Reviews from owners who use heated floors in the bathroom, kitchen or garage confirm its high efficiency in creating a favorable indoor microclimate. No wonder the well-known proverb says that you need to keep your feet warm and your head cold. This temperature distribution for the human body is most consistent with its physiology and does not cause discomfort even during very long periods of use of these systems. Lower surface temperatures, uniform distribution of warm air, economical consumption of oxygen and many other advantages determine the widespread use of heated floors in residential and public spaces.

Choosing heated floors for the bathroom

Despite some difficulties that arise during design and coordination, the installation of heated floors in the bathroom has become the most integral part of modern apartment renovation. A slight increase in the cost of work makes it possible to level out the shortcomings of ventilation systems and floor covering materials and create an insurmountable barrier to dampness, which is fertile ground for the development of microorganisms harmful to humans. Heating the floor in a bathroom, swimming pool or sauna provides pleasant tactile sensations during water procedures. As an example, consider the installation of a heated floor in the bathroom, where this work is most often performed

Types of heated floors

When installing floor heating for residential and public premises, several systems are used, which differ from each other in the heating method, type of coolant and materials used.

Heating system using a liquid coolant, the so-called water heated floor

Water floor for bathroom

It is characterized by the complexity of installation, a large amount of preparatory work and high requirements for the materials used. Requires complex engineering calculations, a large number of shut-off valves and the use of circulation pumps. The large length of pipelines creates increased hydraulic resistance, which limits the use of the system in existing apartment buildings.

Connected to a central heating system, water-heated floors in the bathroom can cause a complete imbalance of the system and a cessation of coolant circulation. The high temperature in the centralized circuit, reaching 75-80 degrees, is unacceptable for heating the floor, which forces you to reduce the circulation rate or mix cold water into the coolant. Such actions cause a decrease in the temperature of heating devices located after the connection point. At a minimum, this guarantees the discontent of neighbors who are forced to freeze in their apartments.

Important! Chapter 4 of the Housing Code of the Russian Federation and Decree of the State Construction Committee of the Russian Federation No. 170 “On approval of the Rules and Standards for the Technical Operation of the Housing Stock” legally prohibit such interventions in the centralized life support systems of the housing stock at the federal level. The broad powers of the subjects of the Federation make it possible to adopt local legislative acts that are in force in specific territories, take, for example, Resolution of the Moscow Government No. 73-PP.

The use of elevator units (units for regulating pressure and coolant flow) to balance the home heating system allows the use of only copper pipes for the coolant in floor heating systems. This significantly increases the cost of the system and makes its installation economically unprofitable. Therefore, water floors in bathrooms have become widespread in individual construction and the design of autonomous heating systems.

Autonomous heat generators, distribution systems and separate system circuits with their own circulation pumps make it possible to obtain the required temperature for the heated floor in any room, absolutely independent of the main heating circuit. Controlled electronic or mechanical control valves maintain the set temperature automatically. Low pressure in the system allows the use of cheaper polymer pipes, reducing the cost of the system without compromising efficiency and durability.

Bathroom floor tiles. Overview of solutions and types of floor tiles

Electric heating system using heating wire

Electric heated floor in the bathroom

The electric heating system is widely used in apartment buildings due to the absence of the need for lengthy approval and can be installed with sufficient electrical power supplied. Relatively low energy consumption, the ability to install inexpensive automation and installation under any finishing coating have brought electric heating well-deserved popularity, and the slightly increased energy costs cannot be compared with the resulting comfort.

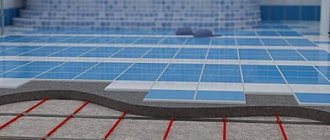

Electric heated floors in the bathroom, the installation of which significantly improves the operational characteristics of the room, requires minimal additional costs for the purchase of equipment and materials. Installation of electric heating fits into the technological operations for arranging a conventional floor. The cable is laid on a heat-insulating base and filled with a cement screed of the subfloor.

