A drill is a construction tool, a kind of hybrid of a hammer drill and a screwdriver. With a drill, you can drill small diameter holes in wood, metal, plastic, ceramics and glass.

On many drills, there is a “hammer” function for drilling small holes in brick and concrete walls for dowels, and if you reduce the speed, insert the cue ball into the chuck, you can use it as a screwdriver.

A good drill can be used not only to make holes in walls or other parts, but also to perform many other functions. Therefore, when going to the store to buy a drill, you need to keep in mind what purposes you will use it for. To properly navigate the endless range of proposed models, you need to know the following things.

Electric drill device

Types of drills

There are currently six modern types of drills popular on the market.

The following stand out:

- Non-percussive instruments. Used for drilling in wood or metal.

- Impact drills are used for drilling concrete and brick.

- Mixers are necessary for stirring mixtures.

- Cordless screwdrivers. You can adjust the rotation speed. Used for drilling holes and screwing in screws and self-tapping screws.

- Corner ones are used for places that are difficult to reach for conventional models.

- Diamond drilling.

Before purchasing a tool, determine its class:

- Domestic;

- Professional;

- Semi-professional.

The combination of quality and cost, as well as a wide selection of attachments, makes the household class truly universal. The optimal time to use such a drill is 15-20 minutes with breaks of the same duration.

The low power of the electric motor and the insufficient level of protection from moisture and external contaminants do not allow the use of tools of this class for a long time.

For long-term work with short breaks, professional tools are suitable. They are specialized and their price is higher than that of household drills. However, professional ones are not intended to perform one-time work.

After this step, you can safely choose the type of drill that suits you.

Types of cartridges

The chuck holds the drill bit or bit. Depending on its type, it is worth selecting the mate. They are classified as follows:

- The most common is the key chuck, which securely holds the drill. But using such a cartridge requires a special tool, and it is quite easy to lose it.

- Keyless chucks make it possible to install a drill without the use of additional equipment; you only need your own hands. It is convenient to use, but a drill with a keyless chuck is more expensive than one equipped with a key chuck. The design of the keyless chuck is ideal for solving everyday problems at the household level, but in the professional field it may not be enough - it is not always able to withstand rapid rotation and reduce the degree of drill fixation.

- A single-clutch quick-release chuck allows you to change a drill with a spindle lock of the installed type - depending on the model, you will have to press a special button or move the ring.

- The counter part of the tool with a Morse taper should be installed in a chuck of type MK2, MK3. It is this connection that ensures that the drill is securely fastened, and heavy bits can be centered with high precision.

- Diamond concrete core bits are installed in a special G 1/2” and 1 1/4” UNC chuck.

- Heavy bits and large diameter drills are fixed with a 19 mm Weldon chuck.

- Some manufacturers' models feature a six-flute shank chuck - 7/16 Hex.

Hammerless drill

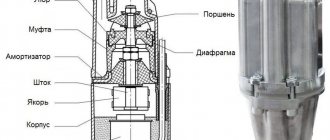

Included in the group of electric drill models. The motor (or electric motor) is the main mechanism of the tool.

To cool the mechanism, there is a fan impeller located on the input shaft, in front of the gearbox itself. Its body for household and semi-professional types is made of plastic.

For professional ones, metal is used, usually aluminum. The drill is started by a trigger switch. Thanks to it, the rotation speed is regulated.

Ammo classes:

- Key. They can be tightened using a wrench;

- Quick-clamping ones provide quick and easy replacement of drills with minimal effort and in a short period of time.

No. 6. Shaft rotation speed and its adjustment

The rotation speed of the drill shaft at idle speed can reach 3500 rpm, but such a frequency is not always necessary. The higher this parameter, the faster you can drill a hole and the smoother its walls will be. High speeds are more necessary for grinding and polishing the surface, but they will also come in handy for impact work. In order to tighten the screw, 400-500 revolutions per minute will be enough.

The versatility of using the tool is ensured by the rotation speed switch. The simplest models use a step switch, while more advanced ones use an electronic switch that clearly responds to pressing force. If you press hard, you get maximum speed.

A speed limiter and soft start will also be useful. The latter allows you to smoothly accelerate the engine and ensures a gradual increase in speed from the minimum to the required one. This allows you to get rid of jerks at the start, overloads and drilling errors.

