Laying cables in pipes underground is a more labor-intensive undertaking than aerial (open method), however, the reliability of such a design in terms of safety is much higher. This method of laying cables is especially popular in summer cottages, where there is a possibility that it could be “borrowed”. Cable installation in pipes is carried out in accordance with the standards prescribed in the rules for electrical installations (PUE).

The use of pipes to protect cables increases the safety of electrical networks

Advantages of laying in the soil

Installation of cables in the soil is carried out using various types of pipes: metal, metal-plastic, low-pressure polyethylene (HDPE). This type of gasket has a number of advantages over the air method:

- laying the cable in a pipe ensures its protection from adverse weather conditions and will also reduce the likelihood of mechanical damage;

Helpful information! The cable laid underground is very easy to replace if necessary. To do this, you just need to dig out the communication and remove the old cable from the line, replacing it with a new one.

- this method eliminates the possibility of fire, which is a very important advantage, especially for houses made of flammable materials (for example, wood);

- additional protection of the wiring in the form of a pipe eliminates the possibility of damage to the cable by rodents;

- such communication (unlike air communication) is not visible and does not spoil the aesthetics of the site;

- in most cases, the cost of such cable installation is lower than with open installation.

Rules for different types of wiring

When choosing wiring for equipment of various types of premises, you should follow the rules set out in GOST 12.1.044. For residential buildings, you need to use three-core cables with copper cores of 1-2.5 mm. The insulation must be non-flammable and not emit smoke when heated. The brands VVG-Pngd, VVGzngd, Flame-X, N2XH, YnKY correspond to these parameters.

For the arrangement of premises made of non-combustible materials, the use of simple conductors is allowed without any restrictions. Powerful consumers operating in continuous mode must be connected to a separate line equipped with an RCD.

What cables are allowed to be used?

According to GOST, it is allowed to lay cable wiring underground, which has certain technical characteristics. A desirable parameter for laying cables in a trench without the use of pipes is the presence of so-called armor . Armored cables, among other things, must also have high waterproofing properties. The installation of such cables can be carried out without protective pipes, however, the cost for them is higher than for budget options that are installed in pipe communications.

Special types of cables are used for underground installation

Let's consider the main types of cables that are allowed to be installed in the soil without protective pipes:

- AVBbShv. Armored cable with aluminum cores inside. The armor is represented by two layers of galvanized steel, covered with an insulating layer on top;

- VBBShv. This cable differs from the previous one only in the material from which the cores are made - it has a copper filling. In terms of other technical characteristics, VBBbShv is similar to AVBbShv. Both of these types are recommended for use for wiring electricity in summer cottages. Also, their properties make it possible to eliminate the use of protective pipes.

- PvBShv. This cable is also an armored type, however, unlike the previous two types, the insulating material of the product is cross-linked polyethylene. This material has high strength characteristics, so it is ideal for laying underground, but its cost is higher. PvBShv is often used in difficult climatic conditions.

In addition, other product options are suitable for underground wiring: AAShp, AAShv, AAB2l, etc. Such models of cable products can be used in soil that has normal acidity.

For soil containing active chemicals of various natures (salt marshes, swamps), the following cable models are perfect: AABL, AAShv, AAB2l, ASB, AAPL, ASPL, AAP2l, AAShp, AVBbShv, AVBbShp, APvBbShv, etc.

Laying a simple cable in a protective pipe will be cheaper than using armored wires

Together with protective pipes, armored cables provide high levels of communication reliability and have a long service life. But not every owner has enough money to equip such wiring. And even more so, the least profitable option is the use of armored cables and pipes. In this case, they use cheaper cable products laid in pipes.

The cable used for installation in underground pipes, as a rule, has a special marking - SIP (self-supporting insulated wire). This type of cable can be used when laying using the trench method only in conjunction with a protective pipe.

Definition of low-current networks and basic requirements for them

The engineering network of a modern building, regardless of its type and affiliation, includes an electrical network, a water and sewerage system, a heating system, as well as low-current systems.

If everything is clear with the three indicated components, every person encounters them in everyday life, then low-current systems cause some confusion for some. Although these devices are used no less often than, for example, a lighting lamp. Low-current systems are Low-current systems that consist of devices that do not consume large currents during operation and are connected to an electrical network of 12 -24 V. The current strength provided by the normal mode of their operation is measured in miles amperes. In technical terminology, these devices and the cable lines connected to them are also called information systems.

The main requirements for the operation of low-current networks include:

- reliability in operation;

- low rate of errors generated;

- low percentage of failures during operation;

- simple management and diagnostics.

