Few people think that the level of comfort in a steam room depends on a well-functioning smoke exhaust system no less than on the design of the heating stove. It is extremely important to choose the right chimney for a private home, and how to do this, we asked specialists from the German company Schiedel, one of the world leaders in the production and supply of chimneys, to clarify the question. Their explanations helped us figure out which chimney design would be optimal and what criteria should be used to select the material.

Pipe parameters are important for stable operation of the furnace Source uenicdn.com

What is important to remember when choosing

Not only its operational characteristics (for example, draft), but also the date of repair depend on which chimney system for a bathhouse you choose. The Schiedel company, being an expert in the development and production of modern chimney systems with 70 years of experience, advises to approach the choice comprehensively. To minimize all risks and troubles, it is convenient to evaluate options according to the following criteria:

- Durability of the design . The factor that ensures long-term trouble-free operation of the chimney is a material that can withstand heat and the destructive effects of condensate for a long time.

- Safety . The manufacturability of the chimney plays a primary role. And it consists of careful installation, precise geometry, and choice of thermal insulation. For a steel chimney system, the grade of steel and the quality (reliability) of the seams are important. Violation of installation technology often leads, for example, to the appearance of backdraft and smoke in the room.

Fireproof passage through the ceiling Source elmin.ru

- Availability . The opportunity to save money is a nice thing, but you need to understand that the cost depends on the quality of the raw materials and the manufacturing method. A budget price is a sign of artisanal technologies and cheap materials. Saving when purchasing leads to problems during operation, additional expenses and a reduction in service life.

- Installation features . They depend on the material and the method of exiting the pipe. Sometimes you need to think about strengthening the foundation.

- Subtleties of service . They are influenced by the pipe configuration, cross-sectional size, and the quality of the material inside the pipe.

Coil installation method

You can install a coil heat exchanger on the chimney of a sauna stove or potbelly stove in a garage or shed. It will serve for heating or for heating water.

To work you will need:

- aluminum or copper tube up to 3 m long;

- 2 3/4″ fittings and a flexible hose for hot water;

- boiler with a float valve for filling with water and a valve for its use;

- tap for draining coolant from the system.

The system installation technology looks like this:

- The first step is to bend the tube so that its cross-section remains unchanged. For copper pipes less than 28mm in diameter, you can use a pipe bender without heating them. But steel, aluminum and products with large diameters require preheating with a blowtorch.

- For bending, you can use dry sand, filling the pipe with it and closing it with plugs on both sides. A spiral bend is made according to the sample, after which sand is poured in and the pipe is washed under water pressure.

- At the end parts of the tube, threads are cut for adapters for fittings, and then connected to the system.

- The resulting coil is mounted on the chimney. If you solder it with tin to the pipe, the heat transfer will be better. Preliminary degreasing is carried out with orthophosphoric acid.

- A storage tank is hung on a support or on the wall a little above the coil. Connect it to the heat exchanger with a flexible connection and install a tap at the bottom of the tank.

Note that for safe and long-term use of a heating coil, you need to install a pump that circulates water in the system and prevents overheating.

Criteria for choosing a chimney: configuration and diameter

The pipe is selected based on the volume of the steam room, that is, after the general layout and dimensions of the steam room become known. The main selection criteria are the pipe configuration and its diameter. The configuration is determined by the following parameters:

- The method of connecting the pipe to a sauna stove (to a fireplace, boiler) . For example, for a metal wood stove, there are usually two options: from behind (side) or from above. You will need an adapter for fixation. Our Permeter chimney system has three installation methods: floor, wall, mounted (on the firebox).

Installation of the pipe from above Source koffkindom.ru

- The method of bringing the pipe to the street . Output through the wall is limited to one hole. This solution will be technologically simpler, but less efficient in operation. A vertical (through the roof) chimney can boast better characteristics, but it is more difficult to install, since its path runs through at least one ceiling and roof. An additional plus is that you can install a “samovar” type water tank on the vertical chimney.

