When producing various finishing works or making furniture, the use of plywood is a common practice. At the same time, home craftsmen are faced with a choice: how to cut plywood and how to achieve a perfect cut without chips. When cutting such material, some difficulties arise: the sheet is large in size, and the structure of its base creates difficulties when sawing. Knowing some features, you can achieve excellent results when working with an electric jigsaw, hand saw or circular saw. The main condition is to ensure reliable fixation of the plywood.

Plywood is a material that is practical to use and easy to process.

How to mill plywood without chipping?

I dilute PVA glue with water and apply it to the surface of the plywood.

roller

I also roll the paper with a rubber roller. I cut gears for watches. Afterwards, the paper is sanded (120 grit) and the gears are obtained without chips

.

Interesting materials:

How to find an application in Samsung Apps? How to find dead AirPods? How to find a dead Airpods? How to find the pH of a solution? How to find a Wi-Fi network on a computer? How to find current through power? How to find downloaded music on iPhone? How to find a scan on a computer? How to find a snail in the garden? How to screw flax onto a thread?

Log houses

Dwellings have been built with logs since ancient times; they also remain a popular material now. Log houses have good heat resistance in winter and coolness in hot weather, environmental friendliness, and sound insulation.

Disadvantages: flammability, shrinkage, various types of destruction by external environmental factors, for this it needs to be treated every year from rotting and various kinds of rodents. The cost of log house housing will be 18,000 - 80,000 per m2, depending on the type of wood.

Features of cutting tools

Each plywood cutting tool has its own characteristics when used. Let's look at the rules for working with plywood with various cutting tools.

Sawing with a circular saw

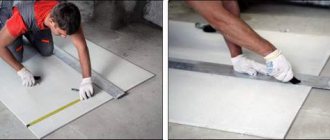

Using a guide when cutting with a circular saw will help avoid unevenness.

To effectively cut a sheet using a circular saw, you should adhere to the following rules:

- Place the plywood sheet on a stable support and make the first cut closer to the middle of the sheet.

- Adjust the cut depth. To do this, lower the disk and start cutting, while the depth of immersion of the disk should be 0.5 cm greater than the thickness of the blade.

- To avoid injury due to the high risk of kickback, position yourself to the side of the saw's line of action.

- Prepare the saw to make the required cut. To do this, you should attach the saw shoe (its part in front) to the blade and install the blade on the cutting line, having previously bent the casing.

- Make sure there are no obstructions at the bottom of the sheet.

- Turn on the saw and slowly plunge its blade into the material. To prevent kickback, hold the saw firmly. After immersing the disk in the slot and installing its shoe on the surface of the sheet, the protective casing should be returned.

- Run the tool along the line to the end of the canvas.

- Turn off the saw and only after it has stopped completely, remove it from the slot.

Cutting with an electric jigsaw

A jigsaw allows you to make high-quality curly cuts

To obtain an even cut, the sequence of actions should be as follows:

- Securely fix the material.

- If possible, cut perpendicular to the grain of the wood, otherwise it will be very difficult to obtain a straight edge.

- Under no circumstances should you put pressure on the tool; this will not increase the cutting speed, but the tool is guaranteed to break.

- The surface of the teeth should be lubricated with oil to facilitate work (subject to working with high-strength wood).

- It is undesirable to use the tool for a long time due to its heating and damage to the engine.

- After use, you need to clean the jigsaw and lubricate it.

Working with a hand saw

Metal saw is good for working with plywood

Working with a hand saw involves a lot more labor compared to a circular saw. To properly cut a sheet of plywood, you need to consider the following rules:

- Make a vertical notch along the cut line. To do this, you need to place a saw blade and pull the blade through to form a groove.

- Tilt the saw blade until an acute angle is formed with the plane of the sheet (from 30 to 400) and begin to make smooth movements.

- To maintain an even cut, the forearm and shoulder should be located in the same plane. If you deviate from the specified direction, you need to slightly bend the saw in the desired direction and continue working.

- To avoid the formation of a fracture, you need to hold the part being sawn off with your unoccupied hand.

- When you finish cutting, you need to return the blade to a vertical position and finish the work by making several movements perpendicular to the sheet of plywood.

This is interesting: the hard coating of laminated plywood imparts heterogeneity to the material, which causes chipping during processing. Another reason for the appearance of such defects is determined by the speed of movement of the cutting edge, the shape of its teeth and the applied forces. Often the jigsaw blade breaks out large pieces of plywood, which is due to the use of saws with large teeth or pushing through the top of the sheet.

