Installing a pipe on the roof is an operation that requires a special approach. In this article we will consider questions about how the chimney passage through the roof should be in order to comply with SNiP standards, as well as protect the structure from moisture penetration and the possibility of fire.

A well-made chimney passage through the roof is a guarantee of long service life of the stove and roof Source houseinform.ru

Chimney installation rules

If the house has a stove, then a chimney is also needed. Although instead of a stove there may be a special tank running on gas. In any case, the house is heated somehow, and combustion products need to be removed. There are several options for removing the pipe through the roof, related to determining the location. It is planned when a house project is being developed. The location is considered relative to the ridge of the roof - a horizontal edge that is located where two slopes meet. The pipe can be installed:

- directly in the ridge;

- at a distance from the ridge.

The first and second options have their pros and cons. On the one hand, it is easier to install a chimney in a ridge. But this is for someone who deals with this particular issue. But for arranging a rafter system, this is more difficult, because you will have to make a gap in the horizontal beam. On the other hand, when the pipe is in the ridge, this guarantees good traction. And the possibility of leakage under it is reduced to a minimum here. But still, most often the chimney is moved relative to the ridge.

Chimney offset relative to the roof ridge Source katlavan.ru

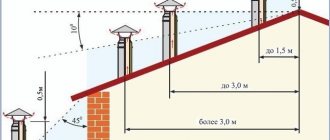

In this case, the following building regulations must be observed:

- If the chimney on the roof is installed at a distance of no more than 1.5 m from the ridge, then the pipe should be 0.5 m higher than it.

- When installed at a distance of 1.5 m to 3 m from the ridge, it is made on the same level with it.

- When the pipe is more than 3 m from the ridge, it can be lower than it, but no more than 10°.

The best option for locating the pipe relative to the ridge is not far from it. If you make the chimney much lower, the risk of damage from falling snow increases.

To ensure good traction, you must adhere to certain standards for placing the chimney relative to the roof ridge Source rekvartira.ru

There is a place where it is generally not recommended to install a pipe - the valley. This is the internal angle that two slopes of a complex roof form when connected. There is always an increased load on it, since precipitation flows there and snow is retained. With such an installation, the possibility of waterproofing damage is very high. This means that there will be leaks.

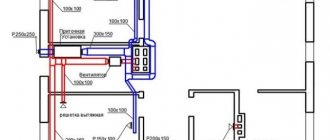

Optimal placement of the heat generator and chimney in the house

Many people are familiar with the expression: “Dance from the stove!” It means that the house should be built around the stove, and not vice versa - the heat generator and chimney are squeezed into an already built cottage by hook or by crook. In other words, it all starts with design. This is the choice of location for the foundation and chimney, for example, under a stone stove or fireplace lined with brick, the size of the indentations when passing through the ceilings and rafters and the chimney outlet through the roof.

If you neglect this rule, the installation of the entire system will become significantly more complicated, which will lead to an increase in construction costs.

Traditionally, the most rational place to place a stove and further install a vertical chimney is the conventional center of the house on the ground floor.

With this scheme, heat flows from the heated furnace are optimally distributed. Additionally, several adjacent rooms are heated, and the chimney ends up in an insulated area and as close as possible to the ridge of the house. We will explain why this is so important below.

Protecting the roof from heat coming from the pipe

When organizing a pipe passage through the roof, it is important to insulate the roof from it. After all, the pipe gets very hot, which increases the fire hazard. The roof is protected using a separate box, the beams and rafters of which are located taking into account the requirements of SNiP. The minimum distance standard from the chimney to the load-bearing beams and rafters is from 130 to 250 mm. The inside of the box is filled with some material that does not burn. For example, it could be basalt or stone wool.

The chimney in no case directly touches the roofing Source barmanlive.ru

Further organization of the pipe outlet depends on what shape it is and what it is made of. The shape of the chimney can be made either as a regular square or round, or in the form of a rectangle or oval. And pipes can be brick, metal, asbestos-cement or ceramic. The material from which the roof is made is also taken into account. This can be slate, metal tiles, corrugated sheets, ondulin, roofing felt or bitumen shingles. Each case has its own characteristics.

