Equipment for pumping water is indispensable in many areas of agriculture, as well as in other areas. The modern “Malysh” pump, whose technical characteristics are often better than foreign analogues, is inexpensive and is suitable for solving almost all these problems. There are several models and types of equipment, the parameters of which should be known before purchasing the device. After all, how long the vibration pump will work depends on this.

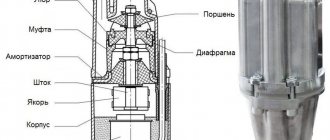

Internal structure of the “Baby” pump Source kolodezman.ru

Pump “Baby”: where is it used?

Most often, an inexpensive vibration pump can be found in garden plots and vegetable gardens. Sometimes it is used on farms and farmsteads. The equipment is a universal device and can be used in the following areas:

- Watering and irrigation . “Malyshok” is used both in small areas and in fields. With its help, water is collected to create artificial ponds and swimming pools, and vice versa, it is pumped out for drainage.

- Cleaning up flooded buildings . Some models with filters that are resistant to contaminated water can be used to remove liquid from flooded areas.

- Injection from a drilling source . The characteristics of the “Malysh” submersible pump allow you to quickly fill containers and the water supply system in a country house or in a small private house.

It is important to understand that different models of equipment are used for clean and contaminated water. So, for purified substances, an option with lower absorption is suitable, and for water with waste fractions, it is better to buy an option with an upper intake.

Using a pump in the country Source userapi.com

Purpose of the deep vibrator

Submersible pumps of the “Malysh” series are produced by the Russian company Livgidromash, whose history goes back almost seventy years. During this time, more than three million units of various pumping equipment rolled off the plant's assembly line.

Despite the wide selection of submersible units that the market offers today, many consumers choose the products of the Livensky plant. And it is no coincidence that “Malysh” pumps, thanks to their good technical characteristics, ease of use and low cost, withstand the competition with dignity.

The Malysh pump is an affordable and easy-to-maintain unit that allows you to provide water to summer cottages that do not have a centralized water supply.

The device, small in size (up to 255 mm) and weight (up to 3.4 kg), will cope with a number of tasks with a bang.

It will provide:

- uninterrupted supply of water from wells and wells having an internal diameter of 8 - 11 cm, as well as any reservoirs with a water temperature not exceeding 35 degrees;

- pumping water from open sources located at a distance of more than one hundred meters from a house or summer cottage;

- transportation of water from the storage tank and directly into the water supply system of the house;

- forming a supply of water for abundant watering of plants in the open ground or in a greenhouse, for maintaining the territory and for other economic purposes;

- pumping water from basements when they are flooded with flood waters;

- filling country pools and draining water;

- pumping dirty water from silted or newly drilled water intake.

It should be noted that “Kid” can work productively only if the amount of impurities of mechanical particles does not exceed 0.01%. When pumping water from heavily silted sources, as well as from rivers with a significant sand content, it is necessary to use a filtration system.

The electric pump can be used for emergency pumping of water from flooded rooms. To avoid mechanical damage, it is necessary to lay a rubber sheet under it.

Water intake: use and operating principle of different products

There are many pump models, and the differences are often due to manufacturers. However, the traditional classification divides equipment into 2 types:

- Upper water intake . The most common option, due to its better protection against clogging. The design is such that the engine is located under the valve, into which water is pumped and supplied further. This prevents excessive heating, and if the water drops below the permissible level, the mechanism automatically turns off. The engine itself remains in the water. Since the suction occurs from above, much less debris from the bottom penetrates inside. The only drawback of the equipment is dry operation in the absence of an idle relay. This is necessary to prevent air from being sucked in.

- Lower water intake . This “Baby” is more often used in deep wells, where it can be installed far from the bottom. It is dangerous to use the device without a thermal protection relay. This is due to the fact that the engine is located above the pipe. The absence of a relay leads to rapid overheating and breakdowns. The equipment also needs sand and debris filters.

The technical characteristics of the “Malysh” water pump differ from different manufacturers. There are 4 classic types of vibration devices.