Temperature sensors installed during installation control the heating of the floor to a set temperature, which is maintained using an electronic thermostat, which looks like an ordinary switch. Modern microprocessor element base allows you to program thermostats literally in minutes, which significantly reduces energy costs. Electric heating has low inertia and high efficiency, which makes operation economically profitable.

The difficulties with installing the electrical cable that arose at an early stage of application were fully taken into account during the subsequent development of the technology. The heating cable is placed on a heat-resistant mesh using special fasteners. The resulting mats are completely ready for installation, are easy to use and can significantly reduce the time it takes to create a heated floor in the bathroom. .

In the production of heating cables, plastic heat-resistant insulation is used, which can withstand much higher temperatures than the maximum heating temperature of the cable. All electrical connections are made at the point where the heater is connected to the thermostat, which guarantees the occurrence of a dangerous electrical potential on the floor surface, and the ability to connect through a differential switch will instantly de-energize the system at the slightest current leakage.

Please note: One of the advantages of electric floor heating is the insignificant thickness of the heating element, which, unlike a water one, can be installed with minimal modifications to the existing floor. This advantage makes cable heating unrivaled in those rooms where it is impossible to make a screed more than 3 cm.

Manufactured in compliance with all technological details, the electric cable heating does not require further maintenance during its entire service life. A high-quality heating cable has a warranty service life of more than ten years, and the service life is not limited.

Electric heating system based on infrared film heaters

Infrared floor heating

Film heating elements, widely advertised recently, are successfully used to create heating systems that emit infrared thermal radiation in the range of 10-15 microns. Infrared rays cause heating of surrounding objects, which transfer secondary heat to the air in the room. Without going into complex technical details, this type of heating can be compared to the effect of sunlight, when even at low air temperatures a person feels comfortable and can even sunbathe when there is snow around.

Repair under the bathroom. Reasons for the need and procedure

The main element in the film heaters on the basis of which infrared heated floors in the bathroom are made is a carbon material, which, when an electric current passes, begins to emit heat rays, heating up to a temperature of no more than 70 degrees. The heater is enclosed in a durable polymer film with high thermal stability and is not subject to combustion. The polymer does not allow electric current to pass through at all and serves as a good insulator of busbars. The film heater has a very small thickness compared to other systems that provide heating for the bathroom floor, and can be mounted directly under the finishing coating.

Such an element consumes less electricity than traditional heaters and therefore reduces operating costs.

Important! However, when installing a heated floor in the bathroom, you must remember that the film heater cannot be laid in a cement screed or tile adhesive, which narrows the types of finishing coatings used. An infrared heater based on carbon rods connected by an electrical wire of increased security is free from this drawback. Such a heater can be safely filled with a cement screed 2-3 cm thick.

Practical advice

Professional builders do not understand why a thin foil-coated heat-insulating material such as penofol is needed. Manufacturers justify its use by the fact that it additionally insulates the base and reflects infrared rays. This is a very dubious argument. Why?

Heat transfer occurs due to three phenomena: thermal conductivity, convection and thermal radiation. The first method is carried out through direct contact of bodies with different temperatures, the second due to the movement of hot and cold air currents and the third due to the emission of infrared rays. If the effectiveness of the first two methods does not depend on body temperature, then the number of infrared rays, taking into account the temperature, increases exponentially. A body with a temperature of 20–30°C emits a tiny amount of infrared rays, and accordingly, there is nothing to reflect. The electrical wires are in close contact with the screed and transfer maximum heat to it, and a small amount of infrared rays are absorbed by the same solution. The effectiveness of foil in the case of heated floors approaches zero, unnecessary loss of time and money.

Penofol

But that's not all. Penofol is a very soft material with an insulation thickness of up to 5 mm. This thickness does not provide any noticeable heat saving effect, you should know this. In addition to being ineffective, penofol causes direct harm. During the manufacture of the base, it bends unevenly, and voids appear between the thin screed and the floor slabs. As a result, the screed cracks and the tiles peel off.

