Home » Building a house » Building materials

Annie Cooper 04/30/2020

34046 Views 1 comment

Oriented strand boards are often used for exterior decoration of building facades and interior work. Their characteristic, rough structure does not always correspond to the style of the room or the wishes of the home owner, so the surface is covered with paints and varnishes. Tips on what and how to paint OSB, and how to properly prepare the material for coating are collected in the material.

Material characteristics

Surface of particle boards

OSB (OSB) or oriented strand board is a sheet building material made from woodworking products (most often flat softwood chips) glued together in 3-4 layers.

The material is formed by hot pressing. The binding element is waterproof phenol-formaldehyde resin with the addition of synthetic wax and boric acid.

The name OSB is a transliteration of the English name OSB - oriented strand board.

The entire slab has a thickness of up to 3.8 cm and a length of up to 2.5 m. For production, chips of a strictly defined size are used: from 0.6 to 4 cm in width and 18 cm in length. The order of the layers in the sheet also matters: the inner ones are laid transversely, and the outer ones - lengthwise.

This structure gives the material the properties of a plywood sheet:

- increases rigidity

- prevents deformation during installation

- increases resistance to mechanical damage

Application of OSB panels

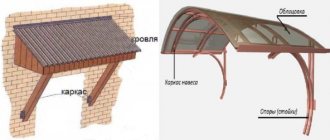

OSB is used as rough flooring (under laminate, carpet, linoleum) or wall material for construction:

- temporary structures

- frames

- small architectural forms

- converting an attic into a living room

The material is also used as a raw material for the production of sandwich panels, I-beams, as a flooring for bitumen shingles on roofs and load-bearing structures of panel formwork.

OSB competes with bakelite and regular plywood as a structural material, and fiberboard, chipboard and plasterboard as a finishing material.

Advantages and disadvantages

Pressed chip sheets

Oriented strand boards are superior to other building materials made from wood products in some performance characteristics:

PROS:

- Show higher fire resistance than fiberboard, chipboard, non-flammability

- They do not have defects in the material structure (delaminations, air voids, knots) unlike solid wood

- Less time-consuming compared to other types of finishing

- Provide high heat and sound insulation

- Cost less than other wood chip materials

- Externally they differ little from wood

- Not affected by wood-boring insects

- Easy to process (drill, cut, glue and paint)

- Lighter than cement bonded particle boards/

MINUSES:

- However, OSB does not provide vapor permeability.

- When heated, it can release harmful substances (due to the phenolic-formaldehyde resin in the composition).

- When used in interior decoration, sheets must be painted or covered with other decorative material.

Benefits of OSB

All the strengths of OSB can be divided into two parts:

- advantages over plywood and chipboard;

- before other materials.

Let's start with the first ones:

price. Of course, wood is cheaper than other finishing materials. Compared to its counterparts, chipboard is cheaper. But, alas, the quality in this case corresponds to the price; strength. Thanks to their multilayer structure, the slabs boast high strength characteristics. True, plywood has approximately the same indicators. But chipboard cannot boast of strength; resistance to moisture. OSB performs well in conditions of high humidity. The same can be said about plywood. But chipboard is destroyed under its influence; environmental friendliness. The material contains synthetic resins, but in small quantities

An important point: the products are labeled indicating the level of environmental friendliness; You need to pay attention to this when purchasing. By the way, according to this indicator, OSB is considered safer than chipboard and plywood

Based on the above, we can conclude that oriented strand boards are better than their closest analogues. Now let's move on to the second group of advantages:

- light weight. The slabs weigh from 15 to 40 kilograms, which makes them easier to install on walls;

- ease of processing. OSB lends itself very well to sanding, cutting, painting and other actions;

- no need to buy special tools for installation;

- large selection of sizes. So, you can choose fairly large slabs to reduce the number of joints to a minimum.

Types of slabs

Laminated Chip Board

There are 4 types of slabs depending on their resistance to moisture and mechanical stress.

| View | Characteristic | Application area |

| OSB-1 | Low resistance to moisture, shock, deformation | Manufacturing of furniture, used as packaging material, upholstery |

| OSB-2 | High strength but unable to withstand moisture | For the manufacture of load-bearing structures, floors, only in dry rooms |

| OSB-3 | High resistance to damage and moisture | For the production of load-bearing beams and structures in any premises |

| OSB-4 | The highest levels of moisture resistance and strength | Can be used for any premises and purposes |

For finishing, the preferred choice is oriented strand sheets of types 2 and 3.