The productivity of the furnace is selected taking into account the volume of the steam room (1 kW of furnace power per 1 cubic meter of steam room). Consequently, the calculation of the diameter depends on the size of the room. According to the rules, for 1 kW of power (for a wood-burning stove) there must be at least 8 cm² of pipe cross-sectional area.

Knowing the minimum required cross-sectional area, you can use the formula for the area of a circle from the school course to calculate the diameter. The resulting value must be rounded up; in any case, the diameter should not be less than the outlet from the furnace to which the pipe is selected. There is an alternative way: the diameter can be selected according to the finished diagram; for this it is enough to know the power.

Methods for removing the pipe Source banipechi.by

Purpose of the element

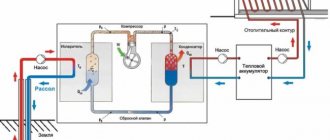

A heat exchanger is used to collect thermal energy passing through the chimney. The source is heated air. The design features of the unit depend on:

- pipe shape and diameter;

- material of manufacture;

- power of the carrier and the device generating heat.

There are air and liquid modifications. The first has a more primitive device, but is not considered the most effective. It requires high-quality material.

The liquid heat exchanger has the shape of a metal coil. It contrasts with the inner plane of the chimney and has a high thermal conductivity. The coil is housed in a metal housing for safety of use and optimal heat transfer. It is insulated on the inside with non-flammable insulation. Most often it is basalt wool.

Heat exchangers differ in the material from which they are made

The structure is installed on the chimney. The edges of the coil are passed through the body and connected to the heating system. An expansion tank is installed in the upper area. Copper tube is best suited for making a coil. In addition, this element is characterized by high efficiency, and therefore its dimensions are several times smaller than those of steel products.

First, the liquid is heated and then expands. After this, it moves along the coil and is sent to the radiator. Here, warm water displaces cool coolant, which is reheated in the coil. There is a constant circulation of coolant in the system.

In order for this process to take place as accurately as possible, it is necessary to calculate the diameter and length of the element, and also accurately determine the angle of inclination of the return and feed. It is important to take into account all these features not so much for the sake of the device to continue to work, but for the sake of preventing water hammer, the consequences of which can be unfavorable. At the same time, the described type of heat exchanger has certain disadvantages:

- Problems in arranging and carrying out calculations.

- Constant control of temperature and pressure indicators.

- Significant coolant consumption. It is caused by the evaporation of moisture from the expansion tank. In winter, when using a water system, the liquid must be drained.

- A significant decrease in the temperature of the exhaust gases, due to which the fuel may not burn completely with a simultaneous decrease in thrust.

Despite all these disadvantages, this heat exchanger can be made by anyone who knows how to handle the tool and has knowledge of physics.

Such a unit has disadvantages

Specifics of choosing a chimney material for a bathhouse

The material for the chimney is selected taking into account the type of stove. In private baths, two types of wood-burning stoves are common:

- Brick . It is equipped with a chimney made of brick, metal or asbestos cement.

- Metal . It is best to remove smoke from it through a steel pipe with a layer of insulation (sandwich). Sometimes there are options made from asbestos cement; you can choose ceramics or glass.

It is better to discard asbestos immediately, since it has a porous structure and is not suitable for use in extreme conditions. On such a surface, the formation and accumulation of condensate increases, which, together with heating, leads to the destruction of the pipe. To reduce the risks of using asbestos cement pipes, it is thermally insulated and lined with bricks.

A chimney for a bathhouse is made of materials that are resistant to fire and conduct heat well. Often there are combined options, for example, a steel pipe lined with brick, or ceramics inside a metal shell.

External chimney made of stainless steel Source metall-sg.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Materials are used with different frequencies for the following reasons:

- Asbestos cement . Fiber-reinforced concrete does not corrode, but due to its porosity, it successfully accumulates condensate. It is chosen because of its low price, but it also comes with problems such as cracking, health hazards, and fire hazards. There are installation restrictions: the pipe cannot be mounted at an angle, and it is impossible to install an inspection.

