This summer I installed plumbing at my dacha. As usual, in order to save money and not buy new parts in stores, you always try to find everything you need in the junk lying around in the barn - old fittings, taps, pipes.

I found several gas taps brought from my old hardware store. I saw that their size was the same as that of water taps - ½ inch.

I thought that, in theory, a gas tap should be more reliable than a water tap and they can be used when installing a water supply system. It’s good that I decided to google first what professionals write about this.

This story was sent by our subscriber Mikhail T.

Design and features of a ball valve for gas

Ball valve for gas

The valve for domestic gas can be used for internal systems and for external lines; elements with a diameter from 2 to 12 inches are most often used. Ball mechanisms are necessary to completely shut off or open the gas flow; their main feature is the locking structure. It has the shape of a ball with a special through hole that corresponds to the diameter of the pipeline. If it is necessary to shut off the fuel supply, turn the valve 90 degrees so that it is located perpendicular to the pipe.

The process of controlling the part is carried out using a lever supplemented with sealed rings. Ball valves have many advantages, including good tightness and high insulating properties. Modern cranes are lightweight due to the use of special metals and alloys, are highly reliable and can be operated for 10 years without malfunctions.

Modern locking mechanism

A simple design guarantees unique performance qualities. Its features include:

- The lock is made in a spherical shape, which determines the main performance qualities.

- The spherical lock has a special hole through which gas passes. Corrosion-resistant materials are used in the manufacture of the sphere. Therefore, it serves for many years.

- Adjustment of the throughput is ensured due to the possibility of rotating the locking mechanism around its axis. Place the lock perpendicular to the pipeline.

The above information determines that the device has only one moving element and high performance.

Ball valve prototypes

The plug tap was known to the ancient Egyptians. Simple and reliable, these devices are still used today. Let us recall the most famous options for their use:

- Samovar. The same one with which tea was always poured from samovars, both the most ancient and modern electric ones.

- Bath. KrB is still used in the washing departments of public baths, for which it received its official name.

- Gas. Familiar to everyone who uses a gas stove, water heater or heating boiler that runs on natural gas.

How does a plug valve work?

The simplest device is the samovar version. There are two components: a body and a cone - a plug with a rectangular cutout and a non-removable handle. The body follows the shape of the cork and has the same internal dimensions. By turning the plug 90 degrees, the slot of the plug is installed along the axis of the product, opening the passage for water. The flow is blocked by turning the plug 90 degrees in the opposite direction. The position of the permanent handle indicates the position “Open” if it is parallel to the axis of the “spout”, and “closed” if the handle becomes perpendicular to the axis of the shut-off valve. In this part, cork and ball devices are very similar. The difference is in the locking organ: a cone in a cork device, and a sphere in a ball device. The difference is visible when it comes to the seal between the locking device and the body of the product.

To prevent leaks, plugs made of soft brass or copper were ground to the housings until the gap was completely eliminated, by repeatedly turning them into place. Gas and bath models are more complex because they operate under pressure, and in the case of the gas version, the slightest leak of the working medium will cause an explosion and fire. These models have a closed bottom, an oil seal with a threaded lid. With ball locking devices, rubbing will not help. Spherical polymer seals are used here.

Characteristics

The main technical characteristics are the following product parameters:

- nominal diameter - from 15 to 50 mm;

- maximum operating pressure - from 10 to 16 atm.;

- type of connection to pipelines - coupling, flange, welded or combined (one of the pipes is welded);

- thread type - internal or external;

- type of control of the locking element - handle - butterfly or lever;

- material of body parts;

- operating temperature range - from -20ºС to 150ºС (depending on the material used to manufacture the device);

- seal tightness class.

The main dimensions of products can be determined from the table:

Types of gas taps

Ball valve device

There are various ball valves for domestic gas, differing from each other in design and appearance. All products consist of a standard set of parts:

- body part made of steel, brass or nickel;

- a section for connecting a pipe;

- neck part for the rod;

- a connecting rod that provides connection between the moving mechanism and the handle;

- shut-off ball to shut off gas.

Additionally, the ball is reinforced with a special seat that prevents it from moving, and is held in it with a ring. The seal, flange and springs are responsible for the tightness and connection of parts of the entire structure.

The main part of the device is the handle, which controls the locking mechanism. It is fixed in one place with a strong nut and is complemented by a stopper that limits its movement.

Ball

Internal structure of a ball valve

Faucets for apartments, houses, offices and businesses can be made of brass or nickel. Elements of the first type have good sealing properties, do not cause difficulties during operation and are suitable for water pipes. Their nickel analogues can be full bore or reduced bore, taking into account the throughput. The most common are valves with external and internal threads, welded, flanged and threaded types.

