Traditional brick and stone chimneys are very aesthetically pleasing. Rhythmic texture, contrasting combination of colors, natural materials - all this makes such chimneys the best choice in terms of design. But in terms of practicality, everything is not so smooth - the installation of brick chimney pipes is complicated, they are easily overgrown with soot and are susceptible to the acidic environment that arises inside the chimney channels due to combustion products. Such pipes are also difficult to clean, and their repair can only be a major one.

Therefore, to remove combustion products from gas and solid fuel boilers, sauna stoves and potbelly stoves, they usually use not brick, but much more practical stainless steel chimneys. If you also make a chimney from metal, then this article will help you figure out how to install such a chimney with your own hands.

How should a chimney be installed?

The chimney is an integral part of the heating system and its placement directly depends on the location of the heating device. The best location for the chimney system is inside the building. In such conditions, the chimney is protected from cold air, and the draft is not affected by wind surges, which makes it stable and optimal. It is best to bring the pipe outside under the very ridge of the roof in order to minimize atmospheric influences on the DS.

In the case when the heating operates constantly, for example, a gas boiler, then there is not much difference where the chimney will be placed - indoors or on the facade. And if the heating is not constant, for example, a stove or fireplace, then problems may arise with their operation. The fact is that the chimney does not generate heat and cannot heat itself. This function is assigned to the heating device. The chimney only needs to reliably and safely remove the flue gases that are formed due to the combustion of fuel to the outside.

Let's imagine a situation: the heating device is not functioning, and the chimney runs along the facade of the building. In this case, heated flue gases stop flowing into the smoke channel; they cool and freeze. And no matter what measures are taken to insulate the chimney (shaft equipment, increasing the thermal insulation layer), the temperature inside the chimney will be almost identical to the outside one.

Let's look at a simple example. Imagine a house under construction that already has walls and a roof, windows and doors installed, but no heating. So, no matter how thick and insulated the walls of the building are, the temperature in the room will be the same as outside.

Advantages of a steel chimney pipe

Chimney pipes are made of metal, ceramics and brick. Metal pipes are currently in greatest demand. Of all the varieties of this material, it is recommended to choose steel. Steel pipes for chimneys are coated with special solutions that make the material resistant to all adverse effects of the internal environment of the chimney.

When choosing a pipe, it is necessary to take into account the parameters of the heating devices and the fuel used. The material from which the pipes are made must withstand higher temperatures than the fuel can create.

When using some types of heating devices, chemically active substances are found among the under-oxidized combustion products. They can damage a chimney that is not sufficiently resistant to chemicals. Some unburned particles can ignite, creating sparks. Therefore, the material from which the pipe is made must be fireproof.

This is interesting! When choosing a pipe, you need to pay attention to the melting point of the material from which it is made. The melting point of steel exceeds 1000 0C - the highest possible indicator encountered when operating heating appliances powered by coal.

The advantages of steel pipes are:

- Easy to install. Steel pipes do not require the installation of a special foundation; they do not require complex engineering solutions or special installation tools. You can install them yourself without prior preparation. Due to the plasticity of the material, complex technical structures can be created.

- Light weight. They are easy to transport, you can lift and move them yourself without a team of workers, which also simplifies installation.

- High temperature resistance. Steel products are suitable for appliances operating on any fuel. They do not melt at maximum temperature loads.

- Chemical inertness. Steel does not interact with chemical reagents that can form as under-oxidized combustion products. These substances are not capable of destroying it.

- Corrosion resistance. This advantage applies to pipes that have a special coating and stainless steel. The material itself quickly corrodes. It is worth considering that in addition to the internal environment, the chimney pipe is affected by external unfavorable factors, for example, precipitation. Preference should be given to coated pipes.

- Smooth inner walls. Combustion products settle on the rough surface, turning into soot, which gradually reduces the clearance. This reduces the draft in the chimney. Steel is completely smooth, the risk of soot settling on their surface is minimal.

We recommend reading: Why heating pipes in an apartment make noise or hum, and how to fix it

The danger of a cold chimney

An air lock often forms in a cold chimney - this is a layer of cold air located inside the channel. It is because of this plug that the flue gases cannot escape. As a result, the gases will flow back into the room, and the heating device will not turn on or simply will not melt.

Ilya ManaevTechnical specialist at Schiedel

It is important to know! If, when lighting a fireplace/stove, smoke comes into the room or the gas boiler does not turn on, then it means that the heating device does not have enough draft. This usually happens when the chimney is cold. To correct the situation, you need to warm up the smoke channel. Crumple up some paper and burn it in the firebox or chimney. Due to this, the internal channel of the chimney will warm up and the necessary draft will appear.

