Among the numerous building materials, plywood should be highlighted. It can be used for a variety of purposes. Good workability determines that the material in question is often used in the independent manufacture of furniture, home decoration, carpentry and other purposes. The most common question is how to bend plywood.

Features and advantages of products made from bent plywood.

Details made from bent plywood allow you to create original interior items of a wide variety of shapes.

Furniture production manufactures furniture from bent plywood using multi-layer veneer. There are more than 200 types of parts made from bent plywood, including interior items, chairs, armchairs, components: armrests for armchairs and chairs, frames and parts of various configurations. Bent-laminated plywood is widely used to create decorative wooden radiator screens, folding stools, as well as for the production of health products, in particular exercise seats. Thanks to the unique structure of chairs and armchairs made of bent plywood

are a bright and original decor for any room, both office and home. Using bent plywood, you can create high-quality, practical furniture of unusual design at an affordable price.

Bent plywood

made from thin sheets of wood. The sheets are produced by sawless division. The sheets are firmly glued together in a given shape. The finished product is particularly durable and flexible.

Currently, a fashionable trend is the combination of bent plywood

with other materials, for example metal. The best option is a combination of bent plywood with steel, aluminum, decorated with glass. As a construction material, bent plywood has ample opportunities for the flight of design imagination. Furniture made from this material is practical, comfortable, and special exercise seats made from bent plywood have a positive effect on human health. From bent plywood you can make original models of sofas, chairs, armchairs, beds, bedside tables, cabinets and many other office and home interior items.

The furniture production plant produces high-quality products from bent-glued plywood (multi-layer veneer - plywood

).

We offer more than 100 types of components

products for the production of executive chairs, staff chairs, chairs on a metal frame, chairs for cafes and bars, armrests for armchairs and chairs. The company's production capabilities and the versatility of the forms allow us to produce an endless number of chair frames and chair parts of any configuration.

Our bent plywood products, plywood, are also used in the manufacture of decorative battery screens, folding stools, and orthopedic products.

Currently, not a single manufacturer of office furniture, staff furniture, upholstered furniture and furniture for cafes and bars can do without the use of products made from bent-glued plywood - plywood.

If you are making furniture from plywood, or are just planning, sooner or later the question arises of how to make a “bent” element of your product from flat plywood. This article will be about this. I will tell and show, or rather, I will try to systematize the methods and secrets of making radius bent volumetric parts from flat plywood.

Let's start with something simple.

The first method of making bent plywood parts

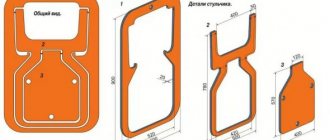

– simply cut out a “bent” part from the sheet. Or several. And arrange them in the right order. Like, for example, here:

As you can see, all the parts of the chair are flat, but the chair as a whole does not have a single plane. You can read more about this project

Or like this:

It has smooth shapes, but still consists of absolutely flat parts.

A further development of the same method is to join flat parts cut in a certain way to obtain curvilinear volumetric shapes. This is how this plywood chair is constructed:

But there is no need to regard this method of manufacturing curved plywood surfaces as very simple and primitive. A further development of the method is gluing plywood parts into one solid mass and cutting out the required shape from it.

Here's an example.

From gluing together flat plywood parts like this

Follow this link

There are detailed drawings and a description of the manufacture of such a plywood chair.

This is a seemingly simple way.

The second method of obtaining bent plywood.

Actually, this sentence contains the whole essence of the method. There is no way to think about any actions on flat plywood. The essence of the method is gluing veneer into a plywood piece of a certain shape and “bending”.

The idea is well shown in this video - Description of the process of producing bent-glued parts from plywood

Here it is very important to make a high-quality matrix on which the veneer will be glued into plywood.

To simplify the matrix manufacturing process, such a device was invented.

Examples of using this method:

A) Plywood chair

The main part of this chair is obtained by gluing veneer into plywood in this matrix

More details

b) Plywood chair

All parts of this chair are obtained by gluing veneer into plywood using special dies.

More details

c) All the details of this chair

made not from sheet plywood, but from plywood obtained independently by gluing veneer in matrices.

More information about this plywood chair -

One could go on and on about examples of the use of this method. Let's move on to the next method.

The third method of obtaining bent plywood surfaces

– through cuts in plywood, which give it flexibility and at the same time do not deprive it of the required level of strength.

