- Attic

The design of the steam room is such that it maintains a constant high temperature, and the air should be moist, saturated with water droplets. But in a closed room with such climatic conditions, mold will certainly grow, and combustion processes will also be disrupted due to the lack of oxygen, not to mention the fact that people inside will have nothing to breathe. Therefore, it is necessary to design ventilation in the bathhouse. We will talk about it in this article.

Is a ventilation system necessary?

When building a steam room, novice builders try to fit all slats and lamellas as tightly as possible, thereby ensuring the absence of temperature losses. This is true, but if you do not leave natural openings or artificially created outlets, then significant smoke is possible when the stove runs on wood or coal. Any fuel leaves traces of combustion. Carbon monoxide in high concentrations will lead to loss of consciousness and the possibility of death, especially if the people in the room are steamed, with unstable pressure, and dilated blood vessels.

Therefore, a ventilation system is required for the following tasks:

- creating the necessary microclimate;

- ventilation and drying of wood to prevent mold or mildew from occurring;

- removal of carbon dioxide, there are people in the steam room, so a constant supply of fresh air is necessary;

- promoting the combustion process, for which oxygen is important;

- eliminating unpleasant odors;

- preserving the slats and shelves in their original form.

The need for ventilation in modern baths

The ventilation of the bathhouse carries out the influx of cold air into the steam room, heating and removing the air that is already humid and cooled after heating. What does a good exhaust system provide:

- quickly removes moist air from the room;

- promotes rapid drying of wooden structures, extends their service life;

- removes carbon dioxide, keeping its concentration at an acceptable level;

- regulates temperature efficiently;

- supports the combustion process in baths with gas and solid fuel stoves, providing air flow.

In a bathhouse with proper ventilation you will never encounter a musty, stagnant, unpleasant odor.

View this post on Instagram

Publication from ATELIER SAUNA - the best for a bath! (@ateliesaun)

The principle of operation of the ventilation system in the bathhouse

The entire ventilation network can be divided into natural, which is located in the walls, roof and foundation and is laid at the beginning of construction, and forced, which is activated only when using a steam room.

Both types work as follows: waste oxygen is displaced and the space is filled with fresh air. The flow has 2 ends - inflow and outflow, respectively, you need at least two holes located according to the rule: inlet hoods are lower than outflow hoods.

Another nuance of the operating principle is that all the gas is taken from where it goes. When there is a connection with the street, everything should go there. Likewise, if in the next room. When the inlet and outlet are at different temperature conditions, the formation of a flow will not work. However, it is recommended to supply/exhaust air from the street, since even in the waiting room it will be humid and insufficiently enriched with oxygen.

Video description

The following video shows an example of such a combination of ventilation and heating:

- If the floor in the steam room and washing room is made in the form of a flooring with slots on a concrete base, an exhaust duct can be made under it by combining the underground of the two rooms and equipping it with a fan. In this case, it is simply necessary, since the trajectory of the movement of air masses is complex, and natural ventilation is unlikely to cope with its task. A channel through a hole in the foundation removes moist exhaust air to the street. The supply opening should be located as close to the stove as possible so that the cold air begins to heat up immediately after entering the room. If openings are made in the walls between adjacent rooms, it will circulate throughout the entire volume, simultaneously warming both the washing room and the rest room.

Scheme of ventilation of a bathhouse through the underground Source youtube.com

Proper ventilation in the sauna steam room

When designing a building, you immediately need to calculate where the shafts will be located and what diameter they will be. And the holes themselves and the dampers are placed on them directly after facing with lamellas. There are 4 types:

| View | Inflow (mm) | Hood (mm) |

| Finnish | 130 | 100 |

| Swedish | 100 | 80 |

| Russian | 100 | 100 |

The most common solution, unfortunately, is the absence of a ventilation system.

The size of the holes directly depends on what you want to get in the end: a Russian steam room or a sauna.

Let's look at an example of a calculation. If the steam room is 3 m by 1.5 m with a height of 2.5 m, that is, approximately 10-11 m3, you need a 20 kW stove. In this case, it is better to use a natural type of air exchange - with an air inlet 10 cm from the floor at a distance of 30 cm from the stove, and a diagonal outlet under the shelves at a height of 80 cm.

In this case, it is necessary to take into account: from under the lining the valve operates in the closed or open position only. It should not be adjusted, as it is made airtight, otherwise the steam will escape. Both outlets do not need to have the same radius, but if more efficient and faster circulation is needed, the first one can be made a little larger or two valves installed in different places. It is strictly forbidden to make it smaller than the supply unit. This is against safety regulations.

It is imperative to install valves on the ventilation holes, which will seal hermetically to the opening when closed - at the time of kindling and heating the steam room. In winter, these doors will be half closed, because the greater the temperature difference, the more air circulates. The hoods should be at the top, and the inflow should be at the bottom. This will allow oxygen to ventilate naturally. The most popular option today: 100 mm – inflow, 80 mm – exhaust.

The "grandfather's" method

There is also an interesting method of ventilating a bathhouse, handed down from our ancestors, which EsKor, a member of our portal, saw in the bathhouse of “one gray-haired grandfather.” In this bathhouse, the only specially made means of ventilation was an vent a meter from the floor, under the shelf. What is the point of such an outlet? It turned out that the gray-haired grandfather “refreshed” the air in the steam room in almost the same way as Nomad, only he prepared a bucket of ice water in advance and poured it onto the shelf either a moment before or immediately after a shock dose of water was charged into the heater.

EsKor

The grandfather explained that the cold water that falls onto the floor from the shelf pulls the steam down, and it takes stale air with it and flies away into the vent. There is no mysticism, physics explains this matter well.

Cold water cools the steam, condensation occurs, the decrease in pressure causes an increased flow of air above the steam layer, and the steam literally falls from the ceiling.

It is clear that this method is not suitable for dry-air baths and steam rooms with a solid floor and no drain.

Types of ventilation

Some 5 years ago no one talked about the ventilation system in the bathhouse; moreover, many argued that it was not needed at all. A window is enough. Times have changed, and now everyone is in favor of ventilation in the bathhouse. At the moment there is a forced and natural look. The chosen option depends on the area of the steam room, climatic conditions, and also on the wishes of the owner.

Natural

It works on the difference in temperature and atmospheric pressure differences inside and outside. This is a very effective and long-used method. There is a nuance for arranging such circulation in the steam room. In the heated room itself, due to the natural laws of physics, it is difficult to provide uniform heat. Typically, the higher you go, the hotter it is, and the floors can stay quite cold. The builder’s task is to think through a system so that a draft does not blow through the feet, and unbearable heat does not accumulate on the ceiling. This can be achieved by dividing the flows into two or three hoods.

Forced

Implemented by electronic control, which depends on the temperature. You can turn the fresh air supply on and off as desired. You can control using a digital device how many degrees should be maintained throughout the entire time of the procedure, as well as what humidity the system needs to be adjusted to.

Typically, such complexes are created for commercial purposes, so they are much more expensive than elements for natural outflow, and installation can only be carried out by specialists.

One of the main disadvantages of using electronic systems is the likelihood of leaving the fan on, which can lead to a wiring ignition and a fire.

Combined

When purchasing an electrical device, make sure that they have maximum protection for all wires and electronics from moisture.

Selecting a type and pattern depending on the wall material

The ventilation system directly depends on the characteristics of the structure itself and the material of its walls. The bathhouse can be a separate room or adjacent to the house. The first option is much better. In such a bathhouse you can install the most economical ventilation option.

The bathhouse adjacent to the house must be dried in the most serious manner. This will protect all walls from rotting. For such a bathhouse, exclusively forced ventilation is used, taking into account the safety of the walls and supporting structures of a residential building.

The bathhouse’s ventilation ducts can be connected to the common ones or separately exit to the street through the roof or through the wall.

Depending on the wall material, experts advise choosing the following types and ventilation schemes:

In brick and frame baths, it is recommended to install ventilation ducts in the walls, leading them to the roof or higher. For inflow, an air duct is laid, a ventilation valve or vents are used in the foundation. It is imperative to supplement the vents with exhaust fans for better removal of exhaust air.

Due to the characteristics of this material, bathhouses made of aerated blocks are equipped with galvanized air ducts made from ready-made pipes. Sometimes a channel is made from galvanized sheets, giving them the appropriate shape and reliably sealing the joints. The ducts must run over the wall.

Natural forced ventilation is allowed in log baths. When the wood breathes, there are the necessary gaps between the logs, windows are provided in all rooms of the bathhouse, gaps from the floor to the bottom edge of the door are 2-3 cm, the construction of additional ventilation channels may not be necessary. But in order not to “drown the street”, it is advisable to provide valves or dampers in the vents.

Advice! When organizing ventilation in the steam room, avoid using plastic elements: corrugations, boxes, plugs. They cannot withstand high temperatures and will melt, releasing harmful substances and acquiring an unaesthetic appearance. Only wood can be used as plugs for vents or hatches, since metal can burn from heat or rust when exposed to moisture.

Salvo - an economical solution for ventilation

If you are not sure that you can correctly calculate the size of the entrances and exits of ventilation ducts or their location, you can use the long-tried “old-fashioned” method - burst ventilation in a Russian steam bath.

Its essence is to quickly ventilate with wide open windows and doors. They are opened for 1-2 minutes. For maximum effect, it is best to use opposite windows and doors.

The method does not require additional financial costs, since you use the elements that are in the bathhouse design.

IMPORTANT! Do not overdo it with ventilation, because you can make the bath too cold. The method is most suitable for Russian baths, which are heated in black.

How to make ventilation in a bathhouse through special vents

These are gratings made in the walls at the level of the floor (20 cm from it) and the ceiling. In this case, you should achieve the maximum distance from each other; this can be achieved if you mount them diagonally, for example, install one between the door and the stove, the second on the opposite wall.

Elements for installing a circulation system, as well as chimneys and tanks for a Russian steam room, can be ordered from Ferrum distributors, who are represented throughout Russia. A wide selection and quality of products will help you build a bath complex with your own hands using Ferrum products. The price list can be viewed on the website.

Vent size

When choosing the size of the exhaust opening, you must follow several rules:

- The largest one should be at the maximum distance from the stove so that the heat does not escape from the steam room in a direct flow.

- The remaining holes can be placed around the perimeter of the ceiling.

- The hole size is calculated based on 24 square meters. cm per cubic meter of room. Most often, the diameter does not exceed 30 cm, but the number is 2 or more.

- The traction force is determined by the height difference between the supply and exhaust openings.

IMPORTANT! Holes cannot be placed opposite each other. This will inevitably cause drafts in the steam room.

Where to place the cold air vent

It is located below. You can create it in the wall, but then at the design stage it is necessary to lay a pipe or shaft that will lead inside. It should be taken into account that fresh air will come from the adjacent room, and, therefore, it should not go out into the street, but into the same room. There is a minus - usually the shelves are installed opposite the entrance structure, and the circulation is felt by everyone present.

Another option involves installing a vent under the sun loungers. In many ways, this is the optimal location - it doesn’t show through and doesn’t spoil the appearance. But it can be difficult to reach it in order to adjust the position of the damper. In such cases, during the bath procedure, the upper outflow doors are moved, and both are opened for ventilation.

And another common and winning option is to place the inflow behind the stove. This simultaneously promotes circulation and heating of the coals. But there are several “buts” - sometimes the stove is installed in a wall, then there is simply no way to organize a damper there. And one more thing - due to the intense heat, plastic doors will melt here and wooden ones may start to catch fire, so only metal ones will do.

The output outflow is simpler; it can be mounted:

- in the ceiling, but then you will have to make an additional box for exhaust through the roof (if there is wet steam in the attic, the wooden rafters will rot);

- in the wall - the best option; it is laid at the time of construction of the building.

How to ensure air flow in a room with a sauna stove

A simplified option is to install an opening window in the steam room. Excess steam will escape through it and fresh air will enter. Plus, it saves on lighting. The box and frame must be made of wood. It is not recommended to install plastic ones - plastic cannot withstand high temperatures and releases toxins when heated.

Another way is to install a supply and exhaust system. Under the floor from the street side, an air duct under the stove enters the room. In this case, the stove becomes a pump - it drives cold air through itself, heats and dries it. The exhaust air exits into an exhaust hole in the wall opposite.

How to make ventilation in a steam bath: hole sizes

The exact calculation of air flow depends on humidity, temperature differences, minimum and maximum values. Experience suggests that the optimal parameters are 10-15 cm; if desired, the outflow diameter can be increased, but flow-through systems cannot be larger.

In this case, it is necessary to install dampers. It is with their help that you will achieve the required radius when weather conditions change

A common misconception is that a person does not have enough oxygen to breathe if the supply is too small. This is not true. For an ordinary person, one cubic meter of air is enough for 1.5 hours.

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

Warming up and insulating the dressing room

Between the locker room/rest room on one side and the steam room on the other, ideally there is a smooth transition between temperature conditions.

There are four options to achieve this:

- The stove opens into both rooms.

- An additional partition between the steam room and the dressing room, combined with the relaxation room.

- Part of the heated air is supplied from the steam room.

- There is a washing room on the direct path from the dressing room to the steam room.

It is also necessary to take care of the insulation of the room. The floor, walls and ceiling are insulated from the cold. Often they use foil insulation, but on a thick layer the foil should be laid manually.

Mineral wool, polystyrene foam and other foam materials, as well as expanded clay, are suitable for insulating the dressing room, but mineral wool will be the best in structure, especially if it is foil-coated

Floor insulation begins by nailing smaller cranial bars to the lower parts of the joists, located in increments of 45-55 cm, longitudinally to the base. A rough covering is placed on top - oblong or wide boards. The subfloor is formed as a continuous floor.

The resulting structure is covered with a waterproofing membrane. Place it so that the layer is completely pressed against the protruding joists. Then, in the space between these slats, a proportionate piece of insulating fabric is laid: slightly larger in width, length and height. Mineral wool is also suitable as thermal insulation. They take more of it, since the material is highly compressed.

A vapor barrier is laid above with a slight overlap on the walls. In the process, pipes that will be in the thickness of the floor or below are insulated.

All that remains is to make the floor itself. The surface can be paved with tiles or boards. Usually they choose wood, this creates a warm floor and maintains the unity of the interiors. The covering must be made continuous, moving the boards as close as possible to each other.

The finishing deteriorates most under the ceiling, so use a thick layer of insulation. Thermal insulation can be collected on the ceiling, between the planks. Place a vapor barrier below, insulation above, then waterproof it. You can cover the top with cement screed and wooden boards.

You can read more about ceiling insulation in this material.

Option for thermal insulation of the ceiling above the dressing room: densely laid expanded clay, hidden in two layers of vapor barrier, and a wooden plank floor without screed

Log houses can be insulated in the finished building, but it is worth planning thermal insulation in advance. It is also worth taking care of the insulation of the front door.

Due to thermal barriers, they effectively combat excess moisture, but condensation can be avoided completely if you constantly do certain things. Keep doors closed and only open briefly. Adjust the shutters in the ventilation grilles.

Use plugs especially during warm-up. After procedures, cool the dressing room through open doors and windows. At the same time, allow short-term drafts. Ventilate each room in turn - through their windows.

Floor ventilation device

Why is this important: a number of factors influence a wooden floor covering; moisture comes from below, from the soil and foundation, and from above from steam. Plus condensation accumulates. Such conditions are favorable for the onset of rotting and for the spread of fungi and mold.

Installing vents under the floorboards is considered the most effective. In this case, there is no draft and the system can be used during bath procedures. Another plus is that ventilation occurs as if from the inside. That is, when ventilating, the upper part of the floor covering dries, and when the hood is running, the lower part dries.

To make this as productive as possible, when installing a drain for water from the steam room, move it to the side so that moisture does not spread under the floorboards.

Requirements for dressing room ventilation

Proper ventilation in the sauna dressing room is organized with your own hands, following the criteria:

- supply and exhaust flows must be of the same volume;

- The direction of the air flow should be strictly organized from the dressing room to the bathroom or vestibule. When the air moves back, foreign odors may get inside;

- the outlet of the ventilation opening is located at a height of at least 2 m above ground level;

- if the hot air flow is removed from the steam room through air ducts, it would be advisable to use it to organize heating of other rooms of the bath;

- for a dressing room, a combined ventilation system will be effective, when a mechanical hood is installed and supply air is supplied naturally;

- the air exchange rate should be 3;

- Mounted fans must be moisture resistant.

Ventilation of the bathhouse foundation

If you already take care of this when laying the foundation, then you will not have rot and mold in the building. Vents with a diameter of 110 mm or more should be installed on all four sides. This will ensure acceptable circulation even if the bathhouse complex is located in the middle of other buildings. It is best to lay these pipes opposite each other.

Choosing the most suitable scheme

If in residential premises constant air exchange is expected, then in bathhouses this is not always convenient, it all depends on the size of the bathhouse and its internal structure.

Ventilation of Russian baths is carried out using the following methods:

- burst ventilation;

- exhaust through a chimney;

- use of special holes.

Burst ventilation is a fancy name for ordinary ventilation. This method is quite appropriate for small steam rooms. The idea is to periodically open windows and doors, thus creating conditions for intensive and short-term ventilation.

Of course, it makes no sense to ventilate during bath procedures.

Burst ventilation in the bathhouse is carried out during breaks between visits to the steam room. To do this, open the doors and windows for a couple of minutes.

The room is ventilated at those moments when there is no one in the steam room, as well as at the end of the process. For ventilation, simply open the window and door to the steam room for just a few minutes.

During this period, the air inside the room will be renewed, and the surfaces will dry out a little, and the walls of the steam room will not cool down, so visitors to the bathhouse will not experience any unpleasant sensations in the future. The possibility of burst ventilation should be provided for at the construction stage of the bathhouse.

Opposite the door you should make a window with a window so that air exchange is carried out correctly. Ideally, the door should be made in the corner, and the window should be placed not opposite, but diagonally and as close to the ceiling as possible. For burst ventilation to be effective, you just need to remember about it. We took a steam bath, took a couple of minutes to ventilate, and you can calmly continue the procedures.

Do not forget about the need for burst ventilation in the bathhouse so that the surfaces have time to dry and the exhaust air is replaced by fresh air

Discharge of exhaust air through a chimney requires the presence of a stove or other suitable device with a chimney duct. In such a furnace there is a blower through which exhaust air is removed.

But for this scheme to work effectively, you need to make sure that enough fresh air enters the room.

If the bathhouse has a heater stove that operates during bathing procedures, ventilation can be carried out through the existing chimney

In log houses, gaps are specially left in the lower crowns of the walls; an alternative option is a small, only 10-15 mm gap under the door to the steam room. If there are no such gaps, and you don’t want to bother with organizing them, it’s enough to just leave the door to the steam room a little open.

Another important condition for organizing exhaust through a chimney is that the stove must burn all the time, otherwise the air will not be removed, and accordingly, the inflow will be limited. If the bathhouse only has a stove designed for short-term use, you will have to choose a different ventilation method.