Another disadvantage of a cold chimney is the unstable operation of the heating-chimney connection. Thrust changes may occur, which will lead to significant excess fuel consumption. And also, a chimney running along the facade will produce more condensation than a pipe located indoors.

Maintenance of the assembled system

During operation, soot growths may appear on the walls of the sandwich chimney, reducing its cross-sectional area, which can lead to smoke in the room and a fire. Therefore, it is necessary to clean the duct at least twice during the heating season. It is convenient to carry out cleaning through the inspection hatch in the plug; if there is none, you can open the plug completely for these purposes by unfastening the clamp.

The condensate collector also requires regular inspection to ensure timely discharge of accumulated liquid. If the condensate drain is connected to the sewer system, then the condition of the connecting tube must also be examined: clean it if it is clogged and replace it if it fails. To clear a clogged drip line, you can use a thin, strong wire.

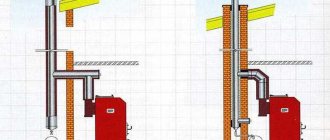

Attachment option

This type of connection of the chimney to the OP is conventionally called an economical option, since the installation of the entire system requires less fasteners when compared with other types of connections. Here the pipe stands and rests directly on the heating device. The connection is simple, but has serious drawbacks. In the mounted version, flue gases are removed by direct flow from the furnace. Because of this, excessive draft is created, which makes the fuel combustion process uneven and also increases its consumption.

Top-mounted chimney connection option

The next problem with a top-mount connection is condensate drainage. During the operation of heating devices, condensate forms, which must be removed from the firebox. Otherwise, condensation or moisture from atmospheric precipitation will fall directly into the firebox, which will lead to a reduction in its service life or destruction. And while a windproof umbrella will protect you from precipitation, there is practically no protection from moisture condensing in the channel.

Another disadvantage of a push-on connection is that it makes cleaning the chimney system more difficult. In this case, to clean the chimney, you need to dismantle the lower elements and securely fasten the upper part of the pipe. Another option is to remove soot from the firebox, if, of course, such a function is provided in the heating device. All this leads to an increase in the cost of cleaning and maintaining the diesel engine.

By condensation or smoke

We must not forget about the main feature of the chimney for a gas boiler: they have high efficiency and a fairly low temperature of the exhaust gases:

Condensation always and quickly forms in the chimneys of a gas boiler.

Therefore, the chimney installation must be done in such a way as to solve the condensation problem. Due to the low temperature of the exhaust gas, chimneys on modern gas boilers are made “through condensate” and not “through smoke”.

VadimProFORUMHOUSE Member

For smoke, this is when the pipe of the lower bend goes inside the pipe of the upper bend, and, accordingly, for condensate - vice versa.

Chimneys for modern gas boilers are collected strictly according to condensate.

This installation method allows condensate to flow calmly down inside the chimney without leaking out (this is dangerous and can cause a fire).

Wall and floor options

These types of connections are similar, except that the weight of the chimney is supported not by the heating device itself, but by fastening elements (console) located on the wall - this is a wall-mounted option. In the floor-standing version, the chimney stands on the floor.

Wall and floor-mounted chimney connection options

This connection option has significant advantages and also simplifies the operation of the chimney system and heating device:

Advantages of wall connection

Design Features

The reliability of the design of lightweight systems is ensured through the use of several layers of modern building materials. The design is called “Chimney Sandwich” in honor of the English sandwich, in which several ingredients are combined in layers. It consists of two pipes made of high-quality steel alloy.

The diameter of the outer pipe is significantly larger than the diameter of the inner one. A layer of thermal insulation material is laid between them, usually non-flammable stone wool. The outer pipe provides protection against damage and mechanical stress. The inner tube can withstand high temperatures. A cushioning layer of mineral wool compensates for the difference in temperature conditions. The thickness of the thermal insulation layer depends on:

- differences in diameters of the inner and outer pipes;

- temperatures during operation;

- the diameter of the stove opening to which the chimney is connected.

Important! Stone wool is a non-flammable material. Therefore, in the event of deformation of the internal steel contour, it will be able to protect against combustion products from entering the chimney.

Sandwich chimney pipes Source i1.wp.com

The principle of assembling a chimney is identical to that of a constructor. You can invite a specialist, but after learning how to make a sandwich pipe for a chimney with your own hands, you can carry out a complex of work yourself. The system consists of parts that are equipped with fasteners for a strong connection with each other. The elements have two types of connections that allow installation using:

- corrugated end elements, which allow easy assembly, but require the use of expensive sealant;

- socket connection, complex due to the need for careful adjustment of parts, but more airtight if installed correctly.