The seat and back of this plywood chair are made from ordinary laminated plywood sheets.

Thanks to the “pattern” of through cuts, the plywood parts have acquired flexibility and exactly follow the contour of the guides along which they are curved.

More information about this plywood chair -

Or here’s another example – again, a plywood rocking chair.

Thanks to these cuts in the plywood, the main plywood part of the rocking chair gained flexibility. And besides, there is also a springy “softness”.

More information about the rocking chair

The fourth method of producing bent plywood parts

– not through cuts.

The essence of the method is well shown in this video

A certain number of parallel blind cuts on one side of a plywood sheet will allow this sheet to be bent along a certain radius. It is applied not only to plywood, but also to wood, MDF and chipboard.

An example of using this method in practice

Plywood chair.

Made using a CNC machine from sheet plywood. You can take a look for more details. There is a good video illustrating the process of making a plywood chair.

Another example is a children's rocking horse

.

Unlike a chair, in this case, to strengthen the structure, the grooves are filled with glue.

for a description of the manufacturing process

Here are the main ways I know of bending plywood. The numbering of methods is conditional. On my website, all projects using “bent plywood” are marked with the appropriate tag - you can easily view and select a couple of ideas for bending plywood. If anyone knows any other ways, please write and I’ll add them!

Despite the huge variety of building materials produced by modern industry, new modifications and varieties appear every year, distinguished by an excellent set of physical and technical parameters and unique specific properties.

One of them is flexible plywood, which has the advantages of natural wood and is characterized by extraordinary flexibility, not typical for other woodworking products. The reason for this flexibility lies in the raw materials used. This is the wood of tropical trees, the wood of which is characterized by low density.

These include:

- Ceiba.

Area of origin: Africa and the Middle East. Wood characteristics: light cream. It is light in weight, soft and durable. It tolerates gluing, painting, polishing, etc. well. - Sumauma, Parika, Faveira.

Area of origin: Africa and South America. Wood characteristics: creamy white to light brown and pinkish. Its structure and composition resembles ceiba. - Keruing.

Area of origin: Indochina and the countries of Asia Minor. Wood characteristics: red or red-brown. Very durable, resinous and hard, can be used in conditions of high humidity.

Recently, flexible plywood made from birch veneer has also become widespread. It owes its specific qualities to the special structure of the layers having a cross arrangement. The main advantage of this flexible type is its availability and lower cost compared to exotic analogues.

Types of flexible wood:

Today on sale you can also find so-called bent or bent-glued plywood, made from thin veneer, sheets of which are glued together during the production process according to sketches of the future product. in the manufacture of furniture. Thanks to its elasticity, strength and ease of processing, this material is very convenient for creating pieces of furniture of the most unimaginable and original shapes.

Bent-laminated plywood is made from peeled veneers of birch, larch, beech, pine and even MDF. To cover its surface, veneer made from valuable wood species, such as walnut, mahogany or oak, is used. Thanks to the use of such spectacular cladding, products made from bent plywood look very expensive and elegant.

The advantages of this material include:

- Wide variety of shapes.

- Homogeneous structure.

- Resistance to abrasion and mechanical stress.

- Spectacular appearance and decorative effect.

Video description

DIY wood putty.

Preparing plywood for puttying

It’s easy to prepare a concrete surface for puttying: clean it of debris, widen all the cracks, remove dust, apply a primer, and dry it. Proper preparation of a wood floor is much more difficult.

Sequencing:

- Soak the base well with drying oil. The liquid should be heated to 60° C, then applied with a brush or roller.

- Dry the treated surface with a hair dryer.

- Repeat the procedure several times.

To check the floor's readiness for applying putty, you need to spill a little water on it. If it begins to form drops, the treatment can be completed. It is important to pay special attention to the outer parts of the material. Otherwise, if moisture penetrates, they will become ruffled and eventually delaminate.

Advice! A water-repellent effect can also be obtained by impregnating plywood sheets with PVA glue.

Drying oil applied to plywood penetrates deeply into the structure of the material and forms a water-repellent film Source stroy-podskazka.ru

Padding

Plywood laid on the floor must be primed. Unlike impregnations aimed at preventing rotting, soil helps improve the quality of putty. After application, it significantly increases the adhesive properties of the surface. In addition, the primer prevents excessive penetration of putty compounds into the wood.

