Antique items invariably evoke admiration for their beauty and the skill of their creators. Rare items that have retained their attractiveness become an unattainable dream due to their high cost. Fans of antiques have found an affordable way to decorate their home and make an antique door with their own hands. There are several methods to decorate your interior in retro style or change your front door beyond recognition. All work is done independently; you don’t need to be an artist or cabinetmaker to do this.

Aging techniques

The front door influences the first impression of the house, therefore, in addition to the reliability and strength of the locks, the owners are concerned with its appearance. Solid wood canvas, even after many years, retains its excellent qualities and natural living beauty. Scuffs and scratches, constant companions of time, make the door less presentable, but there are ways to correct the situation and give a quality item a second life. There are five main techniques by which the door travels into the past:

- applying stain;

- brushing with a wire brush;

- use of paint and paraffin;

- patination;

- craquelure varnish.

When choosing a way to make a door look like an antique, focus on the external features of the canvas, and in the case of interior doors, on the decor of the room.

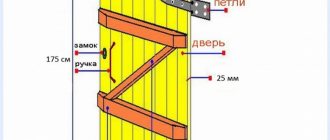

Imitation of antiquity is appropriate on swing doors; sliding or folding structures with such an effect look unnatural. Metal overlays attached to the corners and lock, as well as an unusual forged handle in the shape of a ring or an animal’s head will be an excellent addition to the decor. The style will be supported by massive canopies secured with nails with large brass heads.

Preparing the door leaf

Before starting any artistic work, the door must be prepared. To do this, it is removed from its hinges and laid horizontally on two stools. The canvas is freed from loops, handles and locks. The glass inserts are removed from the canvas along with the glazing beads. The next step is to remove the old paint. To do this, use a hair dryer, it heats up the coating, the paint swells and comes off. Finally, it is cleaned off with a spatula. Small particles of paint are removed by sanding.

If there are chips on the surface, they are rubbed down with putty to match the canvas. The door must be cleaned of dirt and grease.

Brushing

Having prepared the wooden doors, we begin artificial aging of the canvas. Not all tree species are subjected to brushing; it is not used for beech, maple, cherry and exotic trees. Among those that are transformed after processing are pine, larch, walnut and oak. Before starting the process, the surface is cleaned of dirt and grease. This method involves using a wire brush to remove the soft layers of wood. To avoid damaging the natural pattern, brush along the fibers. It is moved with the same speed and pressure so that the processing is uniform.

The finished surface acquires reliefs similar to natural changes in wood. After removing the fibers and sanding, the door is varnished. To enhance the effect, you can apply stain. This method allows you to create the most believable imitation of a rare item.

Description

A brushed hand sander is a universal tool that makes it possible to remove old paint, varnish and traces of corrosion from various types of wood and metal surfaces, as well as to refine a wooden structure. This device has a high level of performance and is used in conjunction with other grinders. The weight of one device does not exceed 5 kg, the number of rotations can reach up to 3000 revolutions, and the roller diameter is 120 mm.

To perform this task, manufacturers suggest using a nylon cylindrical brush. The brushing attachment makes it possible to artificially age the wooden material and remove all loose layers. After treatment, the work surface not only changes its structure, but also its color.

On the shelves of specialized departments of construction stores you can see two types of grinders.

- A tool with a wide body, behind which a shaft with attachments is hidden. The main feature is the presence of two handles and a start button.

- An instrument that has common features with a grinder. Distinctive features are the presence of a cylindrical brush and a handle, which is located parallel to the working shaft. The disadvantage is the lack of ability to adjust the processing depth.

This device consists of the following parts:

- engine;

- charger or wire to the electrical network;

- platform;

- pen;

- regulation and control system;

- working disk.

Two types of brushes are used for surface treatment:

- nylon;

- metal.

The brush has the shape of a cylinder that makes circular movements at high speed. To perform non-standard types of work, experts recommend replacing brushes and special rings.

To perform brushing, cup nylon brushes with abrasive grain on polymer threads are used, which can be attached not only to grinding machines, but also to a conventional drill.

