The well often does not fit into the landscape design of the site. Therefore, improving its appearance is an important matter. At the same time, it should still be convenient to use. Therefore, you need to pay attention to the design of the gate and the strength of the cover over the well. The latter is especially important if the dacha is often visited by children.

Let's think about how you can harmoniously fit a well into the design of your territory.

Source: www.remontbp.com

The need for houses over a well

Firstly, it is needed to protect the water from dirt. In the absence of a tight-fitting lid, various debris gets into the well. Water from such a source is allowed to be used only for technical purposes, for example, for irrigation. The canopy will ensure timely removal of precipitation and melt water, which contains impurities.

In addition, a well house is a way to ensure the safety of children and pets. For this purpose, the structure is equipped with locks and latches. To facilitate the process of collecting water, gates and racks are installed. The simplest version of such a device is a rotating log with a handle. This “duet” is complemented with a chain.

The appearance of a building is as important as its design. It must match the landscape design. An added bonus of a well house is its ease of maintenance.

Set for work

- Woodworking Machine. This device will allow you to process wooden blanks as quickly and efficiently as possible. If you don't have access to a woodworking machine, at least have an electric plane ready.

- Circular Saw.

- Electric jigsaw.

- Hacksaw.

- Nail puller.

- Phillips screwdriver.

- Hammer.

- Pencil.

- Building level.

- Roulette.

- Edged board.

- Beam.

- Fastening elements.

- Roofing material. Choose at your own discretion. The main thing is that the support can properly withstand the weight of the finish, and that the roof itself is in harmony with the surrounding space. For example, slate, roofing felt, and metal tiles are suitable.

- Door.

- Door latch.

- Pen.

- Loops.

Prices for popular models of jigsaws

Jigsaw

Types of houses for wells, their pros and cons

All decorative buildings can be divided into two categories: open and closed. The former are considered easier to manufacture. They can have a pitched or gable roof. The advantages of such structures include a minimum amount of building materials, while the disadvantages are the inability to use them in winter.

To ensure a regular supply of water after the onset of cold weather, you must:

- insulate the building with expanded polystyrene;

- cover the lid and rings with several layers of wood.

The closed well house has more impressive dimensions; it is a real house with a door. The advantage of this design is good thermal insulation. The downside is that construction is more expensive in terms of price and time.

Support nodes

There are 3 types of support nodes. Each of them has features that affect the performance characteristics of the mechanism.

Through-hole mounting

Gate diagram for a well.

Holes of a smaller diameter than the cross-section of the metal axis are drilled in the support posts. Another option: grooves are cut to install axial elements. To ensure the reliability of the structure during rotation, wooden strips or metal blanks are stuffed on top.

The advantage of this option is the speed of production; there is no need to adhere to exact dimensions.

The contact points between wood and metal elements must be lubricated regularly, otherwise creaking will occur when the support unit rubs against the axle.

Due to prolonged use without lubrication, the wood wears out, lateral vibrations appear, and rotation becomes difficult.

With timely maintenance, smooth movement is ensured and the holes are not deformed.

Caprolon bushings

Installation in this case is more complicated: you need to choose the correct hole diameter and maintain alignment. The use of metal elements is impractical; they are susceptible to corrosion and require lubrication.

Caprolon bushings made of polymer material have a number of advantages:

- Do not rust or deform when exposed to a slightly acidic environment.

- They do not require lubrication and operate silently.

- They have a low coefficient of friction, making the material wear-resistant and durable. The characteristics are not affected by the abrasiveness of the axes.

- Do not deform due to temperature changes.

First, washers with a diameter equal to the cross-section of the axle are made. They are inserted into the holes on the racks, then the axles are installed.

Caprolon bushing.

Bearings

The presence of bearings complicates the design; installation requires high precision. If installed incorrectly, beating occurs and the mechanism becomes inconvenient to use. All types of bearings can be used except thrust bearings. The case ones are easy to install: the unit is bolted through holes in the case. Other options require equipping the well posts with hubs.

This version of the unit is the most expensive, but effective: rotation of the axial element does not require much physical effort. However, the bearings should be protected from moisture and lubricated periodically. Bearings with seals are less susceptible to external influences.

Ideas for houses for a well, materials, drawings, production

There are various forms of houses, let's look at the most popular ones.

Option 1: Open visor

This option consists of a simple metal or wooden canopy on two posts. To which the gate is attached.

Option 2: Gable house

First, a drawing is made based on the well ring. The diagram must display all elements taking into account their dimensions. The more accurate the drawing, the lower the likelihood of errors when creating a structure.

They purchase building materials and prepare tools. The list of the latter includes:

- electric plane;

- roulette;

- jigsaw;

- hammer;

- circular saw;

- Phillips screwdriver;

- hacksaw;

- nail puller;

- building level.

To create a well house with a gable roof, you will need the following materials:

- wooden beam (sizes 50x50, 50x100)

- log for the gate;

- boards and door fittings;

- edged boards;

- screws and nails;

- roofing felt or slate.

Don't forget to purchase an antiseptic. It is necessary for processing wooden parts. They must be sanded beforehand.