Corner

The corner gas valve is equipped with inlet and outlet pipes located at an angle of 90 degrees towards each other. This structure allows the element to be used when installing units in hard-to-reach places, as well as in areas where bending of the main line is required.

Threaded

Threaded or coupling parts have a small diameter; they are most often used for domestic gas pipelines. They are connected to the pipeline using a threaded connection, from which they get their name.

Flanged

Flange valves are designed for external gas pipelines with a large diameter. The connection in them is carried out using the flange method using bolts. Such elements are dismountable, which makes it possible to dismantle them and then reinstall them in other areas.

Welded

Elements with a welded structure are also used for external gas pipelines; the diameter of such valves ranges from 10-70 mm. They are connected to the pipes by welding, so in the future these installation areas will not be dismountable. The list of advantages of the elements includes optimal tightness and a high level of reliability; in addition, welded fittings do not require additional maintenance.

Threaded

Welded

Flanged

Angular

Fastening methods

Based on the fixation technique, ball valves are classified into the following types.

- Coupling (threaded). The threaded type mechanism is usually used in private water supply systems of small diameter (no more than 65 millimeters), for gas and for heating systems or liquid media. The sleeve valve is distinguished by its ease of installation. To install the device, given that the pipes are threaded in advance, there is no need for specialized tools or highly qualified specialists.

- Flanged. Devices mounted using specialized elements (flanges) are mainly used for installation on industrial pipelines with a diameter of 50 millimeters or more. Such a device is more durable and sealed.

- Welded. Mounted on metal water pipes by welding. The fixation of such a valve is the most reliable, however, installation of the device requires certain qualifications. For the most part, welded valves are installed on industrial gas pipelines where high sealing is required.

- Combined. They are connected to pipes using various methods. Products of this type are endowed with multifunctionality and are used in a variety of communication systems with the following connections: flange connection plus welding, threaded connection plus welding, and others.

- We have already mentioned a pair of gas keys

. Precisely a pair - because in most apartments of the old building, the supply to the stove is made of rigid pipes; To unscrew the locknut and coupling, you need to hold the drive in a stationary position, not allowing it to turn the valve.- To seal gas threads, FUM tape or synthetic thread with Tangit Unilok sealant can be used. Linen with paint is also suitable, however, the paint is applied to and winding for a relatively long time, and in our case, seconds will count.

- When repairing a tap, a special graphite lubricant for gas taps or regular grease can be used. The graphite base is more practical: it retains its properties longer.

- In addition, when repairing the valve, you will need a 1/2-inch female plug and a flathead screwdriver.

Types of ball gas valves

In addition to the fact that the shut-off valves under consideration differ in diameter, the differences lie in the installation method. The following types of devices are used much more often in gas pipelines:

| Threaded (coupled) | They have a small diameter. In most cases, these products are used in domestic gas pipelines. The connection to the pipeline, as you might guess from the name, is made using a threaded connection. |

| Flanged | They are used in external gas pipelines of enormous diameter. The connection is made using the flange method using bolts. Like threaded ones, these devices are collapsible, i.e. they can be dismantled and then reinstalled. |

| Welded | Like flanged ones, they are used for external gas pipelines. Their diameter can range from 10 to 70 millimeters. The connection to the pipeline is carried out by welding. Accordingly, this installation option is non-removable. The advantages of such products include complete tightness and high reliability. In addition, welded shut-off valves do not require maintenance, i.e. tightening flange connections. |

Advice! In addition to ball valves, there are also plug valves. However, they are less reliable and durable, which is why they have recently been used very rarely.

Conclusion

Currently, gas ball valves are widely used in domestic and industrial gas pipelines. This is due to the fact that they are reliable and durable. The only thing is, when choosing which gas tap is better, you should give preference to more expensive devices from well-known manufacturers, since cheap products may not meet the required quality.

You can get some additional information on this topic from the video in this article.

Did you like the article? Subscribe to our Yandex.Zen channel

Differences from plumbing fittings

Water tap painted red

The gas valve differs from the water tap in the appearance of the lever, which is yellow instead of red, as well as in a number of design features:

- long connecting thread;

- more durable housing and locking mechanism;

- ability to withstand high pressure;

- the presence of strong and sealed rings.

Despite the fact that a standard gas faucet is more expensive, it cannot be replaced with water fittings, since such savings may lead to the replacement of the main elements of the system as a result of an accident.

Expert advice

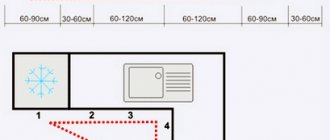

- If the design of the system involves placing a tap and an angle nearby, then it is better to replace them with this type of fittings. This solution will save money and simplify the installation process.