Priming must be carried out only with specialized products intended for finishing wood. Such compositions necessarily contain antiseptic components. They are applied with a roller or brush. The drying time of the surface depends on the external temperature and the level of humidity inside the room. It usually takes up to six hours to dry the treated base.

Attention! You can putty a plywood floor only after the soil has completely dried.

Before you putty the plywood, it must be cleaned of any contaminants and primed Source dekorator-s.ru

Puttying

Putty is applied to plywood panels in the same way as on a concrete base. To do this you will need the following tools: a spatula, a rule. It is important to pay special attention to the joints. The optimal thickness of the putty layer is 2-3 mm.

If any particles remain on the base after the material has dried, they must be removed with sandpaper. But such problems can be prevented by first passing the solution through a nylon or fine sieve. When the surface is completely dry, further finishing is allowed.

Applying putty to plywood is carried out according to the same principle as to concrete or brick Source stroiremdoma.ru

Production and technical specifications

In the process of manufacturing flexible transverse plywood, layers of wood (at least 3) are joined together with a special adhesive composition, after which the sheets are heated and pressed at a certain temperature. As a result of this processing, a unique and unusual material is obtained, which, despite its high strength and lightness, has excellent elasticity and resilience.

Technical parameters and properties of Asian plywood:

Technical parameters and properties of African plywood:

Thus, when evaluating flexible plywood on a five-point scale, it can be given “five” ratings in the categories of “practicality,” “external attractiveness,” and “reliability.” As for availability and price range, here this finishing material deserves a “three” because of its high cost and “exoticism”. The exception is flexible plywood made in China, which combines all of the above advantages and has an affordable price.

Preparation for installation

Plywood sheets cannot be used for laying flooring unless they have been previously acclimatized. The duration of the latter is determined depending on the temperature difference between the new and old environment of the building material.

If the temperature conditions have remained practically unchanged, then the acclimatization period will be at least 24 hours, with a temperature difference of 8°C - three days, in other cases - about a week.

Important! Before laying plywood, it is necessary to check the humidity level in the installation areas. If the amount of moisture exceeds the permissible standards, then you will need to take care of an additional waterproofing layer.

Applications and products

Bent plywood is most widely used in furniture production. In particular, sets for children's rooms are made from it. The main advantage of such products is their original appearance, high strength and the absence of sharp edges and corners that can injure a child. Such plywood is not suitable only for. For these purposes, special ones are used, such as, and others.

In addition, it is the basis for the production of so-called bent-glued elements and products, which include:

- Rocking chairs.

- Office chairs, furniture for cafes and restaurants.

- Elements of upholstered furniture and facade elements of cabinet furniture.

- Flexible bed bases called “latoflexes” or “battens”.

- Decorative and structural components of mirrors, bedside tables, cabinets, etc.

Using the previously used five-point scale, bent plywood products can be assigned “five points” for functionality, decorativeness and ease of use. And for the cost and complexity of manufacturing, they fully deserve a “four” rating, which confirms their high quality, originality and uniqueness.

Press for the production of plywood products:

Bending plywood at home

You can bend plywood, giving it an original and unusual shape, at home. To do this, it must be placed in appropriate conditions, with a certain temperature and humidity.

The main methods used to create bent structures from this material:

- Steaming.

- Gluing.

- Creation of cuts.

- A combination of the above processing methods.

You can make plywood more elastic by doing the following:

- Immerse it in water heated to +95 ⁰С.

In this case, water of the required temperature is poured into an open container of the appropriate size, after which sheets of plywood are lowered into it. Time spent in water: from 5 to 30 minutes. Then they begin to carefully bend the wood. First, a minimal bend is made, and the workpieces are again immersed in hot water, leaving them there for another half hour. After this, the manipulation is repeated until the part acquires the desired shape. - Treat it with hot steam.

For this purpose, you can use a regular kettle or an iron with a steam function. But the main difficulty of this process is that the effect of steam on the material must be constant and long enough, and this is very problematic to achieve at home. In this situation, it is more convenient to work with an iron. The workpiece is wetted and ironed with a well-heated iron. Then the plywood is carefully bent to a small radius. These steps are repeated several times until the desired bend is obtained. - Soak it in warm water.

The most inconvenient method, due to its duration and low efficiency.

The above methods are well suited for making small parts from plywood yourself. In order to bend a large sheet, it is necessary to make cone-shaped cuts in the form of strips, while acting as carefully as possible to prevent the appearance of cracks and chips.

