Thermal insulation of the floor largely determines both the ease of use of a living space and the cost of heating it. To insulate the mentioned structure, a wide variety of materials are used: from budget sawdust and other fillers to traditional mineral wool and foam boards and modern sprayed compounds. Compared to most available types of insulation, Isolon stands out favorably - a material made on the basis of foamed polyethylene with an additional coating in the form of aluminum foil.

Floor insulation with isolon

Next, you are invited to familiarize yourself with the basic information about this modern insulation and study the instructions for its installation in the case of arranging floors made of different materials.

Izolon foil

Is it necessary to put heat-reflecting material under the heated floor on which the tiles are laid?

Gentlemen!

Please tell me, is it necessary to put heat-reflecting material under the heated floor on which the tiles are laid? Actually, they laid it, now the tiles are moving, were they laid incorrectly? Thank you. Rather than placing it incorrectly, it is better not to place it at all. You can have it in the rooms without a reflector. It makes sense to insulate and reflect only on balconies, so as not to flood the street or neighbors’ balcony. and now you have to take everything off and do it again.

Masters online: 207 Orders per week: 1,468 Offers per day: 645

Rather than placing it incorrectly, it is better not to place it at all. You can have it in the rooms without a reflector. It makes sense to insulate and reflect only on balconies, so as not to flood the street or neighbors’ balcony. and now you have to take everything off and do it again.

Thanks Yuri! I looked at the instructions for laying the floor on the manufacturer's website, they warn that tile adhesive should not be placed on the heat reflector (the heat reflector must lie under the screed at least 30 mm). Have you ever had to fix this kind of error, please tell me?

Warm floors like DEVI mats need to be filled with screed, and only then covered with tile adhesive over the screed. It's impossible to fix. Dismantle the tiles while they are still standing, make a screed, and only then glue the tiles

It's a little unclear. what gender and where? But in general, Yuri wrote it correctly - redo it.

The heated floor based on the heating mat was laid as follows: a heat reflector was thrown onto the screed, a heated floor was placed on it, and the whole thing was covered with tiles on a layer of glue of at least 1 cm. Kitchen premises. Thanks Ivan, have you ever had to correct errors of this kind?

Denis, please answer the questions - WHAT floor? WHERE (room)? WHAT is written in the instructions for this floor?

Ivan, Teplolux Mini. The instructions say this: Kitchen room in a panel house apartment.

Thus, that is, using the instruction method, we understand what was done not according to the instructions! PS/read the instructions and everything will be correct!

It's not worth paying for this kind of work. Make them change it.

If I get them to redo it, it will be their 4th retile. I have never met such workers before that I had to figure out all the details myself and, most importantly, the money they asked for was not small.

Well then, just send these specialists away and invite someone from the forum who will give you the most correct solution!

Thank you Vladimir, I realized that the builders who performed this work have absolutely no experience.

NO, this applies to a water floor, and this TP needs to be laid - 1) heat reflector 2) mesh 3) screed 4) TP 5) tile

This is nonsense: mats are placed without a reflector; you can pour SVR (self-leveling solution) directly under the tiles so that there is no vacuum, otherwise it will burn out in voids. And there is a heating cable that is made with a reflector and in a screed and is also called TP. And in this case, swear words. The mats have a maximum heating thickness of 1.8 cm. And depending on the power, the mini seems to be 160W. The mats will not warm up the screed, then you don’t have to waste money, but buy just one thermostat and install it for beauty.

Dear Denis, when installing any (water or electric) heat exchanger under the tile, a heat-reflecting layer is required for greater efficiency and heat transfer. If there is no reflector, then the TP heats no matter what, be it the balcony street, or the ceiling of the lower floor. The reflector reflects heat vertically upward. Next, a warm floor is installed, and it does not matter whether it is water or electric. Next, a screed is made on the TP. Only this way, and no other way. The exception is film TPs that are already glued to a reflective film. But I haven’t seen anything like this in Russia yet. Making a screed after the reflector under the TP is only necessary for those specialists who do not know how to properly install water TP.

You made a mistake, not on the reflector, but on the heat-insulating layer. That is, penoplex, expanded polystyrene, mineral wool, etc. The principle of operation of thermal reflectors is the same as that of a mirror, but unlike mirrors, they reflect infrared radiation rather than visible light. The essence of the installation technology specified by this manufacturer is that the TP must be laid on a solid, durable layer. That is, if you install the tiles directly on a 5-8mm mortar TP (According to the manufacturer’s recommendation). This means that there should naturally be a tie between the heat insulator and the TP. Since the heat insulator is inherently softer than DSP. But the heat insulator is placed where the floor borders on the cold of the street (for example, a balcony). Naturally, you first need to insulate it, then preferably a heat reflector, then a screed, then TP and tiles. If you install a TP in a bathroom, for example, then in order not to heat the neighbor’s ceiling, only a heat reflector is installed. Something like this.

