Aluminum radiators are suitable for installation in any room of a private house or apartment, provided that autonomous heating is available: boiler equipment is installed, the coolant moves in a closed circuit.

Bestsellers

- Aluminum radiator Thermal Standard 500, 3 sections

Enough

1,731 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 16 sections

A lot of

9,232 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 15 sections

To order

8,655 RUR/piece

More details

- Aluminum radiator Thermal Standard 500, 14 sections

Enough

8,078 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 13 sections

Enough

7,501 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 12 sections

Enough

5,924 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 11 sections

Enough

5,347 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 10 sections

Few

5,770 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 9 sections

A lot of

5,193 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 8 sections

A lot of

4,616 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 6 sections

A lot of

3,462 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 5 sections

A lot of

2,885 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 4 sections

A lot of

2,308 ₽/piece

More details

- Aluminum radiator Thermal Standard 500, 7 sections

Enough

4,039 ₽/piece

More details

Some manufacturers, advertising agents and managers insist that aluminum devices are reliable, durable, in no way inferior to traditional cast iron batteries, and even have obvious advantages. There is a fair amount of slyness in this: aluminum alloys are not inert towards aggressive chemicals. “Private owners” do not use them in the water treatment process (with rare exceptions), but public utilities do so regularly (technology requirement: to protect heat exchangers of boilers and routes from corrosion).

Coolant with increased alkalinity values has a destructive effect on aluminum alloys. If we take into account the suspended matter introduced into the water (poor filtration, particles of build-up and rust that have come off the walls of steel pipes) and the possibility of aluminum oxidation, the service life of heating equipment made from this material will be reduced.

The second point is crimping. It is carried out before each season in order to check the readiness of heating systems for winter. The private owner does not do this, but public utilities are obliged to do so. The pressure under which water is pumped into the system significantly exceeds the nominal pressure. Water hammers also occur periodically. Aluminum radiators are not designed for such testing.

Regardless of what the seller claims, for installation in an apartment building with central heating, these batteries should be selected after consultation with a professional. It is prohibited to use cast radiators - only anodized or extruded ones of certain brands (for example, “Thermal”).

Aluminum heating radiators: types and characteristics

There are three main types of aluminum radiators. Despite the same raw materials, manufacturing technology and degree of purification lead to significant differences in performance characteristics, and therefore in the specific application of these batteries.

Die cast

The raw material is high-silicon alloy EN AB 46100 (AlSi9Cu2(Fe)), where the silicon (Si) content should not exceed 10-12%. European and most domestic manufacturers use certified primary aluminum in the manufacture of such radiators. This makes it possible to obtain products with the declared strength characteristics and reduce the risk of corrosion processes. In contrast, almost all Chinese manufacturers use recycled aluminum obtained from scrap. This results in a low-quality alloy, and the radiators themselves, compared to the standard, turn out to be more fragile. In addition, due to the high porosity of the material, heat transfer is significantly reduced. At the moment, radiators made of die-cast aluminum are the most popular in the Russian market.

Die-cast, regular and reinforced version

Extrusion sectional

Unlike cast ones, the production technology of extruded aluminum radiators involves the production of individual elements of sections, as well as the upper and lower manifold separately. Although each part is stronger, multiple joints significantly reduce the overall strength of the product. In addition, some manufacturers, to reduce the cost of the production process, use composite glue rather than argon welding during assembly. The likelihood of leaks in such batteries is much higher, even at standard operating pressure. It should be noted that many sellers pass off extrusion radiators as high-pressure cast ones. It is quite easy to distinguish such products. By the presence of characteristic seams at the junction of the ribs and collectors.

Extruded aluminum heating radiator in section. The connection lines of the elements are clearly visible

Anodized

Made from high purity aluminum (up to 98%). The technology involves anodic oxidation of the entire internal working surface of the radiator. Oxidation changes the structure of the metal surface, as a result of which the product receives protection from almost any type of corrosion. The main technical characteristics of anodized aluminum radiators are significantly higher than those of previous varieties. However, this manufacturing technology is quite expensive, which affects the cost of the final product. Therefore, anodized aluminum radiators have not found wide distribution on the Russian heating products market.

Anodized aluminum radiators

A comparative analysis of the main technical characteristics of aluminum radiators of various types is given in the table.

| Radiator type | Performance characteristics | ||

| Working pressure, atmospheres | Maximum temperature, ºС | Heat dissipation (for one section), W | |

| Die cast | 16-20 | 110 | 100-150 |

| Sectional extrusion | 10-40* | 110*** | 80-100 |

| Anodized | 215** | 140 | 150-200 |

* - In practice, the amount of “return” on extrusion radiators is much greater than on cast ones.

** - Most manufacturers of anodized radiators indicate the maximum pressure to destroy one section. However, prefabricated connections significantly reduce this figure. As a rule, the working pressure does not exceed 50-60 atm.

*** — Extruded sectional radiators assembled using composite gluing technology have a much lower maximum temperature threshold, no more than 85-90ºС.

Anodized radiators can also be produced in the form of panels with a fairly wide selection of standard sizes

Related article:

Which heating radiators are best for an apartment . In this publication we will look at the types of radiators, their advantages and disadvantages, selection criteria, how to correctly calculate the number of radiators and how to install them correctly.