Depending on the outer covering, sheet material can be:

- Varnished

- Laminated

- tongue and groove

The elements are distinguished according to the finishing method:

- with straight edges

- milled (to simplify installation) on both sides

- milled on four sides

Caring for painted OSB

With the correct choice of decorative composition and compliance with the preparation and application technology, further procedures will be as follows:

- After 5-7 years (depending on the composition), a light treatment with a thin layer of diluted solution can be performed to revitalize the surface.

- Significant difficulties arise due to the shrinkage of the house; more serious reconstruction may be required. But if the frame was positioned accurately, observing the gaps, then you will only need to rearrange the moldings on the outside and minor finishing work on the inside, followed by painting in the desired color.

- Worn flooring is re-sanded and varnished.

Painting OSB is not the most difficult process, requiring accuracy and a precise sequence of all actions to obtain a high-quality result.

Manufacturers and prices

Finishing building materials

The most widely used chipboards on the market are those produced in Germany, Romania, Canada and Russia. The main brands with prices per 1 sheet are presented in the table:

| Brand name | Manufacturer country | Price for 1 sheet |

| Glunz | Germany | from 1200 rub. |

| Arbek | Canada | from 800 rub. |

| Norbord | Canada | from 1000 rub. |

| Egger | Romania | from 1000 rub. |

| Talion | Russia | from 500 rub. |

| Kronospan | Austria | from 550 rub. |

| Kalevala | Russia | from 600 rub. |

German sheets from Glünz are considered the highest quality (but also the most expensive); Canadian products have proven themselves well: Arbeck and Norbord. Among Russian-made building materials, OSB brands Kalevala and Talion are popular.

Preparing for painting

Painting sheets of shavings

Before you begin to apply the coloring product to the material indoors, it is prepared. The adhesion of the paint and the durability of the structure depend on the quality of the preparation.

Prepare the already assembled elements in the following sequence:

- Sanding with sandpaper or a sanding machine to eliminate unevenness and mask the recognizable texture of OSB. OSB-3 and OSB-4 sheets are especially carefully sanded, where the wax (varnish) protective coating must be removed. By skipping this step, there is a risk of chips and large chips peeling off

- Blowing wood dust from seams after sanding

- Leveling in places of fastening with self-tapping screws using putty mixtures based on glue and oil, “liquid nails”

- Cleaning dried putty with fine sandpaper to obtain a smooth surface

- Treatment with specialized emulsions that give the material additional resistance to moisture, combustion, fungi, and mold

- Primer with a mixture of alkyd varnish with water or white spirit (in a ratio of 1 to 10). An adhesive primer is also suitable, which will not allow the essential oils in the structure of the slab to bleed through the light pigment. If OSB-3 and OSB-4 are primed, then choose compositions for applying decorative plaster or mosaic

- The perimeter of each element is painted with a brush in 3 layers, the internal space is worked with a roller in 1 layer in one direction.

- Allow the paint to dry completely and apply a second coat.

If the material is coated with water-dispersion compounds, then only 1 layer is placed over the entire surface of the slab - this way the slab will swell evenly.

Preparatory work

Before painting OSB needs to be prepared. This is necessary to ensure good placement of paintwork materials and keep them on the surface.

If you intend to use OSB for cladding wall and ceiling surfaces, it is best to prepare the slabs before installing them on the sheathing.

First of all, sand the entire surface using a hand sander. It should have a sandpaper attachment attached to it. After removing the outer protective layer, the paint will easily get inside the material.

Once sanding is complete, mask off the seams and screw heads. You can use a special putty with increased elasticity, a sealing agent or a special tape. If the joints and holes from the screws need to be hidden entirely, while maintaining the natural color, then sawdust should be added to the putty - they will remain after cutting the sheets.

In this case, you need to ensure that the gaps are carefully filled without going beyond their boundaries. If necessary, after the putty has hardened, you can clean it with a grinding device with a sandpaper attachment.

How to choose a coloring composition

Choosing paint for wood board

To choose a paint for coating sheet particle material, it is recommended to pay attention to the following properties:

- protection from ultraviolet radiation, negative effects of the atmosphere (rain, snow accumulation), fire, rot, mold

- the presence of additives with fire-retardant and adhesion-increasing characteristics

- surface adhesion parameters

- number of layers (to calculate consumption per 1 m2)

It is also worth considering the age of the boards (the older the OSB, the worse it adheres to the surface) and their condition (before painting, the surface is cleaned of dirt, layers of old paint, and treated with antiseptics).