A universal way to organize natural ventilation in a bathhouse is to make special openings for this - vents. In this case, ventilation will be carried out without obstacles, and the intensity of air flows can be regulated using special dampers or adjustable grilles.

The air in the steam room will be gradually renewed. The optimal rate of air exchange is around five or six volumes of the room every hour. Of course, such ventilation must be properly designed and installed so that there are no drafts in the room.

So, you will need to make two holes: supply and exhaust. The cross-sectional area of these holes should vary slightly; the exhaust in the bath should be larger than the inflow. You can make one supply opening and two exhaust openings.

The location of the inflow and exhaust should be done on opposite walls and in corners located diagonally.

In this case, it is best to make the exhaust hole right under the ceiling, higher than the top shelf, and the supply hole should be below, about 30 cm from the floor level. It is best to carry out the influx as close to the stove as possible or even behind it, so that air flows from the street have time to warm up.

What happens if you ignore these recommendations and make holes at approximately the same level? Nothing good, that is. draft. Air flows will cross the room too quickly, and fresh air will simply leave the steam room immediately. It is clear that the effectiveness of such ventilation leaves much to be desired.

The ventilation holes in the steam room are sometimes closed so that the room warms up as quickly as possible, but then the vents must be opened

You should not make holes for exhaust and supply on the same wall, this will also negatively affect air exchange. To obtain sufficient air flow, a round hole is usually made in the bathhouse wall for a pipe with a diameter of 100-200 mm.

For the hood you will need to make the opening a little larger. You can use a slightly larger diameter pipe or two smaller pipes. The main thing is that the total cross-sectional area corresponds to the calculations.

On our website there are several more articles about the rules for arranging ventilation in a bathhouse, we recommend reading:

- Ventilation device in a bathhouse: technical options and popular schemes

- Ventilation in the bath: an overview of traditional schemes and nuances of the device

Ventilation of various auxiliary rooms

The remaining rooms should also have their own circulation.

Attic

A gable window is not enough, as steam often enters this space and can have a negative impact on the rafters. It is optimal to arrange the inflow under the roof canopy, and the outflow at the ridge. So the flows will pass from bottom to top from both sides.

Washing

To organize air exchange, forced ventilation is most often used, which directs flows towards the vestibule.

Ground floor

Owners of private houses can use the basement to build a bathhouse. This is possible, but it requires costs. Now the integrity of the entire house depends on the safety and efficiency of the circulation system. Already at the design stage of the building, it is necessary to provide for the distance between the walls and the insulation, otherwise condensation from the temperature difference will accumulate on the surface.

It is necessary to create forced ventilation, since natural ventilation cannot be provided due to the impossibility of installation near the floor (after all, it is located underground). We recommend entrusting this issue to professionals.

Shower room

Taking into account the fact that in the remaining rooms there is already an inflow and outflow of oxygen, here it is only enough to design ventilation from fans in the ceiling or at the top of the wall so that the unpleasant odors of dampness come out. The same should be done if the bathhouse complex has a toilet.

Waiting room

Here you should also take special care of the circulation of air flows, since due to the close proximity to the steam room, a strong temperature difference and condensation forms on the walls in the room. The supply and exhaust option is suitable in the same way. You can also install windows that allow for quick ventilation.

Natural or forced?

In order to answer the question: natural or forced ventilation for a steam room, you should look at each type.

A natural microclimate is formed independently in the presence of planned vents (openings) or cracks when the air convection processes described above are started in the building.

The advantages include: low cost of implementation, absence of extraneous noise/vibrations from operating devices and the use of natural features. Possible difficulties: errors in the placement of holes, as a result: lack of draft (the opposite - the appearance of excessive drafts); penetration of foreign (most likely unpleasant) odors from the street.

A forced ventilation system uses equipment and materials that create artificial air movement in the required direction. Regulated by special control units. This is a very expensive solution that requires competent design and further implementation. When placed correctly, it is guaranteed to ensure smooth circulation of air flow.