Advantages and disadvantages of use

Aluminum radiators have become widely popular due to their undeniable technical and operational advantages:

- high heat transfer with relatively compact dimensions;

- light weight, greatly facilitating transportation and installation;

- good ratio of cost and heat transfer power;

- aesthetic appearance and durable protective coating (no need for periodic painting).

There are certain technical limitations:

- low resistance to high pressure, especially to water hammer during pressure testing of the heating system;

- sensitivity to coolant quality.

It should be noted that anodized aluminum radiators are completely devoid of these disadvantages.

Decorative design of aluminum radiators using a grille

Special attention should be paid to such a parameter as thermal inertia. On the one hand, unlike cast iron radiators, aluminum radiators will not be able to maintain heat in the room after the boiler is turned off. On the other hand, this gives the widest possibilities for monitoring and managing the temperature in the room. Ultimately, the widespread use of heat regulators and the economic effect of their use turn the low thermal inertia of aluminum radiators into an advantage.

Manufacturers offer various color solutions that fit perfectly into the interior.

Features of application

As already mentioned, aluminum and its alloys used in the manufacture of radiators are highly sensitive to the quality of the coolant. Namely, to its acidity. The normal acidity of the coolant should be within pH=7-8. If there is a deviation from the norm, the protective oxide film is washed away, and as a result of the formation of a new one, hydrogen is released (champagne effect). This causes a lot of troubles, ranging from the formation of air locks to battery failure due to accelerated corrosion. This is especially noticeable in the summer months, when the coolant is drained from the general system and the pipelines are clogged. A large amount of hydrogen released simply ruptures the housing from the inside.

Using a radiator with insufficient strength in a city apartment

When choosing aluminum radiators, it is also necessary to take into account the operating pressure in the system. For centralized networks, the standard is 10-15 atmospheres. However, this is the working pressure. When starting up and checking heating systems for leaks, the pressure test is increased to 1.5-2 times. Thus, for apartments with a centralized system, only anodized aluminum radiators are allowed.

Aluminum radiators are sold in a wide range of standard sizes. In addition, you can independently add and remove sections, optimizing the heat transfer of the battery

In individual heating systems, the operating pressure rarely exceeds 1.5-2 atm. Therefore, any type of aluminum radiators can be used there.

Galvanic couple effect. There is a fairly well-founded opinion among thermal engineers and installers that aluminum radiators cannot be used in conjunction with boilers that are equipped with copper heat exchangers. The reason is the formation of a galvanic aluminum-copper pair, leading to electrochemical corrosion. If it is formed, copper attracts aluminum ions, and, within just a few years of operation, the aluminum on the radiator turns into foil.

Galvanic couple effect. Intense hydrogen release can not only destroy batteries, but also cause a fire

However, this effect can only be achieved in the case of direct contact between copper and aluminum. If PVC pipes are used to transfer coolant or special cadmium-plated, chrome-plated or nickel-plated adapters are used during installation, the galvanic couple is broken.

How to choose the best steel panel radiators

When choosing a device of this type, first of all, pay attention to its power and dimensions, which must correspond to the area of the heated room. To warm up 1 m2 you need at least 0.1 kW of heat energy. Since heat output depends on the area of the units, the length of the radiator can be no more than 60-70% of the width of the window. Batteries from various manufacturers are available on the market; among Russian brands, devices from the brands Lideya, Prado and Conrad have proven themselves to be the best. Consumers included Kermi, Buderus, Purmo, Axis, Rom and Lemax in the rating of the best foreign brands.

Manufacturers: black and white list

Of the main manufacturers whose products are deservedly popular, many Italian companies can be noted:

- Global;

- Fondital;

- Nova;

- Florada;

- Radiatori;

- Sira.

Nami also deserve attention .

Among domestic companies, it is worth noting radiators from Ankor , Rifar (under Global license) and Thermal .

Some Chinese manufacturers operating under a Global license were also included in the white list: Alltermo , Tianrun .

Also, we would like to draw your attention to the list of companies (mostly Chinese), about whose products we found the most negative reviews:

- Oasis;

- Conner;

- Radena;

- Warma.

In addition, during tests carried out in 2022 in the Moscow Vitaterm laboratory, discrepancies between real parameters and declared indicators from 22% to 34.75% were found in the products of the listed companies.

Advantages of purchasing from us

(St. Petersburg) has been operating in the heating equipment market since 1998. Our reputation is confirmed by the absence of complaints, completed deliveries of products to 1,800 objects of varying importance, reliable and long-term relationships with 3,000 contractors.

We guarantee

- Individual approach.

- Impeccable product quality (only from manufacturing companies with a well-deserved reputation).

- Reasonable cost of radiators without surcharges (direct connections with manufacturers, no chain of intermediaries).

- Constant replenishment and expansion of the assortment.

- Ease of finding the necessary equipment (the online store website teplotorg.ru is available 24/7).

- Efficiency (own fleet of vehicles, compact territorial location of administrative and warehouse buildings, fast shipment, delivery to regions).

Popular models and reviews of them

The editors of HomeMyHome present to your attention some consumer reviews of the most popular models of aluminum radiators:

Feedback on the use of aluminum heating radiators “Lammin”:

More details on Otzovik: https://otzovik.com/review_7663127.html

Aluminum heating radiators Lammin

Review of the aluminum radiator “Konner”:

More details on Otzovik: https://otzovik.com/review_7043504.html

Review of the aluminum radiator “Royal Thermo Evolution 350”:

More details on Otzovik: https://otzovik.com/review_4064173.html

Royal Thermo Evolution 350

Review of the aluminum radiator “Mirado Al 500/96”:

More details on Otzovik: https://otzovik.com/review_4043505.html

Feedback on the operation of the Monlan radiator:

More details on Otzovik: https://otzovik.com/review_4154747.html

Selection criteria and calculation of the number of sections

When choosing an aluminum heating radiator, pay attention to the following parameters:

- the presence of a protective oxide film or additional treatment on internal surfaces;

- mandatory availability of a technical passport for the product indicating the main technical characteristics;

- the seller has a certificate of conformity to prevent the purchase of counterfeit products;

- As a rule, prefabricated heating radiators are supplied in 10 sections. Some manufacturers offer radiator options from 3 to 15 sections. Remember that factory assembly is more reliable than one made at home. Therefore, it is advisable to purchase batteries assembled;

- if, according to calculations, a radiator with a number of sections exceeding 10 is needed to heat the room, then it is more efficient to purchase two batteries with the corresponding number of sections;

- Most European manufacturers are very jealous of the quality of their products, so they order various examinations. The presence of an independent test report is a significant advantage of this manufacturer’s products.

Additional parameters of the form factor of an aluminum heating radiator

Important! It is strictly not recommended to purchase aluminum radiators (mainly made in China) marked NF/68/. Research by the independent laboratory AIRAL has revealed a critical asbestos content in such products.

Temperature control

When determining the number of sections for heating a room, the following nuance must be taken into account. Manufacturers indicate the heat transfer rate of one section at a certain temperature. As a rule, it is 70-75ºС. However, in most cases, the temperature of the coolant in heating systems rarely rises above 60ºC. Therefore, the indicator indicated in the technical passport must be reduced by 15-20%.

Correct location in the niche under the window

Selection by parameters

Before purchasing, you need to read the sample passport - it contains all the necessary information. Let's look at what you should pay attention to.

- Operating pressure. For cast aluminum devices without anodizing it is in the range of 6-16 atm. In a private house with autonomous heating, this is quite enough.

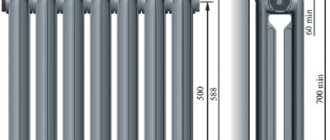

- Center distances. Standard sizes (mm) are 200, 350, 500. Some manufacturers’ models have other size groups, up to 2000. The parameters are selected based on the characteristics of the already installed heating system, when replacing old batteries with aluminum products. This will allow you to avoid having to reinstall pipes.

- Radiator height. This indicator differs from the center distance. To determine it, you need to add 80 mm: 40 at the top and bottom (approximate data).

- Connection of sections. If antifreeze is used in an autonomous system, it is better not to purchase radiators with nipples made of rubber rubber.

Features of self-installation of aluminum heating radiators

If the heating system pipes have appropriate threaded fittings, then replacing any radiators with aluminum ones can be done with your own hands:

- first of all, it is necessary to shut off the heating circuit and drain the water;

- on the purchased radiator you need to find the plugs and pull them out;

- If the heating system is single-pipe, a bypass must be installed. If it is two-pipe, then you can do without it;

- to connect the radiator, it is used in a fitting with a valve, which is screwed on using pipe wrenches;

- To seal the threaded connection, tow or more modern sealing materials are used: Unipack, silicone tape, etc.;

- The packaging shell is removed only after all installation work is completed, which will protect against damage to the front panel.

For positioning on the wall, it is better to purchase brackets with the ability to adjust the height of the position

Securing the radiator with a pipe wrench

Installation process

In general, you should entrust the work of installing a radiator to a qualified specialist. But, knowing all the features, you can control the process yourself.

The installation process consists of several stages:

- Assembly. It is carried out before the entire heating system is installed. At the outer section, auxiliary equipment is installed: plugs, plugs, locking devices, and so on.

- Determination of attachment points. Recommendations for battery placement should be strictly followed to ensure maximum performance of the device.

- Installation of brackets. These elements are fixed with dowels. If desired, a cement solution is used as a fastening material.

- Battery installation. The mounting hooks must be installed so that they are located between the sections of the device. The lower parts have their own holders to prevent sagging. It is very important that the radiator is installed strictly horizontally, for which you need to use a level.

- Connection to the system. Depending on how the sections of the device are located, the heat pipes can be connected by one or two connections. The supply pipes must have a valve or thermostat. In order for all sections to warm up evenly, it is imperative to bleed the remaining air from the system.

Installation of heating equipment is not difficult. If the owner of the house does not have enough experience, it is recommended to seek help from specialists, which will guarantee long and efficient operation of the heating system. Learn how to insulate a wooden floor by following the link.