Criterias of choice

The retail chain offers standard pox boards for renovation of premises, as well as laminated ones, which have different performance characteristics and have different effects on people’s health. When making a purchase, adhere to the following recommendations:

Pay attention to the presence of a certificate from the manufacturer, guaranteeing the environmental safety of the purchased products.

Modern technologies can ensure the production of any slabs, but there are certain sizes

- Use floor boards of the third design (OSB-3), which are most common in specialized stores and are used to form a reliable floor surface due to their high degree of protection from moisture and increased density.

- Use slabs with a thickness of 1 cm when eliminating minor defects in the concrete floor.

- Install material 1-1.5 cm thick to ensure flatness on surfaces that have significant unevenness.

- Mount products 1.5–2.5 cm thick on the joists, depending on the interval between the support bars.

- Calculate the required amount of material to complete the repair, focusing on the most common product dimensions of 1.22 x 1.44 m. Consider the size of the room and the dimensions of the base, focusing on the minimum amount of possible waste.

- Choose a texture and color scheme by purchasing laminated boards, which will allow you to fit harmoniously into the interior.

Indoor painting methods

Particle boards in interior decoration

OSB is coated with paints and varnishes to:

- Additionally protect the material from moisture and reduce the risk of fire

- Disguise the texture of slabs during interior decoration and add decorativeness to them

- Save on cladding with plasterboard or MDF panels

Experts do not recommend covering building materials with water-dispersed acrylic compounds in several layers for exterior work - the slab may swell.

OSB wall panels

For interior work, particle boards cover:

- Oil paint - it has high viscosity and is not absorbed into the material. Provides a reliable, durable coating, but takes quite a long time to dry

- Alkyd paint or enamel. Penetrates deeply into the structure of the chips, so there is no need to varnish the material on top

- Stain. With this type of painting, the natural texture of the slab remains visible. The top of the building material is coated with polyurethane or vinyl varnish to secure it. The desired tone can be obtained by diluting the composition with water, acetone or solvent

- Glazing azure. Transparent thin paint allows the chips to retain their structure and only slightly shades the color

- Transparent varnish or impregnation to preserve the natural texture of the slabs

How to paint the panels outside

Painting slabs outside

For external finishing work - finishing the facade, installing partitions and floors - oriented strand boards are coated with impregnations, varnishes and paints:

- alkyd

- oil

- water-based

- acrylic

- latex

When choosing a material for painting, it is better to choose compositions that contain special additives that protect the slabs from exposure to UV radiation.

The coating must also be vapor permeable, otherwise mold will form on the slabs. An impermeable coating can cause warping of sheet building materials.

Alkyd paint

Alkyd paint

Alkyd paint Its composition includes plant resins, film formers (glyphthalic or pentaphthalic), pigments, purified kerosene, fillers and antiseptics. After coating and drying, a film remains on the surface of the material, which provides additional strength to the OSB.

Dries quickly, is non-toxic, creates a waterproof layer, protects against temperature changes. However, it has a pungent odor and is prone to fire.

If such a composition is applied to the slab before it dries completely, bubbles and peeling will form on the surface. This coating significantly reduces finishing costs, because the alkyd composition eliminates finishing impregnation with varnish.

Water-based mixture

Water-based paint

Water-based mixture The composition of the two-phase mixture includes water and acrylic, fillers, film formers, pigments and a number of functional additives. After drying, the water evaporates, and the polymer layer gives the slab improved performance characteristics.

In addition to such advantages of paint as quick drying, non-toxicity and lack of a strong odor, the advantages include:

- low price

- variety of colors

- high resistance to fire and moisture

- ease of application

- service life up to 10 years and above

External work is carried out at a temperature not lower than +5. In the cold the composition becomes unusable.

For finishing, water-dispersion relief paint with the addition of marble dust or fine chips is also used. Its cost is higher than that of traditional water-based paint, but due to the relief it produces a beautiful decorative look.

Latex composition

Latex composition

Latex composition A type of water-based paint, but instead of acrylic, the binder is a latex additive (based on vinyl, polyvinyl, silicone). The composition is elastic, viscous and durable, giving the surface characteristics of resistance to moisture, aggressive chemicals, UV radiation and temperature changes.

The paint is non-toxic and has no unpleasant odor. Using latex, you can get both a smooth and textured coating.

Acrylic based coating

Acrylic copolymer paints

Acrylic-based coating This raw material covers unevenness of the structure well and gives a uniform tone. It consists of polymers, water and dye, and after drying it leaves a durable film on the surface of the material. It can be matte or glossy; there are many colors in the assortment that do not require additional tinting.

