraulic distributor and battery is welded next to the engine.

- An additional steel frame for the hydraulic system is installed at the rear.

- A handbrake is mounted on the front motorcycle wheel.

Thus, you get a compact three-wheeled mini-tractor made by yourself.

What to choose?

For comparison, we selected machines that are close to each other in characteristics. The most significant difference, apart from the wheel arrangement, is the ability to connect complex active equipment to a mini-tractor. With the Fighter, you can not only cultivate the soil and perform simple harvesting work, but it is also capable of mounting a front-end loader, with which the equipment acts as an assistant on the construction site.

Below is a table showing the various agricultural and utility work that the equipment in question can perform.

| Task | Motoblock "Scout 15 DE" | Mini-tractor "Fighter T-22" |

| Tilling the soil | Up to 50 acres | Up to 100 acres |

| Pioneering | Yes, but it's hard | Yes |

| Hilling, harrowing | Yes | Yes |

| Mowing the grass | Yes, with a front rotary mower | Yes, both front rotary and segmental, and rear rotary |

| Planting vegetables | Yes | Yes |

| Digging up vegetables | Yes | Yes |

| Snow removal | Yes, with a plow and a snow blower | Yes, with a plow, snow blower and sweeper brush |

| Planning work | No | Yes, with front loader and blade |

| Cargo transportation | Yes | Yes |

| Mulching and shredding plants | No | No |

Motoblock capabilities

Let's look at the similarities and differences between a motor-cultivator and a walk-behind tractor. Products of the first category are characterized by their small size, weight and limited functionality. With their help, you can loosen the top layer of soil, provided there are no plant roots in it. Choosing a walk-behind tractor for your dacha allows you to perform a wide range of work that is not limited to loosening or digging.

Having bought a walk-behind tractor for your dacha, you can use it for the following actions:

- Plowing a summer cottage for planting flowers, berries or vegetables. Processing is carried out with a mounted plow. Heavy equipment is capable of lifting virgin soil and processing heavy clay and rocky soil. An inexpensive and reliable unit makes trenches up to 40 cm deep for laying various communications, building fences, laying curbs, and creating a foundation pit.

- Treatment of plowed soil. To improve access to moisture and oxygen for garden crops, harrowing, cultivation and hilling of beds are carried out. At the same time, weeds and large debris are removed.

- Cultivation and cleaning of the territory. With the help of special attachments, snow removal, lawn mowing, collection of mown grass and subsequent loosening of the top layer of soil are carried out.

- Planting and harvesting vegetable crops. Special attachments make it possible to plant and dig up potatoes, onions, garlic and grain crops. The trailed bunker is convenient to use for uniform application of fertilizers into the ground.

- Transportation of various property. To do this, you need to choose a walk-behind tractor that has the ability to attach front and rear adapters, a cart or a winter sled. To transport a heavy trailer (up to 500 kg), the unit must have sufficient power and weight.

It is necessary to consider all these aspects before deciding which walk-behind tractor to purchase for the garden. Let's consider the nuances that you need to pay attention to in order to choose the most suitable model of the unit, what indicators are necessary to perform various works on the site.

Hiller

The hiller is used for hilling potatoes and crops - it loosens the soil and adds it to the roots. Until recently, this work was done manually with hoes, but now you can buy a hiller and provide even row spacing when planting. Manufacturers produce hillers of different types, most often these are plow-shaped, disk and Dutch type for 1-3 rows. For small areas, it is better to choose a single-row model, which is easy to control. Experienced summer residents most often buy disc models that provide high bulk ridges. The hiller is used for cutting furrows when planting potatoes and other crops. It's not as quick or easy as using a potato planter, but it's better than doing it entirely by hand. As a result, you get even row spacing that is easy to hill.

How to choose a snow blower for a walk-behind tractor

Snow blower on the site

Before you buy a unit, you need to decide for what purposes it will be used (only in winter or in other seasons), what area they will have to clean and how often it will be used. Please pay attention to the following parameters:

- Working width. For your own needs, 50–70 cm is enough, depending on the width of the path that will be cleaned.

- Height of snow removed. The standard height for most machines averages about 0.5 m.