Impact drills

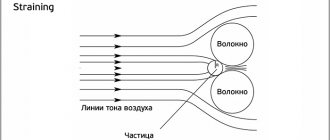

They are necessary for working with hard materials such as concrete or stone. This helps to avoid additional costs for hammer drills. Its features combined with those of a regular drill make it a popular and user-friendly option.

Two operating modes are presented:

- Conventional drilling;

- With a blow.

Areas of application

The direction of application is not limited to one drilling. Even drilling can be carried out on various materials. Usually - wood, metal, concrete and stone, brick and tile, hard soil and even ice.

A drill for concrete requires an impact type and preferably a powerful one. A low-speed one is also suitable for drilling timber. Manual is convenient for drilling ice in winter or taking soil samples in the mountains. There may be general purpose or highly specialized models.

By type of drive there is a networked and cordless drill, by type of power - electric (electric drills), pneumatic, gasoline and manual.

Screwdriver with battery

Lately, manufacturers are increasingly adding batteries to many tools, so there is a whole niche in the construction field.

Types of drills and screwdrivers:

- Regular;

- Angular.

There are usually three speeds, so the tool is equipped with a switch. The first is the weakest, plays the role of a screwdriver. The last one is a powerful drill.

What it is?

The hand drill, also called a power drill, has been used by humans for two millennia. At first it was extremely primitive, representing a bronze lance with a curved upper part and a pointed tip. Subsequently, its design became more advanced, which led to the appearance of a brace - a tool that can boast of having a chuck for securely fastening drills.

As for the popular models of hand drills currently in use, they include a gearbox with gears, the previously mentioned chuck, a handle, a locking handle and a stop tab. Using such tools, you can drill holes in a wide variety of materials: from malleable wood to concrete and highly durable metals.

In addition to drilling, the tool in question can be used to solve the following tasks:

- marking;

- increasing the diameter of existing holes;

- creating sockets for countersunk heads of screws, bolts and rivets;

- performing finishing processing.

In addition, some craftsmen use a hand drill as a replacement for a screwdriver and mixer - provided that a suitable device is secured in its chuck.

Angle drills

When it is necessary to work in confined spaces, this model is indispensable. Toward the working end, the body gradually narrows, which makes it possible to access difficult places.

The smaller the size, the more useful and functional the tool will be. This reduction is possible due to the shortening of the cartridge and the narrowing of the body part.

Drill Rebir IE-1206-1-16/2000ER 2000 W

Photo: market.yandex.ru

Drill Rebir IE 1206-1-16/2000 ER is used for drilling wood, steel, non-ferrous metals and plastic. It is equipped with a powerful motor that provides excellent performance. The ability to adjust the rotation speed allows you to configure the drill to work with a specific type of material. The aluminum gear housing contributes to the long service life of the tool.

Drill Rebir IE-1206-1-16/2000ER 2000 W

Advantages:

- Three-stage gearbox with high torque

- Side handle with soft grip to absorb vibration

- Main ergonomic handle with soft grip and wide switch key

- With the appropriate mixing attachment, the machine can be used as a mixer

- Locking button for continuous operation

- The ability to install in a stationary position allows you to perform work efficiently and with greater convenience

- Maximum diameter of the cutting edge of the drill: for wood, plastic – 70 mm, for steel – 32 mm

Drill mixer

Powerful electric motors are necessary for thorough mixing of building mixtures during their preparation. Most often they have two speeds for mixing solutions with different viscosities.

Paints, putties, different types of glue, lime, etc. are mixed.

Review of manufacturers

Today there is a wide variety of low-speed professional drills on the market. Let's look at the most popular manufacturers and some tool models.

BISON

Russian company specializing in the production of construction tools. Thanks to their reliable design, wide range of models and relatively low price, devices from this manufacturer are in great demand on the Russian market.

Drill mixer BISON ZDM-1200

The most popular model: ZUBR ZDM-1200.

- tool power – 1200 W;

- torque – up to 850;

- weight – 4.5 kg;

- maximum nozzle diameter – 16 mm;

- class – professional.

Makita

A Japanese company that was able to conquer the construction tools market with high quality and long service life. Thanks to their high technical characteristics, the tools of this brand are excellent for professionals who expect to use the equipment for quite a long time.