Penofol can cause cracks in the screed

In the photo - laying a carbon floor on penofol

Practical advice. Some manufacturers in their advertising videos seriously advise laying tiles directly on carbon mats. This, in their opinion, greatly simplifies the process. In this case, the thickness of the glue should be at least two centimeters. Only those who have never laid tiles themselves can advise this; absolutely do not do this.

Do not lay tiles on a thick layer of adhesive

Why? Firstly, the large thickness of the adhesive makes the process of leveling the tiles very difficult. Secondly , a thick layer of glue not only hardens for a very long time, but also causes significant shrinkage. After hardening, the floor surface may become uneven. Thirdly , each tile will be fixed separately, which will cause it to tear off at the slightest omission of glue. Fourthly , you will never be able to press it with such force that the adhesion to the base is uniform and tight. During pressing, the front surface is recessed, and this makes installation even more difficult. And, fifthly , if under the heated floor there is a heat insulator made of foamed soft polymers, then each tile will have its own individual shrinkage. To this list we can add that the cost of glue is much higher than cement-sand mortars for screed.

Go to calculations

Video - Do you need penofol under a heated floor screed?

Choosing a heated floor

Choosing the type of heated floor for the bathroom

After we have examined all possible design options, it's time to consider the factors influencing the choice of heated floors for the bathroom. Having decided to install heated floors in the bathroom, you need to choose the right heating system, based on the characteristics of the room and the nature of the coating:

- In a private house or cottage, despite the high initial costs, it would be best to install water floor heating in the bathroom, resulting in savings using the energy of the installed heating boiler;

- When using electric heating, take into account the existing restrictions on the use of heaters specified by the manufacturer;

- Accurately maintain the installation technology of not only heaters, but also the entire system as a whole, including seemingly minor elements;

- It is imperative to perform thermal and electrical calculations to obtain a balanced heating system that eliminates the occurrence of critical overloads of heating equipment or the power supply system of a house or apartment;

- If you are unsure of the correctness of the calculations performed or compliance with the installation technology, it is better to contact specialists to provide the necessary assistance. Trained and appropriately licensed specialists will perform the work efficiently and will bear certain warranty obligations for the agreed time;

- When starting all work on the design and installation of heated floors, especially in apartment buildings, consult about the possible legal consequences of such work.

Choosing a color

The choice of material for the kitchen is influenced by many factors, including the design of the premises and its colors. If the interior is decorated in a discreet black and white palette in the style of minimalism, then finishing the floor with tiles is the best choice. The staggered installation method looks stylish and expensive.

If there is a ton of white furniture, then a dark floor will help maintain the contrast. The right choice will help to visually expand the space and hide visible imperfections.

Checkerboard finish

Combined coverings look interesting - they are more suitable for a large kitchen. This technique is often used by designers for zoning purposes. It is preferable to lay tiles and linoleum in the work area, and laminate, cork, and parquet in the dining area.

There are many options and combinations, it all depends on taste and imagination.

Installation of floor heating systems in the bathroom

Water heated floor

Installing a water floor in the bathroom

The installed water-heated floor in the bathroom shown in the photo gives a clear idea of the procedure for performing the work:

- It is necessary to prepare the base by removing the old screed and leveling the surface. When laying a water floor, height differences are not allowed, which can serve as pockets for air released when the coolant is heated and can significantly complicate or completely block circulation in pipes of small diameter and considerable length;

- Apply a layer of waterproofing and lay a heat-reflecting screen with applied markings;

- Along the perimeter of the room, lay a tape compensator for thermal expansion of the floor surface when heated;

- To create a more durable screed that operates in the thermal deformation mode, it is necessary to lay a reinforcing mesh with a cell size of 50x50 mm and a wire diameter of 3-4 mm on top of the heat-insulating layer

- The metal-plastic heating pipe is laid either in a spiral or along the perimeter of the room, but with any installation method, the supply and return pipelines must run parallel to each other across the entire area of the room for more uniform heating of the floor surface.

