Maksym

30552 1 1

Maksym July 25, 2016Specialization: country construction, apartment renovation, landscaping of a personal plot, installation and connection of utilities.

Interior of a bathhouse with a homemade stove.

Sooner or later, any owner of a country house thinks about building his own steam bath on his personal plot, in which he can not only wash himself at the end of a working day, but also from time to time relax with close friends and girlfriends, or regularly take medical and health procedures. Currently, you can find a large number of all kinds of technical projects that offer independent construction of baths of almost any type (Russian, Finnish, Turkish, etc.), from inexpensive and accessible materials, however, as is known, the main consumer qualities of any steam bath are mainly , depend on the stove.

A ready-made heater can be purchased at a construction hypermarket, but I believe that a vertical or horizontal sauna stove made from a pipe with your own hands will cost much less than a purchased one, and besides, with a competent approach to work, a homemade stove will retain heat better and can last much longer longer.

Advantages of a brick stove

Brick stove-heater

A stove made of brick has a large closed heater; designs of other materials cannot compete with it in terms of the quality of the steam produced. The advantages of this design are:

- Fire safety;

- long-term heat retention;

- the ability to heat a large area;

- ease of operation and no need to add fuel during the washing process;

- uniform heating of the room;

- lack of contact between stones and combustion products.

The disadvantages of a stone stove include its impressive weight, which requires laying a separate foundation, and the need to preheat the bath.

Metal heaters: pros and cons

Made of metal

If desired, you can weld a steel stove for a bath. A container for stones is installed above its firebox. This option is cheaper and can be manufactured faster and easier than a brick structure. Cast iron cannot be used for metal heaters; cracks will occur when water gets on it. Among the advantages of a steel heating device:

- compact size;

- light weight;

- fast warm-up.

When choosing how to make a heater for a bath, the disadvantages of the stove are also taken into account; rapid cooling after combustion stops, uneven heating of the bath, fire hazard.

The brick stove is installed so that it heats all the rooms. Its front part with the combustion door and ash pan goes to the dressing room. The location for the structure is chosen when designing the bathhouse, because you need to take into account the required distance from the wall to the stove and build a solid foundation.

Scheme of a stove for a brick bath

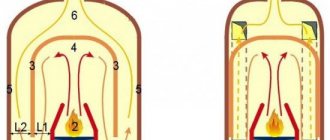

From the above it already follows that there are several basic diagrams of a brick kiln:

- direct flow;

- with smoke circulation;

- bell-shaped

However, each allows for many implementation options. In other words, the above diagrams clearly demonstrate the characteristic, but do not exhaust the possible.

Bath stove design: direct flow

Typically, in a brick kiln, the implementation of a direct-flow design is accompanied by a closed flow-through heater. In this case, there is no reason to fear that the furnace gases will not have time to cool sufficiently before leaving - their passage through the mass of stone filling is quite effective in removing heat.

By the way, the diagram shows that two types of bricks are used in the design of the sauna stove: red refractory and fireclay - they are shown in red and yellow. Please also note that there is a gap between them - this is an essential point.

The advantage of direct-flow can be considered its simplicity, including ease of maintenance. Of course, it is unlikely that you will be able to lay the stones perfectly the first time, but over time you will find their optimal number and location.

Designs of sauna stoves with smoke circulation

You already know the purpose of smoke circulation, but the difficulties associated with it do not yet. In general, everything in the oven is built on compromises. And this system is no exception. Let's start with the fact that horizontal channels are much better than vertical ones both in terms of heat distribution and the durability of the stove - there is no big difference in vertical temperatures, the stove does not crack. But with this arrangement there is another problem: the walls become overgrown with soot. Vertical ones overgrow more slowly, but here you need to clean them once a week, otherwise the draft decreases and the efficiency drops. Therefore, vertical channels turned out to be preferable.

The number of revolutions can vary from 1 to 12, but practice has shown that the optimal number of revolutions does not exceed 4 . As for their cross-section, it should not be too small and too large. In the first case there are more traps for soot, in the second there is ineffective heat extraction.

On a note! The inside of the channels must be as smooth as possible; they are specially cleaned of solution residues for this purpose. When laying, the most even geometry should face inward. The reason is that any roughness is a trap for soot.

Furnace structure in the bathhouse: bell-type

The design of a sauna stove may not contain channels. We have already shown you the structure of a simple bell-type furnace. Now a little more detail.

Its principle is simple: you need to build something like an inverted glass above the firebox, and make an exit to the chimney near its lower edge. This is a fairly clean design that suffers little from soot . The gases move as they want - the heated ones rise to the bottom of the glass, transferring heat to it, while they cool and tend downwards, they are replaced by new portions from the firebox.

Important! It is very easy to light such a stove even after a long break in operation.

However, it also has disadvantages:

- The upper part of the stove warms up well, and for good heating of the steam room it is necessary for the heat to come from below. This is treated with a two-hood system .

- For proper combustion you need skill - in an overheated furnace, gases stop flowing under the hood, it is easier for them to immediately escape into the chimney. It is treated by fine adjustment of the air entering the firebox.

Conclusion! Without experience, you can negate all the advantages of a bell-type stove.

With tank or coil

In an article devoted to a brick stove with a closed heater, we talked about how to correctly position the water tank in the stove structure in a bathhouse so that the water does not heat up too early, does not boil, increasing the humidity with heavy steam, and the tank is convenient to use in conditions of manual filling .

Here we just note that the coil inside the stove seems to us more optimal than the adjacent water tank. It is enough to maintain the angles of inclination of the pipes and the water in the system will flow only due to gravity and thermal convection.

In addition to the coil, a register of any other shape can be placed inside a brick oven. The location can be a firebox, a heater, or even a chimney.

Heater location

Depending on the area of the steam room, a stove of a suitable size is designed. If, as a result, the heater takes up space up to 2 m2, then it can be installed in a specially made niche in the wall. Due to this, heat loss can be prevented, since its combustion will be carried out directly from the steam room. Although in most cases the heater is designed in such a way that its firebox is carried out from the next room.

A sauna stove should be installed so that the heat from it spreads into the dressing room, washing room and steam room. Thanks to this, it will be possible to make a common chimney with three separate chimney channels for a gas boiler, fireplace and heater stove.

What metal is suitable

When selecting and inspecting metal pipes for a future furnace, it is important to pay attention to the following details:

- strength of the metal workpiece;

- pipe thickness;

- no defects or severe metal corrosion.

To eliminate defects, you need to weld patches of a suitable size in problem areas with a small margin.

As for the composition of the metal, it is not recommended to use alloy steel or steel with a high carbon content. The permissible carbon content in steel should not exceed 2%.

You can determine whether a metal is high-carbon or not by the appearance of sparks when grinding with sandpaper or an attachment on a grinder or drill. A high carbon content is indicated by white sparks like stars that pour in different directions. Low carbon content is indicated by yellow sparks that fall in a straight line. Alloy steel produces orange, bright red sparks.

The stove can be made either from a round pipe for a bath or from sheet metal. If in the first case the shape will be close to cylindrical, then in the second the furnace unit will be rectangular.

By choosing a round pipe as a blank, bathhouse owners receive a number of advantages:

- The pipe is easier to work with. Essentially, you have a ready-made firebox at your disposal that does not need to be cut.

- Economical material consumption allows you to reduce money expenses.

- In a round oven, the process of heat and air exchange is many times more efficient.

- The service life of a round stove is longer than a rectangular one made of sheet metal.

In addition to selecting the material, it is important to develop a drawing, a diagram of the future product, indicate the location and method of fastening all structural elements. This will simplify the assembly process of the unit.

Water container

Immediately before building the stove, it is important to determine the volume of the tank in which the water will be heated. The volume of the tank will depend on the intensity of visiting the steam room. So, the calculation is made based on one liter of hot water per person. It is best to use an open container. Although there will be evaporation, there are a number of positive aspects:

- Convenient when filling the container.

- The ability to carry out maintenance or repair of the internal part if necessary, for example, remove scale, clean and dry.

- In winter, completely remove water, protecting the tank from freezing the water in it.

Video description

An example of a vertical stove with a closed, insulated heater is shown in the video:

Above the heater, a water compartment is fenced off with another horizontal spacer and equipped with a tap. Since the water in the “blackie” pipe quickly becomes red from rust, it is often replaced with a stainless steel tank.

Without special electrodes and skills in such work, it is difficult to qualitatively weld ferrous metal with stainless steel. It is better to buy a ready-made tank with a section of the chimney already installed in it and place it on the heater.

Tank for installation on a stove Source prom.st

If space allows, the water tank can be installed separately, connecting it to the firebox with a piece of pipe. One end of it is welded to the wall of the firebox, and the second open end is inserted into the tank, into the lower part of the side wall.

Foundation for a brick stove-heater

If you want the stove you made to last for many years, you should take care of making a reliable foundation for it. In this case, be sure to take into account the following nuances:

- The foundation of the bathhouse and heater must be different, especially if the total mass of the stove exceeds 700 kg. There must be a distance of at least 500 mm between them.

- The foundation for the heater must have a depth below the soil freezing level of an average of 700 mm. In different regions of Russia, the level of soil freezing is different.

- The size of the foundation should be half a brick larger than the stove itself on each side.

So, let's look at the step-by-step process of making a foundation for a stove:

- To begin, dig a pit with a depth below the soil freezing level, on average 700 mm. The size of the pit around the perimeter should be 100–150 mm wider. This will allow you to easily install the formwork, and fill the resulting gap with sand or gravel.

- At the bottom of the pit we make a sand cushion. At the exit it should have a thickness of 150 mm. After pouring a layer of sand, water it with water to compact it. As water is absorbed, the sand will settle, so you will need to add it to the desired thickness.

- When the water is completely absorbed, a layer of stones or broken bricks is poured on top of the sand. It needs to be compacted. The resulting gaps between the stones should be filled with sand and watered. It is very important that the sand fills the space between the battle and the stones as densely as possible. The thickness of this layer, in our example, will be 250 mm.

- If the sand has stopped settling, then the next layer of crushed stone can be backfilled. It also needs to be compacted well.

- Now you need to make formwork from boards 40 mm thick. The internal size of the formwork must correspond to the size of the foundation. The top of the formwork must be leveled. It should be securely fixed in the pit and a reinforcement cage should be placed inside it. There should be 50 mm between the formwork walls and the frame.

- At the next stage, perform concreting. In this case, it is necessary to tamp with a piece of steel reinforcement or a wooden beam. The upper level of liquid concrete must be brought to the edges of the formwork. The surface of the screed should be smooth. As a result, the formwork should be on the same level as the subfloor of the bathhouse. The poured concrete must be left for several days to set.

- When the concrete has acquired sufficient strength, the formwork must be removed. The surface of the concrete is covered with two layers of molten tar. After this, fill the space between the walls of the soil and the concrete with sand or gravel. After this, cover the concreted area with plastic film and wait 7 days. Then you can start laying bricks.

DIY making

In order to make a mesh for a sauna stove yourself, you need to have basic welding and plumbing skills. The adjustable structure is designed for mounting on the chimney pipe of the stove. The height of the product is 80 cm, the side of the square of the base is 30 cm. The volume of stones in such a grid is not sufficient to fully provide the steam room with heat and steam; it is used as additional space for stones.

Sectional design of the furnace

Tools and materials

During manufacturing you will need tools and equipment:

- welding inverter,

- angle grinder with a disk for stripping and cutting metal,

- sandpaper,

- electrodes,

- hand tool.

Materials you will need:

- Corner 40*40, length 80 cm - 4 pcs., length 28 cm - 8 pcs.

- Rod or fittings 12-14 mm long 79 cm - 12 pcs., 28 cm long - 4 pcs.

- Heat-resistant enamel, solvent, brush, rags.

For welding, you will need non-flammable clothing, a welder's mask, durable shoes and split leather leggings. For cleaning and painting - a respirator and protective gloves.

Calculations

A large pile of stones lying in a heater is not at all the best option for warming up and creating good steam. The further the stone is located from the wall of the firebox or chimney, the less it warms up. The steam it produces will be cold, too damp and heavy. After one or two passes, the stone in the upper layer cools down and creates only dampness instead of steam. In order to properly warm up such a heater, you will have to heat the stove for a long time, which increases both the waiting time for steam and the consumption of firewood.

Approximate oven dimensions

The best heat transfer occurs in a layer of 10-15 cm from the heating source. Such stones warm up well and store a large amount of heat. They are able to give it away several times, i.e. You can give as much as you want. Accurate thermodynamic calculations are very complex and require engineering knowledge and skills. Experts usually use a rule of thumb for approximate estimates: for each square meter of steam room area, a mesh volume of 0.1 m3 will be required.

Manufacturing instructions

The quality of the final product will directly depend on how carefully the preparatory work is carried out. These include the following operations:

- Open the blanks. Cut blanks from the rod and angle according to the specified dimensions.

- Cleaning of rust and mechanical contamination from the welding area.

- Degreasing the welding area.

It would be better to clean all the workpieces at the preparatory stage - this will save time in preparation for painting.

Next, the mesh assembly begins:

- weld the short corners into two squares, the upper one is assembled with the shelves inward, and the lower one outward,

- Attach vertical posts to the corners of the lower square (with the angle inward), they must be oriented strictly vertically, checking with a square, to the upper ends of the vertical posts, attach (at several points) the upper square,

- mark the places where the rods are attached, 4 on each side of the square, grab the rods from the inside of the corners,

- at half the height, tie the vertical posts and rods with short pieces, they will play the role of stiffeners,

- make sure that all dimensions and angles of the structure comply with the design values, completely weld all seams,

- clean off slag and scale.

For areas that are difficult to reach with an angle grinder, files and sandpaper should be used.

After completely cleaning the surfaces of the product, it must be degreased. White spirit, gasoline or other organic solvent is suitable for this. Now you can apply a layer of heat-resistant primer, and after it dries, a layer or two of heat-resistant enamel.

Important: If the chimney is already installed on the stove and there is no way to disassemble it, assembly will have to be carried out directly around the chimney pipe.

In this case, the workpieces will need to be completely cleaned before installation - then it will be impossible to get to the inside. During operation, the pipe must be protected from splashes of molten metal.

Masonry bricks

For laying a stove, it is important to purchase well-fired and high-quality bricks. It should not have chips or cracks. Its edges must be smooth. The quality of a brick can be checked very simply. If, when dropped, it falls apart into several large pieces, then the brick is suitable. If, when dropped, it crumbles into many small pieces, then such a batch of bricks is not suitable for a heater.

Masonry mortar

For laying fireclay bricks, a mortar prepared from white fireclay clay is used. You can also purchase a ready-made composition for laying fireclay. You cannot place the entire oven on this solution. Why? This solution is sintered into a monolith at a temperature of 700–800°C. There are no such temperatures in external masonry. Therefore, after a short time it will crack and spill out, which will lead to the destruction of the masonry.

For external masonry, a solution of quartz sand and clay is used in a ratio of 1 (clay) : 5 (sand). The sand must be of river origin or quarry. River sand is somewhat worse, since its grains of sand are round and round, and the solution itself will have worse characteristics. Therefore, preference is given to quarry sand. The sand is sifted through a mesh with cells of 2–2.5 mm. This will prevent large particles from getting into the solution.

As for clay, it can also be obtained from a quarry from a depth of at least two meters. The quality of the clay should be checked. To do this, soak 200 g of clay in water for a day. Then roll the clay into a “bun” and leave it to dry under a canopy in the open air. After 2 days, drop it onto a stone slab from a height of 170 cm. If the “bun” has crumbled into several large parts, then clay is suitable.

The selected clay must be soaked in water to a paste-like state and ground through a sieve. First through large cells, and again through small ones.

Construction of a gas sauna stove

According to statistics of the Russian consumer market, gas stoves are the leaders among such equipment, that is, they are the most in demand. This is due to their compact size, easy operation, the ability to adjust the temperature and other advantages that are due to the simple but effective design of a gas sauna stove.

The furnace body is equipped with a gas burner. On top of the body there is a unit for removing combustible substances, as well as a tray in which stones are placed. There is a thermostat and a fuse, so that if the fire suddenly disappears, the gas supply stops. The combustion device is located under the stone compartment. Some models have a water tank. If it is not included, you can buy it and install it as an add-on. The stones heat up quickly and to a very high temperature. They are watered with water, which creates pleasant steam in the bathhouse.

The operating principle of a gas sauna stove is based on mixing gas and air. Gas supply is adjustable. It is important to remember that natural gas does not have the same high heat output as propane.

There are gas wood stoves. They have removable elements for several types of fuel. In such equipment, the gas burner unit has burners, relief and shut-off valves, as well as filters. For heating with wood, a special receiver for this type of fuel is installed.

Masonry

The masonry process is very painstaking and complex. There are a large number of subtleties and nuances here, understanding some of which comes only with experience. Therefore, to make this work easier for you, this section contains several videos that tell you step by step and show how to lay row by row.

As an example, consider the manufacture of an open small stove-heater. The size of such a stove is 102x62 cm. It is capable of heating a steam room with a tank, while the tank itself is located separately. It uses an interesting water heating system - an open siphon. So, a pipe is welded into the tank at a slight angle, which is sealed at the end. It should be under an open fire in the firebox. As soon as the water in the pipe boils, it rises into the tank, and cold water comes in its place.

The diagram below shows an example of a stove with an open heater:

Diagram of an open heater

And also a diagram of the arrangement of the firebox of an open heater:

Order of the firebox

Below in the diagram is the order of the brickwork of the stove:

Order of brick laying

If you want to make a closed stove-heater, then keep in mind that this is much more difficult to implement. There are many nuances that must be taken into account when laying it. It is quite difficult to describe the entire technological process, so we suggest you watch an introductory video. The peculiarity of such a furnace is that the reservoir for stones is lined with fireclay bricks:

Video about making a closed stove:

It is worth noting that upon completion of the masonry, drying should be 10 days. At the same time, drafts are unacceptable. Only after this time can the first fire be fired.

Photo instructions for ordering the heater stove

Stage 1-4

Stage 5-8

Stage 9-12

Stage 13-16

Stage 17-21

Stage 22-25

Furnace classifications

| Kamenka | Flow-through | Deaf |

| Open | "Black" batch oven | Continuous oven |

| Closed | Batch oven | Continuous or combined oven |

Let us explain: if the heater is running, then the poured water will spill into the firebox. Therefore, you have to wait until the wood burns out, then just supply water. Since combustion stops, the operation of the stove is called “periodic” . Accordingly, the continuous stove is not filled with water and the wood can burn throughout the bathing procedures .

On a note! Most often, metal stoves are permanent, and brick stoves are periodic, but there are exceptions. If a solid heater is made in a brick stove, then such a stove is called a combined stove.

Inertness of the material

So, the fire burns, the stones heat up, and what happens to the steam room? If we need to heat the stones to 300-400 degrees, can you imagine how much the air in the steam room can heat up during this time? And now we come to the next important point: the role of material in the design of sauna stoves, in particular steam room units .

Stoves are either brick or metal . There is no other option. The former are considered very inertial - it takes hours to heat them up, as well as to cool them down . The latter are able to heat up in half an hour and during the same time manage to overheat the steam room. sauna stoves !

When choosing a design, you determine for yourself how inertial its body should be. At your disposal are not only “clean” options: a purely brick, purely metal stove, but also combined ones . For example, you can increase the inertia of a metal stove either by using the internal lining of the firebox and heater, or by using an external sarcophagus casing. Moreover, the option with a casing and lining at the same time is not excluded).

Important! Answer the question, what is the optimal time for lighting the stove for you - it is this that determines the degree of inertia of the body.

Smoke

What happens when fuel burns? Heat is released and combustion products are formed - steam, gases and solids. We call the latter soot, soot , and all together - smoke . At the moment of leaving the furnace, this mixture is also heated to several hundred degrees. And if some heat-intensive obstacle , all this heat will simply fly away into the chimney to increase the greenhouse effect on our planet.

However, once upon a time, not only were there no obstacles, but there were no pipes either. Because they weren’t made from wood! Therefore, the first type of stove according to the method of removing smoke is chimneyless, “black” .

In its simplest version, it is a pile of stones placed in a vault over a fire . In the modern version, it is a brick hearth that keeps the same pile of stones from spreading. But the principle is the same: light a fire under the stones, wait for the wood to burn out, release the smoke outside through a window or door - and you can steam by pouring water on the heated stones.

Then a smoke collector - akin to a kitchen hood - also separated from the stove. A similar option can still be found in the bathhouse today.

Then the chimney pipe . And if it is simply inserted into the stove (into the firebox or heater - it doesn’t matter), then such a stove will be called direct-flow . Heat here is not taken from the furnace gases, so it has the lowest efficiency.

But heat is a pity, so the inventors’ idea went this way: what if we increase the path that the smoke travels inside the stove? smoke circulation system appeared , where smoke is forced to run with obstacles inside channels that lead it up and down, or horizontally to the right and left. The system is excellent for heat extraction, but it has its drawbacks - the channels, especially horizontal ones, must be cleaned regularly , otherwise there will be no draft.

An alternative to the smoke circulation system was the bell-type stove . It has no channels and is practically independent of traction. Hot furnace gases, leaving the firebox, end up under the hood, where they actively share heat with the furnace mass. New portions of hot furnace gases rise, displacing cooled ones down and into the chimney.

However, everything that has been said about the chimney primarily applies to brick stoves . It's rare to see a metal stove with smoke circulation. Usually they are primitive - direct-flow, except that they have flame dividers. And their sizes are much smaller than brick ones, there are no passages, and there is no heat-intensive material - where to take the heat?

The stove ends at the chimney. What remains optional is a tank or heat exchanger , which can also be indicated on the diagram of the sauna stove. But it is better to talk about this when analyzing specific structures, to which, in fact, we are moving on.

Construction of a firebox and ash pit

It is very important to correctly calculate the dimensions of the firebox. In this case, it is worth taking into account various factors, starting from the presence of a collector for heating water and ending with the type of fuel for heating the bath. The average depth of the firebox is 800 mm. 250 mm is allocated for the hot water system, and 550 mm is the usual length of firewood. The height of the firebox can reach 350 mm and the width 400 mm. With such dimensions, 8 to 10 logs of firewood can be placed in the firebox.

Chimney

The heater stove differs from its analogues in that natural stones are used to accumulate heat. The first segment of the pipe passes through just such a compartment with stones. The chimney can also pass inside a container of water to heat it. In all other respects, there are no special differences in the construction of the chimney. It can be assembled from sandwich pipes or ceramic blocks. The manufactured chimney must be insulated.

As for the lower part of the chimney, it is made of steel, right up to the ceiling. It is necessary to install a damper when passing through the ceiling pipe.

The gate is designed to improve combustion intensity, as well as to regulate draft.

If a sandwich pipe is used, then it has two walls, between which there is a heat-insulating material. They can be installed in the area from the ceiling to the fungus on the roof. Basalt mats are used to insulate a brick chimney. They wrap the pipe. Wire is used to secure the mats. An umbrella or fungus must be installed on the chimney. This will protect the chimney pipe from sediment entering it.

When arranging a chimney, you should decide what type it will be: external or internal.

You can learn about other subtleties of arranging a chimney pipe from the video:

Pros and cons of such ovens

The required properties for the material used in the manufacture of the furnace are heat resistance, strength, durability, and corrosion resistance. In addition, it must withstand sudden temperature changes and have good thermal conductivity.

The ferrous metal from which a thick-walled pipe with a diameter of 500-600 mm is made cannot be called completely corrosion-resistant. But it is precisely this type that is optimally suited for the independent production of a sauna stove, as it meets almost all of the requirements listed above.

Having a wall thickness of at least 8 mm, it makes the stove in the bathhouse quite heat-intensive, in which heat is retained when the fuel has already burned out. And the round cross-section inside it allows heat to spread efficiently.

The use of a round-shaped pipe for a stove in a bathhouse reduces the length of welding seams - these are the very first places for corrosion to form , and it is through them that carbon monoxide escapes. In addition, this option remains the cheapest, although prices for ferrous metal are rising.

Finishing

Most often, the stove-heater is left without finishing. Red brick is laid out for jointing, and all bulges and irregularities are sanded. At the same time, it is also practiced to enhance the color of bricks with a solution of sulfuric or hydrochloric acid. However, the stove-heater can be plastered or tiled.

If you decide to plaster, then the layer should be made up to approximately 15 mm. For this work, you can use the following compositions with proportions:

- clay (1) – asbestos (0.2) – sand (2);

- lime (2) – sand (0.2) – asbestos and gypsum (2);

- sand (3) – clay (1) – cement (1) – asbestos (0.2).

Immediately before plastering, the oven is heated. After this, the first continuous layer is wetted and applied. When the first layer has set, the next layer is applied. As a result, the surface of the wall should be rubbed so that the wall is smooth and looks neat. Finally, whitewashing can be done.