To cut cuts, it is better to use an electric jigsaw with a cutter. The depth of cuts – with a sheet thickness of 4-5 mm – is no more than 2 mm. Quantity - in accordance with the bending angle. After sawing, the plywood is clamped onto the template used and using epoxy glue. The drying time of the workpiece is about a day.

In order to obtain beautiful and original high-quality elements as a result of bending, the following points must be taken into account:

- The transverse radius of wood fibers should be much smaller than the longitudinal one.

- Manufactured parts must be stored at a humidity not exceeding 9-11%.

- Bending steamed or heated workpieces must be done before they have cooled down.

In the photo - an original shelf made of bent plywood

DIY bent plywood

After preliminary preparation, the plywood can be bent in accordance with specified patterns.

At home this can be done like this:

- A load is attached at the bend, and the edges of the sheet (supports are placed under them) are pulled together with a rope.

- The plywood is fixed with tape or rope.

- The function of a template can be performed by any structure that has the desired angle of curvature and sufficient strength. For example, fiberboard sheets, cut to the appropriate shape and size.

When making a large part or a non-standard shape, it is better to use a steel sheet as a template. In this case, bending of plywood must be done simultaneously with the workpiece, firmly fastening the sheets together. It will be possible to separate the template only after the structure has dried thoroughly.

You can also bend plywood by gluing its layers together. To do this, first a template is made, and thin layers of wood are laid on it, bending them along a given radius and coated with an adhesive composition (PVA or epoxy).

Each subsequent layer must be laid on the previous one, alternating the direction of the fibers. After drying, the edges of the part are processed with a grinding machine to remove unevenness and glue smudges.

The video will tell you how to bend plywood:

Wood-laminated boards, which we know simply as plywood, have found their use in finishing and furniture production. They have one of the most unique properties; with their help you can create almost any bend. Due to this, it becomes possible to create unique aesthetic designs and effectively use the material.

Now let's talk about how exactly you can make bent plywood

in industrial plywood production and independently at home.

Video description

Laying plywood on a screed.

Installation on plank floors

Laying plywood over plank flooring is the easiest way. The sheets are fastened with ordinary self-tapping screws. If the wooden base is strong, then it will be enough to use sheets with a thickness of 3 mm.

When the boards are very old and rotten in places, they will definitely need to be replaced with new ones. If there are any mechanical defects on the surface, it is recommended to use thicker plywood products (at least 1 cm).

Plywood is laid on a dry and flat surface of a wooden floor, without the use of adhesives and mastics, unless required by base repairs Source green-ply.ru

Advantages of bent plywood

What exactly is plywood sheet? These are thin sheets of wood (veneer) connected to each other using a special composition. The veneers usually used are birch, alder, pine or beech.

Due to these features, the material has the following advantages:

- High level of moisture resistance. Compared to simple wood, the hydrophobicity of plywood is approximately half as high. This makes it possible to use moisture-resistant plywood in rooms with high levels of moisture and when decorating exterior building facades.

There is no warping, and the material is least susceptible to rotting.

Beautiful appearance with wood texture.

Very easy to use by yourself. With such pliable material, work becomes easy.

Resistant to ultraviolet rays, so the material does not fade in the sun.

Low cost. It is much more expensive than natural wood, and also has better technical performance.

Easy to care for. It is possible to use detergents to clean plywood surfaces.

Environmental friendliness. All materials used to make plywood are safe for human health. This makes it possible to place a product made from this material even in a child’s room.

Abrasion resistance. With constant contact with various furniture, hands or feet, it does not wear out.

Long service life. Due to all the above qualities, it has a long service life.

You can create smooth shapes and curves. This quality is great for creating unique and interesting designs, which we will talk about next.

Material calculation

To correctly determine the quantity of products, you must follow the step-by-step instructions:

- The floor surface is measured and all data is transferred to paper. You should get a detailed diagram of the foundation with a lag laying system. This allows you to immediately calculate the order of placement and adjustment of all parts, which is especially important in rooms with ledges and niches.

- The appropriate sheet size is determined and a layout plan is drawn up.

- According to the data obtained, the required number of slabs is calculated.

When installing a floor using joists, first of all it is necessary to draw up an installation diagram for the joists, and then plan the laying of plywood based on it

If the room has the correct shape, it will be easier to calculate the consumption: for this, the size of the object and the dimensions of the sheet are converted into area, and the data in square meters is divided.

