In apartments of the housing stock created several decades ago, and in many private houses, there are batteries manufactured in the same years. Over such a period of operation, their characteristics have deteriorated and one should not expect complete heat transfer from them. While it is easy to update the appearance of radiators, restoring normal operation is sometimes impossible. When planning repairs, it is worth understanding whether the old heating batteries will continue to serve or whether it is better to replace them.

You can try to restore old heating batteries

What are plate heating radiators?

What parts does a plate heating battery consist of?

Plate radiators are a type of convector heating equipment. They are characterized by a large area of the heat exchange part and a minimum number of pipes through which the coolant circulates.

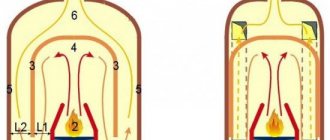

The operating diagram of the device is very simple:

- the coolant under increased pressure is driven through thin pipes of the heating element, giving them its thermal energy;

- the temperature of the metal plates strung on the pipes increases from the heated pipes in a short period of time;

- the air temperature rises quickly between the heated plates;

- light heated air rises up to the ceiling of the room, displacing cold air;

- cold air descends to the convector, where between its plates it increases its temperature.

Unlike other heating devices, plate radiators do not heat the room due to thermal radiation (IR waves), since their surface temperature does not rise to the desired level. Such batteries raise the air temperature in the room only due to air convection.

To maintain the air temperature in the room using a plate convector, you need to remember the feature of the device. Since the pipes of the heating device have a small diameter, the amount of coolant that passes through them per unit time will be insufficient to quickly increase the temperature of the plates. That is why in the heating system where the above equipment is installed, the coolant must circulate under high pressure and be at a high temperature. This will quickly increase the temperature of the plates, and therefore ensure good air convection.

How to increase the efficiency of a heating device? A metal corrugation attached like a protective panel will help increase the power of a plate radiator. This corrugation increases the useful area of the heating element, which is involved in heat exchange. This is why the volume of air that can pass through the convector increases and increases its temperature.

Old plate heating radiators warmed the room due to natural air circulation. As a result, a sharp temperature difference was observed in a large room. It was always warmer at the top than at the floor. The built-in fan helped solve this problem. Modern plate batteries are now classified as volatile equipment (the fan runs on electricity). But in this case, the efficiency of the device increases due to artificial air circulation.

Of steel.

Types of equipment. As can be seen from the photo, plate heating radiators primarily differ from each other in their construction materials.

Today you can buy the following radiators:

- steel - plates and pipes are made of steel. The device is characterized by increased strength and is resistant to water hammer. However, it has a low heat transfer rate;

- copper - if all parts are made of copper, then the battery will have high power and

Made of copper.high heat transfer rate. But its cost will also be high. Therefore, plates made of cheap metals (steel) are most often hung on copper tubes;

- aluminum - they are inexpensive, can quickly raise the air temperature to the desired level, but are not durable. It is not recommended to use them in a central heating circuit. Most often, aluminum pipes are replaced with copper ones, which increases the strength of the device and its cost.

New and old plate heating radiators may differ in the number of workers

Made of aluminum.

contours and convection panels. So, if devices have one circuit and one set of plates, it is designated as device 11. Accordingly, class 22 indicates 2 coils and 2 sets of plates. There is class 21, where there is 1 coil for 2 rows of plates.

In the photo, plate heating radiators can be of various sizes. It is thanks to the variety of sizes that the buyer can choose a product that best suits the parameters of the room and interior design.

Design features of plate radiators

Modern plate convectors are designed with the same simplicity of design as the previous “Soviet” models.

Such radiators consist of the following structural elements:

- A curved - most often U-shaped - piece of pipe, at the ends of which two ball valves are installed.

- A set of plates “strung” on a pipe. Moreover, in most cases, the plates are made of the same material as the pipes.

- Protective casing - a metal box with an open top and bottom. Moreover, inside the casing you can accommodate not just one piece of pipe (thread), but several such “packages” at once.

