The inner part of the window opening in the room is called the slope. Sometimes this opening has a slight slope towards the room. When repairing or replacing a window unit, the slopes become unusable or damaged. For restoration or complete replacement, drywall can be used. Plaster is not convenient in all cases.

This building material will help to avoid all the difficulties associated with the plastering process. Why drywall? Its installation can be carried out in two ways. Using metal structures or glue.

Preparatory work

At the preparatory stage, it is necessary to prepare not only building materials, but also tools. When installing plasterboard slopes, the following steps are performed:

- removing excess foam;

- cutting sheets from gypsum board sheets;

- installation of canvases (on foam or on a frame);

- slope putty;

- painting;

For the manufacture of slopes, moisture-resistant gypsum plasterboard or gypsum fiber sheet (gypsum fiber sheet) is used.

Advantages of window slopes made of sandwich panels

- Thermal insulation - due to the presence of insulation, sandwich panels have good thermal insulation properties;

- No special additional tools are required for their installation;

- Do not rot;

- They tolerate temperature changes well;

- Durability;

- They have soundproofing properties;

- Moisture resistant;

- With not much weight, excellent strength;

- Easy to care for - just wipe regularly with a damp cloth.

Just like any other finishing material, sandwich panels for slopes also have disadvantages.

Disadvantages of slopes made of sandwich panels

- They do not withstand too high temperatures, and they change color and become deformed;

- If exposed to ultraviolet rays for a long time, they may lose their whiteness;

- They are inconvenient to transport; sandwich panels are produced in large sizes (3 meters by 1.5 meters), so they have to be cut on site or ordered delivered.

Dimensions of sandwich panels for window slopes

Such panels for slopes are produced in several sizes. Panel thicknesses of 10, 24 and 32 mm are considered standard. Some companies produce sandwich panels with a thickness of 6, 8 or 16 mm. The size of the panels in width and height is 3 x 1.5 m or 3 x 2 m. The maximum size of sandwiches is 3 x 2 m, this is due to the size of the plastic sheets produced and the pressing machines on which they are glued together.

Stages of installation of slopes made of sandwich panels

At the first stage, the window slopes are cleaned of dirt and all voids are sealed. Then measurements of the slope and cutting of the panels are made, after which they proceed to installation. First, the slope is fixed on top of the window, the starting profile “U” or “J” shape is attached using self-tapping screws.

The panel is then inserted into the profile with a slight slope. The gap between the jumper and the sandwich panel is filled with polyurethane foam. Using liquid nails, the front part of the slope is attached to the opening. The side window slopes are also installed.

Which is better: heated floors or radiators?

Warm floorBatteries

After installing slopes made of sandwich panels, your windows will take on a finished look, and your home will delight you with warmth and comfort.

Cost of sandwich panels for window slopes

The price of such panels is quite affordable, so almost everyone can afford window slopes made from sandwich panels. One panel measuring 1500 x 3000 x 10 mm will cost an average of 800 - 900 rubles.

If you order the installation of slopes from a company, then installing a slope made of sandwich panels will cost around 500 rubles per square meter.

Today there is a lot of talk about the dangers of some building materials, and one of them is polystyrene. And many try to explain their reluctance to use finishing materials made of plastic by the fact that it emits substances harmful to health, while drinking water from plastic glasses that was boiled in a plastic kettle, and eating food packaged in plastic.

Of course, all this is harmful, but we have been living surrounded by plastic for a long time and therefore it is up to you to decide whether to install slopes for windows made of sandwich panels or not.

Video: Installation of slopes without PVC corners (full version)

- External slopes for windows External slopes for windows are often considered unnecessary and unnecessary.

- Window sills To protect the facade of the building and give the window a complete and harmonious look.

- Wooden window slopes Exquisite and elegant wooden window slopes are the most ideal option for finishing.

- Types of slopes for windows A wooden window, just like a diamond, needs a beautiful one.

Installation using a metal guide profile

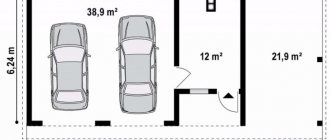

A frame is installed to cover the walls and create a new slope. For the frame, special metal profiles 27x28 mm are used.

Insulation is placed between the wall and the sheet. In this way, the resulting void is filled.

The stages of sheathing work are simple. First of all, the frame is installed.

Then parts are cut out from the sheet to size. The parts are attached to the metal frame with self-tapping screws. The finished structure must be puttied. The putty will cover the screw heads and make the surface smooth. After complete drying, it must be sanded. The finished surface is covered with paint and varnish material.

The method of installing slopes on a frame is outdated. With the advent of low-expanding mounting foams and special adhesive compositions (for example, Knauf Sevener), it is easier to install slopes without a frame.

Plastic slopes

This option for slopes is the “youngest”, and now more than half of consumers are in favor of this finish when deciding which slope is best for a window.

So, the undeniable advantages:

- Smooth surface. Of course, no one will argue about the smoothness and evenness of the surface of the plastic being produced today;

- Quick installation. The simplest type of installation that you can imagine, if you are not yet a master of your craft, and you are choosing which slope for the window is best. We advise you to opt for plastic options;

- Clean work. There will not be as much dirt and debris as when working with plastered window slopes and drywall;

- No finishing work. There is no need for painting or puttying of the seams - it’s installed and that’s it, the work is finished;

- Color selection. Manufacturers today can please consumers with a wide variety of product colors;

- Additional thermal insulation. This material provides additional thermal insulation to the slopes, which is also a very tangible advantage when deciding which slopes are better for windows;

- Possibility of replacement. If in the case of gypsum craton it is necessary to completely repair the slope, then a partial replacement can be completely sufficient.