“Baby” device with upper water intake Source cloudinary.com

Classic model

In this version, vibration equipment is used for small sources with a diameter of more than 10 cm. The pump can be used to supply through a hose at a distance of up to 150-200 m, however, solutions with a limit of up to 100 m are more common. Equipment with cool liquid is used. A lower pipe is used for water intake.

| Properties and parameters of the classical model | |

| What power does it work with? | The model is characterized by an average of 220-245 W |

| Can lift water to heights | up to 40 m |

| Nutrition | 220 V |

| Performance | At 1 m height – 1050 l, at 40 m – 430 l. Parameters are given for hours of operation. |

| Pump lowering depth | no more than 5 m |

| How long can it function? | 2 hours without a break |

| Weight | 3.5 kg |

| What pressure does it give? | 0.4 mPa |

For the “Malysh” pump you need a hose with a diameter of 18-22 mm . When purchasing this model, you need to take into account that the cord is often completely missing from the kit. It is selected according to length based on needs. Options with protective relays and other parts included began to appear. However, the cheapest offers do not include them.

Pump model “Baby classic” Source onlinetrade.ru

Model "Malysh-M"

Almost complete analogue of the previous model. However, the pump is made with a pipe for upper water intake.

Option "Baby-K"

Another version of the basic model, which matches the parameters 100%. However, the package includes an overheat protection relay.

See also: Catalog of companies that specialize in the design and installation of sewerage and water supply

Series "Baby-3"

An improved model of a submersible pump with improved equipment. It is used in wells and boreholes with shallow immersion depth and a diameter of 8 cm. Distinctive features include:

- completely monolithic block, completely insulated along with the electrical wire;

- not so much power required for use in low-yield wells - 165 W;

- Can be submerged to depths of up to 20 m while maintaining a capacity of 0.43 cubic meters. m/hour;

- weight not exceeding 3 kg.

The diameter of the hoses used is 25 mm, or 3/4 inches. Even the factory equipment contains an integrated electrical cable 30 m long.

Pump “Malysh-3” with a long cable Source blogspot.com

Specifications

As has already been said, Malysh submersible pumps have low power - mostly about 250 W, that is, it is not able to create high pressure. Their clones with other names can be found slightly more powerful.

What is also important is the lifting height - this is how far water can be pumped. In the technical specifications, it should be approximately 20% greater than what you need.

Pay attention to the power supply for which this model is designed. Usually this is 200 V with possible small deviations of the order of 5%, but the reality is that the network can be 240 V, and at such a voltage a pump with such characteristics will burn out

The solution is to install a stabilizer or look for a model with a higher operating voltage (a decrease from the operating voltage does not have such a negative effect on the work - the power decreases).

The length of the electric cable can be from 10 meters to 40

Another important indicator is productivity. It is usually indicated in liters per minute or per second. This value shows how much water the unit is able to pump under normal conditions. For this type of equipment, this figure is quite small - about 400 ml/sec. Such a submersible pump Malysh can provide water to one water collection point - one irrigation hose or tap in the house. He is not capable of anything more without additional equipment.

| Name | Water intake | Idle/overheat protection | Power | Performance | Lifting height | Diameter | Immersion depth | Price |

| Malysh-M P 1500 Topol | Upper | no Yes | 240 W | 24 l/min | 60 m | 99 mm | 3m | RUB 1,741 (plastic) |

| Rucheyok-1 Mogilev | Upper | no no | 225 W | 18 l/min | 72 m | 110 mm | RUR 1,459 (cord 10 m) | |

| PATRIOT VP-10B (USA/China) | Upper | no no | 250 W | 18 l/min | 60 m | 98 m | 7 m | RUB 1,760 (cable length 10 m) |

| BELAMOS BV012 (Russia/China) | Lower | no no | 300 W | 16.6 l/min | 70 m | 100 mm | 3m | 2110 RUR (cord 10 m) |

| Malysh-M 1514 Topol | Upper | no Yes | 250 W | 25 l/min | 60 m | 98 mm | 3m | RUR 2,771 (metal, cord 40 m) |

