To select the right pipelines, it is imperative to take into account their geometric parameters. One of the most important indicators is the diameter of PVC, PPE, and cast iron sewer pipes.

A smoothly functioning sewer system is very important in a comfortable human home. The quality of life of each of us directly depends on the correctness of its installation. Only a well-designed and stably operating wastewater disposal system can guarantee cleanliness in a private home and in the larger city.

Type of pipes

For properly organized drainage of wastewater, pipes must be stable, durable and smooth on the inside. There are 2 main materials for making such products: metal and plastic. The latter are divided into 3 types:

- PVC – polyvinyl chloride. Durable and UV resistant, but cannot withstand high temperatures of hot water and exposure to aggressive environments. Used for internal and external sewers.

- PET – polyethylene. Operating functionality within temperatures of -40 +40 C°, not recommended for use in a hot water drain system.

- PP – polypropylene. They can last 100 years and are highly resistant to temperature changes and harsh chemicals. Used in domestic wastewater systems.

The cast iron drainage system is an outdated option. Despite the fact that it is durable and strong, it is completely replaced with plastic. This is not due to the disadvantages of metal, but due to the advantages of PVC.

Plastic pipes are also divided according to density and hardness. It depends on which highway they will be used:

- SN-2. Products made of lightweight material are used in areas with minimal load. The installation is carried out shallowly and not under transport roads.

- SN-4. They have a denser material and can be laid under roads with little traffic.

- SN-8. The densest and heaviest products are intended for use under highways and industrial enterprises.

PVC – polyvinyl chloride pipes

It is important to note that a PVC drainage system is not as durable as a cast iron one, but it is more flexible and easy to install. When properly installed, it can last 50 years.

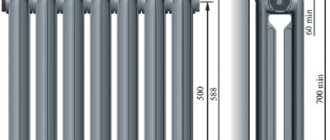

Standard bathroom sink height

When deciding at what height to hang a sink in the bathroom, they are guided by SNiP 3.05.01-85, it regulates the ergonomic distances from the floor to washbasins in different types of rooms; according to the standards, it is equal to:

- 800 mm in public and industrial buildings;

- 700 mm in school and children's medical facilities;

- 500 mm in kindergartens and buildings with disabled people moving with the help of strollers and other devices;

For sinks and sinks, the standard distances from the top edge to the floor have the following values:

- 850 mm in public industrial buildings;

- 850 mm in schools and health care institutions for children;

- 500 mm for preschool institutions and premises with wheelchair users.

For the listed plumbing equipment, height deviations of 20 mm are allowed; if a group of similar devices is installed, a maximum deviation of 45 mm in one direction or another is allowed.

When installing one mixer on a bathtub and a washbasin, its optimal height from the floor to the top edge is 850 mm.

For school facilities, two sink height standards are regulated:

- 550 - 600 mm for primary school students;

- 650 - 850 mm for children of middle and high school age.

Standards from SNiP II-64-80 regulate at what height to install a sink from the floor in gardens and nurseries for children, its values:

- 400 mm for nursery groups;

- 500 mm for preschool groups.

Dimensional parameters of the space in the sink area and its height

Pipe dimensions and area of use

There are certain standards according to which the size of a sewer pipe depends on the area of its use. Thus, a pipeline with a diameter of 40–50 mm is installed in kitchen and sink drains, and 75–100 mm in diameter in the sewer leading from the toilet.

Dependence of diameter and area of use

Standard parameters depend on the volume of water that must leave the container in a certain time. For example, in an apartment in a multi-storey building there are standard toilets, from which a large volume of water along with waste must come out in a short period of time. Therefore, in most cases, for toilets, the diameter of plastic or cast iron pipes is chosen to be at least 110 mm.