Based on such high demands, maintenance of low-current systems should be carried out only by highly qualified specialists in this area.

Only they, with their knowledge and the availability of special diagnostic equipment, can support such information networks at the proper high operating level.

What pipes are used to lay cables in the soil?

Laying cables underground is safer than overhead wiring. Pipes that serve as a protective casing for cables can be made of different materials. Let's consider the main materials of such pipes and their features:

Metal . The metal pipe to protect the cable must have a cross-sectional area that is 2–3 times the diameter of the cable itself. The depth to which the cable is laid in a protective casing, as a rule, depends on the climatic characteristics of the region, namely, on the depth of soil freezing. If the freezing depth reaches the depth of the trench, then it is necessary to additionally secure the pipe to protect it from damage.

Important! Do not use steel pipes for power cables. This material is only suitable for control lines.

Asbestos-cement. Previously, such pipes were used quite often for the trench method of wiring installation, however, today they are used extremely rarely. Installation of such pipes is difficult due to their heavy weight. In addition, asbestos-cement products have low strength indicators and also emit substances harmful to human health. Asbestos cement products are carcinogenic and are not recommended by experts.

Asbestos-cement pipes are quite fragile, which is why their service life is relatively short

Plastic (HDPE, PVC, PP). Today, a plastic protective pipe for laying electrical wiring in a trench is the most popular option of all. This is due to the fact that plastic communications have a number of positive advantages:

- low weight;

- high strength characteristics;

- resistance to corrosive influences;

- high insulating properties;

- long service life.

Plastic pipes come in a wide range of sizes and other characteristics. If necessary, you can choose a product with a smooth or corrugated wall. The most popular plastic pipes are HDPE products, which come in the following varieties:

- light corrugated pipes;

- heavy corrugated pipes;

- halogen-free;

- smooth hard;

- products with two walls.

Tips for properly connecting electrical points

To create effective wiring in an apartment, it is necessary to distribute different directions and combine groups of electrical points in these directions.

So, for laying electrical wiring from the electrical panel, it is worth highlighting the following lines:

- lighting for living rooms, kitchen and corridor;

- electricity supply to living rooms;

- separate power supply to the kitchen;

- lighting and power supply for the bathroom and toilet;

- a separate power line for electric stoves and appliances that consume high power.

For each group it will be necessary to install a special protective shutdown device, which will promptly turn off a specific line, which will protect the wiring and the equipment powered by it from damage.

When connecting electrical points, you should definitely use distribution boxes, since they are, first of all, one of the ways to isolate connections.

It is worth noting that the connection of the electrical panel to the power lines in the apartment should be entrusted to the electricians of the management companies, since this work must be performed exclusively by specialists in accordance with the requirements of legislative documents.

Corrugated pipes for laying cables in the ground

Particular attention should be paid to corrugated pipes for wiring power lines in the soil. Such products can be of two types:

- unreinforced;

- reinforced.

Corrugated pipes are the best option for laying electrical cables underground

Reinforced corrugated pipes are characterized by increased strength. Strength is achieved thanks to special steel wire, which is equipped with reinforced models at the production stage.

Today, double-walled corrugated pipes are becoming increasingly popular. This product includes the following structural elements: a corrugated outer shell consisting of HDPE and a smooth inner shell made of high-density polyethylene (HDPE). A distinctive feature of such a pipe is considered to be a high coefficient of ring stiffness. Thanks to this, such models are able to withstand heavy loads. In addition, installation of the cable into the pipe is carried out without any difficulties, since the smooth inner wall made of LDPE simplifies the process.

The light weight of the pipe also facilitates its installation, and high thermal stability allows double-walled corrugated pipes to be used in different climatic zones. In addition, the positive qualities of double-walled models include: resistance to the destructive effects of corrosion, resistance to ultraviolet rays and a service life that can reach 50 years (in some cases more).

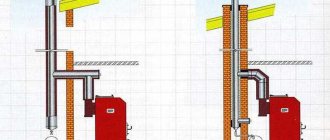

Features of laying cables in metal pipes

For wooden buildings (houses, bathhouses, etc.), it is recommended to lay protective pipes made of metal materials. Such materials include: iron or galvanized steel. The use of galvanized products is more preferable, as they have good resistance to corrosion.

Internal wiring in premises can be laid in metal corrugated and smooth pipes

It is recommended to use DKS pipes for laying cables indoors. The trench use of these pipes is undesirable, however, if such communication is temporary, then it can be done in the soil and from the DCS pipe. To connect individual route segments, as a rule, special threaded fittings are used. The use of such couplings greatly simplifies installation and reduces installation time.