To make work easier, the designers have provided two handles, and special pipes are installed to connect the device to the vacuum cleaner.

The number of revolutions depends on the diameter of the brush surface.

The adjustment system allows you to process products at a high level and at the same time adjust the cleaning depth.

Nozzles can be changed using a hex wrench.

Most grinding machines have auxiliary parameters:

- adjustment of the number of revolutions;

- automatic speed control;

- grinding depth adjustment;

- protection against unauthorized start;

- presence of a dust collector;

- possibility of quick replacement of deformed parts;

- additional protection of the engine from contamination.

The device may include an organizer, a set of metal, abrasive, polymer and nylon brushes, as well as a charger.

Patination

Patination will help create the effect of multiple painting on a pine door. This method requires precision and creativity. The first coat of paint is applied using a spray bottle. It is necessary that the coating is smooth and without streaks. This quality is difficult to achieve using a brush, but you can try. For the main tone, dark paint is used. After it dries, a thin layer of white paint is applied to the door. After letting it dry slightly, wipe down individual areas with a dry rag. The processing is completed with sandpaper, it helps to draw structural dark stripes. The more wear on the canvas, the older it appears. The work is secured with a layer of varnish.

Interior doors with patina are popular, but due to the manual decorating processes used, they are expensive. A little time and imagination will allow you to make such a door yourself with minimal financial costs. In addition to light paint, gold, silver or black are used, depending on this, different patina effects are created.

Applying stain

To create an original color and emphasized wood pattern, water-based stain is used. This composition penetrates the pores of the wood and reacts with tannins. Penetrating deep into the canvas, the stain lifts the wood fibers and makes its structure more prominent. The colors of the stain allow it to be applied to various types of wood, it will highlight light shades, reddish and black. Apply the composition with a foam sponge or brush. The work is carried out in several stages, the first layer being the most abundant. After it dries, you can sand the surface and paint it again. The finished door is waxed.

Craquelure

The technique of aging a surface by creating a pattern in the form of cracks is called craquelure. This type of work requires a special varnish. The effect of an antique surface is created on a light background or using contrasting paint. For aging, craquelure varnish is applied to the grease-free door leaf, and the top is coated with a bitumen-based composition. This enhances the relief of the cracks. Acrylic paint is applied to a dark base over varnish. If the general style of the interior allows, cracks in the door leaf are painted over with gold paint. To make the process easier, buy the composition in cans; it applies easily and neatly to the surface. The choice of colors for the base coat and finishing craquelure is very wide.

What it is?

A grinder or angle grinder is a tool often used in construction and during repair work. If your house needs minor repairs, there is no point in buying powerful and expensive construction equipment. But purchasing such a car would be useful and relatively inexpensive. The versatility of a modern tool is its main advantage: angle grinders are used to saw and cut, grind and level surfaces. The principle of operation of the grinder is simple: operations are performed by rotating attachments.

Discs are divided into three types - sharpening, cutting or grinding (grinding). The operations vary in purpose and complexity; sometimes one machine has to process materials of different hardness, as a rule, stone and steel compounds, as well as wood. Renewed and processed wooden parts, windows, floors and furniture are subjected to grinding.

The attachment on the grinder for sanding wood is a replaceable circle, similar to that for a circular saw. The roughing cutter for primary grinding is made of durable metal, has teeth and is selected according to the diameter for each angle grinder. The size of the teeth is determined by the thickness of the wood layer. The shape of the tooth also matters. Variables are suitable for all types of wood, and trapezoidal ones are used only for soft varieties. The material can also be roughly processed using discs with straight teeth.

Before processing, you need to saw the wood with other sawing cutters. They are monolithic, made of high-strength sheet steel. Some varieties are made with coating on the teeth.

other methods

Solid wood of beech, oak, ash and poplar is aged by chemical treatment. The door is thoroughly cleaned with fine-grained sandpaper and ammonia is applied to the entire surface. It reacts with tannins, causing darkening and brightening of the wood structure. For coniferous species, this method is unacceptable, since such wood does not contain tannins.