- Brick . It is aesthetically pleasing, gives off heat for a long time, and lasts a long time. However, brick is used less and less because of its high cost: a foundation is needed for it, and the material must be fireproof. The disadvantages include difficulties in finding an experienced mason, installation time, and operating features of square masonry (the traction is unstable, soot accumulates quickly).

- Made of black metal . An affordable option with good heat conductivity and significant disadvantages. The significant weight of the pipe makes installation difficult and sometimes requires the construction of a foundation. Rapid heating is dangerous for surrounding materials; a particular danger is rust, which quickly (sometimes within a couple of years) leads to through corrosion.

The weight of a brick chimney can reach a ton. Source wixstatic.com

A chimney in a bathhouse is in many ways similar to the design for a wood-burning fireplace - both are designed for periodic increases in temperature. However, it also has its own specifics. Since they prefer to use wood for the interior decoration of bathhouses, the chimney requires special reliability and high safety. The design of the pipe does not play any role, but its compact location becomes important. Systems made of steel and ceramics most fully meet all requirements.

Steel chimney

Metal pipes for removing combustion products have been used for a long time and willingly, and most modern baths are equipped with just such a design. The popularity is due to the following advantages of the product:

- Resistance to external factors . Steel does not deform during operation under the influence of temperature and atmospheric processes. The smooth inner surface resists corrosion processes well, as it prevents condensation from accumulating excessively, and soot settles slowly

- Safety . This is achieved by sealing the seams. Individual elements are welded or connected through socket joints, using sealant and clamps.

Steel chimney in a Finnish sauna Source finnsauna.fi

- Simple and quick installation . This is possible due to the light weight of the pipe. If the stove is made of steel, then you do not need a strong foundation.

- Long guaranteed service life . For example, the Permeter chimney system manufactured by our company has a 10-year warranty, subject to installation technology and careful operation.

There are three types of smoke ducts; the first is single-walled. These are simple designs consisting of stacked parts of different diameters. They have an attractive price, and their feature, strong heating, can be used to produce hot water if you hang a tank. And yet, despite the benefits, heating cannot be considered a plus, so they strive to neutralize it.

The only way to do this is to use the second type - sandwich systems. They look like double-walled pipes with a heat-insulating layer of non-flammable fiber. Technical basalt fiber (it can be heated up to 600°C) or kaolin wool (its limit reaches 1200°C) is usually used as an insulation layer.

Exiting a sandwich pipe through the roof Source zhk-akvapolis.rf

Mechanism of operation

A metal stove placed in a house, garage or bathhouse must be equipped with a chimney to remove carbon monoxide and organize draft. During the process of heating the furnace, this pipe can reach very high temperatures, about 200-500 ℃, which is unsafe for people in the room.

If you install a heat exchanger on the chimney, you can significantly increase the efficiency of the stove, and also protect yourself from direct contact with a hot surface. In a tank or coil installed on the chimney, the coolant will be water, however, you can also install an air heat exchanger on the chimney pipe. Due to the direct contact of the chimney with the coolant, their temperature indicators are balanced, that is, the water or air gradually heats up, and the walls of the pipe cool down.

As the temperature of the water inside the register rises onto the pipe, it rises upward, where it enters the water tank through a special fitting. Through the inlet fitting located at the bottom of the heat exchanger, cold water enters it, replacing warm water. This circulation continues constantly, and the water can heat up to very high values.

An air radiator on a chimney pipe has a similar operating principle. Cold air enters the heat exchanger from below, and after heating it rises up and is supplied through the pipeline to the heated rooms. In addition, the radiator fins also give off heat. An air heat exchanger is optimal for heating attics in a country house or dressing rooms of a bathhouse, if such rooms are heated only from time to time. It is not advisable to organize water heating in them, since you will have to constantly fill and drain water from the system.