- Release range. Depends on the snow (packed or fresh), the direction and strength of the wind, and the angle of the visor.

- Weight. The more the snow blower weighs, the better the grip and the likelihood of no slipping. On the other hand, it is more difficult to manage.

- Working speed. The optimal value is 2–4 km/h.

- Compatibility with walk-behind tractors - use of the design with different models. Alternatively, you can use special adapters.

- Dimensions (length, depth, height). The larger the snow blower attachment, the more snow it can handle in one go.

- Additional accessories and equipment, for example, a set of blades, a spare belt.

Additional equipment for the walk-behind tractor

Shovel from a barrel on a walk-behind tractor

Don’t rush to throw away the 200-liter barrel that is taking up space in the garage; turn it into an assistant - a shovel-dump that will help out in various situations. We offer several diagrams and drawings that will help create this attachment:

After studying the drawings in detail, prepare all the necessary equipment and materials. To work you will need:

- tin sheets, at least 3 mm thick. The dimensions of the sheets should be 85 x 22 x 45 cm;

- 1 metal stand – a steel pipe is suitable for this;

- 4 stiffening ribs, about 4 mm thick;

- a strip of steel of such length that it can cover the dump. The thickness of the strip must be at least 5 mm;

- 2 eyes for attaching the blade rod;

- set of washers and nuts;

- square pipe, cross-section 4×4 cm and length 1 m;

- a set of drills with a diameter of 5–6 and 8–9 mm;

- flat piece of rubber;

- 2 rods, each 52 cm long;

- 1 sheet of steel, 10–12 mm thick with dimensions 60 x 60 cm;

- welding machine;

- grinder with discs for cutting steel;

- hammer drill or electric drill.

Product comparison table

| Model | engine's type | Fuel tank volume, l | Engine power, l. With. |

| Scout T-15 | diesel | 8 | 15 |

| MasterYard M244 4WD | 25 | 24 | |

| Dong Feng DF-244 (with cabin) | 28 | ||

| STIGA Combi 1066 HQ | petrol | 3,8 | 4,5 |

| MTD Smart RF 125 | 8,43 | ||

| MasterYard CR1838 | 7,5 | 17,5 | |

| MTD Optima LN 200H | 3,8 | 22 |

Required materials and tools

In order to make a shovel for a walk-behind tractor with your own hands, you will need some materials and tools. Depending on the chosen model, these indicators may differ, so you should clarify all the data ahead of time. As a rule, they are indicated on websites where drawings for certain models are located.

But for a universal design you will need the following set of tools:

- steel barrel with a volume of 200 liters;

- iron strip of approximate dimensions 90x105x4 millimeters;

- profile square pipe, 1 meter 40x40 millimeters;

- a set of bolts and nuts of the required parameters;

- metal drills of suitable sizes;

- pliers;

- a set of keys for the corresponding nuts;

- rubber sheet;

- thick sheet of steel;

- Bulgarian;

- a set of discs for an angle grinder;

- welding;

- electric drill.

After all the necessary materials and tools are ready, you should begin assembling the shovel for the walk-behind tractor with your own hands. The simplest snow removal mechanism can be made from a 200-liter old barrel, since from the very beginning it will have a perfectly round shape, which is just right for such a “gadget.” This avoids unnecessary labor costs when heating a sheet of metal and giving it the desired shape.

In order for the device to be reliable and of high quality, it is necessary to weld a knife at the bottom of the bucket. To do this you will need a strip of iron 800x95x3 millimeters. It is necessary to drill three holes of 5-7 millimeters in it. The distance between stripes should not exceed 110 millimeters.

Such actions are mandatory, as this will strengthen the rubber gasket and prevent damage to the asphalt in the area. The knife will be attached to the structure using bolted connections.

Overview of snow removal attachments

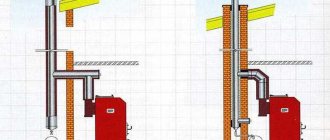

On the domestic market you can find both factory-made and home-made equipment in a wide range. Many mini tractors boast a whole range of different attachments that can replace an entire fleet of vehicles. This includes excavation and construction work, dismantling structures, loading materials, removing snow and debris. If we talk specifically about the snow removal function, the following attachments are used here.