A properly installed sandwich chimney will last 15 years or more. But you need to remember that to prevent soot outbreaks, the system must be cleaned regularly.

Assembling a sandwich chimney with your own hands Source klimatlab.com

Advantages and disadvantages of installing a steel chimney along the facade and indoors

The answer to the question why most people choose a steel chimney is simple:

Let's move on to the pros and cons of installing a chimney system outside and inside the building.

Ilya Manaev

Helpful information! Steel chimney systems are assembled without the use of sealants. All elements have socket connections. The DS parts are inserted into one another and crimped with a clamp. This guarantees tightness and high reliability of the system. Sealing compounds can only be used to connect the chimney and the heating device.

Advantages of installing a chimney on the facade:

- saving space indoors;

- DS cleaning takes place outdoors (no moisture or dirt);

- it is easier to install the chimney to the facade;

- there is no need to violate the integrity of the roof and ceilings.

Disadvantages of a chimney on the facade:

- if the heating device operates irregularly, an air lock may form in the internal chimney channel;

- a pipe running along the facade can reduce the aesthetic component of the building;

- Ice may form if proper condensate drainage is not organized;

- Single-wall chimneys cannot be used; only double-walled insulated steel chimneys are recommended.

Advantages of installing a chimney inside a building:

- optimal traction is created;

- the service life of the chimney is extended when compared with outdoor placement;

- no negative impact of wind loads and precipitation;

- the risk of damage to the chimney by third-party factors is minimized.

Disadvantages of a chimney indoors:

- during installation it is necessary to violate the integrity of the roof and ceilings;

- when the chimney is located in residential premises, cleaning and drainage of condensate is difficult;

- it is difficult to fix the DS to the mounting surface;

- the chimney may not fit into the design of the room.

Video description

How to install a chimney pipe, see the following video:

Connecting a ceramic chimney

Ceramic chimneys themselves are practically eternal, but since this is a rather fragile material, you need to clearly understand how to correctly connect (docking) the metal part of the chimney and the ceramic one.

Docking can only be done in two ways :

- For smoke , a metal pipe is inserted into a ceramic one. It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply rupture the ceramic one.

- For condensate , a metal pipe is placed over a ceramic pipe.

For both methods, specialists use special adapters, which, on one side, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped in a ceramic cord.

The joining should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little by the time it reaches the adapter, which ultimately extends the service life of all materials.

What to look for when installing steel chimney systems

Holes in ceilings, walls and roofs

When the installation parameters of the DS are determined (height, location, type of connection), you need to make holes in the ceiling, wall and roof. When making holes, it is necessary to take into account that the chimney will heat up during operation and this can lead to burns or fire. In this regard, it is necessary to strictly observe the clearances from combustible structures.

Ilya Manaev

It is important to know! Even if the chimney pipe passes through non-combustible structures, small gaps must be left, since the chimney system is a self-supporting independent structure. Its rigid fastening (clamping) to building structures is strictly prohibited!

Before installing the DS and making holes in the building structure, check the fire safety distances specified in the manufacturer's instructions. Russian standards state that the manufacturer of chimney systems must indicate safe distances to combustible structures.

SP 7.13130.2013 Heating, ventilation and air conditioning clause 5.27 The dimensions of grooves and offsets for heat-generating devices and factory-made smoke ducts should be taken in accordance with the technical documentation of the manufacturer.

But today, not every manufacturer can provide such information, and there are even fewer who can confirm it with certificates and test reports. By the presence of these documents, you can distinguish a bona fide chimney manufacturer from those who produce low-quality products.

Fireproof indentations

Requirements for installing a chimney

Installation work is carried out by specialists using all regulatory rules. They are as follows:

- Every heating unit has a single chimney outlet.

- Free and complete exhaust of smoke into the atmosphere is ensured due to the correctly selected height and cross-sectional size of the pipe (clause 5.1.1.VDPO).

- The wall thickness of the metal pipe is not allowed less than 2 mm.

To make a pipe, metal with a thickness of 2 mm or more is taken Source pech-kamin.ru

- To clean smoke channels from soot, recesses with a size of about 250 mm are provided (clause 3.74 of SNiP-91 and clause 5.1.1.VDPO).

- When installing a pipe, the smoke channels are made taking into account no more than three turns, and their rounding is equal to the diameter of the pipe (4.2.17.VDPO).

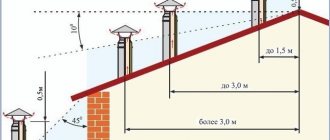

- The chimney for a gas boiler in a private house and the exhaust pipe are installed above the roof ridge in accordance with clause 3.73.SNiP-91: up to 0.5 m - with a flat roof; at the level and above the roof itself - when the pipe is located more than 1.5 meters from the roof ridge.