- The model should be selected depending on the location of the pipeline. There are products designed for installation only on vertical risers and on horizontal sections.

- It is advisable to add an end valve to the irrigation hose with a device designed to concentrate or disperse the flow of liquid. The product will be more efficient in operation.

- Devices with a thermal head should not be covered with furniture or finishing materials and should not be exposed to direct sunlight.

Features of application

In most cases, ball valves are installed in places where gas equipment is used, for example, in the kitchen, and a separate valve is needed for each source of fuel consumption. Shut-off valves can be used to shut off and control flow, for example, a three-way valve makes it possible to direct flow from one pipeline to the next.

The tap for a standard gas pipe in the kitchen must match the features of the system and the type of equipment. Most often, threaded elements are installed in such rooms, which do not cause problems during installation and throughout the entire service life.

Types of water ball valves

Manufacturers offer a wide variety of shut-off, control and mixing valves.

According to the body configuration, locking products are divided into:

- straight;

- corner;

- tees.

Direct ones are the most popular for home use. Angular ones are installed in places where the direction of flow should be changed and its regulation should be provided. This need for plumbing arises when connecting a dishwasher or washing machine. In heating systems when connecting a radiator to the inlet pipe. Tees are installed in a place where it is necessary to cut off one of the flows or redirect the flow.

Based on the type of housing there are:

- with a solid body - they cannot be repaired if broken;

- with a collapsible body - repairable.

For home plumbing, unless the owner is a professional plumber, purchase solid taps. They are cheaper. If they break, they are replaced.

We recommend that you read: Vacuum valve for sewage systems

Products with a moving ball are limited to a diameter of 20 mm. The ball in the locking mechanism is able to move freely. This provides additional sealing, since the ball presses the flow itself against the gasket material.

Based on cross-country ability, ball valves are divided into:

- Full bore - capacity corresponds to the pipeline.

- Reduced - the throughput is reduced due to the smaller diameter of the hole in the locking mechanism. Such taps are placed on heating lines under pressure to mitigate water hammer.

According to the method of connection to the pipe, they are distinguished:

- Threaded. The thread can be the same on both sides (external, internal). Or different, when on one side it is external and on the other internal.

- Combined - on one side there is a thread (any), on the other there is a fitting.

- Designed for welded joints. These are rarely used in the home plumbing system.

- Flanged - have flanges at the ends and are a main version of the locking device.

In individual water supply systems, the first and second types of ball valves are mainly used. The threaded connection is easy to install and can be quickly disassembled if necessary.

According to their performance characteristics, ball valves are distinguished:

- low and high temperature;

- for operation under different pressures, from 16 to 40 atm.

Manufacturers offer a wide selection of ball valve sizes, from standard ½ inch to 200 mm valves.

Based on the material of the case, they are distinguished:

- steel;

- brass;

- polymer - made of unplasticized polyvinyl chloride.

Brass ones are the most expensive, but also the most reliable. Their service life is longer than that of steel (they do not corrode in an aquatic environment). There are no restrictions on the scope of use like plastic ones.

Steel ones are rarely used when installing home communications. Their main area of use is industry.

Polymer ball valves are widely used in the installation of individual water supply systems. Manufacturers offer a range of sizes from 20 mm to 63 mm. The service life of polymer ball valves is guaranteed for 15 years. They are not subject to corrosion. They have a reliable locking mechanism with a floating ball. The push-in connection allows the unit to be dismountable.

We recommend that you read: How to properly secure a sewer pipe to a wall - types of fasteners and installation methods

Note! The area of application of polymer taps is limited to cold water supply. PVC shut-off devices are not intended for use at high temperatures.

Choice

The structure of the ball fittings must be selected in accordance with the parameters of the pipeline and the work being performed. Ball devices for structures transporting liquid and gaseous substances are sold by all companies that supply pipes. Among the entire mass of manufacturers, companies such as Rehau, Valtec, Lavita and AS Gruppe can be distinguished. The products of these companies have been on the market for a long time, they have been tested in practice by a huge number of users and do not raise questions regarding quality. One of the main differences between high-quality devices and their unreliable prototypes is the metal from which the case is made. When choosing a ball valve, first of all, pay attention to the shell of the device - it should be made of leaded brass brand CW617N. Inexpensive Chinese products are often made from recycled brass, which may contain additives that are hazardous to humans. You should not ignore this circumstance and, if necessary, ask the seller for a hygiene certificate and a sanitary-epidemiological certificate for the product.