After everything is prepared, you need to follow the step-by-step assembly algorithm.

It includes several stages:

- Clear the area around the well, level, pour and compact crushed stone, first larger, then smaller (15-20 cm thick).

- Construction of the frame. The base is made from timber (section 50x100 mm). The perimeter of the future structure should be larger than the diameter of the well ring. Attach two support posts with the same cross-section to the frame with metal plates and connect them with a block (50x50 mm). Attach to the sides using 4 posts (50x50 mm), cut them at an angle of 45 degrees for a better fit.

- For strapping, use an edged board (width 12 cm, thickness 4 cm). The next step is to fill the resulting gaps with boards. Leave the side where the door will be located unchanged.

- Making gates. To do this, sand a round beam with a diameter of 20 cm and a width of 4-5 cm less than the gap between the vertical posts. Make holes in it on both sides with a diameter of 2 cm and a depth of 5 cm. The same, but through, drill in the racks and insert metal bushings there. Hang the beam on steel rods with a diameter of 24 mm. Bend the left one at a right angle, leave the right one in the same form. This will make it convenient to collect water. To prevent the gate from deforming, use metal wire. Attach a chain from which the water container will hang.

- Install the assembled system onto the frame. Attach the jibs (they act as amplifiers), install the sheathing, and lay the roofing material. The latter can be replaced with slate.

- Installation of door leaf. To make it you will need boards (20 cm wide) and screws. Secure the resulting canvas with beams (25x30 mm). All that remains is to mount the fittings and hang the finished door.

- Decorate the house as you wish.

Well gate design

The device has the shape of a cylinder mounted on a metal axis. The support unit can be made in the form of rods fixed and rotating on racks. When rotating around an axis, a chain with a water container is wound. A cable or rope can be used.

The technical characteristics are affected by the following features:

- The length of the handle determines the force required to lift the water. The larger the radius of rotation, the less effort required.

- Gate diameter. The wider the drum, the fewer revolutions you need to make to lift the mechanism.

The well gate is made of thick logs. The role of support is played by 2 racks with recesses and elements for fixation. Metal structures are assembled from a thin pipe, a cylinder and wheels for rotation.

Option 3: log house

Its construction will not take much time.

In order to end up with a neat and multifunctional structure, you need to follow the following instructions:

- Install the racks, remembering to secure them with supports.

- Fold the frame using rounded timber (diameter 10 cm). Collecting them crosswise. The 4 bottom ones will be the same, and then with an equal decrease (like a nesting doll).

- Make a gate (see above).

- The final stage of construction is the installation of the roof, its sheathing and covering.

Variations of the structure

The protective structure can be open or closed. In the first case, the likelihood of water freezing in severe frosts increases significantly. Insulating the well ring with an expanded polystyrene foam coat followed by decorative finishing will help save the situation. A closed type design is more practical from the point of view of frost protection. The air layer itself retains heat, and in combination with thermal insulation material it copes perfectly with the functions assigned to it.

The choice of materials when making a house for a well is based on the general architectural concept of the suburban area. If the main structure is a wooden frame, it would be logical to use logs to finish the well ring and boards for the roof. If the exterior of the house contains elements of brick or stone, the corresponding material is used when assembling the structure for the well with your own hands. The top is sheathed with material identical to the roofing of the main building. The proposed design is not an unshakable postulate and is relevant if the house is located within sight of the main building. A well located further away allows you to expand the boundaries of the choice of finishing for the house.

Comment! A wooden house, especially with carving elements, is incredibly attractive, but requires regular maintenance. Otherwise, the appearance will quickly lose its former luster. Siding mounted on a metal profile frame is much easier to maintain.

Another example of a drawing with dimensions will help you navigate the choice of configuration:

Option 4: sheet metal house

Construction costs depend on the complexity of the structure. A well house made of metal sheets will fit well into any landscape design. The structure can have an octagonal, hexagonal or triangular shape.

In addition to sheet metal and corrugated board, you will need profiles, metal rods, a lock and door hinges. The procedure is not complicated:

- Prepare your work surface.

- Make a frame by soldering metal rods. Don't forget to leave room for the door.

- Assemble the roof.

- Weld it to the base.

- Place the structure in its proper place.

- Hang the door.

- Cover the building with a protective compound.

Finishing

If concrete rings were used during the construction of the well, then they must be decorated somehow. Some types of closed well houses can be considered as a modernized version of the superstructure structure.

The construction sequence does not play a special role, but it is still better to start with the arrangement of the well itself, and then, taking into account the thickness and dimensions of the lining, mount the upper part (closed or open).

Natural stone

If there is access to the surface of natural stone nearby, then it can be used to finish the well. As an alternative, there is another option of using granite paving stones.

The sequence of operations is as follows:

- Around the well, part of the soil (more precisely, backfill) is removed to a depth of about 30 cm.

- The bottom is compacted, a cushion of sand and fine crushed stone is filled in (for sandy soils, only crushed stone can be used). Water it with water and compact it.

- Lay out the first layer of stones, connecting them together with cement-sand mortar.