Sectional and plate batteries arranged in a similar way operate according to the following scheme:

- The coolant moves through the pipe under high pressure, practically without cooling.

- Thin plates heat up to high temperatures in just a matter of seconds.

- The temperature of the air inside the case instantly rises by several degrees.

- Warm air rises up through the perforations in the casing cover, and cold air is “sucked” into the housing through holes in the bottom.

As a result, plate heating radiators provide a high rate of thermal convection of air masses, warming up a small room in literally a matter of minutes. However, when heating really large rooms, naturally convection will not be enough. In this case, a tangential fan is installed on the bottom side of the plate convector housing, providing forced convection .

Design and principle of operation of the radiator

Moreover, the intake of air masses is carried out not from the bottom, but through the perforations in the lower part of the side edges of the casing, which makes it possible to “drown” the plate battery in the floor slab, leaving only the upper grid at the level of the floor covering.

Advantages and disadvantages of plate batteries

The undoubted advantage of such heating devices is their high structural strength.

Through such a radiator, coolant can be pumped under a pressure of 20 atmospheres or more - the strength of the structure depends only on the annular rigidity of the pipe, which can withstand pressures of up to 40 bar.

In addition, such a radiator will not leak - it has no internal joints. Other advantages include low cost and good compatibility with cheap thermostats, the operating principle of which is based on dosing the flow of coolant into the heating device.

The obvious “disadvantages” of such heating devices include, firstly, the uniformity of the exterior, the shape of which is determined by the contours of the box-shaped casing, and, secondly, the loss of thermal power due to contact with dust - a significantly smaller volume of air passes through the “clogged” plates.

However, both drawbacks can be easily eliminated - the box-shaped body can be “recessed” into the floor covering or designed as a baseboard, and dust can be easily cleaned with a regular vacuum cleaner.

Types of plate radiators

The classification of the range of plate batteries in most cases is organized according to the following design features:

- By type of pipe and plate material.

- According to the number of “threads” in the casing body.

- According to the diagram for connecting the radiator to the wiring.

- According to the scheme of fastening the casing to the supporting surface.

Based on the first method of classification - Based on the type of material of the pipe and plates - we can distinguish the following types of batteries:

- Steel plate radiators, the main elements of which are made of the same metal. Such heating devices are relatively cheap, but their thermal output leaves much to be desired. Therefore, in combination with high-strength steel tubes, it is customary to use plates made of metals with higher thermal conductivity.

- Copper plate batteries, the elements of which are made of this non-ferrous metal. This radiator provides maximum thermal output. However, not all homeowners can afford such products. Therefore, to reduce the cost of construction, only internal pipes are made from copper, onto which plates of cheaper metal are strung.

Copper plate radiator

The second method of classification - according to the number of “threads” in the body - distinguishes the following types from the assortment:

- Radiators with one heating element - a “package” of one pipe and one set of plates.

- Batteries with two or more heating elements , the design of which includes a pressure manifold that distributes the coolant flow over several “packages”, and a return manifold that collects the “outgoing” coolant for subsequent transfer to the distribution system.

The first type of radiator is cheaper and more compact than the second type. However, the latter option will provide higher thermal power, explained by the larger area of the heating elements (plates and pipes).

The third classification option - according to the wiring diagram - distinguishes the following types of batteries:

- Radiators with side connection . In this case, the battery connections are located on the side surface of the casing. Because of this, the buyer of the battery will have to install special fittings - corners that ensure the pairing of the horizontal heating element (pipe) and the vertical section of the fittings extending from the horizontal pressure or return branch of the wiring. However, if the distribution pipes are laid vertically, then corners are not needed.

- Radiators with bottom connection . In this case, the battery fittings are located in the lower part of the casing, on the bottom side, which makes it easier to connect the radiator to horizontal wiring, while at the same time making installation to a vertical riser difficult.