| Caliber NVT-210/10 (Russia/China) | Upper | no no | 210 W | 12 l/min | 40 m | 78 m | 10 m | 1099 RUR (cord 10 m) |

| Bison MASTER Rodnichok NPV-240-10 | Upper | no no | 240 W | 24 l/min | 60 m | 100 m | 3m | 1869 RUR (cord 10 m) |

| QUATTRO ELEMENTI Acquatico 250 | Upper | no no | 250 W | 17.5 l/min | 75 m | 100 m | 2 m | RUR 2,715 (cord 10 m) |

| Aquarius-3 (Lepse) | Upper | no/is | 265 W | 26 l/min | 40 m | 98 mm | 1900 RUR (cord 10 m) | |

| Baby 25 m (Kursk) | Lower | Not really | 250 W | 7.1 l/min | 40 m | 1920 RUR (cord 25 m) |

Each type of pump is available with a different length of electrical cord and this changes the price (the longer the cord, the more expensive). You can also find varieties with dry run protection, but you can make your own (see below).

The operating principle of the “Baby”

The not too complicated and reliable design, as well as the good characteristics of the Malysh pump, make it an excellent option for simple and economical use. It consists of a sealed housing, protected from liquid penetration, and an electric drive located in it. The drive contains a core, an electrical wire, a vibrator and two coils.

Options with top water injection are equipped with a valve to close the inlet in the absence of water pressure in the top part of the body. In a model with a lower intake, such a valve is located at the bottom.

Review of popular models

There are two types of pressure switches: mechanical and electronic, the latter are much more expensive and are rarely used. The market offers a wide range of devices from domestic and foreign manufacturers, making it easier to select the required model.

RDM-5 Gilex (15 USD) is the most popular high-quality model from a domestic manufacturer.

RDM-5

Characteristics

- range: 1.0 - 4.6 atm.;

- minimum difference: 1 atm.;

- operating current: maximum 10 A;

- protection class: IP 44;

- factory settings: 1.4 atm. and 2.8 atm.

Genebre 3781 1/4″ (10 cu) is a budget model made in Spain.

Genebre 3781 1/4″

Characteristics

- body material: plastic;

- pressure: upper 10 atm;

- connection: threaded 1.4 inches;

- weight: 0.4 kg.

Italtecnica PM/5-3W (13 cu) is an inexpensive device from an Italian manufacturer with a built-in pressure gauge.

Italtecnica PM/5-3W

Characteristics

- maximum current: 12A;

- working pressure: maximum 5 atm;

- lower: adjustment range 1 - 2.5 atm.;

- upper: range 1.8 - 4.5 atm.

Video description

The video below clearly shows the operating features of the pump:

The operating principle of the “Malysh” pump is very simple and is based on the use of alternating current. Its force activates the anchor and the piston, which create movement and force water into the pipe.

You can find a large number of “Baby” type pumps on sale, but they may have a different name. They are made by Chinese, Russian, some European and American brands. Their parameters are approximately the same, and the power is in the range of 220-250 W. The throughput, or performance, of these models can differ by almost 2 times. For example, for the “Malysh MP 1500” it is equal to 24 liters, while for its analogue “Caliber NVT” the figure will be only 12 liters. The diameter of the pumps themselves usually also does not exceed 110 mm.

The cost depends not only on the characteristics of the “Malysh” vibration pump, but also on the length of the cord. The larger it is, the more expensive it is.

Competent DIY repairs

Failures can occur in electrical and mechanical parts. The equipment may fail partially or completely. Partial malfunction of the device may mean either a breakdown of internal parts or a violation of adjustment.

Most often, due to the operation of the device without water, it overheats and the automation fails. For the same reason, the insulation may overheat, the filling will delaminate, and the yoke may fall out of the body. In this case, the pump hums, does not pump liquid, and the body of the product may be damaged. It is possible to avoid such malfunctions by following the operating rules of the pump.

Mechanical failures of the vibration pump occur quite often.