The acrylic composition does not spread, does not fade, dries quickly, has the ability to allow steam to pass through, but is resistant to moisture. It is often used for interior work because it is non-toxic and does not emit harmful substances into the atmosphere when heated.

Oil paint

Oil paints

Oil paint Raw materials using drying oil are rarely used due to their high toxicity and long drying time.

The oil composition leaves a lot of streaks and unevenness, while the coating does not last long, quickly crumbling and peeling off from the surface.

Fire protection

Soppka paint and varnish material

In addition to making the slabs decorative, painting can also be aimed at improving the performance characteristics of OSB. When ignited, particle boards emit caustic phenolic smoke, which is dangerous to humans, so it is important to cover the material with fire-retardant solutions.

Soppka paint is produced specifically to increase the resistance of particle boards to fire. The composition also prevents the development of mold in poorly ventilated areas.

The paint is much more viscous and thick than conventional antiseptics, and creates a protective transparent film on the surface of the material. The mixture is evenly absorbed into the OSB, despite the presence of resins in it, and is not washed out by rain over time.

Non-specialized but high-quality façade glaze Valtti Color Satin from the manufacturer Tikkuril is also suitable for fire bioprotection. It has high hiding power, does not fade in the sun and prevents wood from rotting.

Should I paint or not?

In principle, it is not necessary to paint OSB boards, but in some cases it is a necessity. Why? Painting is a way to create a dense and stable film on the surface of a material. It will perform an additional protective function, preventing the negative effects of moisture and sunlight on the wood.

In addition, some coloring compositions are distinguished by the fact that when dry they form a coating with a very dense texture. Therefore, they will not only protect the wood, but will also help smooth out the unevenness that is sometimes present on the surface of the slabs. By the way, it is for this purpose that many people use varnish compositions, since they are not satisfied with the original appearance of the finishing material.

In addition, painting is the most cost-effective way not only to protect OSB boards from negative influences, but also to give the material a more attractive appearance. And sometimes it is the last factor that is decisive when it comes to whether OSB boards need to be painted.

The best paints for OSB

Toplazur

Paint and varnish materials that are best suited for painting OSB boards with their performance characteristics:

- Cetol Filter 7 Plus from Sikkens is a transparent paint for exterior use based on alkyd resins. The composition includes inhibitors and additives that enhance the moisture resistance of the material. Drying at 20 degrees Celsius and 65% humidity occurs in 15–16 hours

- Toplazur from Belinka is a thick-layer coating with natural wax in its composition. Suitable for both indoor and outdoor use. Dries completely within 10–12 hours after application. When updating, you only need to sand the surface from dirt and dust, and then cover the old layer of glaze with a new one

- Drevolak is a water-based protective acrylic varnish. Elastic, antiseptic and moisture-resistant, imparts dirt-repellent properties. To achieve the desired consistency and viscosity, the composition is diluted with water.

- Oil paint MA-5 from Lakra is a coating based on linseed oil. Dries completely in 24 hours, consumption for a single-layer coating is 1 liter per 10 m2. Characterized by high abrasion resistance, high adhesion

- Facade silicone paint from Southern Accent LLC is a water-dispersion paint that combines the performance characteristics of acrylic and silicate coatings. Reduces the effects of mold, mildew, UV radiation and moisture on particle boards

- Facade latex Element F-8 is a coating based on acrylic copolymers. Weatherproof, consumption is 1 l per 8 m2

Painting nuances

Wide brush

To apply each coating, it is better to use a separate tool suitable for the characteristics of viscosity, relief and absorbency.

You can apply coloring compounds using:

- roller

- wide brush

- spray gun

Recommended combinations of paint and tools are shown in the table.

| Paint type | The better to apply |

| Water-based | Roller with pile from 1.5 cm and above |

| Alkyd | Felt roller or fine-pore foam tool |

| Relief water-dispersion | Hair roller |

| Latex | Wide flat synthetic bristle brush |

| Embossed | Spatula with blade width 500 mm |

Tips for the dyeing process:

- When using alkyd paint, the roller is first dipped into the solution and then rolled out on a horizontal surface so that the mixture is evenly distributed.

- The recommended path of the roller along the wall is in the shape of the letter W: a vertical strip from top to bottom, two strips at an angle of 20 degrees and again a vertical strip from bottom to top.

- When painting with silicone paint, the primer should also be silicone-based for better adhesion

- Relief paint is applied with a spatula, but distributed over the surface with a roller. The thickness of the paint layer and the nature of the relief depend on the forces applied to press the roller.