On a note! To make the task easier, you can use a table with the exact sheet area provided by the manufacturer.

Methods for bending plywood

You can bend plywood using two methods, which we will talk about now. Here it is worth giving a little advice: when using each of the methods, you should not position the top veneer in such a way that the fibers are across the bend, as this may cause a kink.

Bending of layers during gluing

This technique is usually used in production conditions and its meaning is as follows: The use of molds for curved veneer, which are preheated using steam or electric current. Next, plywood sheets glued and bent into the required shape are placed there, the humidity level of which reaches no more than twenty percent. They are placed in them until the glue dries to such an extent that it can perfectly hold the material of the new shape.

It is impossible to find the necessary equipment at home, but you can do it completely differently:

- Glue several thin plywood sheets using wood glue.

Bend it with your own hands to the required position.

Secure around the edges with epoxy mortar.

Wait until completely dry.

The method is quite good, but do not forget that thin veneer should be used for it. If you have a ready-made sheet of plywood of large thickness at your disposal, then you should use another option.

Bending plywood after gluing it

It is difficult to simply bend a thick sheet. It must first undergo special treatment to become softer and more pliable. Only then can the sheet be bent. But first it should be placed in prepared curved veneer.

The following types of processing can be applied:

- In factories, special industrial steam installations are used for such cases.

As for home conditions, you can use steam from a kettle for small parts or a household steam generator.

You can also steam it with a kettle.

If the plywood is large in size, then it should be placed in hot water in order to give the sheet greater elasticity. In this case, it is important to prevent the sheet from delaminating.

Here it is better to use three methods: Leave the plywood in water for half an hour, and then move it into a hard piece and leave it in that position for a week. Wet the workpiece generously with water, bend it a little and iron it with an iron. Then wet it again, bend it and remove all the water. And do this until the required form is achieved. You can also heat it to the required state in an oven, but when using this method, cracks may appear on the material.

After processing is completed, the plywood can be bent using the following methods:

- Place it in the frame template.

This should be done very carefully and reliably, but, first of all, the frame should be made, which will require spending a little more time and effort. In order to secure the product, it is better to use spacers and a belt system.

Use steel strip.

You should tie it to a sheet of plywood and bend it into the required shape. At the same time, the metal will perfectly hold its shape and will not allow it to be lost. Next, you just need to leave the finished structure until it hardens completely.

Using a cut.

This will be especially useful when using a thick product. Several cuts should be made at the site of the intended bend, which will make it possible to make the bend more easily. Then the workpiece is installed in the required position, and the resulting cracks are clogged with adhesive.

Why are these bending methods used?

Using the above methods, you can give smoothness to the shapes. They will maintain their position even after the material dries. Thus, making arches for doors and rounded wall shapes became very easy. But especially wide bent plywood

used in the production of furniture.

This makes it possible:

- Minimize the number of angles that could cause injury. This is especially true for those rooms where children are constantly present. Because their restlessness very often leads to contact with corners.

Make the interior more aesthetically pleasing and meaningful. Because it is more interesting for the eyes to look at smooth lines of transitions, rather than their sharpness. This design move helps to calm down and improve the overall mood.

Making the finished structure more monolithic and eliminating the heavy load of fixing parts. This allows you to greatly enhance the strength and reliability of the finished structure.

Plywood sheets are truly an excellent material, suitable for both finishing and making furniture. Its comparative cheapness and improved technical properties made it a worthy rival to simple wood. What is especially noteworthy is that plywood has an excellent ability to bend into a variety of shapes, which wood cannot boast of. Thanks to this, the interior is filled with special aesthetics.

Most people, when they hear the word “chair,” imagine a product made of natural wood – large, massive, strong. And this is not surprising: this furniture is distinguished by durability, reliability, and everything that is valuable to the consumer. But times are changing, many buyers are coming to the conclusion that using natural raw materials to make furniture is impractical.

Natural material is expensive, a lot of waste is left during production, and the final product has quite a noticeable weight. Plywood chairs do not have such disadvantages, which is why they are in great demand.

Instructions for straightening sheets

Before starting work, wet the warped plywood sheets with water.