- Snow plow. With the help of this canopy, you can level the site and clear it of earth and debris. Most of all, such a blade is used for snow removal in the urban cycle. A snow dump can be purchased ready-made or made by yourself. It is installed in front of the mini tractor and shovels snow while it moves.

- The rotary milling attachment helps remove compacted snow over large areas, after which it can simply be loaded into vehicles or dumped on the side of the road. Such highly efficient attachments can cope even with icy snow and debris several meters high.

- Utilities also provide the unit with an auger to optimize the process. It helps move snow masses formed after snow removal. Thanks to the operation of this hitch, the snow is distributed evenly, without blockages. Another function of the auger attachment is loading snow into a truck or tractor trailer for its subsequent transportation.

- Brushes are used to clean what remains after the blade has been used. The brush equipment is located behind the mini tractor. This hitch has proven itself well when removing snow from asphalt concrete surfaces.

The attachments must be combined correctly. The most commonly used configuration for a mini garden tractor is a blade in the front and a brush in the rear. This kit will allow you to thoroughly clear the area of snow. Instead of a blade, a bucket is sometimes used.

Transmission parameters

Number of gears. A kind of standard that ensures comfortable work with a walk-behind tractor is the presence of at least two gears for moving forward, one for moving in reverse.

Recently, many manufacturers are deviating from this postulate and equipping their walk-behind tractors with gearboxes with a large number of shift stages, which gives the user the opportunity to more flexibly control the speed and traction on the drive axle of the walk-behind tractor. On sale you can find models with eight steps for moving forward and four for moving in reverse.

Gearbox type. By means of a gearbox, the torque is transmitted from the engine shaft to the drive axle and the active attachments of the walk-behind tractor. There are several types of gearbox design:

- Chain. Torque is transmitted from the engine to the drive axle via a chain drive. This is a cheap and fairly reliable way to implement a gearbox. Its advantages include the simplicity and relative reliability of the design. Disadvantages include intolerance to excessive stress. When a high load is applied to a chain, it tends to stretch and may break. In addition, in this type of gearbox only one gear can be implemented for moving forward and backward.

- Worm. The simplest and cheapest way to transmit torque. Since there is nothing more in the system except the worm shaft and the gear it drives, such a gearbox has a fairly high efficiency (98%). However, the resource of the node is very limited and highly depends on the operating conditions and the efforts applied to it. There is no gear change. The speed of rotation of the wheels directly depends on the engine speed.

- The gear-chain reducer has high reliability and service life. The moment from the main gear, as in the case of a chain gearbox, is transmitted to the drive axle by a chain, but the change in the gear ratio occurs by engaging certain pairs of gears. It is in this type of gearbox that the gear shift mechanism is most simply implemented. The weak point is still the same - the chain drive as part of the gearbox.

- Gear reducer. The most expensive and most reliable method of delivering torque to the drive axle. It has high reliability and service life. At the same time, this is the noisiest solution.

If you plan to use the walk-behind tractor in conjunction with active attachments, the best choice would be a model equipped with a gear-chain or gear reducer.

Clutch type. The clutch assembly is an important element of the transmission of any walk-behind tractor. Its task is to transmit torque from the engine shaft to the input shaft of the gearbox (gearbox). Moreover, not just transmission, but timely closing and opening of the mechanical connection between the engine and the gearbox according to user commands. There are several types of clutch:

- belt;

- V-belt;

- disk;

- multi-disc;

- frictional

Most often in the design of a walk-behind tractor you can find either a belt or disk type of clutch. The belt clutch is characterized by its simple and uncomplicated design. The engine shaft and the input shaft of the box are connected to each other by a conventional ribbed or ribbed belt.

When the clutch lever is depressed, the belt is not tensioned and simply slips along the engine shaft pulley. When the lever is released, the belt tension mechanism is activated, and rotation is transmitted to the gearbox shaft. Already from the description of the work, the weak points of this design are visible:

- low efficiency, since a lot of rotational energy is spent on friction;

- the impossibility of transmitting large torque, the belt will slip, heat up and eventually simply break. For this reason, a belt clutch is not used in conjunction with a powerful power plant.