The most popular model: Makita 6014 BR.

- tool power – 850 W;

- torque - 550;

- weight – 2.5 kg;

- maximum nozzle diameter – 16 mm;

- class - household.

STURM

Equipment made in China. The model range includes tools of both low and high price categories. As a rule, tools of this brand have smaller dimensions and weight, with relatively identical technical characteristics. Devices of this brand can be an excellent assistant for both professionals and amateurs.

Drill mixer Sturm ID20131

The most popular model: STURM ID20131.

- tool power – 1100 W;

- torque – up to 800;

- weight – 3.5 kg;

- maximum nozzle diameter – 16 mm;

- class – professional.

Interskol

This company has its own production factory in Russia. This allows you to reduce the cost of transporting equipment and thereby reduce prices. The tools have good basic equipment: a wide variety of attachments, additional handles, etc.

Drill Interskol D-16/1050R

The most popular model: Interskol D-16.

- tool power – 1050 W;

- torque – up to 550;

- weight – 3.8 kg;

- maximum nozzle diameter – 16 mm;

- class – professional.

Model rating

Among each type of drill, the best models of 2021 can be distinguished. Thus, the Hitachi D 10 VC 2 is popular among non-impact drills. This model of electric drill is equipped with a keyless chuck. It allows you to change the drill without the need for a wrench.

It is equipped with a quick-release chuck, which allows you to quickly change the drill without using a key.

- It is possible to adjust the speed.

- Small compact size and weighing 1.3 kg.

- Also used as a screwdriver.

- It has a low cost.

DeWALT DWD115KS

Among the non-impact ones we can also highlight the DeWALT DWD115KS and the Japanese model Makita DP 4700. Their power is enough to drill wood and metal without any problems.

Useful tips

Pneumatic drills are designed for a compressed air pressure of 6 atmospheres, but in any case not lower than 5. Otherwise, the machine will not produce the required torque. The diameter of the supply hose must correspond to the liter flow rate of the pneumatic tool.

When purchasing a compressor, you should pay attention that its performance is higher than the rated air consumption of a pneumatic drill. A little clarification is in order here.

Typically, the compressor's inlet air flow rate is specified. At the output, this value decreases by 30–40%.

Therefore, in order not to make a mistake with the choice, it is necessary to enter a correction factor. For example, the drill data sheet indicates an air flow rate of 800 l/min. To select a compressor, this value should be multiplied by 1.4. This turns out to be 1120 l/min. The compressor, taking into account the reserve, should produce even more.

To increase the service life of pneumatic tools, an air preparation unit is additionally installed at the compressor outlet. The latter includes a filter, lubricator (oil sprayer) and gearbox. When drilling operations are performed at a stationary workplace, the drilling machine is suspended on a balancing beam.

Drum rating

Each of the following devices features quick-release chucks for simple, easy use.

SPARKY BUR 150CET KL

Bulgarian instrument of light weight - 1.5 kg. The user can adjust the rotation. The noise during operation is insignificant; the device itself has a durable, organic body. The manufacturer guarantees high build quality and long service life. Power is 600 W.

The cartridge is not rigid enough to be suitable for long term use. Also, the start is very slow, which can also be a disadvantage for many.

Bosch GSB 1600 RE

The professional model is suitable for working with wood, plastic and ceramics. Power is 700W. The manufacturer claims the quality and reliability of the assembly and the strength of the case, as well as a long-term period of operation. Average weight, 1.9 kg. Has a large number of attachments.

- A distinctive feature of this model is the increased power, which is 701 W.

- This device can be used for drilling wood, metal and plastic products.

- The size of the cartridge and the diameter of the holes that the device allows you to make are exactly the same as the previous model.

- The weight of this drill is 1.9 kg.

Main characteristics

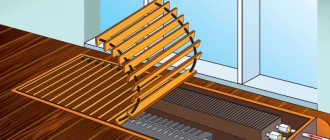

A low-speed drill has the following main characteristics:

- instrument power – from 900 W to 1600 W;

- number of revolutions per minute – 400-650 rpm;

- weight – 3-4.5 kg;

- number of operating modes – 1-3;

- drilling diameter – up to 28 mm.

A low-speed drill can withstand heavy loads for a long period of time. Thanks to these qualities, it is used for large-scale work.