- Lay out all subsequent layers to the edge of the upper ring, filling the seams between the stones with mortar. The sinuses between the finishing and the concrete rings are also clogged with the solution.

- Level the upper part of the masonry with the mortar to the same level as the concrete ring of the well head.

- If the part of the house being built on is made of wood, then a layer of rolled waterproofing must be laid between the concrete and the frame.

Log house made of logs or timber

This option is used when it is necessary to build a well in Russian rustic style using standard concrete rings. The beginning of construction proceeds in exactly the same way as in the previous method - the site is prepared and the base is formed in the form of a strip of stone so that the tree does not lie on the ground. You can also install a small columnar foundation at each corner, which is then hidden with a blind area.

The corner connection of the crowns is usually made in the simplest way - in half a tree. When arranging a log house, you must ensure that the wood does not touch the concrete walls. It is best if the rings are covered with rolled waterproofing.

Note. The “incompatibility” of concrete and wood is taken into account in any structures where they are located nearby.

Sheathing on frame

This is one of the most common modern methods. A beam or any metal profile can be used as a frame, including the one used for installing drywall.

Note. Of course, the anti-vandal properties of Knauf profiles and their analogues are lower than those of conventional angles or channels with a wall thickness of 3 mm, but the strength of the structure assembled with the cladding will be quite acceptable.

Any façade panels are used as frame cladding. But if you choose vinyl siding, then a basement option with a thicker and more durable wall is better suited for the well.

dizlandshafta

Photo

Decor of well houses

Decorating a well house

Unusual design of a house for a well

Well at the dacha

Canopy house

Choosing a place

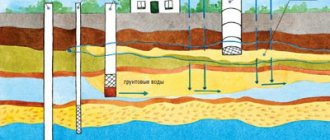

Some summer residents believe that water deposits are everywhere. To do this, it is enough to make a deep hole, which after time will fill with water. Actually this is not true. To construct a concrete well, it is necessary to accurately determine the location of ground sources.

To detect a water layer, it is necessary to use the dowsing method. To do this you will need aluminum rods with curved ends. They are inserted into a special hollow tube. With such a design, it is necessary to explore every meter of the territory.

In places where groundwater occurs, the rods begin to connect with each other. To confirm the information received, it is recommended to re-examine this area.

During the search process, you need to pay attention to vegetation. If it is distinguished by lush greenery, then its roots are located near groundwater.

How to make drainage on a site - the secrets of a master on how to make drainage to drain water yourself!- How to clean a pond: a detailed description of how to clean a pond quickly and easily with your own hands (130 photos + video)

Decorate the site according to Feng Shui: location features, design elements, Feng Shui zones. How to work with a ba gua diagram? Secrets of garden decoration

Before drilling, a test study is carried out. A garden drill is used for this. A depression of 10 m is made in the thickness of the earth. If the presence of liquid is not observed, the drill is further deepened.

Experienced specialists recommend carrying out geological exploration. It will allow you to accurately determine the location of groundwater in the garden area. The only drawback of this procedure is its high cost.

Assembly

After installing the well posts and making holes in them for the axles or fixing the bushings with bearings, you can begin assembling the gate. This is done in the following sequence:

- Rods are inserted into the ends of the log. Metal discs are put on them. They are welded to the rods. If the deck is installed in holes in the racks, and not in recesses, then only a short rod is welded. The long rod remains not bent under the handle and not welded. When laying in recesses, both rods can be welded at once.

- Metal clamps are put on the cylindrical part.

Important: the clamps are put on before any fasteners are screwed in or nails are driven into the wooden deck. This will help protect the log from cracking.

- After this, the end discs can be screwed on.

- A cable or chain is attached to the center of the gate. To do this, a metal bracket is driven into the log.

- Now the entire structure can be installed on support decks with your own hands. When installing into holes, the end part with the welded rod is inserted first. Then a long rod is pushed through the second hole and inserted into the disk and groove on the cylinder. Now the disk can be welded to the second rod. After this, you can bend the long rod into an “L” shape to create a handle.

- A bucket is attached to a chain or cable.

Head drawing

Well house diagram

When creating a well house diagram, you should definitely measure the diameter of your well, as well as the area of space that can be occupied. In the drawing, indicate the following elements:

- base and gables,

- rack with skate,

- gate with cladding,

- roof slopes.

What the effective outcome will be depends to a large extent on the development of your imagination and acquired skills in construction.

If you do not have the opportunity to think through and draw a drawing, then use the variations presented in construction literature or on the Internet.

So, first you should prepare the site for the construction of the head. Of course, it is best to fill it with concrete, but if you fill it with crushed stone, that will also be good. In this case, you should compact it well. Another way to prepare the site is to lay paving slabs. The shape or color of the tiles must match the parameters of the sidewalk paths laid out on your site near the house.

Step-by-step instruction

Making a high-quality house structure requires a careful approach. To do this you need:

- make a drawing of the house for the well with exact dimensions;

- choose the right material that will fully meet the desired characteristics;

- select a working tool according to the selected materials;

- carry out preparatory work, manufacture all the parts and assemble them into a single structure.

Perform antifungal and anti-corrosion treatment.