Let's look at the most common causes of breakdowns:

- Limescale deposits on parts;

- Depressurization of the housing due to mechanical damage;

- Clogging of the insides with dirt;

- Loosening of bolt connections.

If you suspect a malfunction of the device, you must disconnect it from the power supply and remove it from the water. Before disassembling the pump, you should inspect it. Disconnect the supply hose and inspect the device from above for damage. Violation of the integrity of the housing can only be eliminated by completely replacing it. If everything is fine with it, you need to check the resistance of the coils with a tester. If the contacts close, the coil must be replaced.

This usually requires a specialist, because... It is very difficult to do this at home.

Pump repairs should be carried out when it is turned off.

The next step, if the coil is in good condition, is to bleed the pump. If air enters freely or the valve closes when taking a sharp breath into the inlet, then everything is fine with the pump. The device also needs to be shaken; the presence of extraneous sounds indicates a breakdown inside.

The procedure for disassembling and assembling the device

Answering the question “how to repair a baby pump with your own hands?”, first of all, you should clearly understand how to properly disassemble the pump without damaging its main components. Disassembling the device is carried out in the following order:

Pump Baby disassembled

- The first thing to do is to indicate the correct location of the upper and lower parts of the body relative to each other. To do this, a notch is made at the junction of the body and the lid with a nail or other sharp object.

- Next, remove the fixing screws of the cover. Here you need to be very careful not to deform the fasteners or damage the mechanisms inside the device. All screws are unscrewed several turns each and removed simultaneously after maximum loosening. When working with liquid, the bolts may rust and cannot be removed. In this case, the bolts are cut off with a grinder, and new ones are installed in their place.

- Next, the piston, armature and electromagnet are removed, and the gaskets are removed.

The disassembled device is reassembled in the reverse order. There are important points on which the correct functioning of the pump depends:

- First of all, the piston disc must be installed correctly. It is installed on a special saddle. It is important to strictly observe the distance between these components and their mutual parallelism. If the disc does not become parallel to the seat, the stem is most likely bent. In this case, you need to select the correct position of the gasket. The distance from the piston to the magnetic coil must be at least 4 mm.

- When assembling the water pump, you should make sure that the holes in the rubber gasket are clearly in place and coincide with the holes in the housing. Otherwise, moisture may enter the electrical part.

- Before full operation of the device, you should check it in a bucket or barrel. The pump is lowered into the container without connecting a hose. If the device is working properly, a stream of water with a height of 20-30 cm will emerge from the outlet pipe.

2.2 Stages of replacing the compound

- Let's disassemble the device.

- We determine the place where the compound has peeled off from the submersible pump housing. This can be done by lightly tapping the body with a small hammer. In normal areas the sound will be dull, in damaged areas it will be ringing.

- We remove the assembly with the compound from the vibration pump housing.

- Using a grinder, we carefully apply a mesh of notches, up to 2 millimeters deep, to the inside of the body. We make the same mesh on the unit with epoxy compound.

- Cover both areas with notches with glue for glass surfaces (any sealant can be used)

- We return the assembly with the compound to its original position - fix it and wait until the sealant hardens.

- Putting the body back together.

2.1 Steps to set up the vibration electric pump

Before the user becomes determined to disassemble a non-working product, a number of simple manipulations should be performed to establish a preliminary diagnosis:

With an incorrect setting, when air is not blown through the pump, but passes through with suction, the pump can operate at a reduced voltage of less than 200 V.

Before you begin active disassembly of the pump housing, you should leave marks on the joints for proper assembly in the future.

The operating principle of pumping equipment dictates the control of three important parameters of reassembly in the specified order:

- Axial alignment of piston and seat. The sliding of the inlet cup along the gasket makes it very difficult to achieve this when assembling the pump, but misalignment will not allow the pump to operate in principle.

- The piston must be at some distance from its seat. The size of this gap should not exceed 0.5 mm, but be greater than 0. The gap can be adjusted using shims. The correct distance allows air to pass into the outlet pipe for water, and with a greater blowing force, the piston closes the channel.

- It is necessary to maintain parallelism between the piston disc and its seat - their axes must also be parallel.