Once again I focus on the TP instructions. It all depends on the TP. There is still a difference between water and electric, depending on the type, and you need to follow the manufacturer’s recommendations! The nuance is that the heat always goes up, but the manufacturer recommends under the screed or under the coating!

Heat goes to the top, naturally, but when the concrete bottom is colder than the top (screed), then the bottom takes away heat and the heat transfer is less evective. The owner naturally adds tension. The consequence of this is excessive consumption of electricity.

I completely agree, these are truisms. I just don’t understand why there are so many words? I outlined everything above and it’s up to the owner of the apartment to follow the instructions or enter into controversy. argue with brilliant eloquent performers.

Five points. It’s just that sometimes manufacturers write something like this, that it’s not clear what is what.

What does this have to do with instructions? If your knowledge of physics is at the 4th grade level. I have no desire to conduct an educational program with you. And everything I have written is addressed more to the author of the topic than to you.

place a tender on the website and choose who you like. drive those specialists to the neck.

Good evening Denis! Whether to lay a heat reflector or not depends on what kind of heated floor is used and where. If heating mats are laid, then no. If a cable is laid, then an ash reflector is used, but squares are cut out in the foil to better bind the screed solution to the floor. Or, to keep the screed stationary, a mesh is placed on the reflector and then filled with solution. Good luck.

Do you need an underlay for an electric heated floor?

Heated floors are a modern and economical way to heat residential premises. In the Moscow and Moscow region, as in other regions, they are gaining increasing popularity. This type of heating is an excellent alternative to radiator heating and has a number of advantages over it:

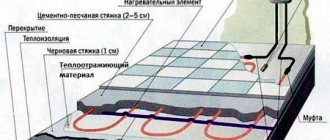

Basically, the design of a heated floor is a “layer cake”, where between the floor below and the floor covering on top there are: waterproofing, thermal insulation, a heating element (water pipe, electric cable, heating mesh), concrete screed.

Warm floors are divided according to the type of heating into:

Mistakes to be made when preparing the foundation

Often, due to insufficient qualifications of a specialist or other reasons, serious shortcomings are made:

- The most common mistake is laying the screed in the shape of a snake. This form does not warm up well, there is a cold return;

- incorrect choice of thermal insulation material, where the required thickness or coating is missing;

- The pitch of pipe placement is poorly calculated, resulting in a “zebra” effect. Experts recommend laying the structure with a distance of 20 centimeters, no more. Otherwise, warm or cold zones may appear;

- There are cases of cracking of the screed due to indentations from the technology. The concrete screed must be at least 7 centimeters thick.

The process of installing a heated floor system is quite labor-intensive; it is better to invite professional workers. This way you will protect yourself from emergency situations and achieve a comfortable life.

Water heated floor

Works on water heating pipes laid between the ceiling and the flooring. Water is heated in a boiler or boiler and supplied through the heating circuit using a pump.

The cooled water goes back into the boiler and so on in a closed cycle. The built-in heat control system will not allow the floor to heat up above the set temperature.

This type of heated floor is good for individual housing, but is completely unsuitable for an apartment building with central heating. Another disadvantage is that if a pipe breaks or leaks, it is often necessary to dismantle the entire structure.

We recommend: How to choose tile adhesive for heated floors?

Electric heated floor

It is also a multilayer structure, where the heat transfer element is a flexible electrical cable or heating rod mats operating from the electrical network. This type of heated floor is not prohibited from being installed in an apartment building.

Unlike a water floor, this floor is not subject to leakage, and if any element breaks, it is enough to dismantle only one section above it.

Electric heated floors, in turn, are divided into:

Regardless of what type of floor has been chosen, an important component is the underlay for heated floors - a heat-insulating material.

SUBSTRATE for heating CABLE

The underlay acts as a separating barrier between the subfloor and the heated floor. If the room has a subfloor made of concrete, then an underlay is required , since the heat through the concrete floor also warms the foundation. And to

To achieve a comfortable temperature on the floor, you will need to warm up the subfloor along with part of the foundation. The reflective layer is laid on the subfloor as a continuous carpet, with an overlap on the walls -

to compensate screed expansion. If necessary, reinforcing mesh is laid. A self-regulating cable or a cable on mats is laid out. Then they are filled with concrete or tile adhesive. After hardening, the substrate protruding along the perimeter is cut off. The underlay/insulation prevents heat from escaping into the subfloor and thus heat is not wasted . The use of a reflective substrate allows you to increase the room temperature by up to 30%.