- The edges of the building material absorb more paint than the front surface, so they need to be covered very carefully

- Structural elements made of OSB are painted at a humidity of no more than 60%

- When using transparent paints, it is better to choose those that contain inhibitors

- It is preferable to apply 2-3 thin layers of paint rather than 1 thick one.

Step-by-step instruction

There are many options for painting OSB. You can use one color and make the surface completely smooth. Some people prefer to work without sanding and maintain the natural texture of the slab. The process is quite simple, and the technology is not much different from treating any other surface.

Large areas are painted using a roller. You can simply and beautifully cover the slab using multilayer technology. It will take a lot of time and patience, but the result is worth it.

Below are step-by-step instructions for painting with imitation natural stone.

- You should first make a sketch of the design, in color and graphic form. This will greatly simplify further work.

- Completely paint the slab with a primer-paint of the main color. The lightest shade is selected. It is convenient to use a spray gun for application. This way the composition will seep into all the textured recesses and will not spoil the natural relief.

- At this stage, you can use a sanding machine to highlight and emphasize the relief. However, this is not necessary.

- The entire area should be divided into elements, the shape of which corresponds to stones or some other objects. It all depends on the features of the chosen design. The markings can be made with a simple pencil, focusing on a pre-drawn diagram. Then, with a brush, you should outline the contours with paint 4-5 tones darker than the base.

- Each decorative fragment should be painted in different shades. The choice depends on the design and is strictly individual.

- Each element must be cleaned. It is not necessary to process the entire stone. You can simply rub it on 1-2 sides to enhance the volume.

- Again you should draw the contours of the stones. The same shade of paint is used as at the beginning.

- Wait until completely dry and apply varnish. The base is selected based on the type of paint.

This type of painting, which imitates other surfaces, is labor-intensive and is suitable for a creative person. However, it is not always possible to be so sophisticated. There is another way that even a beginner can easily handle. A good solution for slabs on walls, you can use only 2 colors of paint. Correctly perform the work according to this scheme.

- Apply pigment primer to the surface. It will be basic and will create an attractive coating. Typically a white polyurethane compound is used. Under normal conditions, the coating will dry in literally 3-4 hours.

- After drying, you should sand the surface again and carefully remove all dust after that. It is best to use a vacuum cleaner.

- You can use a special composition “Mother of Pearl Effect” to create a slight shine on the slab. Apply according to the manufacturer's instructions. It will take about an hour to dry.

- Using a spray gun, apply a patina, which will help to slightly age the surface. After spraying the paint, you need to wait about 10 minutes and remove the excess. For this, sandpaper type P320 is used. After this, all dust should be removed from the OSB again.

- In some cases, you can finish the work already at this stage. The plate turns out attractive and effective.

- Now the more responsible work begins. Mix colored acrylic varnish with stain and spray it onto the OSB. The latter can be replaced with another composition, paint. The varnish should be taken without shine. It will take about 1.5 hours to dry.

- As the composition dries, the color may change slightly, and the slab itself will become more matte. This should be taken into account when choosing materials.

- The finishing coating can be done in any way. Matte or glossy varnishes are used. A popular composition for wall treatment is soft-touch, which creates a matte elastic coating reminiscent of rubber.

You can create very attractive designs based on OSB. It is possible to decorate surfaces with designs and preserve the wood texture. The choice depends solely on the interior, because all elements must be in harmony with each other.

Methods for decorating slabs

Flexible stone cladding

In addition to simple painting with a single-color color, you can use the following methods for decorating oriented strand sheets:

- Coloring with an artificial aging effect. They use acrylic varnish, which is coated with a patina using an airbrush and then sanded.

- Using primer paint. Looks decorative on the facades of frame buildings, applied using a fur roller

- Application of liquid wallpaper. Reduces the emission class of the slab and extends the life of the finish

- Covering with a layer of decorative plaster. With its help you can create relief, patterns and designs on the surface of the slab

- Creating bas-reliefs using polyurethane foam or putty

- Flexible stone cladding

Each owner should decide which paint or varnish to coat OSB boards based on the nature of the work (internal or external) and the conditions of use. When choosing a paint and varnish material, you should pay attention to its composition, performance characteristics and consumption rates per 1 m2. It is also important to consider the structure of the particle board and environmental factors.

Experts talk about different methods of decorative finishing of oriented strand boards in the video:

Different methods of decorative coating of OSB panels

How and how to paint OSB: choosing reliable paint and coating method (Photo & Video) + Reviews

Users share their own experience of painting and long-term operation of painted OSB in the video: