The heating boiler is an accessible source of heat. It is equipped with a sealed tank in which the media is heated to a specific level. Such devices are an acceptable option for increasing the room temperature. Many consumers face a dilemma: “How to choose a heating boiler for their home?” After all, the level of comfort is influenced by the heating mechanism.

The selection parameters will help you determine which is the best domestic heating boiler to buy. You should start from the following characteristics:

- power;

- type of fuel;

- placements;

- installation method and others.

Before making a purchase, you should decide on the model and purpose of the device. If it is needed for the heating function, then a device with a single circuit is suitable. For water and heating, you need boilers with outputs for two connections, like the Ariston CARES X 24 FF model. If the unit operates on mains power (for example, RODA Strom SL 18) or on gas, then its performance is calculated to determine financial costs for the month. We will help you choose and buy the right domestic heating boiler so as not to freeze in winter.

Also useful for information: What to choose - electric or gas boiler? Comparison by 4 parameters

Which solid fuel boiler is better to buy?

There are many different types of solid fuel boilers on the modern market. Each type of equipment has its own technical characteristics and efficiency. To facilitate the process of choosing a solid fuel boiler, you need to have a clear understanding of each type of this equipment.

Natural combustion solid fuel boilers

This type of boiler is characterized by its simple design and affordable cost.

Any type of solid fuel is suitable for operation:

Coal.

Peat briquettes.

Firewood.

Waste from wood processing enterprises.

Pallets.

The best energy performance is achieved when working on coal, which has a high calorific value. Combustion is carried out due to the natural supply of outside air to the firebox. Modern models are equipped with thermostats that change the position of the damper at the entrance to the combustion chamber. During operation, it is necessary to regularly add fuel, remove ash and periodically clean the chimney of soot.

Obvious advantages of such boilers:

- ease of installation;

- fuel availability;

- no dependence on external networks (electric and gas).

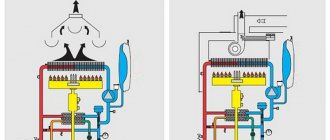

Sectional view of a natural combustion solid fuel boiler.

Long-burning solid fuel boilers

Such devices represent the next step in the development of boiler equipment. They have an improved firebox shape, forced air supply, and an intelligent control system. The programs built into the control unit make it possible to increase the burning time of a single load of firewood by up to 24 hours, which is very convenient for residents. The relationship between the operation of the blower and the circulation pump, adjusted for temperature indicators, allows us to achieve optimal heating conditions for the building.

The peculiarity of these boilers is that the wood in them does not burn simultaneously throughout the entire volume of the firebox. The area of intense oxidation gradually moves from one end of the combustion chamber to the other.

Advantages of such equipment:

- adjustable combustion process with increased heating duration;

- economical fuel consumption;

- simplified maintenance;

- minimal soot formation.

Sectional view of a long-burning solid fuel boiler.

Pyrolysis boilers

Normal operation of boilers of this class occurs in the mode of high-temperature generation of combustible gases. In technology, this process is called pyrolysis. Wood is usually used as fuel, which, from a chemist’s point of view, is a complex mixture of high-molecular compounds. Under the influence of high temperatures and a lack of oxygen, they split into simple gases, which burn, releasing the main amount of heat.

The firebox of such a boiler is usually divided into two compartments. In the main chamber, the firewood smolders, intensely releasing flammable gases. Entering the afterburning zone, they mix with secondary air and burn out completely. The temperature of this stage reaches 1200o C, which guarantees the absence of harmful emissions in the exhaust mixture.

The heat generated in both chambers is generated by a water heat exchanger connected to the heating circuit of the building. Thanks to the complete combustion of fuel and controlled air supply, such boilers demonstrate the highest possible energy efficiency. The disadvantages include increased demands on the quality of the loaded firewood, the relative humidity of which in most cases should not exceed 16%.

Advantages of such equipment:

- high efficiency;

- lengthening the heating period on one fuel load;

- high level of automation;

- minimum of unburnt waste.

Sectional view of a pyrolysis boiler.

Pellet boilers

Pellet boilers operate on specially prepared solid fuel. Pellets are granules made from industrial waste: sawdust, agricultural plant residues, peat. They are distinguished by their convenient shape, low humidity and high calorific value.

Boilers of this category require almost no human intervention in the process of maintaining the fire. It may be enough to pour the granules into the bunker once a week. Automation will do the rest.

Given the availability of pellets, the advantages of such equipment are undeniable:

- economical operation;

- ease of operation and minimal maintenance;

- high level of automation;

- environmental Safety.

Sectional view of a pellet boiler.

Heat exchanger - steel or cast iron

The reliability and efficiency of the heating system largely depends on the material and design of the heat exchanger. Historically, there are two main types of heat exchangers supplied with solid fuel boilers.

Cast iron heat exchangers

Cast iron heat exchangers have a sectional structure. Their main advantages:

- ease of transportation and repair;

- resistance to chemical corrosion;

- ability to work at high temperatures;

- high thermal conductivity;

- acceptable cost.

But we should not forget about the shortcomings. Among them:

- high probability of destruction due to a sharp temperature change, which often happens when cold water is supplied to a hot apparatus;

- Such boilers take a little longer to warm up, but they retain heat for a longer time.

Steel heat exchangers

Steel heat exchangers are almost always manufactured as a single unit with the boiler. Steel is a more ductile material and is not afraid of temperature changes, but with intensive and careless use, thermal fatigue zones can form in the area of the welds, followed by the appearance of cracks. Unlike a cast iron heat exchanger, the design of which allows the replacement of a rejected section, high-quality repair of a steel block is only possible in a factory setting using welding and heat treatment.

Steel heat exchanger for solid fuel boiler.

What you need to know about power

The power of the boiler is its main characteristic. It shows how much thermal energy it is capable of generating per unit of time. This indicator directly depends on the type of fuel used, the size and design features of the equipment. It is laid down at the design stage and is confirmed by numerous tests of the finished sample. Household solid fuel boilers can reach a power of several tens of kW.

We must remember that most solid fuel boilers are adapted to operate on different types of fuel. The manufacturer usually indicates the maximum performance achieved under ideal conditions. When switching from using coal to raw wood, the loss of power can reach 25-30%.

Tips for choosing a boiler

The future owner of a solid fuel boiler should know the following before purchasing:

1. What type of fuel will be most simple and economical to purchase in your area of residence. This can be coal, peat, firewood, organic briquettes or pellets.

2. Determine the required power of the equipment used to heat the building. In general, to heat every 10 square meters of area of a well-insulated house, 1 kW of boiler energy is required. The calculation should be performed with a small margin, since the efficiency of heat transfer gradually decreases over the years of operation.

3. If you need not only to heat the building, but also to produce hot water for household needs, the boiler you purchase must be a double-circuit one.

4. The quality requirements for a boiler used in a cottage with continuous residence must be higher than for a country house visited periodically.

We gradually approached the selection of specific equipment. The proposed rating of solid fuel boilers for heating a private home should help you with this. When compiling it, the technical characteristics, reputation of manufacturers, reviews of specialists and users were taken into account.

How to install the boiler, on the floor or on the wall?

If the cottage has a separate boiler room, then a floor-standing boiler can be installed in it. It requires a large area and additional equipment, but such devices have the highest power.

A prerequisite for the operation of a floor-standing device is a ventilation duct and a chimney. In addition, a circulation pump must be connected to the boiler, which most often runs on electrical energy.

Attention! The larger the cottage, the more powerful the equipment needs to be installed. A universal formula for calculating power: 10 m2 of area multiplied by 1 kW of energy and add 20% of possible heat loss.

A wall-mounted boiler is a kind of mini-boiler room. All the necessary equipment, including the pump, is already built into it; all that remains is to install the chimney. This equipment is less powerful than floor-standing devices, which means it is suitable for small homes.

It makes sense to install a floor-standing boiler in utility rooms where it will not interfere

A double-circuit boiler that heats water or a single-circuit boiler in combination with a boiler.

The best solid fuel direct combustion boilers

Viadrus Hercules U22

The lineup

The model range of this series of Vidarus boilers is represented by seven solid fuel boilers with a capacity from 20 to 49 kW. The most productive of them is capable of heating a building with an area of up to 370 sq.m. All equipment is designed for a maximum pressure in the heating circuit of 4 atm. The operating temperature range in the coolant circulation system is from 60 to 90o C. The manufacturer claims the efficiency of each product at 78%.

Watch the product video

Design features

All models in the presented line are designed for floor installation. They have an open combustion chamber with air supplied due to natural draft. Large doors with a square configuration easily open wide, which is convenient when loading fuel, removing ash and inspecting the condition of internal elements.

The built-in heat exchanger made of high-quality cast iron is adapted to work in a single-circuit heating system. The boilers do not have devices powered from an external electrical network and operate in a completely autonomous mode. All settings are mechanical.

Fuel used. The design of the spacious firebox is designed to use wood as the main fuel, but coal, peat and briquettes can be used.

Zota Topol-M

The lineup

The line of six Zota Topol-M solid fuel boilers begins with a compact 14 kW model, designed to heat a home for an average family, and ends with an 80 kW unit capable of heating a large cottage or industrial workshop. The boilers are designed for operation in systems with pressures up to 3 bar. The efficiency of thermal energy use is 75%.

Watch the product video

Design features

Their distinctive feature is their slightly raised design, which makes it more convenient to open the ash pan door and empty it. The combustion chamber is open type with a chimney connection from the rear wall. There is a built-in temperature sensor. All adjustments are made manually.

A heat exchanger for a single-circuit heating system is mounted inside, connected to 1.5 or 2” pipelines. The boilers operate in autonomous mode. Products of this brand are easy to install and reliable in operation.

Fuel used. The fuel used is wood or coal, for which a special grate is provided.

Bosch Solid 2000 B-2 SFU

The lineup

Solid fuel boilers Bosch Solid 2000 B-2 SFU are presented in a number of models with power from 13.5 to 32 kW. They are capable of heating buildings with a usable area of up to 240 sq.m. Circuit operating parameters: pressure up to 2 bar, heating temperature from 65 to 95o C. Efficiency according to the passport is 76%.

Watch the product video

Design features

The units have a built-in single-section heat exchanger made of cast iron. It is connected to a single-circuit heating system through standard 1 ½” fittings. The boilers are equipped with an open combustion chamber with a chimney with a diameter of 145 mm. For normal operation, a connection to a 220 volt electrical network is required.

There is a temperature regulator and protection against water overheating. The ash pan has a small volume, so it requires regular cleaning. Manufacturer's warranty 2 years. The design is simple, safe and highly reliable.

Fuel used. The boiler is designed to use hard coal. Using this type of fuel it demonstrates high efficiency. When working with wood or briquettes, efficiency decreases noticeably.

Protherm Bober

The lineup

The Protherm Bober series of solid fuel boilers is represented by five models with power from 18 to 45 kW. This range completely covers any private home. The unit is designed to operate as part of a single-circuit heating circuit with a maximum pressure of 3 bar and a coolant temperature of up to 90 ° C. For the correct operation of the control system and activation of the circulation pump, a connection to a household electrical network is required.

Watch the product video

Design features

Boilers of this series are equipped with reliable cast iron heat exchangers. The original design of the combustion chamber increases the efficiency of heat transfer. Exhaust gases are discharged through a chimney with a diameter of 150 mm. For connection to the heating circuit there are 2" pipes. Such boilers are designed for long-term operation.

Fuel used. The declared power is designed to burn wood with a humidity of up to 20%. The manufacturer has provided for the possibility of using coal. In this case, work efficiency increases by several percent.

No. 4 — Lemax Forward 16

Consumers place the Lemax Forward 16 unit in 4th position. This is a classic version of a solid fuel boiler designed for firewood, coal and coke. Power is 17 kW. The body is metal with reliable thermal insulation. Wall thickness – 4 mm. Overheating protection is provided by a cooling jacket. Weight – 90 kg.

Advantages:

- simplicity of design, which ensures low cost;

- optimal price in relation to quality;

- increased reliability;

- reinforced heat exchanger design;

- possibility of loading from above, which facilitates the process;

- energy independence.

Flaws:

- low power;

- reduced efficiency.

The popularity of the device is ensured by its low cost. For heating rooms up to 160 sq.m. it is recognized as the best heat source.

The best long-burning solid fuel boilers

Zota Carbon

The lineup

This domestic series of long-burning solid fuel boilers is represented by models with power from 15 to 60 kW. The equipment is intended for heating residential and industrial buildings. The boiler is single-circuit and has the following coolant parameters: maximum pressure 3 bar; temperature from 65 to 95o C. With optimal settings, efficiency reaches 80%. The boiler is easy to load and has movable grates for ash removal.

Watch the product video

Design features

The boilers are completely energy independent. Control is carried out mechanically. There is protection against overheating of the coolant. A built-in heat exchanger made of high-quality steel is installed. The duration of the combustion process is regulated by changing the flow rate of air entering the combustion chamber.

A chimney with a diameter of 180 mm and pipelines of a 2” circulation circuit are connected to the device from the rear wall.

Fuel used. It is recommended to use coal of fraction 10-50 mm as fuel.

Candle

The lineup

The line of Lithuanian heating equipment Candle includes five long-burning boilers with a power from 18 to 50 kW. They are intended for floor installation in residential or industrial premises. The units are designed to operate autonomously as part of a separate heating system. There is no additional circuit for heating hot water. The device is designed for a pressure of 1.8 bar and a coolant temperature of 90o C.

Watch the product video

Design features

The design of the open-type firebox and automatic air supply adjustment provide for a long combustion mode. The water “jacket” is built into the boiler body. There is automatic protection against overheating. Flue gas outlet pipe 160 mm. The diameter of the circulation circuit fittings is 2”.

Fuel used. Firewood or peat briquettes can be used as fuel.

Stropuva S

The lineup

The line of single-circuit long-burning boilers made in Lithuania includes models with a power of 8, 15, 20, 30 and 40 kW. The buyer can easily choose a suitable unit for heating a private home or small business. The most productive of them is capable of maintaining optimal temperature in a building with an area of up to 300 sq.m. No electrical connection required.

During operation, the combustion zone smoothly shifts in the firebox from top to bottom. Efficiency reaches 91.6%. Maintenance consists of periodically replacing fuel, removing ash and periodically cleaning the gas path, including the chimney.

Watch the product video

Design features

The elongated upward shape of the housing saves usable space during installation. The volumetric firebox allows you to load up to 80 kg of fuel. Precise adjustment of the incoming air extends the burning time of one bookmark to 31 hours. The coolant is heated to 70°C and circulates at a pressure of up to 2 bar. On the rear side there are fittings for connecting a chimney with a diameter of 200 mm and heating water 1 ¼”.

Fuel used. The boiler is designed to use dry wood as the main source of energy.

It will be useful to know: “How to choose a heating radiator?” Conditions of use

Before choosing a boiler for heating a house or apartment, you need to study the market. Selection is influenced by factors including:

- scale of the heated room;

- type of fuel used;

- location.

In order to understand which boiler is best to choose for a country house, country house or cottage, the availability of fuel will help. If gas is supplied, then a good option would be a unit that runs on this type of fuel, for example Leberg Eco-Heater 15.0 E. The main advantages are heating a large area and being environmentally friendly. The disadvantages include bureaucratic red tape for installation. It is also necessary to calculate the number of outputs for connection: one or two.

If there is no gas supply, then it is better to install a boiler that runs on solid fuel. The advantages are:

- environmental friendliness;

- availability of fuel;

- no permission needed to install.