Table on how to choose the internal diameter for a sewer pipe depending on the use of the outlet:

| For dishwasher, washing machine | 25 mm |

| For connecting pipelines to the drain of a bathroom, shower box, sink, kitchen sink | 32 mm |

| Ensuring the installation of a sewerage system in the premises | 50 mm |

| Installation of pressure pipes for external water supply, sewerage, drainpipes, selection of diameter for the toilet | From 110 to 200 mm |

If you have non-standard parameters of water supply systems, then before installing a sewer system you need to determine the relationship between the amount of wastewater and the rate of its discharge. For this, certain geometric parameters are calculated.

In addition to the fact that the correct diameter allows you to calculate the water drainage rate, pipe cleaning is also carried out taking this parameter into account. For example, the technology of sewer cleaning with Kärcher systems is now very popular, but they are used only on pipes with a diameter of 100 mm or more.

Why is it important to choose the right height and consequences if the sink is high or low

The reasons why the correct selection of the height of the sink placement is important can be considered from the point of view of its incorrect location above or below the regulatory requirements. If the sink is lower, possible consequences:

- Elderly people suffering from radiculitis often experience back pain from bending at an acute angle and being in an uncomfortable position.

- Often a cabinet with a mirror is placed above the sink; if you are forced to tilt low, your head will rest against its outer surface - this will interfere with water procedures.

- If the sink is low, it is impossible to install standard-sized objects under it: a household washing machine, a cabinet, a basket with laundry.

- With a low bowl and a standard location of the mixer, due to the large distance between them, the amount of splashes during water procedures will significantly increase, as a result of which you will have to spend additional effort and time cleaning the room.

- A low-mounted sink will disrupt the aesthetics of the room and will cause constant inconvenience when using water, which will be an irritating factor that spoils the mood of the residents every day.

The high location of the sink from the floor level also causes a number of specific problems:

- When placing a cabinet or washing machine under the bowl, a large gap will appear between them - this will disrupt the aesthetics of the room.

- Schoolchildren will find it less convenient to use the washbasin and will have to reach up.

- Small children need to buy a stand of a higher height to use the sink - this will increase the risk of injury from a fall and will require the constant presence of adults.

As can be seen from the listed factors, the standard installation height of a bathroom sink from the floor will help to avoid a lot of unnecessary problems with the ease of use of the equipment and the placement of furniture, laundry baskets or electrical equipment for washing under it.

SNiP 3.05.01-85 for placement of plumbing fixtures

Pipe calculation

To individually select a pipe for installation in houses, cottages or in the country, it is necessary to calculate the permeability. To calculate the useful pipe diameter (internal d), you need to know the following parameters:

- D – outer (external) diameter, mm;

- B – wall thickness, mm;

- m – mass of a linear meter of pipe, g (necessary to take into account the number and type of fastenings if a complete replacement of the pipeline is needed);

- S – cross-sectional area, mm2.

Formulas for calculation:

d = D – 2 b;

S = π/4 (D2 – d2);

V = S * L;

m = ρ * V.

Pipe sizes

Many manufacturers of polyethylene pipes mark most of the required parameters on the communication. But, as a standard, only the outer diameter (D) and wall thickness of the outlet are initially known. The most important parameter is the internal diameter; it is used to connect the pipe to the main and to lay out the sewer system, select additional elements, fittings, etc.

Manufacturer's markings on pipes

Moreover, unlike polypropylene plastic pipes, cast iron sewer lines are initially specified by the manufacturer with a useful internal diameter. Like steel, it is designated DN. It can have different values, in whole numbers, for example, DN 110 or DN 200. This means that this pipe has a nominal water drainage diameter of 110 or 200 millimeters, respectively.

Mirror height

It is difficult to imagine a washstand in a bathroom without a mirror, which is installed separately or in a cabinet designed for storing hygiene items, detergents, medications, and cosmetics. Recommended mirror bottom height:

- 1100 - 1250 mm from the floor;

- 200 mm from the top of the washbasin;

- at eye level if a small mirror sheet is used.

When hanging a mirror, it is important to take into account the proportions; it is convenient for a person to look into it while standing straight, while it is advisable to remove the lower edge from the sink so that drops of water do not fall on it when washing.