Adviсe

To cut a plywood sheet correctly, you must use the right tool and follow some rules:

- Before cutting, you need to take all measurements and check yourself to avoid annoying mistakes;

- During operation, you must monitor the power cord;

- before using the tool, you need to adjust the cutting depth to an unnecessary amount;

- the saw blade must be suitable for cutting plywood;

- the use of a saw must be accompanied by the use of protective gloves and goggles;

- dull saw blades are more dangerous than sharpened ones;

- When sawing plywood, you must be careful not to bring your hands close to the blade;

- Do not start work without skills in using power tools.

Advantages of this group of equipment

If you are thinking about which machine option to choose, then this section will allow you to get acquainted with both the pros and cons of laser equipment. Let's start with the advantages:

| Accuracy | Laser cutting on wood is a high-precision process, because the thickness of the cut is 0.1-0.2 millimeters. If you need to process small parts and make structures of complex shapes, then this option is perfect for any purpose, because the cutter is able to cope with the most complex contours |

| High performance | The cutting speed is very high, which allows you to complete a large amount of work in a short time. This allows you to save energy resources, in addition, your intervention is not needed during work, you simply observe the process and control it |

| Economical | This applies both to energy consumption (powerful motors in other types of equipment use much more electricity) and to material consumption. High precision allows you to work with a minimum amount of waste and use materials economically |

| Multifunctionality | A wood laser cutting machine can not only cut out elements of any size and shape, but is also great for engraving surfaces and creating relief paintings. Many companies earn a lot of money from this type of service, such as engraving on wooden products. |

Important! When choosing a specific model, it is important to decide what materials you will process, because there are installations for wood, plywood, metal, plastic, and there are also universal options that can cope with different types of raw materials.

The equipment can take up quite a lot of space, especially if the desktop has impressive dimensions, so you must have room for installing the machine

Nuances of laser cutting of plywood

Laser cutting has a number of features:

- When cutting, the minimum thickness of the cut is ensured, which allows for optimal cutting of the sheet with maximum accuracy.

- In the area where the beam is working, a darkening appears on the plywood. As power increases, its intensity increases. A little sanding will eliminate the defect.

- No physical effort is required during operation. The process is non-contact, eliminating the risk of deformation of thin sheets.

- The quality of the final result is influenced by the structure of the plywood. It is necessary to take into account multilayers and the presence of tree resin.

- During long-term work, the workplace must be equipped with exhaust ventilation.

- During operation, no shavings or sawdust are formed.

- Before starting work, dust must be removed from the surface of the workpiece.

- It is not recommended to use a laser when cutting varnished plywood.

When using laser modules, you should listen to these recommendations. A 2.1 W laser is quite suitable for engraving. Sheets up to 2 mm thick can be cut with a 3.5 W device, up to 3 mm thick - 5.6 W, and up to 5 mm thick - 8 W. If it is necessary to cut sheets up to 10–12 mm thick, 10–15 W modules should be used.

Lasers for cutting plywood greatly facilitate work and increase cutting accuracy. With the help of such machines you can cut out parts of any complex shape. The most important criterion for choosing equipment is the radiation power. It determines the capabilities of the machine, its productivity, and the thickness of the sheets. As it increases, the cost of the device also increases, which means that an optimal approach to selection is required, taking into account the purpose and specific conditions.

- September 21, 2020

- 12339

Cut plywood with your own hands

- All procedures are carried out according to drawings that are drawn up in advance. This will avoid mistakes.

- The marked slab is laid in the prepared place. It is important to ensure free passage of the disk or saw and rigid, stable placement of the resulting fragments.

- The exposed stop is fixed with clamps.

- Based on the most comfortable position, the largest possible cut is made. It is important to ensure that the parts - especially the part being processed - do not sag or jam the tool. Whenever possible, cutting is carried out without stopping.

- Figure cutting is performed in a single section or fragments, the excess is removed gradually.

Masking tape glued to the cutting line can prevent the appearance of small chips along the edge, but if the disc is selected correctly, then you can do without such manipulations

. For complete safety, it is recommended to work with safety glasses, a mask and a respirator. All processes are carried out carefully; upon completion, the device is disconnected from power.

Source

Figure cutting from plywood

Shaped cutting of plywood is a fairly popular activity among decorators and furniture makers. Using a plywood sheet and special tools, you can make not just a craft, but a real work of art.