Disadvantages of plastic slopes for windows:

- Damage. These slopes do not “sustain mechanical damage;

- Price. Despite the affordable price for this type of finishing, it is still worth choosing more expensively, since cheaper analogues may change color when exposed to sunlight, and your boiling white slopes may become dirty yellow after six months, and hidden ones may also become visible stiffening rib;

- Inconsistency between the colors of the panels themselves and the fittings. Often there is no available color of fittings that would match the shade of the panels themselves, especially if you have chosen some exotic option;

- Inconsistency with the interior. Often, this option for window decoration does not suit the designer’s idea, especially if the interior is designed in a classic style;

- Number of additional extras. Only all purchased planks, profiles and corners will guarantee your room an ideal look.

So, here is a fairly detailed analysis of the most common finishing options, read, think, and then you will find your own answer as to which window slopes are better.

Installation using adhesive composition

The main advantage of this method is that it does not reduce window space. The absence of a metal frame saves space. The covering occurs using a special adhesive composition.

The appearance of the glue resembles powder. It is a dry mixture. Before use, dilute to the desired consistency with water. It is best to dilute in a large container. Stir the composition thoroughly. The mixture should be homogeneous, smooth, without lumps. It is most convenient to mix a large volume with a drill.

Manufacturers recommend applying a primer first. Thanks to it, the surface stops collecting dust. The adhesion of the glue to the primed surface is much stronger. The adhesive mixture is applied to the previously prepared part. The part is attached to the slope only after the primer has completely dried. After installation, the finishing stage begins:

- trim the corners, putty, attach the perforated corner;

- slopes are puttyed, leveled, all fastenings are hidden;

- after the first layer of putty has dried, apply the second;

- the prepared surface is ready for decoration.

What is the best way to finish the slopes of plastic windows: 4 options, expert opinion

To avoid the finishing stage, you can take laminated gypsum board instead of the usual one. But in this case, you will have to use special corners to cover the ends of the sheets.

- Low price.

- A smooth surface that retains its properties for many years and does not require additional finishing or regular maintenance.

- No cracks or temperature changes due to the use of the same material from which the frame is made.

- Additional thermal insulation that strengthens the weak point of the window opening - the seam between the frame and the wall of the room.

The technology for installing slopes made of gypsum fiber boards is practically no different from attaching plasterboard; the advantages will be the same. At the same time, GVL does not have the disadvantages of GCR: it is much stronger and stiffer, and its moisture-resistant version is not at all afraid of a wet environment. When renovating an apartment in a new building or replacing windows, you will have to choose how to finish the openings after installing modern structures with double-glazed windows. To make them, pieces of gypsum board of the required size are used, which are screwed to a profile frame or glued to the sides of the opening. Then the surface of the drywall is primed, puttied and painted.

The space between the wall and the new slopes is insulated with polyurethane foam. Transporting products can be difficult since the sheets are large. However, in some stores they are cut into smaller pieces.

It is important to purchase high-quality material, since otherwise, when exposed to direct sunlight, the panels may lose their shape and turn yellow . The craftsmen are right because due to temperature changes at the junction of the horizontal upper slope and the cracked vertical slope, it is necessary to constantly clear and putty and paint again, but plastic slopes are sealed with a special acrylic sealant and there are no cracks, because acrylic tends to expand.

- good thermal insulation;

- sufficient sound insulation;

- do not require painting;

- easy care: washable with ordinary soapy water;

- quick and easy installation.

After the plaster has completely dried, after 24-48 hours, the surface is rubbed down using sandpaper. All work will take 2-3 days. The process is labor-intensive and dusty. Advantages: low cost, naturalness.

Disadvantage: with high humidity it can crack and crumble. Most suitable for rooms with normal humidity levels: offices, living rooms. Alekha wrote: Guys. What are you arguing about. I’ll say right away that I’m against plastic, it looks too cheap, gypsum board is excellent, not expensive and not labor-intensive! Prok12 wrote: Sandwiches also provide insulation, plaster does not. Drywall can sooner or later get wet, say from rain with an open (tilted) window - this happened to me at work. At first it bubbled, then it turned to dust.

Sandwiches can be easily replaced if necessary; they are joined to the window profile through a U-shaped starting profile - without gaps (I attach the U-profile to the window frame with rivets every 15-20 cm, and with transparent glue). That is, I am for sandwiches - They do not require modification - they do not need to be tinted over time; the service life of such slopes can be compared with the service life of plastic windows. The Teplovik company produces slope finishing using materials such as plastic sandwich panels and plasterboard. If you choose between these completely different types of window treatments, it is difficult to get a definite answer whether plastic or plasterboard slopes are better.

Each of these types of slopes has its own advantages. 1. The main disadvantage of the material is that if the surface of the panel is damaged, the defect (a hole, a deep scratch) cannot be quietly removed. As a result, the entire panel will need to be replaced. Mounted in 2 ways: framed and frameless.

The frameless method is used on flat slopes and involves installing the material using mounting adhesive. The frame method is used for uneven slope surfaces.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Mounting on polyurethane foam with alignment of the window opening

Polyurethane foam is multifunctional. It fastens, levels, insulates. Universal building material. Polyurethane foam is also used to fasten plasterboard slope parts.

Attention! Construction companies recommend making slopes at an angle. This will allow more natural light to enter the room.

The space between the wall and the gypsum board panel is filled with foam. During the filling process, remember that the polyurethane foam increases in volume. Therefore, the space is not completely filled. For additional fixation, you can use masking tape. Or use mineral wool as insulation. It is laid between the sheet and the part.