Video description

What you need to know when choosing a sandwich chimney in the following video:

Ceramic chimney

For stainless steel chimneys, an important factor for flawless operation is high-quality thermal insulation between the sandwich layers. If a stainless steel pipe does not suit you, you can consider an alternative - a ceramic chimney with the following advantages:

- Ceramics is a material that has increased strength and is insensitive to intense heat (up to 1000°C).

Construction of a ceramic pipe Source stroiremdoma.ru

- Energy efficiency . Ceramics accumulate heat well and release it slowly. This property is especially valuable in a bathhouse, but it will also be useful in a residential building, where it will allow you to warm up, for example, an attic.

- Versatility . A ceramic pipe is connected to any stoves, fireplaces or boilers, regardless of the type of fuel.

- Durability . Ceramics are not afraid of temperature changes and chemical corrosion; soot is almost not retained on smooth internal surfaces (which also means high fire safety). Maintenance of such pipes will be minimal.

The downside is the high cost - such a design can hardly be called budget; Besides this, there are other disadvantages:

- Complex (sometimes poorly thought out) installation ; some manufacturers do not guarantee reliable operation.

Installation of ceramic pipes Source sckovcheg.ru

Heat exchanger in the form of a coil

If the installation of the previous type of heating from a chimney pipe requires the ability to operate a welding machine, then the design of a heat exchanger in the form of a coil is much simpler. You just need to wrap a few rings of flexible aluminum or copper pipe around the chimney. These metals have a high level of thermal conductivity and are not destroyed due to corrosion.

The diameter of the tube should be convenient for connecting to the fitting of the storage tank. It is optimal to choose a pipe with a cross-section of no more than 28 mm for bending. The length of such a circuit should not exceed 3 meters in order for the water circulation to be correct. Using a flexible connection, you can connect the tank to the coil.

As a rule, coils are used to heat water, although sometimes for heating small rooms. Coils mounted on the chimneys of a metal furnace with a very high temperature of carbon monoxide perform best.

Video description

About brick, ceramic and steel chimneys in the following video:

- Pipes are quite fragile , so they need a casing for protection. Often the consumer is offered a product without a box and insulation, which leads to additional costs.

- The quality of ceramics varies , making some ceramic chimneys vulnerable to damp environments and acidic condensation.

Most of the shortcomings are neutralized in the UNI ceramic chimney.

Schiedel specialists have developed a system designed for all types of heating devices. The chimney has the following advantages:

- Safety . UNI is a system with a minimum level of heating of the external surface. All elements of the system meet fire safety requirements, which is confirmed by the VNIIPO EMERCOM of Russia.

Features of the UNI chimney Source heatsystems.ru

- Quality . The UNI system is manufactured in accordance with all European and Russian requirements and internal standards. All ceramics for the Schiedel UNI system are produced in Germany, at the Schiedel plant.

- Equipment . The system is equipped with a decorative URATOP shell made of fiber concrete or a stone shell (made of expanded clay concrete blocks) with a front panel made of mineral fiber.

- Life time . All main components: ceramic pipe, insulation, stone shell have a guaranteed service life of 50 years.

The UNI ceramic chimney has been successfully sold in European countries since 1985, as evidenced by the title of sales leader; It has been sold on the Russian market since 2009. The system is used in low-rise and cottage construction, and it can be used both during the construction of new buildings and during reconstruction.

Method of fixing the ceramic system Source samstroy.com

Negative points

Along with the benefits of a heat exchanger on a chimney, it is worth noting a number of negative factors. Firstly, due to this design, the temperature of the exhaust gases is significantly reduced. This can provoke excessive soot accumulation, condensation formation and poor traction.

An important point in arranging such a heating system is to calculate how much water is needed for its full functioning. If there is not enough of it, the system may overheat, the water in it will boil, and the pipes may burst. In addition, it is important to ensure the tightness of the seams.

In any case, installing a heat exchanger allows you to increase the efficiency of any furnace. For safety reasons, at least twice a year, visual diagnostics of the system and its maintenance should be carried out - cleaning soot, replacing defective elements, and so on. Then it will be possible to confidently use the heat exchanger for heating the house and heating water in the bathhouse.