It is also necessary to focus on shut-off and control valves, since in order to reduce the cost of goods, brass is often replaced with ordinary iron, which rusts over time. During operation of such a product, due to corrosion of the locking mechanism, the sealing of the valve may be broken, which will lead to a break in the water supply system.

When choosing a ball valve, it is better to inspect the surface of the valve ball. The sphere should shine like a mirror and be impeccably glossy (the surface of the ball is processed using diamond grinding). All of the above indicates the high quality of the device. If the surface of the shutter ball has a dull shine, a matte coating, or even has roughness, then this indicates that this is a counterfeit. This will affect the throughput of the device in the open state, and specific noise will occur when the liquid medium moves. By the way, even if the locking assembly looks excellent externally, it can be additionally checked using a magnet. If it “sticks” to the sphere, then the ball is made of steel designed for use in electrical engineering. Such material quickly becomes covered with rust and does not withstand long-term use in a humid environment. The magnet is not attracted to brass. In valves for water supply systems, the control lever is always red or black, in devices for gas pipelines it is yellow. If the pipeline system is stretched in conditions of insufficient space, it is advisable to purchase a modification with a small “butterfly” handle.

Features of replacing a gas valve

Ball valves of any type are not immune to breakdowns, so if a fault is detected, the element must be urgently replaced. It is better to entrust this work to gas service specialists. A new tap is purchased based on the diameter of the gas pipeline, which must correspond exactly to it.

Before the expert arrives, you need to light the gas on the stove and close the valve, directing the burner and waiting for it to completely extinguish to allow the remaining fuel to exit the gas pipeline. After completing the work, the specialist must definitely test the shut-off valves for leaks and enter information about replacing the element in the technical passport.

Features of replacing a gas tap

Of course, every shut-off valve can fail; for example, gas taps are not insured against failure. If a malfunction of this device is detected, it must be replaced immediately.

Let us immediately declare that doing this work with your own hands is not allowed! But, some actions will still need to be performed independently.

So, the instructions for replacing this shut-off valve are as follows:

- First of all, it is necessary to tell about the problem to experts from gas work or a personal organization that holds a license to perform similar work.

- After this, you need to purchase a new faucet from a specialized store. You must first measure the diameter of the pipeline so as not to make a mistake when choosing a product.

- When the experts arrive, prepare a technical passport and a gas supply contract. A technical passport is needed to make notes on the work performed.

- After this, you need to light the gas on the stove and turn off the central valve. Leave the burner until it completely extinguishes, so that all the gas leaves the pipeline.

- Upon arrival of experts, it is necessary to open a couple of windows in order to create a draft in the room. This is necessary in case of a gas leak.

- Upon completion of the work, work together with experts to diagnose the installed shut-off valves for leaks.

- At the end of the work, it is necessary to give the workers a technical passport and ask them to make a note in that direction.

Advice! It is possible to identify a gas leak using soap foam. It must be applied to the connection points between the device and the pipeline, and to the valve itself. If a soap ball forms in some place, it means that the shut-off valve is letting gas through.

Upon completion of work, leave the windows open for another 15-30 minutes, which will ensure complete ventilation of the room.

Operating rules

A dielectric coupling is necessary to reduce the impact of stray currents

In order for the ball valve for domestic gas to last as long as possible, standard recommendations must be followed during its maintenance. The element is designed to quickly shut off the gas flow inside the pipeline. It can only be opened and closed using the factory handle; it is prohibited to use any tools for this purpose.

The design of the valve itself is not intended for flow control; the element has only two operating positions: open and closed. If it is half-open, the rapid flow of pumped fuel can cause deformation of the sealing rings, as a result of which the valve will quickly become unusable and will have to be replaced. The element must not be used in environments with contaminants that could cause mechanical damage to the gaskets. Sometimes the fastenings of the rotary handles become loose, in such cases it is necessary to tighten the screws securing them. If there are leaks in the stuffing box seals of the rods, adjust the nuts located under the valve handles.

According to instructions from crane manufacturers, any repair work, including replacement of the device, is prohibited from being carried out independently without the necessary skills.

Purpose

The definition of “ball valve” is equally applicable to a water tap and a valve. These two types of cranes are distinguished by location and purpose. The water tap is the end point of the water supply; the valve is installed between the elements of the water supply.

Ball valves for water supply are designed to completely shut off the main line or to regulate the flow. In shut-off valves, the design provides for two operating positions “closed” and “open”, excluding intermediate ones. To reduce the water supply, redirect the flow or mix two flows, ball valves of a different design are used, which are specially designed for these purposes.

Note! Operating a shut-off ball valve in a half-closed position will lead to its rapid failure.