Cases of non-parallelism:

- large gap between piston sleeve and rod. Such a problem can not only affect the adjustment, but also cause vibration of the operating unit. How to reduce a large gap? It is enough to replace either the bushing or the rod, and the popular method is to seal the rod with improvised material, for example, foil.

- rod is bent. In this case, the problem is unlikely to be corrected, but perhaps parallelism can be achieved by rotating the gasket to 180 0.

A correctly replaced structural element and a correctly assembled electric pump when immersed in water produces a jet of at least 30 cm in height and operates without interruption with a voltage of up to 240 V. Reducing the voltage changes the sound of the pump and can reduce performance.

2.2 Recommendations for disassembling the vibration electric pump

Placing the unit in a vice makes disassembly much easier. By clamping the housing protrusions with jaws, the tightening bolts will give way faster, but you need to loosen them one by one and little by little. Collection after repair is carried out in the same way.

If the pump has been submerged for a long time, most likely the coupling bolts will not give in quickly - you should use penetrating lubricant and make splined slots in the bolt heads. As a last resort, you should carefully cut off the heads of the bolts to separate the body parts of the device.

Features of hose selection

One of the main difficulties when purchasing equipment for many users is choosing the diameter of the hose for the “Malysh” pump. How long the device will last depends on this parameter. When choosing, take into account the following features:

- a nozzle is put on the part of the hose immersed in water to filter dirt and large particles;

- Before starting, the hose must be filled with water;

- if the pump will be used all year round, then you need to select an accessory with high resistance to frost;

- rubber products are not suitable for use with the “Kid”;

- When working with a well, HDPE pipe is used.

The diameter of the hose determines how much water it can pass through. The most common and versatile option is 25 mm or ¾ inch. A smaller diameter can be used if you need to connect communications directly to the water supply system. But the instructions may have certain restrictions.

Reinforced watering hose for “Baby” Source uvelirstudio.ru

What actions are involved in tying a pool?

If this is not done, installation of the equipment by the company’s specialists will not be carried out.

Sending a message

Water washes the outside of the coil and heats up.

Pumps for collapsible frames. Since pipes, wires, all elements are mounted in concrete from which the bowl is poured. At the outlet of the filter, the water is purified to the smallest particles and sent back to the bowl. The cross-section of the neutral protective wiring must be equal to the cross-section of the phase wiring, but in any case should not be less than 2.5 mm2 for copper in terms of mechanical strength. Climate in an indoor pool In the room where the pool is located, there will certainly be constantly high humidity, which over time can negatively affect the finish. This creates a flow. Depending on the volume of the bowl, they are evenly distributed around the perimeter. Pump filters are distinguished between sand and cartridge types.

For large inflatable and frame-type pools, one pump is enough

It is important not only to choose the right size, but also to take into account what material it is made of, as well as what installation method is proposed. Types of pool filters Sand filters. Pool part 9 (equipment piping)

Well: installation rules

Before starting work, the pump must be installed correctly. To do this, use a synthetic cable, tying it to special eyes on the body. The node should be 10 cm from the body or higher. The edges are then seared to secure it.

Important! It is possible to use a metal cable secured at least 2 m from the body on a synthetic rope. Otherwise, the metal will quickly collapse from vibration.

Next, proceed to connecting pipes and hoses:

- A suitable hose is attached to the pipe through which the pump pumps water. It is important that the diameter of the “Malysh” pump hose is larger than the part on which it is installed. However, an accessory that is too narrow will increase the load on the device. The optimal size is 2-3 mm larger.

- If a pipe is used, it is also connected to the pipe with a hose, the length of which must be at least 2 m.

- A metal clamp is used for fastening. To prevent it from jumping off, you can sharpen the pipe with a file to increase adhesion. Or make a groove for a wire clamp. The material for fastening is stainless steel with notches.

Steel clamp for fastening the hose Source boltmix.ru

- After the initial manipulations, the hose, cable and cable are connected and secured with constrictions. The first should be 25-30 cm from the body. For the rest, a step of 1-2 m is assumed. For constrictions, adhesive tape is used, since metal can damage the cord and twine.