Metal chimneys are made of high-quality alloy steel with anti-corrosion coating.

Roof connection and passage

The most important task during the installation of the chimney is to make a high-quality and hermetically sealed connection between the roof and the chimney. Errors when connecting and passing roofs are the most common on construction sites. Violation of the technological process at this stage leads to depressurization and leakage of the roof. Correcting these errors will result in additional costs.

Ilya Manaev

Important! Always ask the specialists how they perform the connection; what materials were used and why the craftsmen chose these particular materials; whether they followed the roofing and DS manufacturers' instructions. It wouldn’t hurt to ask the builders for a certificate of hidden work.

Fragment of instructions for joining

It is easier to make a correct joint on a rectangular shape than on a round one. Therefore, it is better to have a chimney located in the shaft pass through the roof. But for steel DS the presence of its own separate shaft is a rather rare case. And in such situations, the connection is made using special metal (preferably stainless or lead) or silicone roof passages (see Figure 6).

Metal and silicone roof penetrations

We hope that everyone understands: the first option is a more reliable, airtight and durable connection between the roof and the chimney. A silicone roof penetration is unlikely to withstand exposure to precipitation and sunlight for more than two to three years. Over time, its material will become softer and, one way or another, will shrink.

The option of making penetrations from steel (or lead for soft types of roofing) will last many times longer, and will also be more convenient during installation and will make it possible to make a more durable and airtight connection between the roof and the chimney.

Ilya Manaev

It is important to know! If the roof has a small slope, then when installing the chimney externally, you can bypass it or move the chimney vertical away from the wall using special elements of the chimney system - bends. (see Figure 7).

Bypassing the roof with bends

Main mistakes when choosing a flue for a gas boiler

The most common mistakes when installing a pipe for a gas boiler in a private house are:

- Incorrectly chosen height and cross-section of the pipe.

- Lack of heat-insulating material when installing an external chimney or in a transition hole into an unheated attic space.

- Failure to comply with fire safety standards (fire safety rules).

- The pipe removing gas from the boiler is led into the brick channel shaft without liner, which leads to the rapid destruction of this hole.

Installation of steel chimneys made of material that does not meet the requirements (resistance to aggressive environments, high temperatures or thin walls).

Which one is better to choose?

When choosing a smoke exhaust duct, you need to focus on the optimal combination of budget, gas boiler power, type of fuel combustion chamber and general design features of the building.

The installation of an external chimney saves internal space and is safer for the residents of the house, but such systems are susceptible to environmental influences, so their service life is shorter.

Types of chimneys depending on the type of gas combustion chamber:

- Open chamber boilers

Floor-standing gas boilers are often made with an open firebox. Such devices require a chimney that provides consistently good draft. Brick, ceramic, single and sandwich pipe chimneys are suitable. But it should be remembered that a brick chimney is hygroscopic and difficult to install, while a ceramic chimney is very heavy.

- Boilers with a closed combustion chamber

In this case, most craftsmen recommend installing a coaxial chimney, or a system of sandwich pipes, tees and fittings.

Expert advice

Before purchasing the necessary materials for arranging an external chimney, the power of the equipment is determined. It affects the diameter of the pipes. You can also use these expert tips:

- if the heating equipment is equipped with forced draft, then it is not necessary to increase the vertical section of the structure; it is enough to remove the horizontal pipe;

- a horizontal section that is too long helps slow down the smoke flow (the value should not exceed 1-1.5 m);

Rules for installing chimney pipes Source krovgid.com

Inspection openings are installed not only on the outer part of the structure, but also on the internal horizontal element.

Required Tools

After carrying out all the necessary calculations and deciding how to make a chimney pipe yourself, you need to prepare all the required elements. In addition to the list of parts of the sandwich system itself, you need to have on hand a list of the following items:

- clamps for tightening;

- support brackets;

- necessary hardware fasteners;

- heat-resistant sealant;

- grinder, metal scissors;

- spatula for sealant;

- roulette;

- square;

- screwdriver;

- drill and hammer;

- building level.

You also need a marker or construction pencil for marking. When assembling, the joints of the parts must be secured with clamps. The entire resulting structure is fixed vertically along the wall using brackets in increments of 1.5 to 2 meters.

Principle of operation

The operating principle of any chimney is based on a simple law of physics - warm air and vapors are always lighter and tend to rise, while cold air is heavier and, accordingly, settles below.

Due to the difference in temperature between the street (outside the pipe) and hot gases (inside the system), draft appears. Thanks to it, combustion products do not disperse throughout the room, but escape into the atmosphere.