Excess foam is cut off after drying. The seams are sealed with sealant.

As an installation option, you can see a photo report on the installation of slopes made of plastic sandwich panels on polyurethane foam.

DIY window slopes: step-by-step instructions

Slopes on windows with your own hands can be made neat and functional in several ways and using various finishing, insulating or combined materials that combine both qualities. To figure out which option will be easier to install and more suitable for a particular case, you need to consider the most popular of them.

What materials are most often used for installing slopes?

There are three most commonly used methods of giving slopes an aesthetic appearance, each of them is good in its own way and can be used in combination with insulating material. So, PVC panels can be installed on window slopes, plasterboard can be glued or fixed to the sheathing, or the surface can be leveled with a plaster and putty mixture.

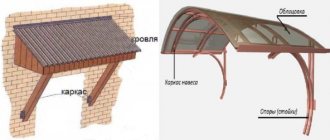

Slopes made of PVC panels

For finishing using this technology, plastic lining and auxiliary fittings are used. They help to hide the edges of the panels at the junctions of horizontal and vertical surfaces, as well as at the lines where they join the window frame and at the outer corners of the slopes.

Slopes made of plastic panels look very nice

In addition to the usual PVC lining, sandwich panels specially manufactured for this purpose are used for cladding, which consist of layers of plastic and foamed polystyrene. This material will facilitate installation, since you will not have to separately adjust and install the insulating material. In addition, this approach also often allows you to do without some elements of fittings.

Sandwich panels perform both decorative and insulating functions

Like regular lining, sandwich panels are great for decorating slopes around plastic windows, especially since, if desired, you can choose the desired PVC color that will be in full harmony with the shade of the window frame.

Plastered slopes

This finishing method can be called traditional. High-quality surfaces will last a long time without losing their neat appearance. However, it should be noted that without a layer of insulating material, plaster cannot become an effective barrier to the cold coming from the window opening. The disadvantages of this method include the labor intensity and duration of arrangement, since the solution is applied in several layers, each of which must dry well. In addition, plastering work requires certain experience in its implementation, and without it, it is quite possible to ruin the surface, wasting time and money.

The old proven method of plastering slopes does not lose its relevance

The process of finishing slopes with plaster mixtures is quite “dirty”, and since it takes a lot of time (sometimes it takes from one and a half to two weeks), the room where the work is being carried out will need to be cleaned daily or not used at all.

Prices for popular types of plaster

Plaster

Plasterboard slopes

Often, apartment and house owners prefer to decorate window slopes with plasterboard. This material is easy to install, it can be used together with insulation, the sheathing is quite durable and perfectly levels surfaces. In essence, drywall is dry plaster, but its installation is much faster than the “wet” version. This method does not cause large pollution in the room during work and does not require much experience to perform it. It is enough to follow the already tested instructions to carry out the finishing carefully and correctly.

Drywall slopes are very convenient for installation work.

Do you want to make window slopes from plasterboard?

The installation process is described in detail in the article on our portal “Do-it-yourself plasterboard slopes”, which can be easily accessed by following the link. There, in the publication, questions about the varieties and performance qualities of this material are well covered.

Tools and materials for installing slopes

Tools for work

To install any of the selected materials, construction tools are required.

Tools required for installation of slopes

A. If plastering work is ahead, then you need to prepare:

B. To install PVC panels, you need to have on hand:

- Sharp construction knife.

- Angle, ruler and tape measure for measuring and adjusting panel blanks.

- A construction syringe for working with sealant or a gun for polyurethane foam.

B. Some tools are needed to install any of the materials listed above:

- Wide brush for applying primer.

- A building level that will help control the alignment of surfaces ideally in vertical and horizontal planes.

- Metal scissors for cutting reinforcing corners or profiles.

Separately, it is necessary to say about the tools intended for preliminary preparation of slope surfaces:

A construction hairdryer - if you can limit yourself to removing the old paint coating.

Necessary materials

A. If plastic slopes are chosen for installation, the following materials will need to be purchased:

- Plastic panels (or lining), the number of which is calculated according to the parameters of the slope. The panels will be needed for installation on the sides and ceiling of the window opening, which means that in order to find out the exact amount of material, you need to measure the height, width of the slopes and thickness of the walls. Typically panels are purchased with a 10÷15% reserve.

- Starting plastic rail, U-shaped.

- A rail having an F-shape (F-profile).

- Profiles for internal corners installed at panel joints.

- Thermal insulation material - polystyrene foam or mineral wool of the required thickness and size. If already insulated sandwich panels are used, then you can do without additional thermal insulation.

- Wooden or plywood slats with a thickness of 100 ÷ 120 mm.

- Self-tapping screws of the required length.

- White silicone for sealing gaps between panels.

- Polyurethane foam - it is better to use “professional” foam in tubes, rather than cheap ones in aerosol cans..

- Staples.

- Primer composition.

B. To finish slopes with plaster, the following materials will be required:

Prices for popular types of antiseptics

Antiseptics

Preparation of slope surfaces

After everything you need has been purchased and prepared, you can proceed to preparing surfaces for installing finishing materials. This process can be carried out in different ways.

- If the window is installed in such a way that there is enough space on the slopes around it to install finishing with insulation, then it is often enough just to remove the old paint, whitewash or wallpaper from these surfaces.

Whitewash or wallpaper from the walls around the window can be easily removed if you first soak them by soaking them several times with water.

Removing old paint using a spatula and a hair dryer

Oil-based or organic-based paint is usually removed with a spatula by heating the surface with a hair dryer.