Examples of mirror heights

Determination of nominal diameter

Regardless of the material from which sewer pipes are made and the scope of their purpose, they have the current standard dimensions:

- D – outer diameter;

- d – diameter from the inside;

- S – wall thickness;

- Dy – conditional pass.

The internal diameter sign is placed on the marking of cast iron products, while the external dimensions are most often indicated on plastic products. The external width of the product for all categories remains unchanged, only the wall thickness changes. For example, if a pipe has D = 33.5 mm, then S can vary within 2.8-4 mm. The level of strength of the product and resistance to internal and external pressure depend on the thickness of the walls. Fluid dynamics engineers, for all internal diameters, use one approximate figure of 25 mm and call it the nominal bore.

Conditional diameter is the maximum throughput of the pipeline. The efficiency and performance of the structure directly depends on its size. If you know the dimensions of the internal lumen, you can choose the right connecting elements so that the sewage system has a holistic appearance without the threat of depressurization.

All products of domestic and foreign production have a nominal diameter that is most suitable to the nearest standard according to GOST 28338-89 and GOST 3262-75.

Determination of nominal diameter

In addition to the sewerage capacity, it is also necessary to calculate its angle of inclination. These parameters directly depend on the size of the product and the material it is made of. Formula for calculating the angle of inclination: V× (H / D)½ ≥ K. Where:

V – speed of wastewater movement; H – degree of filling; D – outer diameter; K is the roughness value of the internal walls, for polymers = 0.5.

Pipe diameter with slope

The greater the slope, the higher the waste flow rate. The sewage system is less clogged and is able to serve a larger number of premises.

Some advice from experts:

Despite the fact that the riser is located vertically, it must have the largest diameter, at least 100 mm. This ensures unimpeded drainage of the maximum volume of wastewater. The outlet design should have a minimum number of turns to minimize the likelihood of clogging. Since it is in these places that hardening most often occurs. The recommended slope should not be less than 12 mm per linear meter. This applies to all categories of sewer pipes. If possible, a 90°C turn should be replaced with two 45°C turns, this reduces the likelihood of solid deposits building up inside the structure.

Compliance with generally accepted rules for organizing wastewater disposal guarantees uninterrupted functionality of the system. In modern projects, a hidden type of installation of the structure is increasingly being practiced. This means that if the installation is carried out incorrectly, difficulties will arise during repair work.

How to choose the right PVC pipes for sewerage

On the sketch of the future sewer system, it is recommended to indicate the length and width of the pipe, angle of inclination, connection points with plumbing, etc. Based on the drawing, calculate the number of plumbing fittings, connecting elements, fittings. Transfer the diagram to the walls and floor, double-check its meaning and calculations. After this, you can begin gating ditches for the structure. Their dimensions must match the diameter of the pipes.

How to choose the right PVC pipes for sewerage

The exiting private pipe must match the width of the riser into which it enters. In multi-storey buildings, the diameter of the main line can be either 110 mm or 200 mm, depending on the number of apartments in the building. If several houses are connected to an underground communication, the diameter can reach 300 mm or more. Underground connections are most often flanged, and above-ground connections are socket-type.

Switching from cast iron to plastic

There are situations when cast iron is installed in the sewerage system and it needs to be changed to PVC. In this case, you must first dismantle the old drainage system:

- Cast iron is cut from the top at a distance of 7.5-10.5 cm from the ceiling, and approximately 80 cm from the tee is left below, the rest is removed with a metal disc. These actions need to be done only until the middle of the structure.

- After this, the rest of the cast iron is removed with a chisel (to do this, it must be inserted into the drilled place and hit with a hammer, then it will fly apart).

- Otherwise, you can take a crowbar or a hammer drill to clear the cement from the pipe, and then use the chisel again.

- After this part of the cast iron is removed, it is necessary to remove the remaining concrete from below and saw off the lower part from the tee, leaving 3-7 cm.

What a joint looks like Source yelpcdn.com

How to determine pipe sizes

Foreign-made polypropylene, polyvinyl chloride and other plastic communications are most often designated by inches. It may also be that you need to install fasteners on the pipeline, but its dimensions are also given in inches, while the pipe is indicated in mm.

Pipe inch thread

To do this, you need to convert the known inch dimensions into millimeter ones. According to the data, 1 inch is 25.4 mm. It turns out that a pipe with a diameter of 2 inches = 50.8 mm, etc. Fractional values are very often used, this is how clamps, fittings, couplings and communications are marked.

Let's look at their meaning in the table:

| In inches | In millimeters | In inches | In millimeters |

| 1/8 | 3,2 | 1 1/8 | 28,6 |

| 1/4 | 6,4 | 1 1/4 | 31,8 |

| 3/8 | 9,5 | 1 3/8 | 34,9 |

| 1/2 | 12,7 | 1 1/2 | 38,1 |

| 5/8 | 15,9 | 1 5/8 | 41,3 |

| 3/4 | 19 | 1 3/4 | 44,4 |

| 7/8 | 22,2 | 1 7/8 | 47,6 |

| 2 1/8 | 54 | 3 1/8 | 79,4 |

| 2 1/4 | 57,2 | 3 1/4 | 82,6 |

| 2 3/8 | 60,3 | 3 3/8 | 85,7 |

| 2 1/2 | 63,5 | 3 1/2 | 88,9 |

| 2 5/8 | 66,7 | 3 5/8 | 92,1 |

| 2 3/4 | 69,8 | 3 3/4 | 95,2 |

| 2 7/8 | 73 | 3 7/8 | 98,4 |

PVC pipes of different diameters

But, when measuring a socket manually, for example, with a ruler, the nearest minimum size is always taken. For example, the diameter in millimeters of a sewer pipe for a sink is 34. It turns out that the outer diameter is 1 ¼ inches. Be careful when selecting sizes, otherwise you will have to buy additional spacers or adapters. But the coupling is selected based on the nearest larger indicator, i.e., 34 mm will be considered 1 3/8 inches.

Video: Joining pipes of different diameters in the sewer system.

Steel two-way communications may have different indicators on different sides; you need to double-check the data. This can be done by experimental measurements with a caliper or plug gauge.

Table: Diameters of ceramic pipes

List of sewer fittings

Only fittings are capable of combining pipes of different types and sizes. Used to connect branches and when turning a structure. The reliability of the system's sealing depends on correctly selected connecting parts.

| Name of the connecting element | Functionality |

| Tee 110×110 mm | Large fitting, used to connect to the central riser and toilet. |

| Reduction 110×50 mm | A special type of fitting that connects pipes with a diameter of 50 mm to a diameter of 110 mm. |

| Bends | Elbows designed to change the direction of pipelines. Suitable for all sewer sizes. Can be installed at an angle of 90° or 45°. |

| Tees | Several pipes are connected into one system. Can be all sizes identical or different. |

| Audit | Designed for places with an increased risk of contamination, equipped with special removable covers. |

| Stubs | They are selected for a certain pipeline diameter and installed at the ends. |

Installation features

Actually, most of the information has already been told, all that remains is to assemble the purchased components in accordance with the design idea.

Pipes are assembled from the riser (inlet pipe) towards the consumer. In other words, the pipes that are closest to the drainage point into the common house riser are installed first.

At each connection, the pipe should fit into the socket of the previous one by approximately 50 mm. If the cuff in the socket is too tight and you cannot insert the outlet, then you need to lubricate the cuff with liquid soap or detergent - things will go much easier.

Plastic pipes are cut using any available means: a grinder, a hacksaw. You can even do the cutting with a regular wood hacksaw. The main thing is to clean the cut edge from all kinds of burrs - burrs inside the pipe will cause blockage, and burrs on the outside will prevent the parts from being assembled properly.