The underlay performs a waterproofing function, protecting the floor from the penetration of moisture and steam into it, both from above and from below. The substrate also levels the surface. When using material more than 2 mm, the substrate performs an acoustic function, reducing the amount of noise and vibration.

Laying features

The substrate can be laid with the reflective side in any direction. The reflective effect will remain in any case. It must be laid with a continuous carpet and have the same thickness over its entire area. It is imperative to take into account the overlap on the walls to compensate for the expansion of concrete. The individual panels are joined end-to-end, and the seams must be taped.

Operating procedure

Material

The substrate/insulation consists of NPE with a closed cell structure; it is this structure that gives a low thermal conductivity coefficient, good elasticity and zero moisture absorption. The reflective layer consists of a composite of aluminum and lavsan, this combination gives the material unique characteristics - it does not conduct electric current , and is very resistant to concrete and alkaline solutions. The material has increased mechanical strength . The low density of the substrate allows the material to act as sound insulation .

The most important characteristics of the underlay/floor insulation

PHOTO installation under WARM FLOOR

You can order or find out more by calling the toll-free number: 8-800, which is listed in the contacts.

Characteristics of insulation

There are several types of penofol:

- A. Foiling is applied from one surface. It is used for insulating floors, walls, and for insulating communications.

- B. Foiling on both sides. The main place of use is for insulating interior partitions, as well as for interfloor coverings.

- C. Foil on one side, self-adhesive base on the other, covered with a film that protects against gluing in the roll.

- Super – NET. Area of application: insulation of networks, pipelines, process equipment, and also as sound insulation in cars.

- ALP. Laminated with polyethylene film. Used for insulation of outbuildings in agriculture.

- M - R. Foil-coated on one side, has a relief surface.

The most common and frequently used penofol for flooring is type A, B, C.

These types have the same operating temperature range, which varies from -60 to +100 degrees.

The thermal reflection coefficient is also the same, from 95 to 97%.

The weight of one cubic meter for A is 44 kilograms, for B - 54 and for C - 74.

Moisture resistance when immersed in water for a day is 0.7 percent for A, 0.6 for B, and 0.35 for C.

The vapor permeability of these species does not exceed 0.001 mg/mchPa.

Types of substrates

The underfloor heating is a flexible flooring that is located between the floor slab and the heating element. The substrate has a number of functions:

Since the substrate has several purposes, it must meet certain requirements:

We recommend: How to calculate the length of a heated floor?

Mineral types of substrate include fiberglass. It is a rolled material made of fiberglass. Fiberglass does not get wet, does not burn, but has minimal thermal insulation. Used as a contour between the water-heated floor and the coating.

Natural types include cork, jute, and felt substrates. These are easy to use, environmentally friendly materials.

Without special impregnation, they are quickly exposed to destructive biological influences, that is, they become infected with fungus and bacteria, which significantly reduces their service life.

The above types of materials are used as a substrate between the screed and the floor covering, for example, under laminate.

Advantages and disadvantages

As mentioned above, a substrate with a foil surface is an excellent material for saving energy. In addition, foil has a number of other advantages, but there are also disadvantages.

| pros | Minuses |

| Does not affect the height of the floor, since the foil material is only 2-10 mm thick. | High cost is the main disadvantage. |

| It is not difficult to install, so even an inexperienced person can handle the job. | It is not recommended to use a mineral substrate with a metallized layer for heated floors, since toxic substances are released during the heating process. |

| It has soundproofing and waterproofing properties. | Using such a substrate in rooms with high humidity significantly reduces its service life. A foil-coated product is recommended. |

| Withstands heating up to +90 degrees and more. | Dissolves upon direct contact with cement. |

| Most products with foil are equipped with markings, which simplifies the process of laying heating elements. | |

| There are models with a sticky layer, this makes installation easier. | |

| Reduces heat loss and promotes its uniform distribution. |

It should be noted that the foil product is strong and durable if installed and used correctly.

Installation of heated floors under tiles

Today I will tell you step by step how to lay a heated floor under the tiles. We will install the electric heated floor, which I wrote about in this article. Well, let’s not delay, let’s start the installation......

Installation of heated floors under tiles

What you need

Warm floors for tiles were purchased from us. We will also need a thermostat for a heated floor, a substrate for a heated floor, a grinder with a cutting wheel for brick and concrete (for cutting walls and floors), as well as a drill or hammer drill for drilling a wall (with a Pobedit drill bit). If all this is available, you can begin installation.