There are combined types for a bath: steam room ventilation, which combines both of these directions and has the pros and cons of each option.

If you decide to do ventilation yourself, it’s better to go with natural ventilation - it is more in line with the spirit of the bathhouse than the use of intricate devices. However, we do not dissuade you from using forced supply and exhaust ventilation.

How to arrange ventilation in a bathhouse and steam room - calculation of the scheme

We have already mentioned the standard value: 1 cubic meter of space requires 24 cubic centimeters of bends. When choosing pipes, they often choose pipeline pipes - they are inexpensive and effective, but we recommend assembling such a system from Ferrum stainless chimneys; they have a long service life and do not deteriorate from constant interaction with moisture. The standard diameter is 10 centimeters. So, the cross-sectional area is 78.5 cm2. One such box is enough for 3.27 m3 of room volume.

We calculate the number of cubic meters. Let's assume that the steam room has dimensions of 2 by 2 m2, the ceilings are also 2 m high. Multiply everything, we get 8 m3. Divide this by 3.27 = 2.45. Round up to three. As a result, you need to organize 3 boxes with a diameter of 10 cm for the entire steam room.

Video description

It is easy to find units on sale that are specifically designed for baths and saunas - these are the ones shown in this video:

It is also necessary to decide on the power of the device, since excess power is completely unnecessary here and is even contraindicated. This is easy to do if you know the volume of the ventilated room and the air exchange rate recommended for baths, which is 5.

For example, for a 2x3 m steam room with a height of 2.2 m, the fan power is calculated as follows:

2 x 3 x 2.2 x 5 = 66 m3/h

Advice! Buy a device with variable adjustable power and a timer that will periodically turn the device on and off. You can fully automate the system by including humidity and temperature sensors configured to certain values, upon reaching which they will start the fan.

If desired, you can assemble an automated system with remote control Source nevoton.ru

Such devices, depending on the design, can be installed directly in the exhaust vent (duct fans) or on the wall behind it.

Ventilation device

There are several solutions:

- The location of the window next to the stove or under it. There should be at least 25-35 cm above the floor. In this case, the flow moves below, then rises along the opposite wall.

- Both holes are on the same surface, which is not recommended, but does occur. Then be sure to install a fan on the hood. This is true when the steam room has only one wall facing the street, and the rest are adjacent to residential areas.

- Gaps in the flooring, if you have a multi-layer leaky floor, can attract air, let it pass into the space under the covering, and then return it back up again. This ensures good ventilation of the floorboards.

- If the inflow is located opposite the stove, then it will only work if the heating is working.

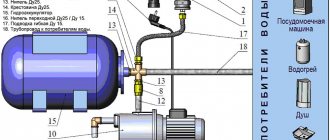

All these types are presented schematically in the picture:

In the article we told you how to properly make ventilation in a bathhouse, showed diagrams and explained the structure of the steam room. Design your bath complex together with high-quality Ferrum products. On the website you will find chimneys and components for arranging a bathhouse. Soak up the fun with Ferrum.

Optimal layout for a steam room

There are many schemes with different advantages. Here is one common scheme according to which ventilation in a steam room can be arranged with your own hands. It also allows you to adjust the air flow to maintain one or another mode.

Optimal steam room ventilation scheme

Let's take a closer look. Stove and door on one side. Air flow behind the stove and through the bottom slot of the door. Opposite, two exhaust ducts are mounted (one under the ceiling, the other above the shelf), connected to each other by a pipe or duct.

- During the heating period of the steam room, both exhaust openings are closed, and the supply openings remain open.

- During the soaring period, the upper exhaust valve is closed and the lower one is opened. The circulation of air masses begins: from the stove it rushes to the ceiling, resting against the wall and descends. It is partially pulled outward by the lower flap, and the remaining part continues to move lower to the floor and back up.

- After steaming, to dry the bath, open both exhaust valves.