There is no need to pretend to be a tropical downpour: your task is to slightly moisten the material, and not to soak the veneer into a mush. If only the corners or other areas of the sheet are bent, then wet rags are placed on them. The same is done on the reverse side. As soon as the wood is properly wet, take an iron heated to medium temperature and iron the curved areas with it. There is no need to immediately correct mistakes. Your task is only to warm the material to the point where you cannot put your hand on a wet, hot surface.

When this task is completed, place the sheets on a hard (necessarily flat) surface, and place pressure on top.

Professional trick. To achieve “factory” alignment, straight plywood is first placed on the sheet, and only then a weight is placed.

Professionals advise: take sandbags (but only burlap) for oppression. Sand absorbs excess moisture, and the weight of such a load is distributed evenly.

Another note. If you do not want the material placed on top to get wet, place a suitable piece of thick plastic film on the wet, straightened veneer. It must be removed every other day!

If you need to straighten a compact piece of plywood, then it is steamed over boiling water until the wood is wet. Then the sheet is placed under pressure (as in the example already described). When you need to straighten a dozen or two pieces of plywood, selecting a load for each is a waste of time. The sheets are stacked on top of each other, and a load of sufficient mass is placed on the last one.

Advantages

Special plywood is used to produce chairs. Buyers can be sure that this furniture will serve for a long time, will be durable and resistant to the negative influence of various environmental factors. Plywood chairs (whether it is a regular seat, a transformer or a rocking chair) have positive aspects. They:

- regardless of the low weight of the source material, they have high strength, reliability and stability;

- are produced in a wide variety of designs: from an ordinary-looking piece of furniture to a unique design creation with curves and carved lines, a curved back and seat;

- differ in shape and size, allowing the buyer to find the most convenient option taking into account the characteristics of the room area;

- have a low cost, which significantly increases the number of buyers;

- imply restoration and repair if, during use, the product has lost its attractive appearance;

- easy to use and maintain and can be coated with varnish or stain;

- mobile: they can be moved, transferred from room to room, transported to other installation objects, and put away in a corner when not needed.

When choosing plywood chairs, it is important not to fall for the trick of a dishonest seller.

For the production of chairs, plywood of the first or second grade is used. It is predominantly bent-laminated, meets existing GOSTs and SanPINs, does not harm human health, is environmentally friendly and is approved for use in the furniture industry.

About choosing a method

The choice of method depends on the characteristics of the future product. They are as follows:

- The bending radius across is much smaller than along. The product can be bent or rounded at different radii; as it increases, the strength decreases.

- The part that has been bent should be stored in a dry room with low humidity. If this condition is not observed, the product may lose its shape.

- When choosing the steaming method, the shape is transferred to the workpiece before cooling. In this case, it is much more difficult to straighten the part. Alignment is associated with returning the structure to its original state. If the bending was carried out in violation of the technology, then the veneer distribution alternated incorrectly.

Even minor defects can cause the part to fail to bend; if force is applied, it may burst. Products can be bent from plywood according to a template, for which the home workbench is equipped with special clamps.

Styles

High-quality furniture plywood guarantees the production of interior items that are different in appearance. At the same time, it is not so important what type of material the stylish product was made from (bent, carved, layered). When you skillfully work with any type of material, you can get beautiful designs that fit perfectly into a variety of interior styles. Plywood chairs are relevant in the interior of classical and modern styles.

For example, country and eco

They approve of everything natural: floor and wall coverings, textiles, interior items. Plywood chairs of traditional shapes and colors will fit perfectly into the decor of this style. They can fit into the classics, even if the style prefers natural raw materials with imitation wood.

If the highest grade veneered plywood was used to create the chairs, decorated with various decorative details, plywood chairs have the right to decorate the interior of the vintage and baroque styles.

To successfully fit products into other interior compositions, you need to play with color through painting, varnishing, and pasting with a special film. When purchasing, it is important to choose products that are designed in the desired colors, have the appropriate shape, decoration and texture. For any design specialist, working with plywood furniture will not be difficult. Such products can harmoniously fit into any style, having a sense of taste and a special vision of style.

Necessary equipment

The required fixtures and tools largely depend on which bending method has been chosen. In some cases you need:

- A template by which a form is given. How to level plywood? For straightening, a regular board with the required rigidity is often used.

- Device for clamping a workpiece.

When choosing a moistening method, you need a bath in which the workpiece will be soaked. In case of steaming, an airtight container is required. An electric tool, such as a grinder, is used to create grooves.