Mixing glue using a low-speed drill

All drills should be divided according to the type of intended load.

- Lightweight devices - for interior fine finishing. Average power 700-1000 W.

- Heavy equipment – for carrying out large construction work. Average power 1000-1500 W.

When choosing a new tool, you should carefully consider the process of selecting the necessary characteristics. The higher the power, the higher the weight of the device and, accordingly, the price.

Rating of companies

There are a large number of companies producing equipment and tools in the construction industry. Based on customer reviews and long-term observations, it is possible to create a rating of drill manufacturers.

MAKITA

Japanese manufacturer, operating since 1915. Widely appreciated among professionals.

The company monitors product quality as well as customer requirements. Sales are carried out in European countries, North America and, of course, Japan.

- Makita has a wide range of models, from hammerless drills to diamond drills.

- The power of the devices starts from 230 W and reaches 1700 W.

- You can find a drill for both home repairs and professional work.

METABO

One of the recognizable companies in the domestic market. The German brand is known for its quality and reasonable prices.

The first electric drill was created here in 1934, and then the first impact drill.

- The company's goal is to continue to create new models, improving the tool.

- Thanks to decades of experience in the industry, METABO can offer customers drills of any type and model.

- These include standard models with a minimum set of functions, as well as impact drills and drill mixers.

- Minimum weight – 1.3 kg. Power can reach 1800 W.

BOSCH

Another company from Germany that has conquered the world stage. Today, Bosch products are sold in more than 150 countries. There are 7 representative offices in the Russian Federation.

- The company invests heavily in constant research, which helps expand the range and improve models.

- Only high-quality materials are used in production, and combined with ergonomics and simple controls, the tools are incredibly convenient and pleasant to use.

The price/quality ratio favorably distinguishes the company from the rest and puts it in first place.

DEWALT

An American company that is one of the leaders in the global market.

The high price is justified by the high quality, which is why the brand remains less popular than those previously listed.

The company's main models are impact drills. Their power reaches 1300 W. All products are provided with a warranty period of 3 years.

HITACHI

Another large concern in Japan, which appeared in 1910. Now the company produces computers, medical and industrial equipment, and electronics.

- The company's drills are designed for long-term use.

- The cases, as the manufacturer assures, are made of high-strength materials to prevent serious damage.

- Drills stand out for their ergonomics, compact size and fairly light weight.

The tools are suitable for home work and professional use.

Tool Features

There are 4 main cases in which high torque is unacceptable.

- cutting threads on pipes and other structures;

- mixing various construction, repair and finishing mixtures;

- preparing large holes;

- flaring

A low-speed drill is good because even when doing significant work at high power, it will not overheat. For comparison: trying to do the same thing with a simple tool can lead not only to its stopping, but even to breakage.

Since low-torque drills are usually heavy, most of them are equipped with a pair of handles. Holding such a tool with both hands is both easier and safer. Typical parameters for a low speed drill are:

- power from 0.9 to 1.6 kW;

- rotation rate from 400 to 650 turns per minute;

- weight from 3 to 4.5 kg;

- Punchable holes up to 2.8 cm.

Photos of the best drill models of 2022

How to choose a nozzle

If for some reason the device was missing a nozzle, it is important to know how to select it correctly. Most models have a special standard thread on the spindle, which allows you to securely fix the nozzle. This standard has been adopted by many major manufacturers and, at the moment, choosing a suitable nozzle is not difficult.

Many models are equipped with a movable coupling with a self-clamping mechanism. A key for such tools is not required, and the diameter of the drill or stirrer can be selected independently using the information provided in the operating instructions.

Movable coupling with self-clamping mechanism

The maximum nozzle size is set by the manufacturer. This indicator depends on the technical characteristics of the device.

Why do you need a soft start?

The presence of such a launch is a very important point. When starting a powerful power tool connected to the network, a surge of inrush current occurs, which is many times higher than the rated current of the motor, and the voltage in the network sags. Although this surge is short-lived, it causes increased wear on the brushes, the motor commutator and all the tool elements through which it flows. This can cause failure of the tool itself, especially Chinese ones, with unreliable windings that can burn out during switching on at the most inopportune moment. There is also a large mechanical jerk during startup, which leads to rapid wear of the gearbox. Such a start extends the life of the power tool and increases the level of comfort during operation.