Choosing a place

Before laying the heated floor, you need to decide on the installation location! I install it in the shower room; there is no need to cover the entire space with flooring, because it is not at all necessary to warm up part of the floor under the shower stall, under the toilet and under the sink with a cabinet. Because this is money thrown away - why heat the floor where we don’t walk? Therefore, I will put it approximately like this, I have already measured everything.

Floors lie precisely in the space where people will walk.

Underfloor heating: selection rules, characteristics, best brands, installation tips

Author: Nikolay Strelkovsky

Warm floors are of two types, depending on the heating method.

Selecting and laying the underlay under the heated floor

Mermen

Heating is carried out by a pipeline system, the coolant is hot water.

Water heated floor

They are used in most cases in private homes; when connecting hot water in multi-apartment buildings, big problems arise due to the disagreement of management companies to give permission to connect to common building heating networks for two reasons. Firstly, in this case it is difficult for them to control the specific consumption of thermal energy by each consumer individually. Secondly, boilers may not be able to withstand a significant increase in energy consumption.

Water heated floor diagram

It is not always possible to install a separate heating boiler in city apartments, and such installation, together with the price of the equipment, is quite expensive.

Electrical

Standard electrical diagram for connecting an infrared film heated floor

The temperature rises due to the resistance of the current conductors. From school we know the formula Q (energy released) = I (current strength) × R (conductor resistance) .

Connection diagram for cable heated floors

Depending on the physical characteristics of the conductors, heated floors can be film (infrared) or cable (conducting elements are ordinary flexible cables and improved insulation). Electric floors have their own difficulties; during their installation, it is necessary to take into account the parameters of the existing wiring and special protective fittings.

Infrared heated floor diagram

To effectively heat floors, the power per square meter must be at least 250 kW; in total, larger values are used.

Currently, manufacturers produce a wide range of substrates, differing in linear characteristics, materials of manufacture and the ability to perform additional functions.

Power of electric heated floor

Electricity consumption of film heated floors

Warm floor marking

What to look for when choosing substrates

A very important point, we consider it necessary to consider this issue before moving on to a direct description of the various types of underfloor heating. It should be borne in mind that absolutely all manufacturers are trying to increase sales of their products; to do this, they often advertise them in every possible way, including using not entirely benign methods.

What should you really pay attention to when selecting the optimal substrate option?

Thermal conductivity indicators. The lower they are, the more efficiently the substrate works. These parameters depend on the thickness and materials of manufacture of the products. To enhance the effect, modern substrates have a foil top layer - due to the reflection of infrared rays, heat saving indicators increase by approximately 20–30%. As for heat conservation, all materials used meet today's stringent requirements of housing construction standards.

Main characteristics of insulation

There are several types of penofol available for sale:

- Class A. Has a foil surface on one side. Can be used for thermal insulation of wall surfaces, floor coverings, and insulation of communications.

- Class B. Foiling is done on both sides of the material. Area of application: thermal insulation of partitions between rooms and ceilings between floors.

- Class C. Has foil on one side only. The other is coated with a self-adhesive compound and film, which protects the material from sticking together inside the roll.

- Super class - NET. It is used for insulation of communication networks, pipelines, production equipment, and also as a sound insulator in automotive production.

- ALP class. A thin film of polyethylene is applied to the surface. It is used mainly in agriculture for the purpose of thermal insulation of commercial buildings.

- Class M - R. One of the sides contains foil, the other is distinguished by its relief.

The most common types of penofol are types A, B and C. They are also most often used for floor insulation.

- These varieties have approximately equal operating temperature ranges, ranging from -60 to +100 degrees Celsius.

- Thermal reflectance ranges from 95 to 97%.

- The mass of one cubic meter of type A penofol is 44 kg. B - 54 kg, C - 74 kg.

- The level of moisture resistance when the material is soaked in water is 0.7% for type A, 0.6% for type B and 0.35% for type C.

- The vapor permeability index of all varieties is no more than 0.001 mg/mchPa.

Substrates for underfloor heating with electric heating

Under these types of heated floors, thin substrates made of technical pressed cork, Folgoplast, Polifom, Thermod, TMpro and other foamed polymers are used.

Reflective thermal insulation Foil-plastic

Cross-linked polyethylene foam "Polifom"

The latter, by the way, are much superior to their competitors in their ability to withstand loads; due to this feature, the scope of their use is expanding. Substrates with increased thickness parameters are made from extruded polystyrene foam. The material has high physical strength characteristics and can be used as a base for a concrete screed. The underlay is used under all types of electrically heated floors, including ordinary ones with flexible conductors.