However, the belt clutch itself is very simple and incredibly repairable. You just need to have a spare belt, and repairs can be carried out in the field. Buying spare parts won’t hurt your pocket either.

The situation is somewhat different with disc types of clutches. Their operating principle is based on the ability to control friction forces. The driven disk is pressed against the driving disk with great force, resulting in a strong mechanical connection for transmitting torque.

The disc-type clutch is extremely reliable and, when used correctly, does not cause much trouble for the operator. Disadvantages include the high cost of the design and the impossibility of carrying out repairs in the field.

Difference and similarity

If you do not take into account the fact that a more powerful engine is installed on a mini-tractor, then in general it can be compared with a walk-behind tractor. For a more rational experiment, let’s compare the heavy diesel Scout 15 DE walk-behind tractor and the Fighter T-22 mini-tractor. Let's compare both cars one by one.

Dimensions of the walk-behind tractor: length - 218 cm, width - 89 cm, and height - 125 cm. Ground clearance (or ground clearance) is 20 cm. Structural weight, not counting attachments, is 310 kg. This large weight is ensured by the installed single-cylinder diesel engine, whose power is 15 horsepower. "Scout 15 DE" is the most powerful model from the Scout brand line.

If you delve deeper into the inside of the machine, the attachments are connected to a single-point hitch and a power take-off gear shaft. The track on the unit is not adjustable and is 75 cm, while the wheel size is 6''–12'. Torque from the engine to the gearbox is transmitted by a pair of V-belts, and the gearbox itself is combined, driven by a spur gear.

From external details: the car has one headlight, with the ability to switch low and high beams. There is no instrument panel as such, but an ammeter is located on the electric starter. The machine is controlled using the handle: unlocking the right and left axles, gas and brake.

Let's move on to the Fighter T-22 mini-tractor. The dimensions of the machine are not very different from the walk-behind tractor: it is 248 cm long, much larger in width - 125 cm, the height of the steering wheel is the same - 125 cm, and if we take into account the exhaust pipe, the height is 181 cm.

The technical characteristics differ significantly from the Scout. The attachment is connected to a single-point mechanism with a chain drive, which ensures the raising and lowering of the equipment. The lifting capacity of the mounted system is 120 kg. Torque from the engine is transmitted by V-belts in constant tension.

External mechanisms are also more diverse. All the main sensors and indicators are displayed on the dashboard: voltmeter, coolant temperature sensor, oil pressure sensor, engine hour meter. The car is equipped with a full lighting system with dimensions and brake lights. The turning radius of the machine is 2 meters.

The best garden tractor-riders

Machines of this type work like a lawn mower, so they have their own selection criteria:

- Cutting width. For a small area, 60–70 cm is enough, for a large area you need 90–120 so that the process does not drag on.

- Grass release. Determine where the waste is discharged - outside or into a separate compartment, whether the cutting height can be adjusted.

- Mulching attachment. The mown hay will be crushed and scattered with fertilizer useful for the soil.

STIGA Combi 1066 HQ

The compact Swiss-made tractor-rider is equipped with an American 4-stroke engine with a power of 4.2 liters. s., making 2450 rpm. The machine is intended for basic rural work, areas up to 1500 m². Due to the small volume of the fuel tank (3.8 l), in large areas you will have to refuel several times. There is enough air cooling for such a small engine, you can work continuously.

The maneuverability of this rider is not much better than that of mini-tractors - the minimum turning radius is 77.5 cm, and it is inconvenient to work near trees. In lawnmower mode, the machine cleans a strip 66 cm wide. The cutting height is selected from 6 positions from 30 to 76 mm. Everything is dumped into the soft 150L grass catcher or discharged from the side and rear. The tractor is controlled by pedals. Maximum acceleration – 6.2 km/h.

Price:

- 159990 rub.