- A strong crossbar is installed on top, on which the cable is fixed. You can also make a hook on the side wall for this purpose.

- Immerse the equipment to the required depth in accordance with the instructions.

During installation, it is important to remember that the “Baby” should not come into contact with the walls of the well or well.

Advice! When installing in a well with a low water level with a cable length of up to 5 m, the product must be suspended on a spring gasket to the crossbar.

This approach will reduce vibration. You can use a piece of rubber to distribute the weight.

Troubleshooting algorithm

Troubleshooting.

If the unit pumps water poorly or stops working completely, you need to turn it off and lift it up. Then you should disconnect the hose and check if there are any obvious damage to the device.

Stage 1: careful external inspection

If microcracks are visible on the surface of the case, it will have to be replaced. If the integrity of the unit is not compromised, a tester should check the resistance of the coils (the norm is about 10 Ohms) and the absence of short circuits to the metal casing. Replacement of a burnt coil should be entrusted to a specialist.

Then you need to blow lightly into both pipes of the pump - the air should flow unhindered. When exhaling sharply into the supply hole, the valve should close.

You should shake the device. Extraneous sounds are a signal of possible destruction of the mechanical part or peeling of the compound. We rinse the unit with a stream of water to free it from dirty impurities.

Then we immerse the device for 5-6 hours in water with the addition of 9% table vinegar to dissolve limescale. Rinse it again with clean water.

Then, gradually loosening the locknut and clamping nut on the water intake of the pump, we repair the valve clearances. The norm is 0.5-0.8 mm. A precisely adjusted device, lowered into a container of water without a hose, produces a fountain 0.5-1 m high.

Stage 2: A closer look from the inside

To find the defect, disassembling the unit is required. You can do this yourself. Necessary:

To find the cause of the failure, it is necessary to disassemble the pump.

- Scratch the symbols on the body with a sharp object

so that later during assembly you can accurately align the lower and upper parts along them. - Unscrew all the screws

securing the pump cover at the same time. If they are very rusty, cut off the caps with a grinder. - Remove the piston, core, rubber gaskets.

Reassemble the device in exactly the reverse order. In this case it is necessary:

- accurately seat the piston disk; it itself must be at a distance of at least 4 mm from the coil;

- align the housing holes and gaskets, otherwise the unit will be depressurized;

- free all of its internal space from litter;

- check the pump in a container of water - if it is working properly, a fountain 0.5-1 m high should appear.

Step 3: Troubleshooting the Electrical Problem

If you need electrical repairs, it is better to contact the factory. It is easier and cheaper to replace a burnt coil with a new unit.

If the electromagnet has completely peeled off, you can try to fix this problem yourself:

- remove the electromagnet;

- apply intersecting grooves up to 2 mm deep on it and on the inner surface of the body with a grinder;

- lubricate the compound with glass sealant and press the magnet into its original place using a press;

- After the composition has hardened, assemble the pump.

Stage 4: Correction of mechanical problems

Procedure:

- A tear in the membrane can be repaired with rubber glue.

- A torn shock absorber should be replaced with a new part.

- A worn piston must also be replaced. You need to remove the bushing from it and press it into the new part. It is necessary to adjust the gap between the piston and the body to 4-5 mm by removing or adding washers.

- The required distance between the anchor and the yoke is achieved by adjusting the washers and locknuts, the final tightening of which is carried out when it is 6-8 mm.

- The projections of the coils and the rod armature must necessarily coincide. Adjustment is made by loosening the nuts.

- A gap of 0.6-0.8 mm between the new valve and the water intake hole is achieved by tightening the screw.

The operating conditions of the vibration pump must be strictly observed. They are described in detail in the technical data sheet of the device. Then the likelihood of “Baby” breakdowns will be minimal.

Video description

What to do if the pump gets stuck in the well after installation is shown in this video:

Horizontal installation in a river or lake

Since the technical characteristics of the Malysh pump allow it to be immersed even in natural open sources of water, it is important to install the equipment correctly. The process is different from installation in a well.