If the base is not very level and requires leveling, then you can use substrates made of plywood, OSB and chipboard.

Important. For electric floors, it is not recommended to use substrates with an aluminum reflective layer. In the event of an insulation failure, an unexpected current leak occurs with possible negative consequences. The reflective layer should be on vacuum-coated polyethylene film.

Lavsan substrate Izobond PP

When choosing a specific brand, you need to take into account two initial factors.

Choose the underlay depending on the floor finish

Warm floor pie, example

Heated floor schemes

These parameters should be taken into account when designing the height of door and window openings. During repairs, it is necessary to take all construction measures to reduce the thickness of the heated floor - you will not have to solve problems with reducing the height of doors, etc. The ideal option is that the installed heated floor does not interfere with the opening/closing of doors, acceptable - the door leaf and vertical trims are needed for several trim centimeters from the bottom. The most unpleasant option is that it becomes necessary to raise the lintel of the doorway; the heating system requires alteration.

Under linoleum, only hard substrates are used and either a thin screed is made. The technology for laying substrates depends on the materials of manufacture; during work, you must follow the manufacturers' instructions.

Laying technology

Laying the substrate is an important step when installing infrared heated floors. Therefore, when installing it, you must follow a number of rules:

- when using fiberboard sheets or magnesite boards, the screed should first be covered with aluminum foil;

- in cases of polymer metallized film, its reflective side should be positioned upward;

- the insulating material must cover the entire surface of the heated room.

As when installing the underlay into the “pie” of any heated floor, the underlay for infrared film is mounted on a clean base equipped with a vapor barrier layer (polyethylene).

The insulation is spread over the entire area of the room, reflective side up, with a distance of 100 mm from the walls. These openings are closed with a tape damper. The joints are taped with special metallized tape. To prevent the material from moving when the floor is in use, it is attached to the base with double-sided tape.

After this, the infrared film is mounted; there should be no air gaps between it and the substrate. Then the finishing coat is applied.

The efficiency of the floor, and therefore the comfort in the house, depends on the correct and high-quality installation of the underlay.

Substrates for underfloor heating with water heating

Due to the fact that water floors in most cases have a top cement-sand screed, the substrates are subject to more stringent requirements than for electrically heated floors.

How to lay heated floors on plywood

Laying the substrate and installing underfloor heating pipes

When choosing the thickness of the substrate, you need to take into account the effectiveness of the thermal insulation of the base. If the house is wooden and the floors are thermally insulated with mineral wool, then the thickness of the substrate may be insignificant. And vice versa, if the substrate serves as the main thermal insulation material, then its thermal conductivity should be minimal. The aluminum heat-reflecting film on the front part has a great positive effect; its presence is welcomed by all professionals.

Foil underfloor heating fomisol with markings

Foiled polystyrene foam with markings

Warm water floors can be installed under laminate, linoleum, ceramic tiles or natural and artificial stone coatings. The physical characteristics of finishing floor coverings have a significant impact on the choice of technical characteristics and linear parameters of the substrate. The greater the weight of the flooring, the stronger the underlay should be.

Pay attention to the thickness of the heated floor cake

The correct selection of all elements of a heated floor, taking into account the widest possible list of individual features, increases the efficiency of its functioning, reduces the estimated cost of construction and installation work and increases the duration of operation. The optimal choice can only be made if it is made consciously on the basis of knowledge about the varieties and technical characteristics of various types of substrates.

Other indicators

No less significant points are environmental safety and the cost of materials. Resin and plastic have the ability to release toxic substances into the air. Safety depends on the concentration of the substances. The requirements for underlays for heated floors are more stringent, since they are used in conditions of elevated temperatures. Heat saving costs can be optimized if special technical knowledge is available.

The substrate can withstand heavy loads

At the same time, there are parameters that do not play a special role when assessing the effectiveness of heated floors. These include the noise absorption rate. Absolutely any materials used in this area do not transmit sound well enough. They create obstacles in front of air flows that facilitate the conduction of sound waves.

Another indicator that is worth paying attention to is waterproofing. Aluminum foil does not allow water or steam to pass through

The question of the need for waterproofing for heating systems is especially significant. When it comes to water systems, quickly detecting leaks will reduce the owner's losses. Accordingly, the structure will be less exposed to high humidity. The situation with electrical systems is much more complicated. Water is not allowed here, as it causes short circuits.

How to choose a underlay for a heated floor: