C:\10\11TXT

Due to lack of space in the house, it is not always possible to implement a full flight of stairs to the second floor. For those who have similar problems, it will be useful to know that there is a staircase with winder steps that fits perfectly into the space even in small areas. Let's look at what designs there are and how to correctly calculate the project.

Flight of stairs with winder steps Source vestnikao.ru

Requirements for turning while marching

The main principle in the construction of any structure in the house should be safety. And only then is it allowed to think about comfort. Stairs with winder steps must fully comply with these two conditions.

We can formulate the technical requirements that should accompany the construction of such a structure:

- Maintaining proportions. All steps in the flight must be the same height. As a rule, the size does not fall below 100 mm and does not exceed 160.

- The angle of inclination of the march cannot be more than 45 degrees. And the optimal number is 30. With such a steepness, the most comfortable movement is possible.

- The minimum width of the march should be 90 cm. It is clear that the developer is free to increase this parameter at his own discretion.

- The free passage height should be set in the range from 190 to 200 cm. But standard values can be replaced with individual ones. Usually they take a person’s height and add another 10 cm to it.

- Quality fencing is a must. Their height can vary from 90 to 120 cm.

Reliable fencing for a flight of stairs Source koffkindom.ru

- The flight of stairs to the second floor should contain no more than 16 steps. This is due to the lack of an intermediate resting area.

- The overhang of the tread of the winder step should not exceed 5 cm.

All materials must be of high quality and have a high strength rating. And the assembled staircase with winder steps is stable. This is necessary so that it can withstand the weight of several people standing on it at the same time. And there are special requirements for the size of the winder step itself.

The state standard notes that:

- The depth of the tread at the widest point should not exceed 40 cm.

- The narrowest point should be at least 10 cm.

- In the central part the tread should be 20 cm.

Those who are going to build a staircase with two “winder” turns (180 degrees) should remember that between the two flights there must be a gap measuring at least one quarter of the width of the flight of stairs. If these rules are neglected, the steps at the turn will have a depth of less than 10 cm. And this is prohibited by safety rules for movement.

Competent through span between two marches Source monolitmaster.net

If we abandon this through span and make the tread depth standard, we will have to reduce their number and increase the height of each winder step. Safety will be maintained, but comfort will be completely disrupted. And the person will have to make additional efforts to go through the turn.

Preliminary data calculation

Knowing the height between levels and the formula for comfortable movement, you can calculate the length of the flight of stairs and the number of expected steps. For example, the specified height between floors is 2600 mm. We will select the height of the degrees from the recommended range of 120 mm. Let's make all the calculations to build the drawing:

- Tread depth. Let's take as a basis the formula for comfortable movement (2A+B=C), where A is the height of the riser, B is the depth of the tread, C is the average statistical step length of a person (620 mm), transforming, we get the data: 620-2*120=380 mm. The depth of the steps exceeded the recommended range (up to 320 mm). Therefore, in practice it is possible to change the height of the riser;

- Number of steps. Knowing the height of the opening and the size of the riser, by dividing the first parameter by the second, we get the result: 2600/120 = 21.66 pcs. Round up to 22 pcs. The recommended number is 16. By revising the riser height, you can reduce the number of steps to the optimal value;

- Length of flight of stairs. Knowing the depth and number of steps, multiplying them, we get the result: 22*380= 8,360 mm. The length of each march will be: 8,360/2=4,180 mm.

The example shows that it is better to reconsider the parameters of the steps. This will significantly save space. For example, with a riser height of 150 mm, the tread depth will become 300 mm, and the length of the staircase will be 5,400. This will save 3 sq. m. usable area of the house.

Constructive decisions

The choice of the type of staircase structure will be influenced by the layout of the room. Since winder steps are mainly located where there is no space for a transition platform, the final design is determined by the availability of free space.

Such structures can be divided into 3 types:

- L-shaped staircase with winder steps that rotate 90 degrees.

- A U-shaped structure with two turns and a final turn of 180 degrees.

- Curved design, where the number of turns is calculated individually.

Staircase with smooth curves Source fotocdn.net

See also: Catalog of companies that specialize in the design and reconstruction of houses of any complexity

The latter type includes popular spiral staircases and curved structures with smooth bends and turns. And the materials for structures are not only popular metal and wood, but also concrete. But with the development of technology, you can often find stairs with winder steps made of high-strength glass or transparent plastic.

Structurally, the buildings are divided into the following:

- made on stringers;

- collected on bowstrings;

- with steps fixed in cantilever;

- suspended on rails;

- combined.

In the latter case, the model is assembled partially on both stringers and bowstrings. You can find a union of a stringer and a blank wall, into which one of the sides of the step enters. Or everything is the same, but instead of a stringer, either a bowstring or a bowstring is used. There are frequent cases of construction being performed on a monostring.

Materials

After the calculations have been completed and the project has been prepared, you should decide on the type of wood from which the staircase will be built. For such structures, it is best to use hardwood that can withstand heavy loads, such as oak, ash, walnut and beech.

They are all approximately in the same density category, but differ in price and susceptibility to rotting. Thus, the walnut does not have sufficient durability and has an average cost. Ash is resistant to destruction, but also much higher in price. Pine is also suitable, but requires more careful processing.

Advantages and disadvantages

The main advantage over other designs is that the winder staircase with a turn is compact enough to fit even in the smallest space. An excellent example is screw structures, which are included in this category due to the shape of their steps.

Screw design Source grao.biz

In addition, the following advantages can be listed:

- The design looks quite modern and fits most design styles.

- For many models, their construction requires much less materials than a straight march.

- The smooth turn is very convenient when moving, in any direction.

- the choice of materials is limited only by the financial capabilities of the developer.

The main disadvantage is the difficulty in making calculations. After all, the design is not considered simple. And the fact that two people have difficulty passing each other on a narrow passage can be taken as a non-critical situation. Because it’s still possible to separate. Or you can do it one at a time.

Technical data for drawings

To correctly draw up a diagram of a winder staircase, it is necessary to take into account all the standards listed above, the dimensions of the premises and link them to the plan. To do this, proceed to the following steps:

- Determine the location of the structure.

- Make the appropriate measurements: the width of the opening, the height from the finished floor of the first floor to the surface of the floor of the second.

- Draw a plan of the first or basement floor on a scale with detail. If there are openings, windows, ledges, niches in the place where the stairs will be mounted, they are marked on the drawing with reference to the walls and floor.

- Select the type of structure and building material for it.

- Make preliminary calculations on the number, height and depth of steps.

Diagram and drawing of a winder staircase

This data will help make the correct selection of a design that will ensure compliance with building codes.

Independent calculations using the method of proportions

They say if you want everything done well, do it yourself. Therefore, independent calculations of the amount of materials, searching for the right angles and calculating strength are necessary for your own peace of mind. Confidence that the structure will withstand extreme weight and last for many years.

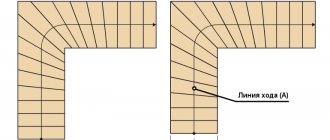

Step-by-step calculation of a staircase with winder steps at 90 degrees:

- In the drawing, a circle is drawn with a diameter equal to the width of the flight of stairs. This is how the running section is planned.

- A line is drawn from the upper left corner through the center of the circle at an angle of 45 degrees. This will become the axis of rotation.

- It is necessary to outline a vertical line entering the circle from below and exiting horizontally from the right. This is the driving route.

- Next, the entire line of movement is divided into segments that are equal to the width of the step. On straight sections these will be ordinary segments, and along the circumference – chords.

- Two straight marches are completely drawn along the planned segments. It should be remembered that part of the straight steps adjacent to the circle will subsequently change.

Calculation of winder steps Source olestnicah.ru

- The outer edges of straight marches must be connected by lines forming a right angle. This part is responsible for the running section.

- A line is drawn parallel to the horizontal route and a line parallel to the vertical one. These lines are drawn along the edges of the steps, which will not be modified in the future. And at the intersection point A is marked.

- Lines are drawn from it that will intersect all the extreme points of the segments and chords along the line of motion.

- After this, you can select the contours of the winder steps.

Now all that remains is to scale and find out the exact dimensions of each part. It is better to draw on lined graph paper. This will allow you to easily convert the dimensions of the selected material to actual size. But experts note that graphical constructions cannot be compared exactly with computer calculations.

Drafting

Before starting work on the manufacture of stairs, it is necessary to draw up a drawing of the future structure. In order for the product to be used safely, it is necessary to calculate all the geometric parameters and choose the correct slope. In this regard, the scheme provides significant assistance.

When designing, the following parameters are developed:

- When calculating the total number of steps, the distance between floors is taken taking into account the thickness of the floor and divided by the height of the step.

- The length of the structure is determined by multiplying the width of the steps by their number.

- The area is calculated by multiplying the length of the product by the width of the flight.

- Using the Pythagorean theorem, the size of the stringers is calculated. One leg is the height of the staircase, and the second is the projection of the stringers on the horizontal axis.

- The calculated values are included in the drawing.

If the resulting dimensions do not allow you to fit into the existing space, you need to adjust them.

Installation features

The structures are often combined. More common options are when the metal frame is trimmed with wood. It is used more often than other materials for steps. Even if the structure is completely poured from concrete, in a residential building they try to line the steps with wood.

It should be noted that reality often does not correspond to the drawings. And when the winder staircase with a turn is already at the stage of final assembly, it is often necessary to correct errors right on the go.

Possible problems encountered during installation:

- Bad material comes across. For example, unseasoned wood. Or her class is below normal. That is, having more than one knot on one linear meter. This is reflected in the service life of either the entire product or part of it.

Knotty board Source wallbox.ru

- Errors in cutting. This occurs when scaling, when the drawing dimensions are transferred to the material. Such errors are often inevitable and during installation it is necessary to have a tool on hand for final adjustment of parts.

- Distortion of elements. Neglecting to frequently check the position of the structure at the building level can lead to loss of evenness of the frame. Each stage of assembly must be controlled by the device.