Prepare the pump in the same way as for a well: put on a hose and tighten it. And the body is protected with a rubber sheet 2-3 mm thick. Immerse the structure in water and turn it on.

Control method

It is quite acceptable to constantly maintain the circulation of hot water in the pipes, but this is uneconomical and unjustified. Hot water is not used constantly. At night, while all the residents are sleeping, it is useless to keep the water in the pipes hot, the same applies to the time when everyone is at work or school.

If the pipes are laid out correctly, then thermal insulation is required, so that once hot water gets into the pipes, it does not cool down instantly. Therefore, there is no need to constantly pump water from the boiler into the pipes and back; periodic operation of the pump is sufficient, which reduces the load on it and the hot water system as a whole. There is no need to talk about saving electricity, since the consumption of the recirculation pump is low.

Two main control methods are used:

- according to temperature sensor readings;

- according to a timer (schedule).

Both options are in demand, although they differ significantly in their operating principles.

By temperature sensor

Grundfos UP 15-14 BT 80

In this case, the pump control unit relies on the readings of a temperature sensor immersed in water inside the circuit pipes. The pump resumes operation as soon as the water has cooled to a certain threshold temperature. This approach significantly reduces the load on the equipment and constantly keeps the water in the pipes heated. In addition, the safety of the hot water supply increases. Having set a sufficiently high response threshold, water is pumped more often through the boiler, where it is additionally heated and disinfected.

By timer

Grundfos UP 15-14 BU

The control unit alternately turns the pump on and off based on the time delays set in the settings. Knowing exactly the parameters of the hot water system, the length of the pipes and their internal volume, thermal insulation and average heat loss, you can select the optimal time during which the water will not have time to cool down. The pump is turned on by a timer signal and pumps all the water. In this case, the duration of operation is also calculated based on the volume of pipes and pump performance.

Another advantage of the timer is the ability to schedule the operation of the recirculation pump for a day or even a week. It is in this case that downtime when hot water is not used is taken into account.

Frequent breakdowns and options for eliminating them

Some users experience that the device does not pump water. The most common causes and ways to solve them include:

- loosening the locknut in the pump - you can tighten it and get rid of the problem;

- breakdown of the pumping cuff - the product is disassembled, a part is found that looks like 2 saucers, and it is replaced with a new one;

- output of the pumping rod - it is located next to the motor and requires professional repair.

Sometimes the pressure switch fails. It can also only be repaired at a service center.

Internal structure of the “Baby” Source oboiman.ru

What to do if the device does not work well

If the pump is not functioning well, its power has decreased and there is no pressure, you should try to rinse it with clean water; perhaps the reason is that it is clogged with debris. Disassembly of the “Baby” is required if the causes of the breakdown were not established during an external inspection.

The repair includes the following steps:

- It is necessary to unscrew the bolts on the body connecting the two parts of the device. If they are rusty and cannot be twisted by hand, you can cut them off with a grinder.

- The piston and other internal parts should be cleaned of dirt. The pump coil is treated with a compound; it must be removed from the housing.

- The reel needs to be inspected, repaired and rewinded. If the rewind is burned out, you should replace it with a new one.

- An ohmmeter is used to check the functionality of the power cord. If it malfunctions, it can be shortened or a new one installed.

- Assembly of the device. Be sure to properly align the holes through which the water flows.

Check the functionality of the pump. If there is additional noise, the bolts need to be tightened better.

How to extend the life of the pump

In order not to fall over time, and to ensure that it works properly throughout its entire service life, it is important to follow some recommendations:

- replacing ferrous metal bolts with stainless steel ones;

- regular check of fasteners on the body and in the piston area;

- you can close the bolts with a layer of superglue;

- regular inspection - once a year the pump is disassembled, cleaned, cracked elements are replaced;

- When the level in the source constantly changes, models with upper water intake are purchased.

Before use, it is important to study the data sheet for the pump. Although many models have the same characteristics, their use may vary greatly.

Is it possible, in principle, to use your pressure switch with your pump?