A ball stop valve is installed on water pipes:

- for each branch of wiring to household appliances (water heater, washing machine, dishwasher);

- for each water supply line leading to the sink, bathtub, shower;

- for an individual outlet from the main water supply line (for introducing a water supply system into an apartment or house).

The installation scheme of an internal water supply system with the installation of a shut-off device on each section of the distribution somewhat increases the cost and complicates the installation of communications, but in the long term it is more profitable. In the event of a pipe break or failure of any household appliance, a ball valve allows you to quickly shut off the water supply to the problem area. At the same time, residents still have the opportunity to use running water.

A water-folding ball valve is installed separately for cold or hot water, and is also a common type of mixer. A ball mixer is a valve that is opened and closed not by rotating a knob, but by a lever, turning it left and right to adjust the temperature and up and down to control the flow force.

Note! A regulating ball valve for water supply can be installed to save water consumption for drainage, for example, at a kitchen sink. Here it will combine all the functions: flow reduction, complete overlap, free flow.

Ball valves are used in classic individual heating systems and when installing heated floors. Shut-off valves allow you to isolate individual radiators from the main system, thus regulating the temperature in the room. In the event of a radiator breakdown, this allows you to avoid stopping the heating operation for repairs.

We recommend that you read: Pressure pipes for communications made of polyethylene - characteristics and scope of use

The choice of shut-off valves for a heating system is limited by certain requirements for temperature and internal pressure. Not every ball valve is suitable for this due to its operational characteristics.

Classification by installation location

According to the installation principle, boilers serving two communication circuits are floor-mounted, wall-mounted and parapet-mounted. Each option has its own special characteristics.

Based on them, the client can choose the most suitable installation method for himself, in which the equipment will be conveniently located, will not “eat up” the usable area and will not cause problems during operation.

Floor-standing boilers

Floor-standing units are high-power devices that can heat and provide hot water not only to a standard apartment or residential building, but also to a large industrial premises, public building or structure.

If a double-circuit boiler is planned to be used not only for heating and supplying domestic hot water, but also for replenishing warm water floors, the basic unit is equipped with an additional circuit

Due to their large size and significant weight (up to 100 kg for some models), floor-standing gas boilers are not installed in the kitchen, but are placed in a separate room directly on the foundation or on the floor.

Features of wall equipment

A mounted appliance is a progressive type of household heating equipment. Due to its compact size, a geyser can be installed in the kitchen or other small rooms. It can be combined with any type of interior solution and fits organically into the overall design.

A double-circuit wall-hung boiler can be placed not only in the kitchen, but also in the pantry. It will take up minimal space and will not interfere with furniture or other household appliances

Despite its small size, a wall-mounted boiler has the same functionality as a floor-standing device, but has less power. It consists of a burner, an expansion tank, a pump for forced movement of the coolant, a pressure gauge and automatic sensors that make it possible to use the fuel resource with maximum efficiency.

All communication elements are “hidden” under a beautiful, modern case and do not spoil the appearance of the product.

The flow of gas to the burner is controlled by a built-in safety system. In the event of an unexpected interruption of the resource supply, the unit’s functioning completely stops. When fuel starts flowing again, the automation automatically activates the equipment and the boiler continues to operate in standard mode.

The automatic control unit allows you to set the device any operating parameters that are most suitable for the user. It is possible to set your own temperature conditions for different times of the day, thus ensuring economical consumption of fuel resources.

Nuances of parapet devices

A parapet boiler is a cross between a floor-mounted and a wall-mounted unit. It has a closed combustion chamber and does not create harmful emissions. Does not require the installation of an additional chimney. The combustion products are removed through a coaxial chimney laid in the outer wall.

A parapet-type boiler is the best option for heating equipment for small rooms with a weak ventilation system. The device is designed so that during operation it does not emit combustion products into the atmosphere of the room in which it is installed.

The device is mainly used to provide hot water and full heating to small houses and apartments in high-rise buildings where it is not possible to install a classic vertical chimney. The basic power ranges from 7 to 15 kW, but despite such low figures, the unit successfully copes with the assigned tasks.

The main advantage of parapet equipment is the ability to connect heating and water supply communications to the central gas system and pipelines from any side convenient for the user.

Manufacturers of household gas taps

When choosing shut-off valves, you need to pay attention to all the details and purchase only high-quality products from well-known manufacturers. Products from Italian companies FIV, Valtec and Bugatti have proven themselves best. Devices from the German brands Dungs and Profactor, the Polish brands Broen Ballomax and Efar, as well as the Russian concern LD are also of good quality.

It is not recommended to save money and give preference to Chinese manufacturers, since such fittings do not meet international standards and requirements.