Commissioning

Before you are going to light the stove, you should let it dry thoroughly. To do this, open the doors, vent and vents open for 7 days, this way the oven will dry out faster. If the stove does not smoke when lighting, it means the draft is good.

You should not rush to light the stove. Otherwise, if there is insufficient drying, cracks may form in the masonry.

Suitable pipe sizes

Steel pipe as the main raw material for the furnace has a number of advantages. Among them:

- resistance to damage;

- good level of heat transfer;

- rapid heating of the room;

- minimal expansion when heated;

- use of any type of fuel;

- minimum number of welds.

The disadvantages of a metal stove are the same rapid cooling of the room as heating, uneven distribution of heat in the room. To eliminate them, the stove is often lined with bricks.

530 mm

For a steam room of standard sizes, a pipe measuring 530 millimeters is good. A stove made from it will be quite powerful; the wood will burn for a long time, providing good performance. Available in horizontal and vertical versions.

640 mm

A good material option for a large steam room in a bath complex. The large firebox allows you to place a lot of firewood at once, increasing the break between loads to 8 hours.

426 mm

This diameter is enough for a small steam room in a seasonal building, where bathing procedures are combined with washing or dousing with cold water in one room.

It is important to note that cast pipes without seams are an excellent option for small furnace parts; their diameter does not exceed 250 mm. To make the main part of the furnace, it is better to take pieces of spiral pipes - they are reliable and will cost the same as scrap metal. If you can’t find these, you should take straight-seam ones.

Selection of stones

River stone

Based on the name of the stove, it uses special stones that undergo sanitary and geological examination. As for the specific choice of stone, there are several options:

- Soapstone chlorite.

- Jade.

- Gabbro-diabase.

- Raspberry quartzite.

- Porphyrite.

For baths, sea stones are considered to be the best option. However, such an opinion is unfounded. As practice shows, river stone can withstand high temperatures much better. Sea stone is destroyed very quickly, as it does not have sufficient strength.

Types of stones

But in addition to the type of stone, you should choose the right size and shape. For example, these could be medium stones with a smooth structure. Remember that there must be enough stones, as this affects the quality of heating and steam release.

So, when deciding which stone is best to use for a stove, remember not only practicality, but also the beauty of the room. Beautifully shaped stones will be a real decoration of a Russian bathhouse.

In this article we familiarized ourselves with the most common type of stove that is used to equip a Russian bath. As you can see, the process of its construction is quite complex and responsible. Therefore, there is no need to rush to start work. Carefully study all the recommendations in this article, diagrams, photographs and video material.

Design and principle of operation

At its core, a sauna stove-fireplace is a body made of refractory and high-strength metal, inside which heat exchange processes take place. Effective heating of the stove is ensured by a labyrinth heat exchanger inside the stove; heat flows through it, which gives off its heat to the stones located along the path to the chimney pipe. The stones become hot and heat the air.

The main advantage and characteristic feature of such a stove, compared to other stoves, is the fireplace door, which allows you to unhinderedly contemplate the combustion process, without the risk of things burning around the fireplace.

Typically, the door is made of glass-ceramic, which is translucent and resistant to high temperatures, which guarantees the integrity of the fireplace.

Photo

Kamenka buller (buleryan)

Sauna stove-heater “Breneran”

Stove Sayany Vitra Termofor

Stove for Russian bath

Made of cast iron

In the steam room, the heater is combined with a fireplace in the dressing room

Fireclay furnace fencing

Homemade stove-stove

Did the article help you?

Installation Rules

The requirements and recommendations for installing the furnace are the same as for other metal units.

- These relatively lightweight structures can be installed on a concrete screed without a foundation.

- If the floor is wooden along the joists, you need to pour or lay out a solid foundation from blocks.

- To reduce infrared radiation from hot metal and reduce the risk of burns, you can line a pipe sauna stove with bricks or simply separate it with a brick screen.

- The distance from the stove to the walls must be at least 20 cm.

- At the point where the chimney passes through the ceilings, a cut-out is arranged in the form of a metal box filled with non-flammable material, for example, stone wool.

The ceiling around the pipe is covered with a sheet of iron Source izhevsk.ru

- A metal sheet is also placed on the floor before the firebox to prevent accidental fire from sparks and embers.