You can achieve a dark color and a relief structure of the fibers by singeing the door - the canvas is burned with an open fire of a blowtorch. After heat treatment, the surface is polished. The final touch is varnish or stain. Creating a rare door is an interesting and creative process; it gives you a chance to show your artistic taste and individuality. All methods of influencing wood are available at home and do not require expensive compounds and tools.

Vibration grinder

Vibration grinder

Sanding pad

Another name is surface grinding

car. The working unit of this tool is a rectangular base on which a sheet of sandpaper is attached. Grinding and polishing is carried out by fast back-and-forth movements of the sole (about 20,000 vibrations per minute (333.3 Hz) with an amplitude of about 2 mm). The most common two methods of attaching sandpaper are:

- Using a pressing mechanism on both sides of the sole.

- Using Velcro - the paper is simply applied with its base to the sole, which has this feature.

The sanding sheet and pad have several holes to drain dust from the work area into a dust container or vacuum cleaner. The main purpose is grinding and polishing.

Delta grinder

It is a type of vibration grinding machine. The delta sander is distinguished by a delta-shaped (triangular, like an iron) sole shape, which allows you to work in hard-to-reach places - in corners, among protrusions and other similar places. The universal cutter can perform the functions of a delta sander when installing the appropriate equipment (a triangular sole with a sticky base) and a sanding sheet).

Video

In one video you will see how to age wood using firing, brushing and oiling:

- 1 Preparatory work

- 2 Surface finishing: 5 ways

- 3 Brushing

- 4 Painting with stain

- 5 Patination technology

- 6 Fabric abrasion

- 7 Craquelure

- 8 Videos

- 9 Photos

“We are greeted by our clothes, we are seen off by our minds” - these words are mainly applicable to people, but if we talk about our home, then such “clothes” can be called the door of the house. It plays an important role: it creates a good impression both of the housing and of the owner himself. In our age of artificial materials, many have forgotten that natural wooden doors have always been in trend and were considered a symbol of reliability. And antique-made things attract people with their sophistication and appearance. So let's look at how to make an antique door with your own hands.

Where is brushed wood used?

The bulk of the brushed material is used for the production of furniture and other interior items, and is used for interior decoration.

The use of brushed wood in the interior Source ratatum.com

From such wood you can make any “antique” furniture: cabinets, chests of drawers, beds, shelves, etc., cover the walls with panels made of aged wood, renew the floor, decorate the fireplace with a shelf made of it. Brushed wood is used to make small decorative items, such as jewelry boxes.

Beautiful box in country style Source yandex.net

Artificially aged wood can be used as a finishing material not only for residential buildings, but also for bars, restaurants, billiard halls, cafes and similar establishments. They will help create a unique, cozy atmosphere.

Preparatory work

Before starting work, you should remove the doors from their hinges and place them horizontally on a hard surface. Two stools are suitable for this purpose. Then, using a hair dryer, you need to remove the old paint. How to do this? By heating paint, which will swell under the influence of temperature. Now it can be easily removed with a spatula.

The next step is to seal all the gaps, cracks and potholes formed during operation. To do this, you will need putty, the color of which should be close to the shade of the wood.

Ideally, use a furniture varnish based on beeswax. It is not cheap, however, if you want to make your entrance doors beautiful, reflecting the color and texture of natural wood in its full glory, then you should not skimp on finishing materials.

The final stage is sanding. In order for the paint to lie smoothly in the future, you need to polish it thoroughly. Doing this by hand is difficult and time-consuming, so a grinding machine will help. Now you need to decide how to decorate the door.

Machine Applications

All three stages of finishing can be performed on special grinding machines or using other electrical equipment: grinders for smooth or angular surfaces. There are homemade brushing machines. It is difficult and expensive to make a full-fledged machine with your own hands, working like a thickness planer, so they use the same grinder with several metal and nylon attachments.

Full mechanization of work makes sense for large volumes of wood that require brushing. In such a situation, investments in the acquisition and operation of units will be justified. Common types of home repair and construction work can be quite successfully done with an angle grinder, which every craftsman has.