Cleaned slopes must be primed with an antiseptic primer to avoid the appearance of mold stains under the finishing, which can not only ruin the walls and finishing, but also introduce an unpleasant odor and a very unhealthy atmosphere into the living quarters. The fact is that the fungus can be dangerous to the health of residents, so this stage of work should not be neglected.

Mandatory priming of the base surface of the slopes

The application of primer is most often carried out in several layers, each time after the previous one has completely dried. Not only smooth surfaces are processed, but also hard-to-reach corners - for this you need to use a narrow brush.

This method is used in cases where a very small distance is left between the window frame and the slope, which does not allow the window to be fully opened. Another situation where this drastic measure cannot be avoided is the impossibility of installing slope insulation or even ordinary plastic panels.

To quickly remove a layer of plaster, a hammer drill with a special attachment called a chisel-scapula is used. It lifts well all the layers applied to the wall, and they are removed in fairly large pieces.

Slope finishing

To make it easy to install a particular material on slopes, it is necessary to consider each option step by step.

Finishing work begins after the primer applied to the wall is well absorbed and completely dry.

Finishing slopes with plaster without insulation

The process of plastering surfaces around the window is as follows:

| Illustration | Brief description of the operation performed |

| The first step is to install guides made of a metal profile or wooden slats around the window niche. It should be noted that a metal guide is preferable, as it has lower adhesion than wood - it will be easier to remove. The guides are aligned to the building level and secured to the wall using dowels. The profile should protrude beyond the corner of the window opening to the thickness of the future plaster layer. | |

| Another guide from a perforated corner is placed near the window frame. It is oriented towards the profile installed around the opening, since the sketched plaster will be aligned along the plane specified by these two guides. The corner is installed on gypsum-based putty, as it dries quite quickly. | |

| The next step is to pour the plaster mixture onto the wall. Sometimes it is replaced with ordinary cement mortar, which is mixed from cement and well-sifted sand, that is, in no case should it be interspersed with small pebbles. The task of this stage is to make the outer corner smooth and create the necessary plaster layer. | |

| The same work is carried out on the ceiling part of the slope. | |

| After the mortar is thrown onto the slope, it needs to be leveled using a rule, a trowel or a level lath. This layer is leveled, so to speak, roughly, the main thing is that the solution fills all the voids and the edge of the slope, approximately forming an even angle. Leveling should be carried out after the solution has set. The process is carried out from below, from the window sill. The rule is installed on the guides and carefully rises up, leveling the scattered solution, the excess of which is immediately removed. Having completed this work, the slopes are left to dry completely. | |

| Next, the external guides are removed from the dried slopes, and perforated painting corners are installed on the formed corners using gypsum putty, which will reliably strengthen the edges of the slopes. Having installed them along the entire height and width of the opening, you need to wait until the gypsum composition dries completely - this process will take about half an hour. | |

| When the putty has dried and the corner is securely attached to the wall and slope, another layer of plaster is applied to their surface, which should be the same height as the installed painting corner. It is leveled in the same way, starting from the window sill, using a rule that goes up to the ceiling plane. From the outside, the edge of the corner is compared with the wall with a solution that is applied with a spatula. Internal corners are formed with a corner spatula, which grasps two planes and the joint between them at once. The leveled slopes are left until completely dry and then primed. | |

| The last layer consists of finishing putty, and is applied with a thickness of no more than 1-1.5 mm. | |

| The work is carried out with a wide spatula, with light pressure on it, movements from the window frame towards the room. If marks from the edges of the tool remain on the surface, they must be carefully smoothed out. | |

| The last stage is the final smoothing of the surface using grout. The process is carried out in a circular motion counterclockwise. After such sanding, before painting, it is recommended to prime the slopes again. The primer will not allow the paint to be absorbed into the putty, so the painting will be even. |

For clarity, here is a detailed video instruction on plastering window slopes.

Video: how to properly plaster window slopes

Finishing slopes with plaster with insulation

In this finishing option, some stages are similar to the first method, but it also has its own characteristics, so it is worth considering separately.

| Illustration | Brief description of the operation performed |

| The insulation is mounted on a primed, flat surface. Therefore, if, after chipping the old plaster, chips and potholes are found, they will need to be leveled with a putty or plaster mixture using a wide spatula. After the repair layer and primer have dried, they proceed to gluing polystyrene foam panels, which should have a thickness of no more than 15 mm. | |

| The material is fixed to mounting foam, which is best applied directly to the insulation, or to mounting adhesive like “liquid nails.” The part coated with strips of glue is pressed tightly against the slopes. The foam is installed first on the side walls, and then on the ceiling part of the slopes. If necessary, the joints between the foam sheets are additionally filled with foam. | |

| If the slopes are wide enough, then the insulating panels are additionally fixed to the wall using “fungi” fasteners. To do this, using a hammer drill, holes are drilled in the wall directly through polystyrene foam, into which dowels called “fungi” are inserted. Then special expansion nails are installed and driven into them. Using this fastening, you need to take into account the thickness of the insulation, since the fungus should be recessed into the wall by 50 ÷ 60 mm, and its cap should be level with the surface of the foam or be slightly recessed into it, by 1 - 1.5 mm. | |

| Having glued the foam, which will level the surfaces and corners, we proceed to reinforcing its surface - only in this case will the finish last a long time. Corners with reinforcing fiberglass mesh are mounted on the outer corners using glue or gypsum-based putty. The glue is applied with a spatula to the edge of the slope, then the corner is pressed onto it, and the excess adhesive that protrudes through the holes is immediately removed. | |

| On the outside, the corner is also glued with glue or putty. You can also use cement-based glue, but if you need the surface to be treated to dry quickly, it is recommended to use a gypsum composition. The mesh is pressed into the applied composition using a spatula, and its excess is leveled or removed. | |

| Next, the mesh is attached to all foam surfaces. It can be glued to an already applied thin layer of putty or attached to buttons, and the solution can then be applied on top of the mesh, leveling it. This layer will become a preparatory layer for the finishing putty, which is applied to the dried surface. The final leveling layer and other work are performed in the same way as in the first option. |

Video: how to level plastered slopes with putty

Find out several affordable ways to finish window slopes from the outside from our new article.