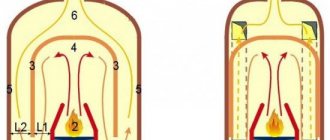

Features of the design of a long-burning furnace

Of all the variety of metal ovens, installations with a long combustion function (convection ovens) are in great demand and popularity. Such ovens are easy to use and very economical. They are equally well suited for small country houses, multi-storey private houses, workshops, warehouses, etc.

The main features of such furnaces include:

- Increased volume of the firebox, accommodating a large amount of firewood.

- Dividing the firebox into two chambers that perform different functions. Gas is burned in one, wood is smoldering in the other.

- The presence of a special bumper inside the firebox that prevents the open flame from engulfing the chimney.

The combustion process itself is radically different from the operation of an ordinary metal furnace. The firewood is ignited in the upper part of the firebox, and air is supplied here. The supply volume is regulated by a damper. The fire spreads downward, and the intensity of the flame cannot be called strong; the process is more like smoldering.

As the wood smolders, pyrolysis gas is also released, which moves into a separate chamber of the firebox, mixes with air and also burns, further increasing the efficiency of the installation.

During operation of a long-burning stove, less heat is generated, allowing the room temperature to be maintained at the same level. Much less firewood is consumed, and the combustion products entering the chimney have a low concentration of harmful substances.

Building regulations

The installation of chimneys is determined by the provisions of SNiP 41-01-2003.

The chimney design must meet the following regulatory requirements:

- the minimum height must be at least 5 meters from the burning point or grate,

- the pipe must rise above the flat roof to a height of at least 1 meter,

- when located on the roof slope at a distance of less than 1.5 m to the ridge, the pipe should be 0.5 m higher than the ridge,

- when located on the roof slope at a distance of 1.5-3 m to the ridge, the pipe may not be lower than the ridge,

- when located on the roof slope at a distance of more than 3 m to the ridge - the angle between the horizontal and the line passing through the ridge and the top of the pipe should be no more than 10°,

Buleryan stove: advantages and disadvantages

Bullerjan is one of the types of long-burning stoves that operates on the principle of convection.

Stove Buleryan

The design was developed by Canadian inventor Eric Darnell in 1975, after which the rights to the patent were purchased by German businessmen who launched serial production of stoves under this brand.

The stove combines the functionality of a standard wood-burning firebox, air heater and gas generator. Buleryan is able to work in two modes:

- Kindling. More air is supplied to burning wood, which contributes to its rapid combustion and accelerated heating of the room.

- Gasification. The oxygen supply is reduced to a minimum. The firewood gradually smolders, and the room warms up more slowly. In this operating mode, one stack of firewood will be enough for 10-12 hours of continuous operation.

We recommend that you read: Characteristics of sewer pipes of red-brown or red color

The power of such a furnace depends, first of all, on its dimensions. It can be enough not only to heat a private home, but also for large industrial buildings and warehouses.

Among Buleryan's shortcomings, we note:

- Ability to work exclusively with wood.

- High soot content in exhaust gases.

- Soot also forms condensation in the chimney from a mixture of tar, water and soot. After a long period of inactivity, there will be an unpleasant odor when burning.

- Some experience will be required to operate the oven correctly.

Step-by-step instructions on how to install a heat exchanger with your own hands

The Kuznetsov heat exchanger is installed instead of one of the chimney sections - for this part of the chimney will have to be dismantled. If a chimney is installed from one long pipe, you will have to cut out part of the chimney and install the structure using welding.

Installation methods

The heat exchanger is installed at a certain distance from the heating unit - 200-500 mm, more is possible.

If the chimney is prefabricated, then it is necessary to disassemble part of the chimney. The heat exchanger pipes are cut so that the length of the heat exchanger structure is equal to the dismantled chimney section. The heat exchanger is mounted in the chimney and sealed using heat-resistant sealant. The top of the heat exchanger is painted with heat-resistant paint.