Brushing

The beauty of this method is that in the end result it will be difficult to determine whether it is a “fake” or a real rare item. Only a professional can understand this.

This technique includes 4 main stages:

- First you need a metal brush. Choose a brush with a stiff wire. With its help, you need to remove and deform the soft layers of wood. After this treatment, the surface will become embossed, and you will give the canvas structure. This should be done carefully, ensuring that the surface and depth of the structure are uniform.

- During work, the surface becomes shaggy and linty. This effect is not needed, so the wood will need to be tidied up. Here the same metal brush comes into play, only with soft wire. It will not pull out new fibers, but will allow you to get rid of old hangnails. Such work is carried out exclusively along the fibers; in no case do it across, as the structure will deteriorate and the wood will look torn.

- To bring the surface to the desired “condition” you need a soft polymer brush. Use it to remove small lint. We do everything as in the first and second stages.

- The last stage is applying a decorative coating. To do this, use wax-containing oil. First, you need to fill the recesses with a dark shade of oil, and cover the entire surface of the canvas with a lighter shade. If desired, you can do the opposite.

It is important to note that not all types of wood are suitable for such manipulations. For example, products made from birch or beech have a poor structure, but oak or pine doors are ideal.

Operating rules

The quality and speed of work depends on the correct choice of the required device. The following parameters influence the choice of the desired device:

- purpose and scope of use;

- frequency of use and volumes of planned work;

- type of food;

- price range;

- availability of quality certificates;

- country of manufacture;

- ease of use and ergonomics.

When working with a grinding machine, professional craftsmen recommend following the following sequence:

- connection to an electrical power source;

- holding the tool securely;

- turning on the device;

- warming up and gaining speed;

- surface treatment.

After finishing work, be sure to clean the device and lubricate all working parts. For complete dust collection, it is necessary to regularly inspect the dust collector.

To replace parts, you must choose products from the same manufacturer.

For long-term storage of the device, use only warm rooms with good ventilation.

When working with an electrical device, it is imperative to use personal protective equipment and follow safety rules that will help avoid injuries and damage to the tool.

It would not be superfluous to list the most common types of breakdowns of brushed grinding electric tools and how to eliminate them:

- oxidation of copper plates in carbon brushes - surface treatment with a rubber eraser;

- violation of the integrity of the winding - removal of the deformed part and installation of a new one;

- failure of the device control buttons - installation of new structural elements;

- deformation of rotor bearings and bevel gears - installation of new parts.

The time range for free elimination of defects is set independently by the manufacturer or seller. This service will not be provided if defects were caused by improper use, transportation or storage. When contacting the seller to solve a problem with a tool, you must provide him with all the documents, checks and receipts that confirm the purchase of the goods from him. The name of the service organization is indicated in the device passport.

To perform high-quality polishing, cleaning and grinding of various surfaces, modern manufacturers produce a huge range of grinding tools, which are widely used not only by professional builders, but also by home craftsmen. These devices significantly reduce the period of work completion and improve its quality.

Before you go shopping, you need to study all the features of this device and be sure to consult with professional builders.

Beginners should understand that a high-quality electrical device cannot have a low price.

See below for a detailed video review of the brush grinder.

Painting with stain

This is a fairly cheap and simple method. You will need a water-based stain. This process is quite painstaking, so be patient.

The product is covered with a layer of paint. Next, wash off the stain using a sponge. Also, depressions and chips in the wood are additionally processed with a brush. After the surface has dried, the final layer of stain is applied. When dry again, the workpiece is coated with alkaline primer using a brush. After this, you need to apply antique wax and rub it thoroughly with a wire brush along the grain. After this treatment, the doors will retain their aged appearance for many years.

Patination technology

This method involves using several paints with different shades. The method is not the easiest, so you will need to follow a clear sequence and rules. The work order is as follows:

- Cover with a base coat of paint. It's best to use a spray bottle, but if you don't have one, a brush will do. The main condition is not to leave streaks or drips from the brush. It will be difficult to achieve this, and some will even say that doing it with a brush or roller is simply unrealistic. Although if you want, you can do anything, you just need a little patience. After painting, the doors need to dry. It is recommended to start the next stage in a few days.