Important! When laying such communications, you should take care of grounding. Grounding for such structures is a mandatory measure, which is specified in the relevant documentation.

In addition, it is worth remembering that the slope of the route is towards the electrical distribution panel. Pipes, as well as the joints between pipes, must be painted to protect communications from corrosion. Such structures are not suitable for indoor work, since painted pipes do not adhere well to concrete poured into the floor.

Reduce Electrical Interference

To reduce electrical interference in the cable of an apartment (house), you need to:

- The antenna effect can be reduced by reducing the cable installation height

- Use shielded cables

- Use termination cables with ferrite rings

- Place sensitive devices closer to the floor

In the end, it is worth recalling once again that if you do not have specific knowledge in the field of wiring, in no case should you undertake such work. It is better to entrust this procedure to professionals who have extensive experience. They should be entrusted with all the work, from the selection of wires to further installation of the system. Also, highly qualified specialists will be able to service low-current networks. After all, they have been working professionally in this field for several years and know the main nuances and subtleties of carrying out this work. This is the only way to achieve complete safety and reliability.

Features of laying cables in plastic pipes

Installation of electrical cables in low-density polyethylene pipes has several features that are worth paying attention to. First of all, in order to exclude unforeseen circumstances, it is recommended to prepare a drawing of the future route.

It is advisable to fix the communication at certain intervals, which, depending on the specific case, can range from 60 to 80 cm. The structure is secured along its entire length with special staples or clips.

Pipes with cables inside should be securely fastened to all surfaces along which wiring runs.

In order to pull the power line through the pipe, special broaches are used, with which the pipe is equipped at the factory. If there is no broach, it can be replaced with ordinary metal wire.

Unlike a metal route, the elements of which are joined using threaded connecting elements, the joining of individual segments of a plastic pipeline is carried out using special soldering equipment. The electrical cable is connected using special couplings. In addition, if the communication is mounted vertically, it is recommended to slope it to eliminate the possibility of condensation accumulating in it. Compliance with the above rules will allow you to obtain a durable and reliable design.

Construction of the trench

Arranging a trench is an important aspect of installing a power line into the ground. Many people turn a blind eye to this, however, the rules should still be followed. Let's consider the basic requirements that underground cable installation must meet:

- the pipeline must have a depth in the soil of no less than 70 cm. If installation is carried out in non-standard climatic conditions, this figure will be correspondingly higher;

- It is important to remember that the distance of the communication being laid to the foundation must be at least 60 cm. It is strictly forbidden to lay a route under the foundation ;

- The width of the trench is determined by the diameter of the pipe. In turn, the diameter of the pipeline must correspond to the number of cables. If several conductors are placed in the channel, the distance between them must be at least 10 cm;

- Before arranging a ditch, it is necessary to study the plan of a specific site. This is necessary in order to select the correct location of the trench. According to the PUE, the cable is laid in the pipe at appropriate distances from other communications (the route must be at least 2 m from the gas pipeline, and also no closer than 1 m from the water supply);

Construction of trenches must be carried out in accordance with the PUE; laying of warning tape is mandatory

Helpful information! In some cases, to strengthen such communication when the soil subsides, owners use ordinary bricks. It is not recommended to use hollow bricks for these purposes.

- It is imperative to put a tape on top of the route, which will warn that a power cable is laid here. After this, it is necessary to again fill in a layer of sand and earth (with a slide of 10–15 cm).

Wire laying

To ensure that the wire is not damaged and lasts a long time, the following rules are followed during its installation:

in one trench it is allowed to place no more than 6 wires with a voltage of 6 to 10 kV;- it is allowed to lay two cables with a voltage of 35 kV in one trench;

- no more than 1 bundle of control wires can be laid next to these cables;

- trench width for one wire at voltages up to 10 kV - 20 cm, at voltages up to 35 kV - 30 cm;

- in the presence of harmful soil conditions, the wire is laid on overpasses;

- laying is carried out with a small margin of distance;

- A wavy or “snake” gasket is allowed.

The distance between wires of different power loads is:

- 100 mm for wires up to 10 kV;

- 250 mm for wires from 20 to 35 kV;

- 500 mm for cables from 110 to 220 kV.

Laying takes place in certain weather conditions. The norm is to carry out work in dry, clear weather with no precipitation. In winter, the cable is preheated. At temperatures from -20, work outside is carried out for no more than 1 hour.

The process of laying one cable with a power of up to 35 kW

To lay an electrical wire with a power of up to 35 kV, follow the step-by-step steps:

- Acceptance of the route. The cable line route must be accepted according to the act from the builders.