Installation of plastic slopes

Installation is carried out in the same way as described above, but in this case a certain space is left for the insulation.

1 - attaching the starting U-shaped rail to the window frame or wooden beam;

2 - installation of a wooden batten on the outer edge of the slope;

3 - attaching the J-profile to a wooden batten - this profile will serve to secure the platband at the completion of the work;

4 - installation of insulating material between the wall and the PVC panel;

5 — installation of a regular or sandwich panel in the starting profile;

6 - installation of the CL profile, which snaps onto the protruding part of the J profile. Additionally, it can be glued to the wall and panel using white silicone or sealant.

Video: installation of plastic window slopes

Sandwich panels can be installed on the surface of slopes in another way without the use of fitting profiles, but using polyurethane foam, sealant or liquid nails. The gaps between the planes, in this case, are sealed with white silicone.

Installing sandwich panels directly on slope walls is quite simple, but an important condition for it is a more or less flat surface, so before installing the finishing material, it needs to be leveled and dried.

Further, the work is carried out as follows:

- Dimensions are taken from the slopes and sandwich panels are cut along them.

- Then one of the selected adhesives is applied to them, and the panel is pressed against the surface of the slope.

If polyurethane foam is used for installation, the ceiling panel of the window opening is glued first.

The ceiling plane is sprayed with water from a spray bottle - this will increase the adhesion of the surfaces.

Then the foam is applied along the perimeter of the glued part in a thin strip, since it tends to expand quite strongly, and with a large amount of it, the foam can squeeze the finishing material from the wall.

- Having pressed the material to the surface, you need to hold it for 5 ÷ 7 minutes, and then install supports and leave until it dries completely and the foam expands. The support can be made from a planed board, which is pressed against the panel, which is supported with bars, placing them on the window sill.

- After this, the side panels of the slopes are mounted in the same way.

- Then, if there are unfilled gaps between the slope wall and the finishing, they are additionally foamed. When the foam dries and expands, its protruding excess is cut off with a sharp stationery knife.

- Next, the joints between the wall and the finishing material should be closed with a special profile, which is called a platband. It is made in the form of a corner and can have different widths, which allows them to cover the unsightliness of a joint even of large width. The casing is glued to the “liquid nails” and held in place while they dry using masking tape.

- If for some reason small gaps have formed between the panels, they are carefully filled with white silicone, which after drying will be almost invisible.

It should be noted that there are other ways of performing work on finishing slopes, which are somewhat different from those described above, but the principle of their implementation is unchanged.

Having decided on all the criteria, you can take measurements and purchase everything you need for work.

Making slopes on windows yourself is not so difficult if you approach this process with extreme care, take accurate measurements, and select all the necessary components correctly.

Is it possible to install a plastic window with double-glazed windows yourself?

Installation of slopes is the final stage of installing a window system. In order for the windows to be truly insulated according to all the rules, it is necessary to take into account many nuances even during the installation of the frames.

How to properly install a plastic window is in the corresponding publication on our portal.

Finishing

After all the preparatory and main work is done. The structure is assembled and installed. The final finishing is coming. It includes several basic and important steps:

- getting rid of all irregularities;

- forming an outer corner, applying putty;

- alignment of side joints;

- applying a primer;

- applying final putty;

- painting with water-based paint and varnish enamel intended for interior work.

Finishing with tiles

And if the window is in the bathroom or kitchen, then which slopes are better for plastic windows in this case? Cladding with ceramic tiles. At first glance, this type of finishing is ideal, as it combines practical and aesthetic advantages of design.

But with a deep analysis, it is possible to identify facts of thermal insulation violation due to poor contact between the window and the tile. The required time and effort for the work, which includes, in addition to laying tiles, also plastering, also has a negative impact.

And the combination of several types of work and the use of different materials will also affect the cost of workers’ services.

Types and features of gypsum sheets

Today, the construction market offers a wide range of plasterboard sheets. Various internal works are performed from sheets of this material. They make partitions, window slopes, niches, ceilings and much more.

The material is universal. Easy to install. Available for purchase. Easy to use. The service life is not limited. The main component is gypsum. It is this that gives strength to the sheet. Its advantage is that it does not emit substances harmful to humans into the atmosphere. Structures made from this material do not withstand strong physical impact. It is not recommended for leveling floors.

Plasterboard slopes

When deciding which window slopes are better, many choose the plasterboard option. Let's look at what exactly attracts them so much:

- Simple device technology. Without a doubt, any beginner can make such slopes for windows; it will only be enough to purchase the material;

- Installation speed. With skill, installation of one slope takes no more than 2 hours;

- Low cost. Materials for work are quite accessible to all consumers, and this is often the most decisive argument when deciding which slopes for windows are better.