Criterias of choice

When choosing a bracket, consider the following factors:

- chimney diameter;

- maximum and average distance from the wall;

- wall material and pipe material.

If the distance from the wall is short, plate wall mounts are chosen; as the clearance increases, you will have to switch to cantilever structures.

A small diameter pipe can be secured with a clamp on a stud; for heavy sandwich structures, a more reliable fastening will be required.

Installation of a round pipe

Often in construction a circular chimney section is used. To pass a round pipe through the roof and seal it tightly, special flexible adapters are used. They are made from heat-resistant polymer with elastic properties. In appearance, such an adapter looks like a funnel, at the base of which there can be a circle or a square. The base is called an apron, it is made in the form of wide fields. Since the material is elastic, it easily takes on different configurations. Therefore it has a wide range of applications. Such adapters can be used on roofs with any covering and slope angle.

Exit of a round pipe through an ondulin roof Source nashaotdelka.ru

The main thing is to choose an adapter that will match the diameter of the pipe. Although there are universal options for such products. They are made in the form of a stepped pyramid. To adjust their size to the pipe, the excess is simply cut off with scissors. Elastic adapters are attached to the roof using bolts or metal studs. They are installed in holes on the flange, which presses the adapter to the roof. The space between the flange and the roof surface is lubricated with a sealant that can withstand temperature changes.

Universal adapter for passing a round pipe through the roof Source pinterest.it

Insulation of the chimney structure

When installing a chimney on the roof, an insulated chimney has a number of advantages:

- The efficiency of the furnace increases several times.

- The level of safety during operation of the unit becomes higher.

- The stove acquires an aesthetic appearance.

To make three-level waterproofing on a gable roof, you need:

- First, prime the structure with polymer mastic and stick on a superdiffusion membrane, wrapping its edges, which will ensure a sealed joint between the chimney and the roof, even when moisture enters.

- Install metal corners at the top and bottom. The upper metal sheets are laid on the lower ones so that the moisture flows downwards by gravity. Experts recommend laying the bottom tie up to the eaves of the roof.

- Nail additional bars onto the sheathing to secure the corners.

- Treat parts with sealant.

- Secure the resulting structure with dowels.

- Lay ondulin end-to-end, using bitumen mastic to treat the seams.

- Place a special apron made of ceramics, plastic or other materials in a circle on top of the ondulin, using onduflesh to seal.

Features of a sandwich chimney

A type of round pipe is a sandwich chimney. It consists of two pipes of different diameters, between which there is a heat-resistant thermal insulation material. They are made of stainless steel. The sandwich chimney is in great demand because it provides stable draft, does not heat up, is easy to install and looks beautiful in appearance.

The passage through the roof of a sandwich chimney can also be done using an elastic adapter. However, it may not be in harmony with its mirror surface. In this case, a metal adapter is used, the material of which is also stainless steel. It is not flexible, so you must take into account the diameter of the pipe and the angle of the roof slope.

Ondulin surface

Ondulin is otherwise called “Euroslate”. According to its characteristics, it does not have reliability and durability. Therefore, it is necessary to cut a hole in the roofing surface and fill it with heat-resistant material, which, in turn, will prevent the penetration of moisture.

To waterproof the ondulin surface, install an apron or use a flexible tape - Onduflesh. This coating requires additional ventilation.

Passage through metal tiles

Metal tiles are sheets of steel, copper or aluminum, which are coated with a polymer layer. In appearance they resemble natural tiles, which are folded in even rows. This roofing material is very popular. If a round pipe is to be passed through the metal tile, flexible adapters are used, which we have already described. When using a square or rectangular brick pipe, a different method of installation is used. It is as follows:

- The connecting unit is being manufactured. It consists of two aprons - internal (main) and external (decorative). The material of manufacture is thin aluminum sheet or tin.

- Before the metal tiles are laid, an internal apron is installed on the sheathing. These are 4 strips located on 4 sides of the pipe. They simultaneously extend under the metal tile (no less than 250 mm) and onto the pipe (no less than 150 mm).