- When the surface is ready, apply the next layer of paint with a different shade. In this case, there is no need to use a spray bottle. Need a brush. It is important to apply the paint in a thin layer. You should not immerse the brush deep into the container, as drips are inevitable. The essence of these manipulations is to draw structural stripes.

- Then we wait until the paint begins to dry, but do not let it dry completely. We create abrasions using a dry rag. As a result, the lower, dark base will be visible through the light tone of the paint, which will give the door a shabby look and the feeling that it has been painted more than once, a couple of decades apart. All this needs to be opened with varnish.

Creating cracks

When the doors are old and have been painted many times, the coating on them often cracks, creating an artistic web. But you don’t have to wait for such cracks to appear; you can do them yourself in just a couple of hours.

The technology for creating cracks is called crackle, and the compounds that promote their appearance are called craquelure. As a rule, these are varnishes with special properties. The ingredients included in their composition tear the paintwork applied on top of it or in the lower layer.

Varnish-craquelure

Different varnishes act differently, they can be one- or two-step, so before use you need to study the instructions:

- The simplest method using a one-component composition is that the craquelure is applied to the dried paint coating in a thin layer, and it cracks under the influence of the active components.

- Another method involves applying craquelure between two layers of paints of different colors. In this case, the top layer is damaged, and the bottom layer is visible through the cracks.

The crackle method can be used to decorate not only wooden, but also iron doors to look antique. And also combine it with other methods of aging. Look at the examples:

Small dark cracks

Large light “web”

Combination of crackle and abrasions

The effect of cracks in certain places

Peeling paint effect

Metal door with the effect of an old coating

If you wish, you can do without special compounds and get a similar result using other means, most of which can be found in any home:

- PVA glue. The glue is applied to the canvas in a thick layer and, without allowing it to dry, it is painted with acrylic paint. After which the painted product is dried with a hair dryer. Hot air will cause the paint on the adhesive to crack.

Waterproof PVA glue

- Vinegar. Regular table vinegar 9%, if poured onto a freshly painted coating, will also cause it to crack.

After drying, the vinegar is washed off and the fabric is dried.

- Gelatin, egg white. When covering a door leaf with raw protein or brewed gelatin, it will not be the paint that will crack, but the coating itself. Therefore, the effect will be there, but not as pronounced.

Edible gelatin

- Aluminum powder. It is also called silverfish. The door is varnished and after 20-30 minutes they begin to dry it with a hairdryer. Drying too quickly will cause the composition to lose its integrity and the varnish to crack. You need to carefully rub the powder into them and sweep away the excess.

Serebryanka

Whatever method you use, the result needs to be consolidated. Therefore, after final drying, the canvas is opened with colorless varnish.

Fabric wear

The work also takes place in several stages. At the first stage, the surface is painted, after which paraffin is applied to different areas.

After this, it is treated with another layer of paint. The tone of this paint should be lighter. When everything is dry, carefully remove the paraffin with a spatula. Then the surface must be sanded and covered with stain.

Craquelure

The technology for producing deep and small cracks in a painted canvas is called craquelure. Why? Craquelure is a material that creates the effect of breaking an integral layer. Anyone can age entrance or interior doors using this method. If you strictly follow the instructions, the result will be the best.

The first step is to apply the base paint. When the surface is dry, you need to spray the finishing coat (craquelure) onto it. As a result, the components will cause the base layer of paint to become covered with a web in the form of decorative cracks. This will take a few minutes. Oddly enough, but that's all. There shouldn't be any difficulties.

Which paint color to choose is entirely your decision; the shade options are very different. There are no rules or advice here. You can take into account the color of the trim in your home or room.

Of course, there are many more technologies for aging doors: carving, adding metal or wooden overlays, painting and more. But these methods are quite complex. The methods described above will be enough to give your door several decades of life.