Advantages:

- dimensions;

- operates quietly (noise level – 98 dB);

- mulching attachment included;

- quick start - electronic ignition system Magnetron;

- the seat is comfortable, the steering wheel is upholstered;

- tool compartment at hand;

- gives a signal when the grass catcher is full;

- rear wheels are enlarged for greater maneuverability;

- economical consumption of gasoline;

- smooth ride.

Flaws:

- there is no pull-out lever for the grass catcher;

- not for tall grass.

MTD Smart RF 125

A good inexpensive American mini tractor for household use with a gasoline engine of our own production (MTD), 344 cm³ and 8.43 hp. With. In a minute it makes 2800 revolutions. The cooling is air, so you should not use this garden tractor for a long time. The fuel tank holds only 3.8 liters of gasoline, which also leads to short operation of the machine. The front headlights are powerful and illuminate the area well at night.

- Transport tax when selling a car - calculation formula and deregistration of the car

- Health benefits of hot showers

- Making an appointment with the Pension Fund through the State Services website or by phone - advantages and disadvantages

The tractor is very maneuverable, the minimum turning radius is 46 cm. The stepped automatic transmission and 6 forward gears make gear shifting (using a pedal) and driving smooth. The machine works like a lawn mower. In one pass, it creates a strip 92 cm wide, and the cutting height varies in 5 levels: from 30 to 95 mm. The grass is thrown to the side or back through plastic blowers and does not fall under the wheels.

Price:

- 150990 rub.

Advantages:

- compact;

- comparable to additional attachments;

- will pass through difficult terrain;

- economical engine;

- easy to operate;

- reliable - cast steel frame;

- comfortable seat and steering wheel design;

- even walks through thick, tall grass.

Flaws:

- you need to regularly tighten the knife belts;

- There is no grass catcher included.

MasterYard CR1838

A small-sized garden tractor with a gasoline engine is designed for working in a large vegetable garden. Suitable for areas up to 8000 m². High power and continuously variable automatic transmission provide the car with a smooth ride. Maneuverability is excellent, the minimum turning radius is 36 cm, so it is convenient to work in small areas. Due to the size of the wheels, the tractor travels better on level ground. The speed is low: 9 km/h forward and 7 km/h backward.

The multifunctional mini-tractor copes well with the role of a lawn mower: it cuts smoothly, the height varies from 30 to 90 mm. The mown is finely chopped and goes into a soft grass catcher with a capacity of 300 liters. When it is full, the machine beeps. In emergency situations, the engine is switched off. This tractor is also used for snow removal and landscaping - there is a tow bar at the rear for additional equipment.

Price:

- 279990 rub.

Advantages:

- large fuel tank volume (7.5 l);

- anti-vibration system installed;

- knives made of durable steel;

- works quickly on large areas;

- reliable assembly;

- deep tread - tires do not leave marks on the lawn;

- the grass catcher does not need to be cleaned during mowing, even large areas;

- wheel chains for driving on ice (included);

- motor quality.

Flaws:

- price.

MTD Optima LN 200H

The best-performing mini garden tractor from an American manufacturer has a power of 22 hp. pp., runs on a 2-cylinder gasoline engine and is suitable for areas larger than 3500 m²: parks, sports stadiums. The gearbox is continuously variable, the speed and type of movement (forward or reverse) change smoothly. There is not enough air cooling for such a powerful engine, so breaks are needed in operation to extend the life of the machine.

The tractor's grass catcher capacity is only 240 liters, but the cuttings are stacked compactly due to cutting with knives. The machine makes the strip wider than the standard one - 105 cm, so work with the lawn goes quickly. It’s easy to remove 20 acres in an hour. The cutting height changes from 30 to 95 mm in 5 steps, the knives firmly hold the set value. Additionally, you can buy a mulching attachment from MTD or other third-party equipment.

Price:

- RUB 310,990

Advantages:

- high power;

- easily walks on any terrain - follows the contour of the earth;

- wheels on bearings;

- smooth ride;

- It’s convenient to work along fences and near trees;

- the operator's seat is height adjustable;

- the deck is washed with a stream of water;

- The grass catcher can be easily emptied using a special lever.

Flaws:

- small fuel tank (3.8 l).