As a result, owners of heating systems with horizontal wiring are recommended to use batteries with a bottom connection, and owners of systems with vertical risers are recommended to use batteries with a side connection. Although the latter option can be adapted to horizontal wiring using a cheap fitting - an angle.

The fourth classification option - according to the method of attachment to the supporting surface - distinguishes the following types of radiators:

- Mounted batteries , the housing of which is attached to the wall using special brackets.

- Built-in batteries , the housing of which is “recessed” into the floor, resting on the floor slab at the bottom.

Moreover, it is the mounted radiators that are most widespread. After all, the installation of batteries “recessed” into the floor requires a lot of effort aimed at arranging a niche and hidden wiring.

Steel plate radiators - general information

Steel plate radiators are commonly called “accordions”. The appearance of an accordion is created by plates strung on a coolant pipe.

A distinctive feature of such radiators is their high reliability. There are no connections in a plate radiator except for the coolant inlet and outlet. As a result, the radiator itself simply cannot leak; there is nowhere for the coolant to break through.

Thanks to the large number of plates and the direct movement of the coolant, the convector heats up to a high temperature. To protect against touches, the main frame of the radiator is covered with a decorative casing. Convection holes are made in the top cover of the casing.

Convectors have low thermal inertia, which means they can be controlled automatically, that is, thermostats can be installed in systems with plate radiators.

pros

- Reliability and durability. Cast iron is unpretentious to the coolant; it will not be damaged even by large fractions or aggressive chemical impurities, often contained in water from Russian thermal power plants. The maximum permissible coolant temperature reaches 130-150 degrees. With regular cleaning, the service life of such a battery can be decades.

- High heat capacity and thermal inertia. Such batteries give off heat for a long time, which after switching off can remain in them up to one third of the original volume. However, this same feature of the material is also its disadvantage - more about this in the corresponding section.

Connection options for heating elements

Connecting a plate battery.

Any factory-made plate heating element is equipped with a kit with a built-in valve insert. It, together with the thermostat, participates in the process of adjusting the temperature of the radiator. In addition, there are batteries with an integrated complex through which they are connected to the heating circuit pipes located under the floor or mounted in the wall.

Convectors in most cases can have either a side or bottom connection. In the case of the lateral connection method, the fittings of the heating element are brought out to the side of its casing. With horizontal heating wiring, the owner of the battery will have to buy a special fitting. It will help adapt a horizontally located device and a vertically rising section of reinforcement from a horizontal contour. Things are better if the heating circuit runs vertically through the room. Then the fitting is not needed.

With a bottom connection, the radiator pipes exit to the surface of the casing from below. This simplifies the connection of the heating element to a horizontal circuit, but complicates the installation process in the case of vertical wiring.

A steel plate heating radiator should only be connected to a system with forced coolant circulation. Otherwise, water will move at a low speed through the system, which will degrade the performance of the heating element.

It is not recommended to install steel plate convectors in a heating system with an open expansion tank. In this case, the coolant is regularly enriched with oxygen due to direct contact with air. As a result, the acidity of the coolant increases, which leads to corrosion of the inner surface of the radiator tubes. Their service life is reduced.

If water convectors are nevertheless installed in an open heating system, then the circuit must be equipped with an anti-diffusion barrier. It prevents oxygen from entering the heating circuit.

Installation work

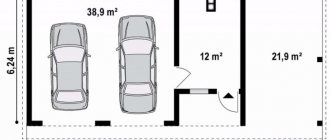

The batteries are installed under the window, which is explained by compensation for heat when street air enters through the window opening.

When installing, be sure to consider the following criteria:

- The distance from the wall is 2 centimeters.

- From the floor - 12 cm.

- From the window sill - 10 cm.

The parameters presented are not a strict rule, but only recommendations.

Now let's look at the instructions for replacing radiators.