- The apron elements are installed in a groove - a groove that is cut along the perimeter of the pipe to a depth of 10 to 15 mm. The groove is cleaned and filled with fire-resistant sealant.

To install an apron, you need to make a special groove in the pipe Source experttrub.ru

- The apron is attached to the pipe using heat-resistant dowels. The joints between the four planks are soldered. On the slats that are located on the sides, sides are made, the purpose of which is to drain water down.

- The lower part of the apron is installed on the so-called tie - a sheet of metal with sides. This ensures water drainage from the chimney to the bottom of the roof. The width of the tie should be greater than that of the pipe by at least 0.5 m on both sides. Its length depends on the distance from the pipe to the edge of the roof.

- After installing the tie and interior apron, the metal tiles are laid.

- An external apron is installed on top. It is usually a corrugated sheet of lead or aluminum. There is a decorative strip in its upper part. It is attached to the pipe using self-tapping screws. The attachment point is slightly higher than parts of the inner apron. Before fixing the decorative strips, the fastening points are coated with sealant. To attach the corrugated sheet, its back side is provided with a self-adhesive coating.

Finished chimney pipe passed through a metal tile Source tproekt.com

Parameters for proper operation of the device

A properly installed chimney creates natural draft and removes combustion products through a channel, preventing them from entering the room. Sometimes you can even evaluate the operation of a chimney visually - by the presence of smoke in the room or the color of the flame. Excessive draft is determined by a white flame and a characteristic hum, while a bright orange flame indicates insufficient draft. A special device, an anemometer, will help you take more accurate measurements.

Related article: Construction of an attic roof for a private house

If traction needs to be strengthened, you can use one of the following methods:

- Install the deflector. However, it must be taken into account that deflectors improve traction only in the presence of strong wind.

- Install a special umbrella on the chimney. Using a sensor located under the hood, the umbrella regulates the combustion temperature.

- Increase the height of the pipe.

- Use a turbine nozzle.

Installing a chimney through corrugated sheeting

Corrugated sheeting is a sheet of metal produced by cold rolling and then profiled. Mainly made of steel, but can be made of copper and aluminum. The sheet has ribs of oval, square, trapezoidal or polygonal shape. A special coating is made on top, which gives it anti-corrosion properties. Corrugated sheeting is often used as a roofing material.

To pass the chimney through the roof, in the case of a square or rectangular pipe, a device in the form of two aprons and a tie is used. The method is the same as for a metal roof. Installing round pipes in corrugated sheeting is not recommended, because it is difficult to cut the correct circular section into it. But if you still make a round chimney, the pipe is insulated using a universal elastic adapter.

Accessories for running round pipes Source metalsteel.com.pl

Passage through ondulin

Ondulin looks like regular slate, but its material is completely different. This is compressed cellulose, which is treated with bitumen impregnation. It comes in a variety of colors, is water resistant, but burns quite well. Therefore, when a passage through the roof is organized, maximum attention is paid to filling it with fire-resistant materials. The hole for the pipe in the ondulin is made large. To insulate the junction of the roof and the chimney, an apron is used, which is placed under the roof. In this case, elastic self-adhesive tape “Onduflesh” is used, made of bitumen with an aluminum insert.

Brick pipe passed through ondulin Source seaside-home.ru

Possible installation errors

Errors in the design of smoke exhaust systems can lead to significant problems, including fire. To avoid them, you should focus on the provisions of SNiP and fire safety. The heat generated by the chimney and contact with flammable materials should not be underestimated.

No place

One common mistake is saving space. This approach is especially relevant for installing chimneys in ready-made roofs. It is important to understand that the thermal insulation layer, joints and connections may no longer hold back hot air over time. In this case, its constant impact on nearby materials often leads to ignition.

To prevent such an outcome, observe the recommended distances between structural elements. Also, in preparation for the heating season, all joints and sealing are checked.

Incorrect insulation

Many people use building insulation to protect materials from heat. This reduces the quality of thermal insulation and increases the risk of fire.