- Exposure to moisture. In the presence of excess moisture, this slope, unfortunately, can collapse, and the same moisture can cause the formation of mold, which simply cannot be removed from the plasterboard sheet; the damaged sheet will need to be replaced;

- Major renovation. If for other types a partial replacement is possible, then here, as already written above, a complete rework of the slope will have to be carried out.

- Indoor use only. If plastered window slopes can also be installed “outside,” then plasterboard ones are intended exclusively for “indoor work.”

Regular plasterboard

It is a laminated material. Plaster is placed between thick cardboard. Regular plasterboard is gray. Its markings are blue. Used for interior decoration of residential premises. The humidity level should not exceed 70%. At high humidity levels, the material is destroyed. Use only in dry rooms.

The width of the material is 1 meter 20 centimeters. The length is 2 m 30 cm and 2 m 50 cm. Thickness is 10 mm. Without special additional additives. The properties of gypsum plasterboard are standard. Easy to use. To work, it is enough to have a minimum of tools. Does not release heat outside. The design is fragile to physical impact.

Creating a slope using the gluing method

This method does not require a startup profile. It is applicable when the surface is fairly flat, but creating a slope by gluing is quite difficult.

- All details of the future slope are cut out.

- The top part is installed first. A special guide corner is screwed to it in advance, into which its upper part is inserted and glued. Precise installation will allow you to avoid mistakes during further installation of the side elements.

- The remaining elements are glued.

In most cases, glue is applied to the entire plane. Typically, the approximate drying time for a specific brand of assembly adhesive is indicated on the packaging. If there is a need to reduce the setting time, then the glue is spread in strips. All work is controlled using a building level.

Moisture-resistant gypsum plasterboard

In the store you can find moisture-resistant gypsum plasterboard by its standard green color. The layers are treated with special moisture-resistant impregnations. They improve the properties of gypsum plasterboard. It is more resistant to high humidity. Recognized as a universal building material. Use in rooms with humidity above 90%.

Sheet thickness 12.5 mm. The main advantage is fire resistant. When in contact with fire, it burns slowly without producing large quantities of acrid smoke. Does not emit toxic volatile substances. Withstands wet and dry cleaning. The scope of application is wider than that of a conventional one. Used to create partitions, multi-level ceilings, and leveling walls.

Plaster for drywall

The plasterboard sheet is not the final finishing element, so additional materials will need to be applied on top of it. There are, of course, decorative varieties, but they do not look very attractive and are only suitable for office decoration.

For a home environment, a more delicate approach is needed. And here people often turn their attention to the possibility of combining two competing materials. The question of what is the best plaster for drywall is constantly encountered in construction stores. And here it is also worth giving a separate list:

- • Decorative plaster is great for working with drywall, as it allows for a beautiful design and does not require too much time. It is usually supplied as a ready-to-use mixture that does not require dilution with water, so there will be no difficulties with application.

- • Leveling plaster, on the other hand, will be thinned with water, so it can only be applied to moisture-resistant cardboard.

All sales consultants are well aware of the above points, so they will help the client make the right choice.

Gypsum fiber GVL

It differs from the standard conventional plasterboard. Has a homogeneous structure. There are no outer cardboard shells. Consists of 80% gypsum, 20% cellulose. Available in rectangular shape. Production is prescribed in GOST R 51829-2001.

It is highly resistant to physical impact; if necessary, you can hammer a nail. A distinctive feature is a high level of sound insulation. GVL does not crumble. Resistant to frost. Resistant to moisture, does not get wet or swell. Eco-friendly and easy to install. Operation is not limited. Has disadvantages: fragile; weighs more than regular plasterboard; high price.

What to make window slopes from

Plasterboard slopes look just as good as plaster ones. But at the same time, the installation cycle is shorter, there is no dampness and special dirt. However, there are also a lot of disadvantages. The next plus is that slopes made of sandwich panels do not require any finishing and are installed within one day.

For many who have just replaced a window with a new one, this is the only viable option. One day and that's it. Hence another advantage - the cheap price of such slopes. All you need is foam and tape.

Well, and sealant. Assembling slopes from gypsum plasterboard is a technically more complex task. You can, of course, put them on Perlfix mounting adhesive, but personally I never liked this method. I either assemble the slopes entirely on the frame, or combine the frame with glue. I sew the inner part of the slopes onto the frame, and glue the outer part.

This allows for additional insulation. Namely, lay mineral wool under the gypsum board along the entire perimeter. Fourthly, cracks on plaster slopes can appear not only around the perimeter, but anywhere, this has been verified. Therefore, a prerequisite is to glue their entire area with fiberglass, and only in solid sheets without joints.

Well, and besides, in residential apartments, after replacing an old window with a new one, the plastering method is difficult to apply. It's long, it's dirty, it's damp. And lastly, if the paint on a slope becomes dirty, it is almost impossible to wash it without leaving marks; you will have to repaint it.

Gypsum fiber non-flammable GVL

It is a homogeneous sheet. Belongs to the group of fire-resistant, slightly flammable. You can hammer nails and screw in self-tapping screws. Density is achieved through additional components. The density is equal to expanded clay concrete. Doesn't crumble. Resistant to mechanical stress and frost. At high humidity, it absorbs excess. And when there is a shortage, he gives. The itself is very fragile. You have to work with it carefully.

If you want to extend the service life. Do not cover the surface with silicate paints, putty, or liquid glass-based enamel.

Author of the site

Possible difficulties and errors

Mistakes when installing plasterboard slopes:

- The joints along the edges are poorly sealed, which allows moisture and dirt access to the gap between the finish and the internal filling of the sheet.

- It is not advisable to make the frame from wooden guides - they become deformed and dry out.