- Preparatory work. When the trench is dug and the sand bed is arranged, it is necessary to check the installation of support posts for the end couplings, the absence of water in the trench, and the passability of block pipes if the wire is placed in a casing.

- Drum installation. The drum is removed no earlier than 1 day before the start of work. Its external inspection is carried out, installation is carried out, smooth running is ensured, and linear rollers are placed.

- Laying. Straight sections do not require a large number of people. If the cable is laid at an angle, a worker must be there. One worker monitors the unrolling and feeding of the cable, several workers accompany the end and beginning of the wire. The laying speed does not exceed 30 meters per minute.

At the end, the cable is sprinkled with a layer of sand or soft soil. In case of risk of damage, the cable is additionally protected with bricks. A warning tape is also laid at a distance of 25 cm from the surface of the wire. At the final stage, the trench is backfilled and compactions are made every 200 mm.

Laying mutually redundant wires

According to clause 2.1.16 of the PUE, it is prohibited to lay mutually redundant cables with a power of up to 42 V with wires with a power of over 42 V

Laying cables under the road

The laying of cables under the road in pipes is carried out with the permission of the organization on whose balance sheet the road is located. This point is especially relevant for routes located in populated areas, since other communications may pass under them. If laying under the road is carried out in a holiday village, then such an event must be agreed upon with the administration.

The rules for installing a power line in a protective casing under an unpaved road surface are the same as for conventional installation. The depth, arrangement of the sand cushion, backfill and other parameters coincide with the usual installation of communications. The electrical cable is laid in a pipe under a paved road, usually using the puncture method. Puncture involves the use of special equipment and is a trenchless method of arranging communications, however, the cost of such work is quite high.

Methods for installing sockets and switches

Surface-mounted and built-in socket

Installation of sockets and switches, as well as wiring, can be done in an open or closed way.

The first option is used for arranging rooms whose walls are made of flammable materials or their thickness is insufficient for installing mounting boxes (socket boxes). In some cases, such a decision is made to save effort and time during the construction process or when previously installed wiring fails. Fastening is carried out directly on the load-bearing surface. The disadvantages of outdoor installation are that the housings of the devices protrude 4-6 cm above the surface of the walls and spoil the interior of the premises. In addition, the likelihood of damage or demolition of the product increases due to careless movement, moving furniture and large household appliances.

The closed method of mounting a socket can be used in combination with all types of cable routing. First, holes are made in the wall into which plastic cups are attached to the putty. After crystallization of the solution, the socket is connected to the wires and firmly fixed in a plastic box. If you do not take into account the difficulties of slotting and drilling holes, this method is more reliable, practical and aesthetically pleasing.

How to properly lay a cable in the ground?

First of all, it is necessary to draw up a plan for laying the power cable in the protective pipe. Next, a phased installation of communication is carried out. Let's consider the process of installing communications by digging a trench:

- First, the pipe is laid at the bottom of the trench. Laying is done on soil with a sand cushion. The sand layer should be at least 10 cm.

- Next, the cable is pulled using a wire.

- At the third stage, the communication is covered with a layer of sand (so that the pipe is not visible).

- After this, we fill the trench with a layer of earth and compact it with our feet. The layer should be approximately 15 cm.

- We place warning tape on top of the trench, which performs a warning function.

- Then the channel is completely filled with earth and compacted.

Note! After installation, it is necessary to carry out a test measurement of the cable insulation.

This kind of work can be done without much difficulty with your own hands. In order not to encounter difficulties when laying cables in a pipe, it is recommended to carefully consider the issue and study all the rules and regulations associated with the installation of such communications. In addition, it is recommended to contact an electrician who will advise you on this issue.

Line layout diagrams

The principle of wiring power lines is simple - the higher the load, the thicker the wire or cable should be. At the entrance to the apartment, the cable must have the largest cross-section, since the entire apartment load falls on it. For branches to distribution points and lighting, a wire of a smaller cross-section is used.

Based on these requirements, three electrical wiring options were developed:

- Daisy chain circuit (bus connection). This is the laying of a common power line with a large cross-section cable, from which branches are laid through distribution boxes to consumers;

- The radial scheme is considered more reliable. It is implemented as a supply of separate wires from the distribution board to each point of distribution or consumption. The disadvantage of the scheme is the high consumption of wire or cable;

- The last scheme is a combined one, assembled on the basis of a loop and a radial one.

In new buildings, combined wiring is used, in houses of old construction - the first two variants of circuits.

Important! You cannot hide electrical wiring in the joints and seams of walls - PUE Chapter 7.1.