The use of mineral wool and expanded clay is considered optimal. Basalt wool is also used. In this matter, it is important to take into account the heating intensity of the chimney pipe and the duration of exposure to high temperatures on the heat-insulating layer.

Failure to comply with maintenance instructions

Heating systems and chimneys are demanding not only for installation, but also for subsequent maintenance. Chimney ducts must be regularly cleaned of soot. Cracks may occur in brickwork, leading to hot air leaks. At the joints of prefabricated structures, the tightness may also be compromised.

It is recommended that systems be inspected at least twice a year, usually before and after the heating season. This also applies to the joints of the roof and chimney. The integrity of the sealant is checked and updated if necessary. They also pay attention to the space under the roof and the serviceability of the chimney under the roof near the rafters and beams.

Installation of a chimney in a soft roof

Soft roofing is a flammable material, so it is important here that there is a gap of 13 to 25 mm between the pipe and the covering. The passage of the chimney through the roof is organized depending on its shape - flat or pitched. The material from which the pipe is made also plays a role. If the roof is flat, consisting of a concrete slab and the pipe is not made of brick, the passage is made as follows:

- Around the pipe at a distance of about 15 cm along the perimeter, everything is removed, right down to the concrete.

- The formwork is being installed.

- Concrete is poured so that a side is formed, the height of which is 15 cm.

- The roofing covering is applied to the walls.

- Where the roofing material connects to the side, a metal strip is installed. Fastening is done using dowels.

- An ebb tide is installed on the side.

If the pipe is brick, there is no concrete side. In this case, roofing material is placed on it and a metal apron is installed on top. A groove is made in the wall of the pipe (depth 1.5 cm), into which the edge of the apron is inserted.

When passing a pipe through a soft roof, many nuances must be taken into account Source teplospec.com

The junction is filled with sealant. In the case of a pitched roof, waterproofing is carried out as on other coverings, that is, using aprons (for square and rectangular pipes), as well as flexible or metal adapters (for round ones).

Fire safety

The wooden rafter system and some layers of the roofing pie (waterproofing, vapor barrier) cannot withstand heat and can ignite or melt. The safety of system elements that are not fire resistant is ensured by installing a special box around the perimeter of the hole in the roof.

Violation of safety rules

The box is mounted from a wooden block; it should be located flush with the sheathing, on the outside of the roof. Along the perimeter of the box, on the outside, the edges of the vapor barrier are fixed - a carpet made of roofing felt or other waterproofing material, as well as the edges of the vapor barrier membrane on the room side, if we are talking about an insulated roof. In both cases, a cross-shaped cut is made in the panel and triangular fragments of material are tucked inside. For fastening, nails with wide heads or staples are used, and sealant or adhesive tape allows you to achieve a tight seal between the materials around the perimeter of the wooden box.

The passage through the roof of the chimney provides for thermal insulation of the chimney with basalt wool or other non-combustible materials. If possible, an air gap of 5–7 cm wide is left between the insulation layer and the chimney itself.

Box insulation with basalt wool

If the installation of a chimney involves the use of a special element - a penetration, when choosing it, first of all, make sure that the element is made of a material that is resistant to temperature changes.

Please note: do not use materials that are not designed to withstand high temperatures, such as pipes and roof penetrations for ventilation ducts.

Installing a chimney in a finished roof

If the chimney is not installed at the construction stage of the house, but in a finished roof, the following is done:

- There is a place for output taking into account the requirements of SNiP. This should be the space between the cross beam and the rafters.

- A box is made of beams, the cross-section of which is equal to the cross-section of the rafters. The box is made such that the width of its sides is 0.5 m greater than the diameter of the pipe.

- A hole is cut in the roof equal to the perimeter of the box. To comply with it, through holes are drilled from the inside in the corners of the box.

- The roofing material is bent outward, a pipe is inserted into the hole and secured.

- The box is sealed with fire-resistant material for thermal insulation.

- The junction of the pipe and the roof is sealed. The flange (adapter) is being installed.

The pipe must be routed only through an adapter Source rinnipool.ru