Determination of thermal power of plate heating devices

The formula for determining the thermal power that a steel plate heating radiator can produce, and a real example of calculating this parameter, are given below. To calculate the power of the device, it is enough to know the heat loss coefficient of the heated room, the area of the room and its total volume. The passport of any radiator indicates its calculated power at a hot water temperature in the system of 600C. The attached documentation also contains recommendations for the heated area for a specific radiator model.

The thermal output (power) of heating devices depends on the length of the body and the number of plates. The standard height of radiators is 200 mm, the number of plates varies. For example, heat transfer for a radiator with one tube and a body length of 600 mm will be equal to ≈ 347 W. When the length is increased to 3000 mm, the heat transfer will increase to 1730 W. But with the same body length (3000 mm) and an increase in pipes to 4, heat transfer there will already be 4179 W, and with a body length of 1000 mm, four tubes with coolant will give 1393 W of power. Therefore, which radiator is best to buy for a specific room is determined based on the following requirements:

- To heat 1 m2 of a room with a ceiling height of 3 m, you need to spend 100 W;

- For a room with an area of 16 m2, the radiator must have a thermal power of 1600 W, provided that the room has no more than one window, the room is not corner and the ceiling has a height of no more than 3 m. For other initial conditions, correction factors Kp are introduced:

- For two windows Kp = 1.8 / 1600 x 1.8 = 2880 W;

- For a corner room Kp = 1.8 / 2880 x 1.8 = 5184 W;

- For a ceiling 2.65 meters high Kp = 2.65 / 3.0 = 0.88 / 5148 W x 0.88 = 4547 W;

- For PVC windows Kp = 0.8 / 4547 W x 3637 W.

A standard metal-plastic window is 1400 mm wide, so to fully block cold air flows, a radiator of four sections 1400 mm long, with a power of 1950 W, is installed underneath it.

Power table

The heating radiator works like this:

- Under pressure or gravity, the coolant moves through the battery tubes, heating them;

- The tubes heat the plates welded to them, and together the structure heats the air between the radiator elements, which rises up to the ceiling of the room;

- Cold air masses, under the pressure of warm air, fall down to the radiator, where they heat up;

- Then the cycle repeats.

That is, in any radiators, the room is heated with coolant due to air convection.

Plate radiators have one distinctive feature: due to the small diameter of the coil, an insufficient amount of coolant passes through them per unit time to heat the room, so it is necessary either to keep the temperature in the boiler constantly high, or to install radiators with a large number of plates (sections).

High power radiators

To increase the efficiency of a plate heating battery, a metal corrugation is placed on its body, which at the same time serves as a protective casing. The corrugated surface increases the heat transfer area, which leads to an increase in the volume of warm air.

In older models of plate radiators, convection (movement) of air occurred naturally - due to the movement of warm and cold air flows. New models have built-in electric fans, and therefore you only need to increase the coolant temperature without increasing the radiator area in order to achieve the maximum possible heat transfer from the device. That is, in modern models artificial (forced) convection occurs.

Plate radiator with fan

Today, manufacturers offer to buy radiators made from the following materials and different designs:

- The steel radiator has both tubes and steel plates. Although its strength is high, heat transfer is characterized by inertia;

- The copper radiator has increased power and heat transfer. All this is accompanied by the high cost of the device, but if you decide to buy it, choose a copper coil and steel plates: it will be cheaper and will not affect the quality and durability of the radiator;

- An aluminum radiator is the cheapest model with minimal heat transfer inertia, but it cools down as quickly as it heats up. The body is not as durable as the first two models, and the metal itself is susceptible to corrosion due to poor-quality coolant. Therefore, it is better not to install such devices in central heating.