The pressure switch connects not only to electricity, but also to water. For water connection there is a nut that is rigidly attached to the relay. This means that when screwing the pressure switch to the pump, you will have to twist the relay itself. Thus, first of all, figure out whether you have the ability to turn this relay clockwise on the pump? Will it fit? Will it hit other pipes or the pump housing itself?

We will assume that this issue has been resolved positively, since otherwise you need to look on the spot and, for example, take care of some kind of extension cord or something similar.

The pressure switch has a water inlet that is not quite standard in diameter. For most household relays this is a quarter inch. For professional relays, the connection diameter may be larger. You should definitely take care of this issue and, if necessary, buy a brass adapter for the required diameter.

Previously, in the production of automatic pumping stations, a special and completely standard part was used, popularly called a herringbone. This is such a nice piece of brass pipe, 10 or 12 centimeters long and 1 inch in diameter. The herringbone is screwed at one end onto the outlet pipe of the pump and has standard “outputs” for connecting a pressure gauge, pressure switch, accumulator tank and the water line itself. Now everything has become much more complicated. There are pumps where the pressure switch is screwed directly onto the pump or into very inappropriate, at first glance, places. This variety makes my job of writing detailed instructions quite difficult.

Briefly about the main thing

The budget pump “Malysh”, the technical characteristics of which make the equipment universal, is used to remove water from flooded areas and to treat plantings on the site. The most reliable option is a top-type pump.

The key parameters of the standard models “Malysh” and “Malysh-M” include:

- average power 220 W;

- immersion depth – from 3 to 7 m;

- productivity – 12-20 l per minute;

- water supply for a length - from 100 m;

- Some models are equipped with overheating protection.

There is also a newer model that has reduced power and can be immersed to a shallower depth for efficient operation. This is “Kid-3”.

When connecting the pump, polymer hoses or pipes are used. It is very important to install it strictly following the instructions, securely fixing the hoses with a clamp and preventing the body from rubbing against other elements.

Connecting a well pump to power supply with a control unit (automation unit)

Direct connection of the pump is fraught with rapid failure of the pump. The main cause of the malfunction is the pump running idle when the water level drops.

For simple water supply systems, the best option is to include ready-made (factory) automation units in the water supply scheme (example in the photo). Sometimes such units are called deep-well pump control stations. Sometimes with a hydraulic controller. They are needed:

- For smooth start and smooth stop of the pump;

- For automatic pressure maintenance;

- Protection of the pump from “dry pumping”, without water;

- Protection of the pump from power surges;

- Protection against lack of water intake;

- Network overload protection.

Block models are different and the set of listed functions may change. An automatic control unit for a well pump is a necessary device, and that is why reputable companies include it in the pump package, often with limited functionality.

The automation unit (hydraulic controller) is quite compact in appearance. The connection is also simple, and a simple electrical circuit of a well pump with a control unit can be represented as follows.

However, for longer operation of the automation unit, it is better to consider the diagram of its connection through a contactor. The controller will ensure simultaneous activation of the automation unit with the submersible pump.

General information

The “Malysh” pump is used only for pumping clean liquid. If you pump too contaminated water, it can quickly fail. It is used for the following purposes:

- collection of water into storage tanks;

- watering garden plots;

- water supply for a dacha, private house, cottage.

The “Malysh” electric pump is capable of pumping liquid from the nearest body of water (lake, river, pond), as well as from a well. It can also be used to dispense liquid from a reservoir or well. In the latter case there are some nuances. The fact is that, by its type, “Baby” is a vibration device. During operation, it creates vibrations, as a result of which small particles (sand, clay, silt) rise from the bottom and are sucked into the apparatus. If this happens to a well, the maximum it can lead to is clouding of the well fluid. But in the well, the device may soon silt up.

The unit itself is compact - up to 255 mm, weighs about 3.4 kg. Productive operation of this device is possible only if there is a small amount of mechanical impurities (up to 0.01%). Pumping liquid from rivers with a large sand content, as well as from sources that are too silted, requires the use of a filtration system in parallel with the Malysh pump.