To facilitate this operation, it is necessary to draw up a scale sketch, lay out the route and apply markings directly to the underlying surface. Only then is the pipe laid, and the remaining drawing must be saved so that after some time you have an idea of where the heating pipe runs.

- depending on the thickness of the screed, which can be from 30 to 70 mm, it is necessary to install the pipe on supports of the appropriate height to ensure the flow of the laid mortar and prevent the formation of voids;

- When choosing a pipe for a heated floor, you do not need to make thermal calculations. The maximum length of a pipe with an internal diameter of 16 mm is 80 m, and a thicker pipe with an internal diameter of 20 mm can be laid no more than 100 m. The shorter the heated floor line, the lower the hydraulic resistance, the higher the temperature and the more economical the heating system.

- After laying the heated floor in the bathroom is completed, a screed of the required thickness is poured and carefully smoothed to obtain a flat surface. After pouring the screed, it is necessary to soak the concrete until it fully sets and gains strength for at least seven days and only then proceed to further work on the floor covering;

- To put the floor into operation, it is necessary to connect the supply and return pipelines to a special distribution system, which is performed when piping the boiler.

Electric heated floor

Installing an electric floor in the bathroom

- An electric heated floor based on a heating cable is laid similarly to a water one, taking into account the smaller diameter of the cable. All preparatory and waterproofing operations are similar;

- To make it easier to install such a floor, it is better to buy ready-made thermomats for the bathroom: with its small size, the increase in price will not be significant, and the quality of the installation will increase significantly;

- When laying an electric heated floor, we must not forget about the presence of a temperature sensor, which is mounted between the cable branches at a short distance from the wall, which increases the accuracy of measuring the floor temperature. An electronic thermostat can be installed directly next to the light switch or in any convenient place for use. It is better if it is protected from excessive moisture, and especially direct water, which can damage the electronic device;

- After checking all electrical connections for short circuits and contact of current conductors with surrounding structures, you can test turn on the heated floor, and then, disconnecting it from the electrical network, fill the screed and ensure that the solution dries completely.

Note! The heater can be turned on no earlier than 28 days after filling. This is due to the possibility of cracking of the screed and damage to the heating cable of the heated floor.

Infrared heated floor

Installation of infrared floor in the bathroom

- When installing an infrared heated floor in a bathroom under linoleum or waterproof laminate, it is necessary to correctly select the power of the heating film. The store can tell you which film from a particular manufacturer is needed when purchasing. The power value is indicated on the side surface of the film and is indicated by the value “W/m” (watt per 1 linear meter);

- Before laying the film, a layer of thermal insulation with a foil layer is applied to the prepared floor surface to reflect the rays towards the room. This increases the heating capacity of the floor and prevents heat loss in the floor slabs;

- When laying infrared film in the bathroom, you must remember about high-quality insulation of electrical connections and connect the floor to the electrical network only through a differential switch.

- The film is laid as a continuous carpet, and given its excellent heating ability, the installation area can be reduced by 15% without compromising the heating ability of the floor;

- An infrared floor in a bathroom based on carbon rods is laid similarly to an electric floor based on a heating cable, but differs in the heating method, which is similar to a film heater. Such an infrared heater can be placed in a screed or directly in a thick layer of tile adhesive;

- When installing film heated floors in the bathroom, you must strictly follow the manufacturer's instructions to ensure high quality installation and durability of the heater.

By installing a heated floor system, you can save some money and avoid installing a heated floor under the bathtub and toilet, where it will not perform its functions to the required extent.

Choosing coverage

Practical coverings in the kitchen are simply indispensable for a modern person. They must meet the following requirements:

- Hygiene - easy to clean from dirt, grease, and easy to withstand the effects of aggressive household chemicals.

- Moisture resistance. The forge in the entire house is the second room in terms of humidity after the bathroom, where the floor surface is actively influenced by water.

- Wear resistance - the floor must be resistant to abrasion, durable and reliable.

- Impact resistance. Preference should be given to a coating that can withstand falling heavy objects without damage.