- Do not reinforce the corners of the wall near the slope with a profile.

- The joints between the panels must be puttied (however, this is done for finishing cladding), and the gaps between them and the frame must be sealed with sealant.

- The sides are confused: the front side should be facing the room (it is a little rough, usually without markings, on it the factory edges point in the same direction).

- With the frame method of fastening, the heads of the hardware should not stick out - this will make puttying difficult. If you pass it with a spatula and it catches this element, then the self-tapping screw must be tightened.

- Using a hacksaw with large teeth to cut sheets will lead to loose edges, jagged edges, and the quality of the joint will deteriorate.

- Neglect of putty and primer. It is necessary to process the entire sheet, not just the joints.

- Finishing with plaster and paint is important, as it will prevent the penetration of moisture and contamination. If it is not there, then, for example, the upper slope may sag.

Important! If you do not reliably foam the gaps between the frame, seal them poorly, or install a vapor-permeable gasket, the insulation will get wet.

But condensation is not always caused by poor-quality insulation - it often occurs when the windows are poorly adjusted, the sealing elements in the double-glazed windows themselves are damaged, or the ventilation in the room is impaired.

The process of installing gypsum boards is simple: using screws on the frame or using glue. Calculations and cutting of sheets and profiles will also not be difficult to do.

But there are such difficulties :

- Situations where the adhesive method is difficult to apply, for example, when the gap between the window frame and the wall is too narrow to place a panel there. Then they use fixation on the frame, one side of the profile of which is attached with thin screws to the window frame.

- Additional and final finishing significantly increases labor intensity. If leveling the base can be neglected, then these manipulations are mandatory, and it is advisable to do them efficiently.

Choosing a mounting method

Master finishers practice the installation of window and door slopes in two main ways:

- Plasterboard blanks are attached to U-shaped profiles screwed to the ends of the walls and the window frame.

- A gypsum board sheet cut strictly to size is placed on gypsum glue and polyurethane foam.

Note. There is a third option - combined. The end of the workpiece adjacent to the window is fixed to the frame, and the inside of the sheet is fixed with an adhesive mixture.

We will not consider the pros and cons of each option; the task is to choose the right method that meets the installation conditions. We suggest using simple recommendations:

- The structure of the frame is logical with thick walls and a wide frame - too much adhesive will be needed to fix the drywall.

- When it is necessary to increase the slope angle or to join the plasterboard finishing of a room, fastening is also done on profiles.

- If the width of the wall is small and the frame is close together, the gypsum board is placed with glue.

In the first case, the slope trim starts from the plane of the frame and covers part of the window profile (door frame). The second option involves the adjoining of the trim to the outer part of the frame and therefore looks more aesthetically pleasing.

Technologies and materials

The traditional option for finishing window slopes is to apply plaster to them. Today this option is no longer considered by many masters. It is difficult to perform, dirty and requires a lot of time to carry out. After all, it will not be possible to apply the plaster solution in one go. The plaster slope is multi-layered, and each layer must dry well before applying the next one.

Therefore, two other options are taken into account:

- plastic finished products are used;

- make from drywall.

How are the two options different from each other? In principle, there are few differences, especially when it comes to editing. But the material itself has a different structure.

A plastic slope is a ready-made product that can be selected to match the width of the area being sealed. It just needs to be installed at the destination. No additional actions are performed. Finishing window slopes with plasterboard requires cutting sections from a large sheet that exactly fit the size of the site. After installation, the plasterboard plane will have to be further modified and decorated.

So, the question of how to seal the slopes on the windows can be closed. The options are presented, the choice is yours.

Sealing drywall joints - from installing sheets to puttying joints

One of the final stages of working with plasterboard sheets is sealing plasterboard joints . The durability of the repair depends on how well it was made - after all, if the seams were sealed incorrectly, then cracks will appear at the joints. The advice given in the article will help you avoid such troubles.

Types of edges and gaps between sheets of drywall ↑

First of all, it’s worth talking about what types of longitudinal edges there are. The transverse edge of all types of this material, be it simple, water-resistant or fire-resistant sheets, is always straight and not covered with a layer of cardboard. So, the longitudinal edge could be as follows:

- Direct (PC marking). The joints between such sheets intended for rough finishing are not sealed. This edge, as a rule, is made not on plasterboard, but on gypsum fiber sheets.

- Semicircular, thinned on the front side (PLUK). When sealing seams, sickle and putty are used. This is the type of edge that can be found most often on drywall.

- Beveled (UK). Sealing seams in sheets with such an edge is a very labor-intensive process, performed in at least three stages with the obligatory use of a serpyanka. The beveled edge is almost as common as the PLUK.

- Rounded (ZK). When sealing such seams, drywall joint tape is not used.

- Semicircular (PLC). Processing of joints with this type of edge is carried out in two stages without the use of a serpyanka. It is desirable that the putty be as durable and high quality as possible.

- Folded (FC). Just like the PC edge, it is most often done on gypsum fiber board sheets intended for rough finishing.

There are several other types of edges, but it is almost impossible to see them on the shelves of domestic stores. As mentioned above, most often manufacturers make drywall with edges such as PLUK and UK. Such edges do not require any processing after installation of the sheets, so you can immediately begin to putty them.

If we are not talking about a factory-made edge, but about a self-made edge, which is formed after cutting drywall to the required size, then it needs to be thinned. To do this, a special tool is used that chamfers the edge of the sheet. However, this can be done with an ordinary wallpaper knife with a sharp blade. When processing an edge, you need to cut about two to three millimeters of gypsum from it at an angle of 45°.