The only drawback is control of the combustion process and periodic adding of firewood or coal.

When it is not possible to install gas or solid fuel equipment, an electric installation is a good option. The main advantage is safety and ease of use, small dimensions of the unit, and the ability to mount it anywhere. In order for the device to function without interruption, it is necessary to increase the power of the power supply network.

We also suggest that you read: “How to choose a geyser.”

The best pyrolysis solid fuel boilers

Buderus Logano S171

The lineup

Floor-standing pyrolysis boilers made in Germany, Buderus Logano S171, are available in four modifications with a power of 20, 30, 40 and 50 kW. They operate automatically and do not require constant human supervision. Their performance is sufficient to heat low-rise buildings of various sizes. Equipment efficiency reaches 87%. For normal operation, a connection to a 220 volt electrical network is required. Electricity consumption does not exceed 80 W. The unit is reliable and easy to use. Manufacturer's warranty 2 years.

Watch the product video

Design features

The boiler has a spacious open-type combustion chamber with a two-stage air supply circuit. Exhaust gases are discharged through a chimney with a diameter of 180 mm. Wide doors facilitate the process of loading fuel and inspecting internal devices. The design pressure in the heating circuit is 3 bar. The coolant temperature is 55-85o C. Overheating protection is provided.

Fuel used. The main source of energy is dry firewood up to 50 cm long. The burning time of one bookmark is 3 hours.

Ecosystem ProBurn Lambda

The lineup

Bulgarian single-circuit pyrolysis boilers are available in two versions with a capacity of 25 and 30 kW. Their performance is sufficient to heat a medium-sized private house. To operate the automatic control system, a connection to a standard electrical network is required.

The unit is designed to heat circulating water up to 90o C. The maximum pressure in the circuit is 3 atmospheres. There is protection against overheating of the coolant. The boiler is easy to maintain and highly efficient. A 12 month warranty is provided.

Watch the product video

Design features

There is a pipe with a diameter of 150 mm for connecting the chimney and 1 ½” fittings for the circulation circuit. In the area where the flue gases exit the furnace, a probe is installed that measures the oxygen concentration. It gives control signals to the damper that regulates the air supply.

Fuel used. Regular wood is used as fuel.

Atmos DC 18S, 22S, 25S, 32S, 50S, 70S

The lineup

The line of elegant pyrolysis boilers of this brand includes a number of models with a power from 20 to 70 kW. They are intended for floor installation in residential, industrial and warehouse premises. The equipment is highly efficient and reliable. For correct operation of the automatic control system, the unit requires power from a 220 volt network. Maximum power consumption is 50 W.

The intelligent control system for air flow entering the combustion chamber ensures the efficiency of each model at 91%.

Watch the product video

Design features

The devices are distinguished by spacious fireboxes of a special configuration, wide doors and a convenient control panel. The heat exchanger is designed for a maximum pressure of 2.5 bar. Maximum heating of the coolant is 90o C. When overheating, a protective lock is triggered. The exhaust gas outlet pipe is adapted for connecting chimneys of various diameters.

Fuel used. To load the firebox, use firewood with a relative humidity of no more than 20%.

Kiturami KRH-35A

The lineup

This floor-standing boiler of the Korean brand is designed for heating residential and industrial premises with an area of up to 280 sq.m. It has two heat exchange circuits that work for heating and heating hot water for household needs. They are designed for operating pressures of 2 and 3.5 bar respectively. For correct operation of the equipment, a connection to an electrical network is required.

This model has a remote control unit with the ability to select several operating modes. Automation protects equipment from overheating and freezing of the coolant. Unit efficiency is 91%.

Watch the product video

Fuel used. The main difference of the presented brand is its versatility. The boiler can operate not only on solid fuel, but also on diesel fuel. When loading coal, its power reaches 35 kW. With the liquid fuel version it decreases to 24.4 kW.