Homemade dump

Self-dumps for agricultural machinery (motoblocks, tractors, ATVs, etc.) significantly facilitate the process of snow removal. This is especially noticeable with large piles. Any snow-clearing “gadget” for equipment consists of three elements: a working element that is in contact with the snow, a mechanism for adjusting the angle of rotation, and a fastening unit with the equipment.

Although factory models have many different types of designs for any agricultural device, self-assembly of a snow clearing element is simple and can significantly save money.

With the help of a homemade device, you can not only remove snow in winter, but also remove debris, level the area and other necessary functions.

It doesn’t matter what design the owner uses - a factory one or a do-it-yourself blade. In any case, it will have three positions:

- slope angle to the left 30 degrees;

- slope angle to the right 30 degrees;

- straight position.

Before starting snow removal work, the shovel blade should be installed in the desired position, based on three possible ones. After determining and establishing the required position, it is fixed using metal cotter pins. The width of the snow throwing area is usually one meter, but provided that the thickness of the steel used is 3-4 millimeters.

A little about us

We have connected the largest network of authorized service centers throughout Russia and strictly control the quality of repairs, spare parts and customer service in each service.

36 service centers throughout the Russian Federation

We sell equipment wholesale and retail in Russia, Belarus, Kazakhstan and Europe, so we purchase large quantities of goods only directly from manufacturers, due to which we receive the best purchasing prices. In turn, we also offer our customers the best prices, and for most products we were able to implement the “Best Price Guarantee” program. By purchasing from us, you do not overpay to unnecessary intermediaries.

Factory price

When purchasing equipment in our warehouse store in Moscow, you can not only see the entire range presented, conduct test drives of the models you like, but also receive an additional 3% discount on the cost of the equipment upon pickup.

Discount for pickup -3% of the purchase amount

By purchasing from us, you receive equipment that is completely ready for use: all the necessary oils and liquids are poured into it, the main working units are adjusted and a test run is carried out to identify manufacturing defects.

Free pre-sale preparation

We will help you solve any questions or problems that arise during the operation of the equipment even after the end of the warranty period. You can always get a free consultation by phone from service center specialists, order a mechanic to come to your home, bring the equipment to the service center or order spare parts.

Preferential after-sales service

We have reached agreements with almost all banks and leasing companies in Russia. Every day we analyze loan and leasing offers, offering our clients the best options to choose from.

The best conditions for loans and leasing

The best service, wherever you are! Any malfunction in the equipment will be eliminated by the experienced specialists of our field service, right at your home, even during the post-warranty period. (During the warranty period, mechanic work and spare parts are free)

Field service operating throughout the Russian Federation

You can carry out free TO for 4 months at any of the 36 authorized service centers. Free TO includes: diagnostics and adjustment of all components and assemblies, lubrication of all necessary parts and oil change, tightening of fasteners and connections, and even replacement of consumables not included in the warranty.

Free maintenance for 4 months

We will deliver your order right to your doorstep anywhere in Russia. The calculation is made after you are sure of the completeness and quality of the goods. Find out the exact cost of delivery by calling (free call)

Delivery to your doorstep anywhere in the Russian Federation

If the purchase does not meet your expectations, then we will return all your money, even though small-sized agricultural equipment is not subject to exchange or return according to law.

We will return all your money if you are not satisfied with your purchase.

So after all: a walk-behind tractor or a mini tractor?

At their core, these two types of agricultural machinery are quite similar. Both use draft power, have wheels, and have almost the same functionality. Attachments, both the mini tractor and the walk-behind tractor, are used in full. In general, if it were not for power, performance and size, we can say that they are, in principle, the same and there is no difference in what to take.

To say that a walk-behind tractor is worse and a mini tractor is better is also wrong. They have their pros and cons, and the choice of what to buy depends only on the specific type of work and its volume that is planned to be performed using these units.

If you have a farm, then a small mini tractor is a good choice for any farmer and will help out at any time. If the subsidiary farm does not have significant dimensions, then it is quite possible to get by with a walk-behind tractor. There is no point in buying equipment “for growth.” After all, it turns out that the money invested will not be worked out: you will not be able to fully use all the functionality of the purchase.