The choice of tool for this procedure depends on the complexity of the pattern and the thickness of the plywood sheet. If the bend radius does not exceed 1 cm, then you can use a hand jigsaw. A round hole is made using a drill. When the bending radius exceeds 3 cm, you should use an electric jigsaw. Which saw is suitable for plywood? Remember that the finer the teeth of the saw, the smoother and more complete the cut edges will be. For this purpose, for very small and complex figures it is better to buy a metal canvas.

It is better to apply the sketch on the back side of the sheet. In this case, if the chips rise, it will not be noticeable. At the same time, you should not rush, because the quality of the future product depends on the drawing. Drawings for cutting out plywood are available in large quantities on the Internet. Here you can find everything: from children's crafts to the most complex patterns.

You can create a craft from plywood using the following tools:

- hand jigsaw

- laser machine

- electric jigsaw

- CNC milling machine.

What materials and mechanisms will be required

To make a simple laser cutter with your own hands, you will need the following materials and technical devices:

- laser pointer;

- a regular flashlight equipped with rechargeable batteries;

- an old burner drive (CD/DVD-RW) equipped with a laser drive (it is not at all necessary that such a drive be in working condition);

- soldering iron;

- set of locksmith tools.

The higher the write speed of the drive, the more powerful the laser cutter will be.

Thus, you can make a simple laser cutting device using materials that are easy to find in your home workshop or garage.

How to cut plywood? Choosing a tool and file for a jigsaw

- Tools for cutting plywood: what to choose? — Power tools — Hand tools — Which is better?

- Plywood saw for a jigsaw: what to pay attention to?

- How to cut plywood without chipping?

- Where to order plywood cutting

- Where to buy plywood?

For a home craftsman, it can be quite difficult to obtain a high-quality, chip-free cut of plywood. This requires not only certain skills, but also the “right” tool.

Ensuring a perfectly clean cut

For most parts, it is enough to reduce the chip size to 0.2–0.5 mm. Such small irregularities in the cut edge are not noticeable; if desired, they can be easily eliminated by chamfering with an emery block or covering them with a wax corrector pencil. It is also possible to grind the end with sandpaper if a sufficient allowance was given during cutting.

However, even at home, it is possible to achieve cut quality comparable to the result of a cutting machine with two high-speed disks. This is only possible when the tool moves along a guide rail, or, in extreme cases, along a temporary stop bar.

First you need to make two cuts about 0.5 mm deep on both sides of the part to indicate the thickness of the cut. Along the edges of the cutting line, you need to scratch two grooves under an even ruler. This is done either with a segmented or oblique shoemaker's knife (for chipboard and uncoated wood), or with a sharply sharpened drill or pobedit cutter (for laminated materials).

The depth of the grooves should be at least half the thickness of the outer layer, which is non-uniform in relation to the main body of material. This method requires high precision in matching the grooves and the cutting line, but this is the only way to ensure a perfectly even cut end that does not require additional processing.

Festool - a tool for professionals

Industrial Equipment LLC is the official dealer of Festool. Buy German quality on individual terms!

Why do you need to cut plywood?

Standard sized plywood sheets are rarely used and usually need to be sawed

Plywood is used in many construction and renovation projects. In addition, it is the safest and easiest to handle option for making home furniture, especially children's furniture. Sheets have to be sawed, cut, bent and cut.

The complexity of such work lies in the structure of the material. In regular wood, the wood grains are oriented in one direction, which makes work easier by allowing you to choose the right tool for each direction. In the chip material the fiber has no orientation at all; the user has to deal with a relatively homogeneous composition.

Plywood is a multilayer wood-laminated board in which the wood fibers in each layer are oriented perpendicular to each other. When sawing, the tool simultaneously works with several planes . This makes it very difficult to work, especially manually. You have to put in more effort. The cut often turns out uneven, with chips . This property is especially pronounced during complex cutting, when it is necessary to perform a rounding.

Blocks

There are many different types of blocks. The most common foam blocks and gas blocks. Gas blocks and foam blocks have gained great popularity in the construction of private houses in a short time. They have a number of advantages, good heat resistance, sound insulation, lightweight in size compared to other materials, due to this, lower costs for the foundation. Disadvantages: quite fragile, they need to be lined as they quickly absorb moisture due to their porous structure. The cost of a house made of foam blocks will be 11,000 - 20,000 rubles. m2.