Before installing the stairs, you must wait until the building has completely settled. Otherwise, the flight of stairs may subsequently become skewed. Because of this, cracks and unpleasant squeaking may appear during use.

Useful tips

Wooden stairs require special care. To achieve this, the following measures are being taken:

- Cleaning is done with a wet cloth without using detergents.

- The surface is wiped with a dry cloth with added wax.

- The structure must not be allowed to dry out.

- It is necessary to correct all problems in a timely manner: creaks, unsticking joints and loosening of fasteners.

Luxurious wood construction

Helpful information! Such a system shrinks. Therefore, you should not mount it tightly right away. It should sit for several weeks.

Do-it-yourself installation and proper care will create a durable and beautiful product that will last for many years.

Briefly about the main thing

When the small area of the room does not allow installing a straight flight of stairs at the required angle, then a more compact design can be used. A staircase with winder steps will fit perfectly into any interior and perform the functions of a lift no worse than other structures. And most importantly, it will save space and provide a comfortable lifting angle.

But in order not to spoil the design of the room, you need to choose a decent model. After all, the same staircase can look completely different. This also applies to materials that will be involved in construction and design solutions. But the most important thing when choosing such a complex structure is competent calculations. They are either performed independently or entrusted with the work to specialists.

Online calculators

If you have difficulties with independently calculating the winder steps for a wooden staircase, you can use these calculators for turns of 90° and 180°. The advantages of this design approach:

- It is enough to indicate the required dimensions, and you will receive a diagram with all the parameters without unnecessary divisions and multiplications;

- the result can also be prepared in 3D, which will allow you to visually evaluate the design and simplify its manufacture.

- By specifying the materials, you will also receive a construction estimate.

Step-by-step construction instructions

Finally, you can start making the staircase itself. The scheme described below is designed for a person who knows what it is to “weld metal”, but is not ready to do something complex, with an abundance of details.

So, a metal staircase is assembled both separately from the site and locally.

The second option is often preferable.

This scheme is standard, other options can be adjusted to it: with a ramp, with wooden steps, with stone, tiled ones. Naturally, the porch should be in harmony with the house, and the staircase should be a harmonious beginning of the structure. To do this, you need to carefully choose the design of the future structure, looking closely at other options for stairs for a porch in a country house or in a country house.

Technology and stages of manufacturing stairs with winder steps

In modern hardware stores you can purchase all the necessary parts for installing a corner staircase to the second floor. After purchasing, you just need to assemble the kit according to the included instructions. However, many owners of country houses prefer to build these products themselves.

Such a structure can be built in several stages:

- Creation of stringers.

- Construction of winder steps.

- Assembly of the prepared structure.

- Installation of railings and decor (if necessary).

Next, let's look at each stage in more detail.

Fastening stringers

The work starts from the top so that all the shortcomings fall on the bottom, where it will be incomparably easier to correct them. Stringers are attached to the ceiling using steel angles, bolts or self-tapping screws. The lower part must be inserted into the support beam. To do this, a groove is hollowed out or cut out on it. Its dimensions are 2 cm in depth, and its width and length are 1 mm less than the end. This is necessary so that the stringer fits tightly. To ensure reliable fixation, prepare a paste of sawdust and wood glue. It is placed inside and the stringer is beaten with a mallet.

The wall element is fastened similarly at the top, and at the bottom it is fixed to a metal corner to a support of a smaller cross-section, having previously cut out the end for laying the winder step. All work is carried out with strict observance of the level, otherwise future steps will not lie parallel to the floor.

Important points when making and installing stairs with your own hands

During construction and subsequent installation, the advice of professional workers should be followed. Here are the most important of them:

- Fastening is done only using stainless steel connecting elements (so as not to damage the main part over time).

- You need to use not only self-tapping screws. Hidden glue fasteners will increase the durability of the structure and have a positive effect on its strength.

- Keep an eye on your creation. In some places, over time you will have to tighten the fasteners a little or install additional supports.

Using the above tips, the owner of a private house will be able to independently build any type of staircase.

Additional Information

In order to clearly and efficiently produce steps for a wooden device, you should consider in detail the sequence of actions for making an L-shaped structure. The width of the product is 9.3 meters. The length of the opening is 229 centimeters. The ceiling height is 268 centimeters.

The product contains two marches. The first has eight steps. The last of them should coincide with the second floor landing. We make the second march from two components. It has three turning steps. The angle of rotation of the parts is 30 degrees.

For the product, it is necessary to create two stringers with parameters of 50×300×3000 millimeters. The first of them is attached to the near wall. The second one is fixed to a pole with parameters 100×100×2500 mm.

The steps have dimensions of 900x300x40 millimeters. The turntable has parameters – 900×900×40 mm.

Sawing stringers

For the load-bearing parts of the staircase, a template is made - a right triangle with the dimensions of the step depth and riser height marked. It is cut out of plywood or using a square. They mark with a pencil, check the rule - the thin part of the width of the board is no more than 15 cm - and cut out the excess.

It is better to use a jigsaw - it will carefully cut the parts along the intended lines. The ends of the prepared boards are immediately sanded to prevent them from splintering.