No. 6 – Bourgeois-K MODERN-24

In 6th place in the ranking is the Bulgarian unit Burzhuy-K MODERN-24 pyrolysis type. Boiler power – 24 kW. Loading chamber volume – 110 l. Dimensions - 50x118x80 cm. The boiler is designed for burning wood, but other solid fuels can be used - briquettes, pellets, peat and coal. Warm-up temperature - up to 95 degrees. Capable of heating a room up to 250 sq.m.

Advantages of the device:

- adjustable power;

- optimization of the fuel combustion process;

- environmental cleanliness;

- work up to 12 hours on one bookmark;

- energy independence;

- increased efficiency (more than 90%);

- low cost;

- simultaneous connection to the heating system and water supply.

Among the shortcomings are:

- mechanical control;

- significant dimensions.

These disadvantages are incomparable with the advantages that provide high reliability and absolute safety.

The best pellet boilers with hopper

Buderus Logano S181

German single-circuit solid fuel boilers Buderus Logano series S181 are presented in three models with a power of 15, 20 and 27 kW. They are used to heat low-rise residential and industrial buildings with an area of up to 216 sq.m. The equipment is designed to work with fine fractions of coal or pellets.

Watch the product video

Design features

Structurally, the products consist of two blocks installed in direct contact:

- the boiler itself with a combustion chamber, heat exchanger and control unit;

- a spacious bunker for storing fuel reserves with the ability to dose it into the combustion chamber.

To activate the mechanisms and operate the automation system, a power supply of 220 volts is required. The boiler is capable of heating the circulating coolant up to 80o C.

The heat exchanger is designed for a pressure of 3 bar. In case of overheating, automatic protection is triggered. Human participation in regulating the combustion process is almost not required. The efficiency of models in this range is 88%.

ACV TKAN

The lineup

The line of solid fuel boilers of the Belgian ACV brand is represented by household and industrial units with a power from 60 to 300 kW. They have one heating circuit for coolant circulating through the building’s heating system. The installed electrical equipment requires connection to an alternating current network of 220 volts.

Watch the product video

Design features

The unit consists of a housing with elements located inside it: a combustion chamber, an ash pan and heat exchange equipment. A spacious hopper with a supply of pellets is attached to the side. The heat exchanger is made of copper. This material conducts heat excellently, is not afraid of corrosion and is almost resistant to the adhesion of layers of scale and dirt. The equipment can withstand a pressure of 3 bar and heats the circulating water to 80o C.

Such boilers are designed for long-term operation without human control. Their efficiency reaches 90%.

Zota 15S Pellet

The lineup

Pellet boilers of this Russian brand are represented by a long range of heating devices with a power from 15 to 130 kW. They have one heating circuit and are used exclusively for heating rooms. Maximum parameters of the circulating coolant:

- pressure 3 bar;

- temperature 95o C.

In case of overheating, a lock is triggered. The device is distinguished by the presence of a large bunker designed to store a supply of pellets and feed them into the firebox. It allows you to leave the boiler for a long time without direct human control.

For the automation and transport line to function, the unit must be connected to a household electrical network. On the rear wall there are fittings for connecting a chimney with a diameter of 150 mm and heating pipelines of 2".

Watch the product video

Design features

If there are no pellets, you can switch to using regular firewood. To do this, you will have to install the additional grate included in the delivery set and disconnect the secondary air supply tubes. Boilers of this brand are not only simple and unpretentious, but also achieve an efficiency of 90%.

No. 3 - Buderus Logano S181-25E

The top three of the TOP is opened by the Buderus Logano S181-25E model. This device is rightly considered one of the best wood-burning boilers. Its power reaches 27 kW. The installation is equipped with control devices. Fuel can be wood and coal, incl. brown. The coolant heats up to 90-95 degrees.

Advantages of the unit:

- long service life (more than 30 years);

- fast heating;

- reliable protection against overheating;

- Ease of Management;

- enlarged loading chamber;

- economical fuel consumption.

The main disadvantage is reduced efficiency (less than 85%). However, high-quality German assembly and increased reliability bring the boiler to the leading position in the rating.