When installing drywall sheets, you need to leave a gap of no more than seven millimeters between them. This distance between the sheets will allow them to contract and expand freely with changes in temperature and humidity. For the same purpose, gaps are left - a centimeter between the drywall and the floor and a five-millimeter gap between the plasterboard and the ceiling. All seams are subsequently puttied and covered with plinth on the floor.

How to join drywall correctly? ↑

As with any work, joining plasterboard sheets has its own nuances. Firstly, all joints between sheets must be made on profiles, and under no circumstances should they hang in the air. This rule applies not only to longitudinal, but also to transverse joints. Secondly, if the length of the plasterboard sheet is less than the height of the wall, then the cut and whole sheets must be joined in a checkerboard pattern. In practice, it looks like this: a whole sheet is placed below, a cut sheet is placed at the top; then cut off at the bottom, whole at the top, and so on.

If the drywall on the wall is attached in two rows, the second one must be shifted relative to the first by 60 cm. The sheet width is 120 cm, the first to be mounted is half of the sheet cut along the longitudinal line.

The joining of drywall in the corners is done one by one: first, the first sheet is attached to one of the installed corner posts, and then the second sheet is attached to another profile standing in the corner. The gap between the sheets forming the corner should not be more than one centimeter. Subsequently, a special perforated corner is mounted on the outer corners, and the inner corners are sealed using putty and sickle.

How to seal drywall joints and what do you need to know for this? ↑

After all the sheets have been secured and the “non-native” seams have been unstitched, you can begin to putty the joints . To do this, use a gypsum-based composition, which is diluted with water in the required proportion. In this case, you should not buy a cheap mixture, since it may crack later. Also, for puttying you will need a metal spatula 15 cm wide. They use it to collect ready-made putty, which is applied to the seam. In this case, the spatula must be pressed lightly so that the mixture completely fills the joint. Then serpyanka or paper reinforcing tape is glued along the seam, which is then sealed again.

When gluing reinforcing tape or serpyanka, you need to ensure that their middle falls exactly in the middle of the seam; their cuts need to be overlapped.

The seam must be flush with the drywall - this is verified using a level. This must be strictly monitored, since the gypsum composition is practically impossible to polish. After the putty on the seams has completely dried, you can begin to putty the drywall.

At the end of the preparatory work, the opening is completely cleaned of dirt. Everything is swept and dried. In order not to damage the window or door frame, it is sealed with masking tape and cardboard. Installation is simple, and after installing drywall, the openings are beautiful, smooth and strong.

There are other design methods, but using gypsum plasterboard is simpler and cheaper, especially if the seam on the window or doorway is large.

Installation using putty

Finishing putty can be used as an adhesive material - it has better adhesion. The putty should have a paste-like consistency.

Finishing slopes with plasterboard with your own hands using putty is done in the following way:

- when the surface is cleaned of dirt and dust, it is moistened with water;

- on parts made in advance, putty should be applied in the form of separate islands;

Putty is applied to the panel in strokes - The product is placed in the required position and moved so that the adhesive mass spreads. In this position, the slope is left for 12 hours, supported if necessary;

After installing the drywall, install a support - After a while, the support can be removed and wait for the adhesive mixture to dry completely.

Pros and cons of use

Strengths and weaknesses of slopes for plastic windows made of gypsum fiber/plasterboard boards:

| Advantages | Flaws |

| Simple measurements and installation itself (especially with glue). It’s easy to set the angle of dawn: just place the panel or frame profile along the marks. | Drywall is less moisture resistant when compared to plaster, since its solidity is lower, it is porous, and contains cardboard and cellulose. But it is gypsum fiber that is compared with it in this aspect. |

| We immediately get a flat surface - there is no need to carefully level the slope wall, just clean it well. Usually it is puttied, but you can get by with just a primer or even without it. | If damaged, restoration is impossible, unlike plaster. If the panel swells from moisture, it cannot be returned to its original form. |

| The opportunity to make high-quality insulation of the slope easier. Simply inserting the material between the slab and the wall reduces the need for expansion joints. | Insulation and insulation are simpler, but still required. |

| The method is cheaper than finishing with plaster. | It is not enough just to install the panels - you also need to finish them: seal the edges with adhesive, prime, putty, plaster or paint, and before that, strengthen the corners of the wall. |

| High speed of work. On average, one window will take about 45 minutes. up to 3 hours. When plastering, you need to do several layers (three are recommended for slopes) and wait until they dry. | Opening the door suddenly will damage the panel. But this can be solved with special moderators. |

| The humidity in the room should not be higher than 75%. | The strength of the material is low. |

| No special experience is required for installation. This distinguishes the material favorably from plaster, which can only be done efficiently by experienced specialists. | Over time, the finish coat may peel off. |

| The walls “breathe”. The material is completely environmentally friendly and is superior to plastic in this parameter. | |

| Hygroscopicity. When there is an excess of moisture, it absorbs it, and when there is a lack, it releases it, which has a good effect on the microclimate in the room. |

Peculiarity! The main advantages of drywall are as follows: installation does not require special experience, it is much faster (no need to do several layers, etc.), some measures can be neglected (leveling the base), the work itself is much cheaper if you use the services of craftsmen.

Finishing puttying and plastering is simplified; any cladding can be used; the aesthetics of these finishes are equal.

If the adhesive method is used, then the installation is elementary - the slabs just need to be placed on the composition. The downside is the need for finishing with the same plaster without or with subsequent painting, but, of course, this is not as difficult as if the slopes were initially finished with it.

We consider the need for insulation and expansion joints as a feature , since they are required to one degree or another for most types of materials.