The biggest difference is, of course, power. It is clear that the mini tractor will in any case be superior to its younger brother. But, at the same time, powerful and heavy walk-behind tractors, capable of plowing virgin arable land, tightly held together by the roots of grass and bushes, can easily replace light mini-tractors. Moreover, any heavy walk-behind tractor will cost much less than the lightest mini tractor.

The second difference is the control of technology. The mini tractor has a full-fledged driver's seat with a steering wheel and seat, gas and brake pedals, and a gear control lever. In this case, a person spends a minimal amount of energy: only on controlling the unit from a convenient place and that’s all.

You can easily adjust the depth of plowing and control other aspects. But to operate a heavy walk-behind tractor you need physical strength and dexterity. It is less maneuverable, in this case, than a mini tractor. Your back and arms will get very tired, especially when operating diesel walk-behind tractors without a vibration damping system.

The next difference is the price. It is clear without clarification that a mini tractor will cost much more than the most powerful and functional walk-behind tractor. The cost of a walk-behind tractor starts from 30,000 rubles and can reach up to half a million for the most modern models with solid efficiency. And mini tractors start at half a million per unit of equipment and can easily reach five to seven million rubles.

To make the right choice between a mini tractor and a walk-behind tractor, you need to:

· determine the area of land for cultivation;

· understand what kind of soil is on the site - virgin, soft, viscous, clay, and so on;

· what kind of work will need to be done the most;

· whether equipment is needed as transport and what and in what quantity will be transported.

After answering all these questions, it will not be difficult to find out the power of the required unit and decide whether to buy a walk-behind tractor or a mini tractor.

Small tips: for an area of up to two hectares, a mini tractor is absolutely useless. A walk-behind tractor can also handle this: for a plot of up to 60 acres, a light type of equipment is suitable, from 60 to 100 - a medium one, and everything above a hundred acres - a heavy diesel one.

Lands over two hectares already require a mini tractor, which will be optimal for cultivating plots of this size.

The material was prepared for you by master Roman. Leader of the column: useful tips for clients of the online store Levsha.RF

Price range

Today the market offers a wide selection of mini tractors with various characteristics, the price of which ranges from 300 thousand rubles to a million. A good garden mini tractor will cost the potential owner between 150 and 250 thousand rubles.

A unit made in Korea can cost from 600 to 900 thousand rubles. The equipment of this producing country has proven itself to be a reliable assistant in agricultural work. Service centers existing in Russia carry out the necessary maintenance work. The service life of Korean equipment reaches 20 years.

European-made mini tractors (Kubota, JohnDeere, Goldini) are on a par with Korean manufacturers in terms of quality and ease of use. The units have also proven themselves to be excellent. However, they cost much more and are inaccessible to buyers with average financial capabilities. In addition, there is a possibility of delays in the supply of spare parts.

The buyer should consider the issue of purchasing a used mini tractor in detail. It is likely that such equipment will cost less at first, but there is always the possibility that you will have to frequently search for and change spare parts, which will require additional costs. For example, for Japanese mini tractor there will be no service support and it is difficult to find operating instructions in Russian. In any case, used equipment has already worked well for several years with the previous owner, and the new owner will have to exhaust the service life with continuous repairs and replacement of spare parts.

Owner reviews

Egor, 39 years old:

Hello. Two years ago I purchased a walk-behind shovel LM-100. I'm sticking to the Neva. During operation, I discovered that things would go more efficiently if weights of 10 kg each were attached to the wheels of the walk-behind tractor. More weight of the walk-behind tractor means more weight of snow can move the blade. In addition, in loose, high snow, it is better to use lugs.

Victor, 41 years old:

I use the blade to the Centaur, the angle of attack is adjustable left and right (30 degrees) and straight. The set includes knives - steel and rubber. The canopy saves both from snow and from dirt - in the summer and autumn I collect heaps of garbage from the garden. The simplicity of the design and the price are amazing!

Yuri, 44 years old:

I didn’t want to spend money on buying a finished product, so I decided to make it myself. In my father’s bins I found a gas cylinder, pipes, corners and work began to boil. I found the drawings on the Internet, did a little digging, and came out with a pretty good blade.