These requirements do not apply to every coating. But in addition to this, it should suit the overall interior of the room, look aesthetically pleasing, and be recommended for use with heated floors. It is better to study the characteristics of the finish in advance to make the right choice.

Tile

This is the optimal choice of covering for the kitchen when planning additional heating installation. Ceramic tiles retain their environmental friendliness even with strong heating. It also does not collapse or crack with repeated heating and cooling, it has maximum moisture resistance, and is easy to clean.

Tile

But a high heating rate is not always good for your feet.

You need to choose the material wisely. For example, where there is not a lot of load on the floor, thinner tile coverings are also suitable. This will allow for better heating.

When selecting a specific type of material, attention should be paid to the following criteria:

- Hardness - it is measured on the ten-step Mohs scale. For an apartment, an indicator of 5–6 is suitable.

- Water absorption. In a room with high humidity, the water absorption of the tiles should not exceed 3 - 6%.

- Wear resistance. There are 5 different classes. For light loads on the floor, class 2 material is suitable, and in other situations, class 3 and 4.

- Chemical resistance. The tile itself is a durable coating, but it is especially important to pay attention to this characteristic for the kitchen.

- Porosity. When laying with heated floors, the density of the tiles should not be too low.

After laying the tiles, the floor must be checked for evenness. You can turn on the heating only after the glue has completely dried, otherwise the quality of the work will be ruined.

Self-leveling coating

Self-leveling flooring is a good choice for the kitchen. A screed is not required for its design, because it is capable of leveling itself. Minimal maintenance is required for such a surface; self-leveling floors are easy to clean and are not afraid of moisture, scratches, or impacts.

Another advantage is the ability to choose original colors, even if you want to create a 3D effect.

But such finishing is still considered a new product, so the cost is not the most affordable. The quality largely depends on the professionalism of the installer. Some do the job sloppy, as a result the floor looks uneven, and in the light of the sun every dot or swollen bubble is visible.

Before choosing this option, you need to find a reputable company that will do the job perfectly.

When installed correctly, the surface has a long service life - more than 50 years. It retains its original appearance for a long time.

Cork

As a cork covering for the kitchen, adhesive varieties are more suitable. The advantages of using them in the kitchen include:

- if it falls and hits the floor, the dishes will not break;

- It’s nice to walk barefoot;

- the material is an excellent heat insulator;

- good sound insulation;

- does not support combustion;

- does not release toxins;

- does not slip.

Cork

Despite many positive reviews and advantages, there are also disadvantages:

- high price, more laminate, linoleum;

- use of special glue and varnish for finishing;

- it is unacceptable to leave even minimal unevenness on the base under the cork surface;

- You won’t be able to lay the floor yourself without the services of professionals;

- high probability of scratches - easily damaged when rearranging furniture with metal legs, falling sharp objects or from the claws of animals.

There is an opinion that cork flooring is prohibited from being used with a heated flooring system. It is not true. You can conduct an experiment yourself, put a piece of floor on the battery. The material conducts heat well and is not prone to fire.

Advantages and disadvantages

Having decided to install a heated floor in the kitchen, you need to know all the advantages and disadvantages of this heating system.

Advantages of this heating:

- uniform heating of the room;

- the surface dries quickly after washing;

- there are no complicated settings and it is possible to regulate the temperature level;

- long service life - up to 40 years.

Among the disadvantages:

- difficulties when installing a heating system - dismantling of the floor covering is required;

- increased room temperature can lead to faster spoilage of food;

- high cost of equipment;

- When using electrical structures, energy consumption increases.

How to install

Each manufacturer has subtle differences, but there are two main types of installation: wet and dry. Wet installations are embedded in concrete during initial assembly (that is, while the concrete is still “wet”) or in a layer of additional concrete screed. The dry method involves laying in a layer below or above the subfloor (or sometimes sandwiched between two layers under the floor) and below the finished floor. Dry installation systems are a newer technology and are more popular today. They are especially good when installing the system into an existing home because they do not require pouring additional concrete screed.