Radiators made of different alloys

Corrosion resistance level

The average values are presented in the table.

| Corrosion resistance (mm/year) of cast iron | |||||||||

| Cast iron | terms of Use | ||||||||

| Industrial environment | Chamber with 0.3% SO2 additive | Sheath liquid at 25 °C | Sea water* | 10% at 50 °C | 3% at 10-19 °C | 5% acid | |||

| sulfuric | salt | nitrogen | |||||||

| White | — | — | — | 0,05 | — | — | — | — | — |

| Grey | 0,14 | 0,24 | 0,27 | 0,06 | 0,02 | 0,08 | 31 | 27 | 26 |

| Lasting | — | — | — | — | — | — | — | — | — |

| ferrite | 0,18 | 0,29 | 0,22 | 0,06 | 0,01 | 0,08 | — | — | — |

| ferrite and pearlite | 0,18 | 0,24 | 0,26 | — | — | 0,08 | — | — | — |

| perlite | 0,14 | 0,22 | 0,29 | 0,06 | 0,01 | 0,08 | — | — | — |

| Malleable | — | — | — | 0,06 | — | — | — | — | — |

| Corrosion-resistant type 4N 15D7 | — | — | 0,05 | 0,02 | — | — | 0,15 | 0,3 | 21 |

| Silicon ChS 15 | — | — | — | — | — | — | 0,13 | 0,13 | — |

| *when tested in running water, corrosion is higher. The rate is 1 g/(m2∗h) = 1.2 mm/year. |

Procedure for calculating thermal power

Knowing the thermal power of one section will allow you to find out the required number, but how to calculate this parameter.

This article will look at several options on how to make the necessary calculations depending on different variables:

Power calculation by area

It is based on sanitary standards, according to which 1 kilowatt of thermal energy (100 watts per m²) should be available per 10 “squares” of space. When making calculations, it is necessary to take into account the correction factor corresponding to a certain region of Russia. For example, for Yakutia and Chukotka it is 2, for the Far East it is 1.6, and for the southern regions and republics it ranges from 0.7 to 0.9 (about

New cast iron batteries

If the advantages of a cast iron battery outweigh its disadvantages for you, we can recommend you high-quality modern cast iron batteries. In the Santekhbomba store you will find several practical options - the STI Nova 500 and STI Nova 300 models are presented to your attention. They differ from each other in size and power characteristics - for example, the “older” model 500 has a heat transfer of 150 W per section, section weight at the same time it is 4.2 kg, volume – 0.52 l. For the 300 model, these figures are respectively 120 W, 2.9 kg and 0.3 l, while it is 20 cm lower. Both radiators have an original design; a heat-resistant polymer coating is applied to the surface.

For those who prefer a familiar design, the classic MC-140 model is perfect. Consisting of 7 sections of 150 W each, it looks almost the same as “those” Soviet batteries. And, of course, it is still heavy, since it is made of real cast iron. However, you haven’t forgotten what advantages this material has, have you?

Connecting radiators

- As is already known, before sale, a plate radiator is equipped with a tap and a valve insert with a thermostat for automatically adjusting the temperature of the coolant and air in the room;

- Some models are equipped with mechanisms for connecting the radiator to the heating circuit under the floor or built into the walls of the room;

- The main radiator connection diagrams are side or bottom: With side connection, the connections of the radiator fitting are on the sides, which does not interfere with connecting them to a vertical riser. With a horizontal connection, the radiator is connected through a fitting.

- With a bottom connection, the radiator fittings are brought out from below, so a horizontal connection does not pose a problem, but for a vertical circuit, the radiator is connected through fittings.

Bottom radiator connection

Lateral radiator connection

Practical and organizational implications

The principle of operation of plate devices is the same as that of water ones - they increase and maintain the temperature in the room due to the flow of warm air.

- The reliability and strength of steel radiators is much higher than that of devices made of other alloys and metals, therefore they are recommended for use in a central heating system.

- Copper radiators are not destroyed by corrosion, but it is better not to install them in high-pressure systems. Another drawback is the high price.

- Aluminum radiators are the cheapest of all, have excellent heat dissipation, but have a mechanically weak body, which also quickly corrodes in an acidic environment.

Since the connection of plate heating devices is carried out through the lower or side fittings, they can be mounted directly on the floor, built into the floor surface or hung on the wall of the room. For each individual case, you can choose your own design and technical equipment of the device.